Nichrome in 3D Printing: Exploring Thermal Applications

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in 3D Printing: Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in electrical heating applications for decades. Its unique properties, including high electrical resistance and excellent heat tolerance, have made it a staple in various industries. In recent years, the 3D printing sector has begun to explore the potential of Nichrome, recognizing its thermal characteristics as a valuable asset in additive manufacturing processes.

The evolution of 3D printing technology has been marked by continuous innovation in materials and techniques. As the industry strives for more versatile and efficient printing methods, the integration of Nichrome presents an exciting frontier. The alloy's ability to generate controlled heat when an electric current passes through it opens up new possibilities for enhancing print quality, expanding material options, and improving overall printing efficiency.

The primary objective of exploring thermal applications of Nichrome in 3D printing is to leverage its heat-generating capabilities to address several challenges in the additive manufacturing process. One key goal is to improve the adhesion and layer bonding of printed materials, particularly for high-temperature polymers and composites. By incorporating Nichrome elements into printing beds or extruders, researchers aim to achieve more precise temperature control during the printing process.

Another significant objective is to expand the range of printable materials. Many advanced polymers and metal powders require specific thermal conditions for optimal printing. Nichrome's controllable heating properties could enable 3D printers to work with a broader spectrum of materials, including those with high melting points or specific thermal requirements.

Furthermore, the integration of Nichrome in 3D printing systems aims to enhance print speed and efficiency. By providing localized heating, it may be possible to reduce overall energy consumption and printing times, particularly for large-scale or industrial applications. This could lead to more cost-effective and sustainable 3D printing processes.

The exploration of Nichrome in 3D printing also seeks to improve the post-processing capabilities of printed objects. Controlled heating elements could be used for in-situ annealing or stress relief of printed parts, potentially eliminating the need for separate post-processing steps and improving the overall quality and mechanical properties of the final products.

As research in this field progresses, the ultimate goal is to develop new 3D printing technologies that seamlessly integrate Nichrome's thermal properties. This could lead to the creation of hybrid printing systems that combine traditional additive manufacturing techniques with advanced thermal management, opening up new avenues for innovation in fields such as aerospace, automotive, and medical device manufacturing.

The evolution of 3D printing technology has been marked by continuous innovation in materials and techniques. As the industry strives for more versatile and efficient printing methods, the integration of Nichrome presents an exciting frontier. The alloy's ability to generate controlled heat when an electric current passes through it opens up new possibilities for enhancing print quality, expanding material options, and improving overall printing efficiency.

The primary objective of exploring thermal applications of Nichrome in 3D printing is to leverage its heat-generating capabilities to address several challenges in the additive manufacturing process. One key goal is to improve the adhesion and layer bonding of printed materials, particularly for high-temperature polymers and composites. By incorporating Nichrome elements into printing beds or extruders, researchers aim to achieve more precise temperature control during the printing process.

Another significant objective is to expand the range of printable materials. Many advanced polymers and metal powders require specific thermal conditions for optimal printing. Nichrome's controllable heating properties could enable 3D printers to work with a broader spectrum of materials, including those with high melting points or specific thermal requirements.

Furthermore, the integration of Nichrome in 3D printing systems aims to enhance print speed and efficiency. By providing localized heating, it may be possible to reduce overall energy consumption and printing times, particularly for large-scale or industrial applications. This could lead to more cost-effective and sustainable 3D printing processes.

The exploration of Nichrome in 3D printing also seeks to improve the post-processing capabilities of printed objects. Controlled heating elements could be used for in-situ annealing or stress relief of printed parts, potentially eliminating the need for separate post-processing steps and improving the overall quality and mechanical properties of the final products.

As research in this field progresses, the ultimate goal is to develop new 3D printing technologies that seamlessly integrate Nichrome's thermal properties. This could lead to the creation of hybrid printing systems that combine traditional additive manufacturing techniques with advanced thermal management, opening up new avenues for innovation in fields such as aerospace, automotive, and medical device manufacturing.

Market Analysis for Thermal 3D Printing Applications

The thermal 3D printing market has been experiencing significant growth in recent years, driven by the increasing demand for advanced manufacturing technologies across various industries. The global market for thermal 3D printing applications is projected to expand at a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is primarily attributed to the rising adoption of 3D printing technologies in aerospace, automotive, healthcare, and consumer goods sectors.

