The use of KERS in aerial drone endurance enhancement

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

KERS for Drones: Background and Objectives

Kinetic Energy Recovery Systems (KERS) have emerged as a promising technology for enhancing the endurance of aerial drones. Originally developed for automotive applications, particularly in Formula One racing, KERS has found new potential in the field of unmanned aerial vehicles (UAVs). The primary objective of implementing KERS in drones is to significantly extend their flight time and operational range, addressing one of the most critical limitations in drone technology.

The evolution of KERS technology can be traced back to the early 2000s in the automotive industry. Its adaptation for drone use represents a innovative cross-pollination of technologies between different sectors. The core principle of KERS involves capturing the kinetic energy that would otherwise be lost during deceleration or descent, converting it into electrical energy, and storing it for later use. In the context of drones, this translates to harnessing energy during descent or when encountering downdrafts, potentially transforming these traditionally energy-consuming phases of flight into energy-generating opportunities.

The development of KERS for drones is driven by the increasing demand for longer-endurance UAVs across various applications. These include surveillance, search and rescue operations, agricultural monitoring, and long-distance delivery services. As the drone industry continues to expand, the need for more efficient power management systems becomes paramount. KERS presents a viable solution to this challenge, offering the potential to dramatically increase flight times without significantly increasing the drone's weight or compromising its payload capacity.

Current technological goals for KERS in drones focus on several key areas. Firstly, there is a push to optimize the energy conversion efficiency, aiming to capture and utilize as much kinetic energy as possible during flight. Secondly, researchers are working on miniaturizing KERS components to make them suitable for smaller drones without adding excessive weight. Another critical objective is to develop intelligent control systems that can seamlessly integrate KERS with existing drone power management systems, ensuring optimal energy utilization throughout the flight envelope.

The implementation of KERS in drones also aligns with broader trends in sustainable technology development. By improving energy efficiency and potentially reducing the need for frequent battery replacements or recharges, KERS contributes to reducing the environmental impact of drone operations. This aspect is particularly relevant as drones become more prevalent in commercial and industrial applications, where sustainability is an increasingly important consideration.

As research and development in this field progress, the integration of KERS with other emerging technologies, such as advanced materials for lightweight construction and improved battery technologies, is expected to yield synergistic benefits. The ultimate aim is to create a new generation of high-endurance drones capable of extended missions that were previously unfeasible, opening up new possibilities in fields ranging from environmental monitoring to disaster response and beyond.

The evolution of KERS technology can be traced back to the early 2000s in the automotive industry. Its adaptation for drone use represents a innovative cross-pollination of technologies between different sectors. The core principle of KERS involves capturing the kinetic energy that would otherwise be lost during deceleration or descent, converting it into electrical energy, and storing it for later use. In the context of drones, this translates to harnessing energy during descent or when encountering downdrafts, potentially transforming these traditionally energy-consuming phases of flight into energy-generating opportunities.

The development of KERS for drones is driven by the increasing demand for longer-endurance UAVs across various applications. These include surveillance, search and rescue operations, agricultural monitoring, and long-distance delivery services. As the drone industry continues to expand, the need for more efficient power management systems becomes paramount. KERS presents a viable solution to this challenge, offering the potential to dramatically increase flight times without significantly increasing the drone's weight or compromising its payload capacity.

Current technological goals for KERS in drones focus on several key areas. Firstly, there is a push to optimize the energy conversion efficiency, aiming to capture and utilize as much kinetic energy as possible during flight. Secondly, researchers are working on miniaturizing KERS components to make them suitable for smaller drones without adding excessive weight. Another critical objective is to develop intelligent control systems that can seamlessly integrate KERS with existing drone power management systems, ensuring optimal energy utilization throughout the flight envelope.

The implementation of KERS in drones also aligns with broader trends in sustainable technology development. By improving energy efficiency and potentially reducing the need for frequent battery replacements or recharges, KERS contributes to reducing the environmental impact of drone operations. This aspect is particularly relevant as drones become more prevalent in commercial and industrial applications, where sustainability is an increasingly important consideration.

As research and development in this field progress, the integration of KERS with other emerging technologies, such as advanced materials for lightweight construction and improved battery technologies, is expected to yield synergistic benefits. The ultimate aim is to create a new generation of high-endurance drones capable of extended missions that were previously unfeasible, opening up new possibilities in fields ranging from environmental monitoring to disaster response and beyond.

Market Analysis for Extended Drone Flight Time

The market for extended drone flight time solutions, particularly those utilizing Kinetic Energy Recovery Systems (KERS), is experiencing significant growth and transformation. This trend is driven by the increasing demand for drones with longer endurance capabilities across various industries. The commercial drone market, valued at $13.44 billion in 2022, is projected to reach $55.8 billion by 2030, with a compound annual growth rate (CAGR) of 19.9%.

Extended flight time is a critical factor in drone applications, directly impacting operational efficiency and cost-effectiveness. Industries such as agriculture, surveying, search and rescue, and logistics are particularly interested in drones with enhanced endurance. For instance, in precision agriculture, longer flight times allow for more comprehensive field mapping and crop monitoring in a single mission, reducing the need for multiple flights and improving overall productivity.

The integration of KERS technology in drones represents a promising solution to the endurance challenge. This innovation has the potential to significantly extend flight times by harnessing and reusing kinetic energy that would otherwise be lost. The market for KERS-equipped drones is still in its early stages but is expected to grow rapidly as the technology matures and proves its effectiveness in real-world applications.

Key market drivers for extended drone flight time solutions include the increasing adoption of drones in commercial and industrial applications, stringent regulations promoting safer and more efficient drone operations, and the growing need for cost-effective aerial solutions. Additionally, the rising demand for long-range drone delivery services, especially in e-commerce and healthcare sectors, is fueling the need for drones with extended endurance capabilities.

However, the market also faces challenges. The high initial cost of advanced energy recovery systems like KERS may limit adoption, particularly among smaller operators. Regulatory hurdles related to extended flight times and the use of new technologies in drones also pose potential barriers to market growth. Despite these challenges, the overall market outlook remains positive, with technological advancements and increasing awareness of the benefits of extended flight times driving continued growth.

In conclusion, the market for extended drone flight time solutions, especially those incorporating KERS technology, presents significant opportunities. As the technology evolves and becomes more cost-effective, it is expected to play a crucial role in shaping the future of the drone industry, enabling new applications and enhancing the capabilities of existing drone operations across various sectors.

Extended flight time is a critical factor in drone applications, directly impacting operational efficiency and cost-effectiveness. Industries such as agriculture, surveying, search and rescue, and logistics are particularly interested in drones with enhanced endurance. For instance, in precision agriculture, longer flight times allow for more comprehensive field mapping and crop monitoring in a single mission, reducing the need for multiple flights and improving overall productivity.

The integration of KERS technology in drones represents a promising solution to the endurance challenge. This innovation has the potential to significantly extend flight times by harnessing and reusing kinetic energy that would otherwise be lost. The market for KERS-equipped drones is still in its early stages but is expected to grow rapidly as the technology matures and proves its effectiveness in real-world applications.

Key market drivers for extended drone flight time solutions include the increasing adoption of drones in commercial and industrial applications, stringent regulations promoting safer and more efficient drone operations, and the growing need for cost-effective aerial solutions. Additionally, the rising demand for long-range drone delivery services, especially in e-commerce and healthcare sectors, is fueling the need for drones with extended endurance capabilities.

However, the market also faces challenges. The high initial cost of advanced energy recovery systems like KERS may limit adoption, particularly among smaller operators. Regulatory hurdles related to extended flight times and the use of new technologies in drones also pose potential barriers to market growth. Despite these challenges, the overall market outlook remains positive, with technological advancements and increasing awareness of the benefits of extended flight times driving continued growth.

In conclusion, the market for extended drone flight time solutions, especially those incorporating KERS technology, presents significant opportunities. As the technology evolves and becomes more cost-effective, it is expected to play a crucial role in shaping the future of the drone industry, enabling new applications and enhancing the capabilities of existing drone operations across various sectors.

Current KERS Technology in Aerial Applications

Kinetic Energy Recovery Systems (KERS) have gained significant traction in aerial applications, particularly in enhancing the endurance of drones. The current state of KERS technology in aerial applications primarily focuses on harnessing and repurposing energy that would otherwise be lost during flight operations.