The aerospace industry has emerged as a key driver for thermal 3D printing applications, particularly in the production of complex components and lightweight structures. The automotive sector is also embracing this technology for rapid prototyping and manufacturing of customized parts. In the healthcare industry, thermal 3D printing is gaining traction for producing patient-specific implants and prosthetics.

The market for thermal 3D printing materials, including Nichrome, is expected to witness substantial growth. Nichrome, an alloy of nickel and chromium, offers excellent thermal properties and resistance to high temperatures, making it suitable for various 3D printing applications. The demand for Nichrome in 3D printing is anticipated to increase, especially in industries requiring heat-resistant components.

Geographically, North America and Europe currently dominate the thermal 3D printing market, owing to the presence of major industry players and early adoption of advanced manufacturing technologies. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in additive manufacturing technologies.

The market is characterized by intense competition among key players, including 3D Systems, Stratasys, EOS GmbH, and Materialise NV. These companies are focusing on developing innovative thermal 3D printing solutions and expanding their product portfolios to gain a competitive edge. Additionally, collaborations between material suppliers and 3D printer manufacturers are becoming more prevalent, aiming to develop specialized materials for specific applications.

Despite the positive outlook, the thermal 3D printing market faces challenges such as high initial investment costs and the need for skilled operators. However, ongoing technological advancements and increasing awareness about the benefits of 3D printing are expected to drive market growth in the long term. The integration of thermal 3D printing with other emerging technologies, such as artificial intelligence and the Internet of Things, is likely to create new opportunities and further expand the market potential.

The aerospace industry has emerged as a key driver for thermal 3D printing applications, particularly in the production of complex components and lightweight structures. The automotive sector is also embracing this technology for rapid prototyping and manufacturing of customized parts. In the healthcare industry, thermal 3D printing is gaining traction for producing patient-specific implants and prosthetics.

The market for thermal 3D printing materials, including Nichrome, is expected to witness substantial growth. Nichrome, an alloy of nickel and chromium, offers excellent thermal properties and resistance to high temperatures, making it suitable for various 3D printing applications. The demand for Nichrome in 3D printing is anticipated to increase, especially in industries requiring heat-resistant components.

Geographically, North America and Europe currently dominate the thermal 3D printing market, owing to the presence of major industry players and early adoption of advanced manufacturing technologies. However, the Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in additive manufacturing technologies.

The market is characterized by intense competition among key players, including 3D Systems, Stratasys, EOS GmbH, and Materialise NV. These companies are focusing on developing innovative thermal 3D printing solutions and expanding their product portfolios to gain a competitive edge. Additionally, collaborations between material suppliers and 3D printer manufacturers are becoming more prevalent, aiming to develop specialized materials for specific applications.

Despite the positive outlook, the thermal 3D printing market faces challenges such as high initial investment costs and the need for skilled operators. However, ongoing technological advancements and increasing awareness about the benefits of 3D printing are expected to drive market growth in the long term. The integration of thermal 3D printing with other emerging technologies, such as artificial intelligence and the Internet of Things, is likely to create new opportunities and further expand the market potential.

Current Challenges in Nichrome-based 3D Printing

Despite the promising potential of Nichrome in 3D printing applications, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the precise control of temperature distribution across the Nichrome heating element. The non-uniform heating characteristics of Nichrome wire can lead to inconsistent melting of printing materials, resulting in poor print quality and structural integrity.

Another major challenge lies in the integration of Nichrome heating elements into existing 3D printer designs. The incorporation of these elements often requires substantial modifications to printer hardware and control systems, which can be both costly and time-consuming. Furthermore, the added complexity may introduce new points of failure and increase maintenance requirements.

The durability and longevity of Nichrome elements in 3D printing applications also present significant concerns. The repeated heating and cooling cycles, coupled with potential exposure to various printing materials, can lead to accelerated wear and degradation of the Nichrome wire. This not only affects print quality over time but also necessitates frequent replacements, impacting overall operational efficiency.

Heat management and safety considerations pose additional challenges. The high temperatures generated by Nichrome elements require robust thermal insulation and heat dissipation mechanisms to prevent damage to other printer components and ensure user safety. Developing effective cooling systems that do not compromise print quality or speed remains a complex engineering task.