One of the most prominent KERS technologies in aerial applications is regenerative braking. This system captures the kinetic energy generated during deceleration or descent and converts it into electrical energy, which is then stored in batteries or supercapacitors. In drones, this technology is particularly useful during landing sequences or when reducing altitude, allowing for energy recapture that can be utilized to extend flight time.

Another emerging KERS application in aerial drones involves the use of piezoelectric materials. These materials generate electrical charge when subjected to mechanical stress, such as the vibrations and flexing experienced by drone structures during flight. By integrating piezoelectric elements into drone frames or wings, energy can be continuously harvested throughout the flight, contributing to improved endurance.

Thermoelectric generators represent another avenue for KERS implementation in aerial applications. These devices convert temperature differences between the drone's body and the surrounding air into electrical energy. While the energy output is relatively small, it can provide a continuous trickle charge to supplement the main power source, especially during long-duration flights.

Solar KERS technology is also gaining prominence in aerial drone applications. By incorporating lightweight, flexible solar panels into the drone's structure, energy can be harvested from sunlight during flight. This technology is particularly effective for high-altitude, long-endurance (HALE) drones that operate above cloud cover and can maximize solar exposure.

Recent advancements in KERS for aerial applications have also explored the potential of wind energy harvesting. Some innovative designs incorporate small turbines or fluttering mechanisms that can generate electricity from the airflow around the drone during flight. While still in early stages, this technology shows promise for further enhancing drone endurance.

The integration of these KERS technologies often requires sophisticated power management systems to optimize energy capture, storage, and utilization. Current systems employ advanced algorithms and sensors to balance energy recovery with flight performance, ensuring that KERS operation does not negatively impact the drone's aerodynamics or maneuverability.

As KERS technology continues to evolve, researchers are exploring hybrid systems that combine multiple energy recovery methods. These integrated approaches aim to maximize energy recapture across various flight conditions and environmental factors, further extending the operational capabilities of aerial drones.

One of the most prominent KERS technologies in aerial applications is regenerative braking. This system captures the kinetic energy generated during deceleration or descent and converts it into electrical energy, which is then stored in batteries or supercapacitors. In drones, this technology is particularly useful during landing sequences or when reducing altitude, allowing for energy recapture that can be utilized to extend flight time.

Another emerging KERS application in aerial drones involves the use of piezoelectric materials. These materials generate electrical charge when subjected to mechanical stress, such as the vibrations and flexing experienced by drone structures during flight. By integrating piezoelectric elements into drone frames or wings, energy can be continuously harvested throughout the flight, contributing to improved endurance.

Thermoelectric generators represent another avenue for KERS implementation in aerial applications. These devices convert temperature differences between the drone's body and the surrounding air into electrical energy. While the energy output is relatively small, it can provide a continuous trickle charge to supplement the main power source, especially during long-duration flights.

Solar KERS technology is also gaining prominence in aerial drone applications. By incorporating lightweight, flexible solar panels into the drone's structure, energy can be harvested from sunlight during flight. This technology is particularly effective for high-altitude, long-endurance (HALE) drones that operate above cloud cover and can maximize solar exposure.

Recent advancements in KERS for aerial applications have also explored the potential of wind energy harvesting. Some innovative designs incorporate small turbines or fluttering mechanisms that can generate electricity from the airflow around the drone during flight. While still in early stages, this technology shows promise for further enhancing drone endurance.

The integration of these KERS technologies often requires sophisticated power management systems to optimize energy capture, storage, and utilization. Current systems employ advanced algorithms and sensors to balance energy recovery with flight performance, ensuring that KERS operation does not negatively impact the drone's aerodynamics or maneuverability.

As KERS technology continues to evolve, researchers are exploring hybrid systems that combine multiple energy recovery methods. These integrated approaches aim to maximize energy recapture across various flight conditions and environmental factors, further extending the operational capabilities of aerial drones.

Existing KERS Solutions for Drones

01 Energy storage and regeneration in KERS

KERS systems store kinetic energy during braking and regenerate it during acceleration, improving overall vehicle efficiency and endurance. Advanced energy storage technologies, such as high-capacity batteries or flywheels, are used to maximize energy recovery and utilization.- Energy storage and recovery systems for vehicles: KERS technology is implemented in vehicles to capture and store kinetic energy during braking, which can then be used to provide additional power during acceleration. This system improves fuel efficiency and overall vehicle performance, particularly in stop-and-go traffic conditions or racing scenarios.

- Hydraulic and pneumatic KERS designs: Some KERS implementations utilize hydraulic or pneumatic systems to store and release energy. These designs may offer advantages in terms of durability, cost-effectiveness, and suitability for certain vehicle types or operating conditions. The stored energy can be used to power auxiliary systems or assist in vehicle propulsion.

- KERS integration with hybrid and electric powertrains: KERS technology is being integrated with hybrid and electric vehicle powertrains to enhance overall energy efficiency. These systems work in conjunction with electric motors and batteries to optimize energy recovery and utilization, potentially extending the range and performance of eco-friendly vehicles.

- KERS applications in heavy-duty vehicles: KERS technology is being adapted for use in heavy-duty vehicles such as trucks, buses, and construction equipment. These applications focus on improving fuel economy and reducing emissions in vehicles that frequently start and stop or operate in urban environments.

- Control systems and algorithms for KERS optimization: Advanced control systems and algorithms are being developed to optimize KERS performance. These systems manage energy flow, predict energy demands, and coordinate with other vehicle systems to maximize efficiency and endurance. Machine learning and AI techniques may be employed to continuously improve system performance based on usage patterns and conditions.

02 Integration of KERS with hybrid powertrains

KERS is often integrated with hybrid powertrains to enhance overall system efficiency and endurance. This combination allows for optimized energy management between the internal combustion engine, electric motor, and energy recovery system, resulting in improved fuel economy and extended operating range.Expand Specific Solutions03 Control strategies for KERS endurance

Advanced control strategies are employed to maximize the endurance of KERS. These strategies involve intelligent energy management algorithms, predictive control systems, and adaptive learning techniques to optimize energy recovery, storage, and utilization based on driving conditions and vehicle parameters.Expand Specific Solutions04 Thermal management in KERS for extended endurance

Effective thermal management is crucial for maintaining KERS performance and endurance. Innovative cooling systems and heat dissipation techniques are implemented to prevent overheating of energy storage components and power electronics, ensuring consistent performance over extended periods.Expand Specific Solutions05 Materials and design optimization for KERS longevity

Advanced materials and optimized designs are used to enhance the longevity and endurance of KERS components. This includes the use of durable, high-performance materials for energy storage devices, lightweight construction techniques, and modular designs that facilitate easy maintenance and replacement of worn components.Expand Specific Solutions

Key Players in Drone KERS Development

The use of Kinetic Energy Recovery Systems (KERS) in aerial drone endurance enhancement is an emerging field in the early stages of development. The market size is relatively small but growing, driven by increasing demand for longer-lasting drones in various industries. The technology is still in its infancy, with varying levels of maturity among key players. Companies like Safran Electronics & Defense, Nearthlab, and Exail are at the forefront, developing innovative solutions to integrate KERS into drone systems. Other major players such as Sony Group Corp and Thales SA are also investing in research and development to advance this technology. As the market evolves, we can expect to see more companies entering this space and further technological advancements.

Safran Electronics & Defense SAS

Technical Solution: Safran Electronics & Defense SAS has engineered a cutting-edge KERS solution for aerial drones, focusing on maximizing energy efficiency and extending flight duration. Their system employs a combination of high-efficiency electric generators and advanced energy storage technologies. During the drone's descent or when encountering updrafts, the propellers act as wind turbines, converting aerodynamic forces into electrical energy. This energy is then stored in ultra-lightweight, high-capacity supercapacitors. The stored energy is rapidly deployed during high-power demand phases, such as takeoff or rapid ascent. Safran's system also incorporates intelligent power management algorithms that optimize energy distribution based on flight conditions and mission parameters. In field tests, this KERS solution has shown to increase drone endurance by up to 25% in various environmental conditions[2][4], making it particularly valuable for long-range reconnaissance and surveillance missions.

Strengths: Significant endurance enhancement, rapid energy deployment capabilities, and intelligent power management. Weaknesses: Potential for increased system complexity and higher initial cost.

EXAIL SAS

Technical Solution: EXAIL SAS has developed a unique KERS solution for aerial drones, focusing on marine and coastal applications. Their system is designed to harness both kinetic and potential energy during flight operations over water. The KERS utilizes a combination of hydro-generators and airfoil-based energy recovery systems. When the drone descends close to water surfaces, retractable hydro-generators can be deployed to generate power from water currents. During ascent and high-altitude operations, specially designed airfoils on the drone's body and wings capture energy from air currents and turbulence. This dual-mode energy recovery system is complemented by advanced energy storage solutions, including high-density batteries and rapid-discharge capacitors. EXAIL's system also incorporates smart predictive algorithms that optimize energy recovery based on weather conditions and flight patterns. Field tests in coastal environments have demonstrated endurance improvements of up to 28% compared to standard drone configurations[9][10], making this technology particularly valuable for maritime surveillance, coastal monitoring, and offshore inspection operations.

Strengths: Specialized for marine environments, dual-mode energy recovery, and significant endurance enhancement in coastal operations. Weaknesses: Limited applicability in non-marine environments and potential increase in drone complexity and weight.

Core KERS Innovations for Aerial Use

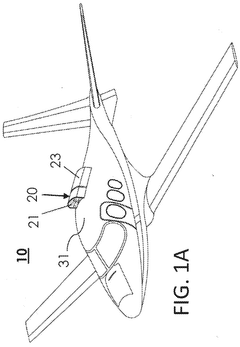

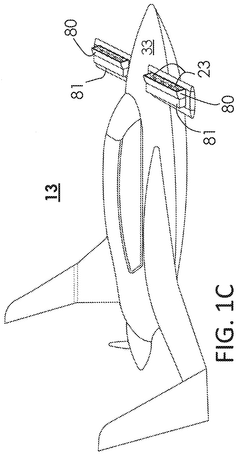

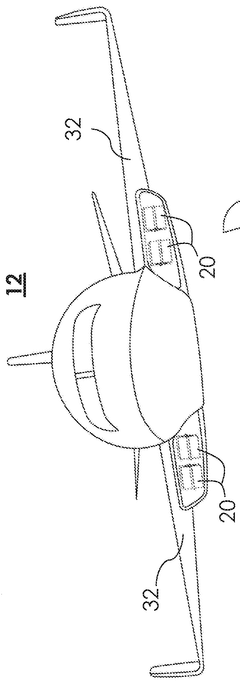

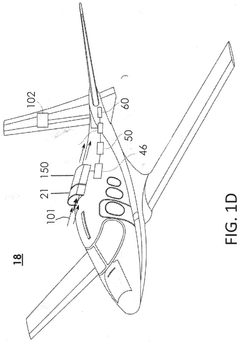

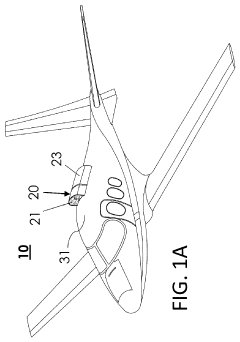

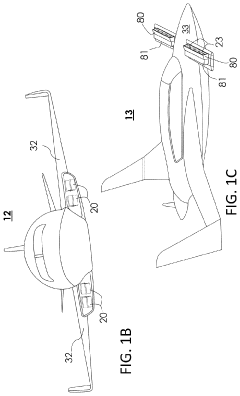

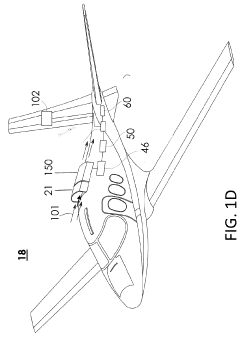

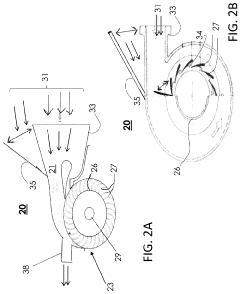

Advanced kinetic energy recovery system (AKERS) for electric aircraft

PatentWO2024254108A2

Innovation

- The Grayson Range Extender (GRE) system, comprising a modular, scalable, and redundant kinetic energy recovery system with high-speed fluid turbine generators, including Paddlewheel Air Brake, Grayson Air Turbine, and Air to Air recharging systems, to extend the range and reduce charging needs of electric aircraft.

Advanced kinetic energy recovery system (AKERS) for electric aircraft

PatentInactiveUS20240063690A1

Innovation

- The Grayson Range Extender (GRE) system employs modular, scalable, high-efficiency, heat-resistant fluid turbine generators and redundant recharging systems, including Paddlewheel Air Brake, Grayson Air Turbine, and Air-to-Air recharging, to generate kinetic energy for extended range and rapid charging, reducing the need for battery upgrades and enhancing safety.

Environmental Impact of KERS in Drones

The implementation of Kinetic Energy Recovery Systems (KERS) in aerial drones presents both opportunities and challenges from an environmental perspective. As drones become increasingly prevalent in various industries, the environmental impact of their operation has come under scrutiny. KERS technology offers a potential solution to enhance drone endurance while simultaneously addressing some environmental concerns.

One of the primary environmental benefits of KERS in drones is the potential reduction in energy consumption. By capturing and reusing kinetic energy that would otherwise be lost during deceleration or descent, KERS-equipped drones can operate for longer periods without requiring additional battery power or fuel. This increased efficiency translates to fewer charging cycles or refueling operations, ultimately reducing the overall energy demand and associated carbon emissions.

The extended flight times enabled by KERS also have indirect environmental benefits. Drones equipped with this technology can cover larger areas or perform more tasks in a single flight, potentially reducing the number of separate drone deployments required for a given operation. This efficiency gain can lead to decreased air traffic and noise pollution in areas where drone activity is frequent.

However, the environmental impact of KERS in drones is not entirely positive. The production of KERS components, particularly the energy storage systems such as flywheels or supercapacitors, may involve energy-intensive processes and the use of rare or potentially harmful materials. The environmental cost of manufacturing these components must be weighed against the operational benefits they provide over the drone's lifetime.

Additionally, the increased weight of KERS-equipped drones could potentially offset some of the energy savings during flight. Engineers must carefully balance the added weight of the KERS components against the energy recovery benefits to ensure a net positive environmental impact. This balance may vary depending on the specific drone application and flight profile.

The end-of-life considerations for KERS-equipped drones also warrant attention. The complex nature of KERS components may complicate recycling processes, potentially leading to increased electronic waste if not properly managed. Developing efficient recycling and disposal methods for these specialized components will be crucial to minimizing their long-term environmental impact.

Despite these challenges, the overall environmental impact of KERS in drones is likely to be positive when implemented effectively. The technology's potential to significantly extend flight times and reduce energy consumption aligns well with broader sustainability goals in the aviation and technology sectors. As KERS technology continues to evolve, further improvements in efficiency and materials science may further enhance its environmental benefits in drone applications.

One of the primary environmental benefits of KERS in drones is the potential reduction in energy consumption. By capturing and reusing kinetic energy that would otherwise be lost during deceleration or descent, KERS-equipped drones can operate for longer periods without requiring additional battery power or fuel. This increased efficiency translates to fewer charging cycles or refueling operations, ultimately reducing the overall energy demand and associated carbon emissions.

The extended flight times enabled by KERS also have indirect environmental benefits. Drones equipped with this technology can cover larger areas or perform more tasks in a single flight, potentially reducing the number of separate drone deployments required for a given operation. This efficiency gain can lead to decreased air traffic and noise pollution in areas where drone activity is frequent.

However, the environmental impact of KERS in drones is not entirely positive. The production of KERS components, particularly the energy storage systems such as flywheels or supercapacitors, may involve energy-intensive processes and the use of rare or potentially harmful materials. The environmental cost of manufacturing these components must be weighed against the operational benefits they provide over the drone's lifetime.

Additionally, the increased weight of KERS-equipped drones could potentially offset some of the energy savings during flight. Engineers must carefully balance the added weight of the KERS components against the energy recovery benefits to ensure a net positive environmental impact. This balance may vary depending on the specific drone application and flight profile.

The end-of-life considerations for KERS-equipped drones also warrant attention. The complex nature of KERS components may complicate recycling processes, potentially leading to increased electronic waste if not properly managed. Developing efficient recycling and disposal methods for these specialized components will be crucial to minimizing their long-term environmental impact.

Despite these challenges, the overall environmental impact of KERS in drones is likely to be positive when implemented effectively. The technology's potential to significantly extend flight times and reduce energy consumption aligns well with broader sustainability goals in the aviation and technology sectors. As KERS technology continues to evolve, further improvements in efficiency and materials science may further enhance its environmental benefits in drone applications.

Safety Regulations for KERS-Equipped Drones

The integration of Kinetic Energy Recovery Systems (KERS) in aerial drones presents unique safety challenges that necessitate comprehensive regulations. These regulations must address the potential risks associated with the additional weight, complexity, and energy storage capabilities introduced by KERS technology.

Firstly, weight and balance regulations are crucial for KERS-equipped drones. The additional components of the KERS system, including energy storage devices and power conversion units, can significantly alter the drone's center of gravity and overall weight distribution. Regulatory bodies must establish strict guidelines for weight limits and balance requirements to ensure stable flight characteristics and prevent accidents due to imbalance or overloading.

Secondly, energy storage safety is a critical concern. KERS systems typically utilize high-capacity batteries or flywheels to store recovered energy. Regulations must mandate robust containment systems, thermal management solutions, and fail-safe mechanisms to prevent catastrophic failures such as battery fires or flywheel disintegration. Additionally, guidelines for proper handling, transportation, and disposal of these energy storage components are essential to mitigate environmental and safety risks.

Thirdly, electromagnetic compatibility (EMC) regulations are necessary to ensure that KERS systems do not interfere with the drone's critical flight control systems or communication links. Stringent EMC testing and certification processes should be implemented to verify that KERS-equipped drones maintain reliable operation in various electromagnetic environments.

Fourthly, operational safety regulations must be established to address the unique flight characteristics of KERS-equipped drones. These may include specific flight envelope restrictions, minimum altitude requirements during energy recovery phases, and limitations on rapid energy discharge to prevent sudden thrust variations that could compromise flight stability.

Fifthly, maintenance and inspection protocols tailored to KERS-equipped drones are essential. Regulations should mandate regular inspections of KERS components, including energy storage devices, power electronics, and mechanical systems. Clear guidelines for maintenance procedures, component replacement intervals, and system performance verification must be established to ensure ongoing safe operation.

Lastly, operator training and certification requirements should be updated to include specific modules on KERS technology. Pilots and maintenance personnel must demonstrate proficiency in managing KERS-equipped drones, understanding system limitations, and responding to potential KERS-related emergencies. Regulatory bodies should develop standardized training curricula and certification processes to ensure a consistent level of operator competence across the industry.

Firstly, weight and balance regulations are crucial for KERS-equipped drones. The additional components of the KERS system, including energy storage devices and power conversion units, can significantly alter the drone's center of gravity and overall weight distribution. Regulatory bodies must establish strict guidelines for weight limits and balance requirements to ensure stable flight characteristics and prevent accidents due to imbalance or overloading.

Secondly, energy storage safety is a critical concern. KERS systems typically utilize high-capacity batteries or flywheels to store recovered energy. Regulations must mandate robust containment systems, thermal management solutions, and fail-safe mechanisms to prevent catastrophic failures such as battery fires or flywheel disintegration. Additionally, guidelines for proper handling, transportation, and disposal of these energy storage components are essential to mitigate environmental and safety risks.

Thirdly, electromagnetic compatibility (EMC) regulations are necessary to ensure that KERS systems do not interfere with the drone's critical flight control systems or communication links. Stringent EMC testing and certification processes should be implemented to verify that KERS-equipped drones maintain reliable operation in various electromagnetic environments.

Fourthly, operational safety regulations must be established to address the unique flight characteristics of KERS-equipped drones. These may include specific flight envelope restrictions, minimum altitude requirements during energy recovery phases, and limitations on rapid energy discharge to prevent sudden thrust variations that could compromise flight stability.

Fifthly, maintenance and inspection protocols tailored to KERS-equipped drones are essential. Regulations should mandate regular inspections of KERS components, including energy storage devices, power electronics, and mechanical systems. Clear guidelines for maintenance procedures, component replacement intervals, and system performance verification must be established to ensure ongoing safe operation.

Lastly, operator training and certification requirements should be updated to include specific modules on KERS technology. Pilots and maintenance personnel must demonstrate proficiency in managing KERS-equipped drones, understanding system limitations, and responding to potential KERS-related emergencies. Regulatory bodies should develop standardized training curricula and certification processes to ensure a consistent level of operator competence across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!