The optimization of power consumption and energy efficiency in Nichrome-based 3D printing systems is another area of concern. The high power requirements of Nichrome heating elements can lead to increased energy costs and may limit the portability and accessibility of 3D printers in certain environments.

Lastly, the development of suitable control algorithms and software interfaces for Nichrome-based heating systems presents a significant challenge. These systems must accurately regulate temperature based on various factors such as print speed, material properties, and environmental conditions, requiring sophisticated sensing and control mechanisms.

Addressing these challenges will be crucial for realizing the full potential of Nichrome in 3D printing applications and advancing the field towards more efficient, reliable, and versatile printing technologies.

Another major challenge lies in the integration of Nichrome heating elements into existing 3D printer designs. The incorporation of these elements often requires substantial modifications to printer hardware and control systems, which can be both costly and time-consuming. Furthermore, the added complexity may introduce new points of failure and increase maintenance requirements.

The durability and longevity of Nichrome elements in 3D printing applications also present significant concerns. The repeated heating and cooling cycles, coupled with potential exposure to various printing materials, can lead to accelerated wear and degradation of the Nichrome wire. This not only affects print quality over time but also necessitates frequent replacements, impacting overall operational efficiency.

Heat management and safety considerations pose additional challenges. The high temperatures generated by Nichrome elements require robust thermal insulation and heat dissipation mechanisms to prevent damage to other printer components and ensure user safety. Developing effective cooling systems that do not compromise print quality or speed remains a complex engineering task.

The optimization of power consumption and energy efficiency in Nichrome-based 3D printing systems is another area of concern. The high power requirements of Nichrome heating elements can lead to increased energy costs and may limit the portability and accessibility of 3D printers in certain environments.

Lastly, the development of suitable control algorithms and software interfaces for Nichrome-based heating systems presents a significant challenge. These systems must accurately regulate temperature based on various factors such as print speed, material properties, and environmental conditions, requiring sophisticated sensing and control mechanisms.

Addressing these challenges will be crucial for realizing the full potential of Nichrome in 3D printing applications and advancing the field towards more efficient, reliable, and versatile printing technologies.

Existing Nichrome Thermal Solutions for 3D Printing

01 Thermal conductivity and resistivity

Nichrome exhibits specific thermal conductivity and electrical resistivity properties, making it suitable for various applications requiring controlled heat generation. These properties are crucial in designing heating elements and temperature sensors.- Thermal conductivity and resistivity: Nichrome exhibits specific thermal conductivity and electrical resistivity properties, making it suitable for various applications requiring controlled heat generation and distribution. These properties are crucial in designing heating elements and temperature sensors.

- Temperature coefficient of resistance: The temperature coefficient of resistance for nichrome is relatively low, allowing for stable electrical resistance over a wide range of temperatures. This characteristic is valuable in precision measurement devices and temperature control systems.

- High-temperature stability: Nichrome maintains its structural integrity and electrical properties at elevated temperatures, making it ideal for high-temperature applications such as furnaces, ovens, and industrial heating equipment. Its resistance to oxidation contributes to its longevity in these environments.

- Thermal expansion characteristics: The thermal expansion coefficient of nichrome is an important consideration in applications where dimensional stability is crucial. Understanding and accounting for thermal expansion helps in designing components that maintain their shape and function across temperature ranges.

- Heat dissipation and thermal management: Nichrome's thermal properties play a significant role in heat dissipation and thermal management systems. Its ability to generate and distribute heat efficiently is utilized in various applications, including electronic devices and industrial processes.

02 Temperature coefficient of resistance

The temperature coefficient of resistance for nichrome is relatively low, allowing for stable electrical resistance over a wide temperature range. This characteristic is valuable in precision measurement devices and temperature control systems.Expand Specific Solutions03 High-temperature stability

Nichrome demonstrates excellent stability at high temperatures, maintaining its mechanical and electrical properties. This makes it ideal for use in furnaces, ovens, and other high-temperature applications where consistent performance is critical.Expand Specific Solutions04 Oxidation resistance

Nichrome forms a protective oxide layer when exposed to high temperatures, providing resistance to further oxidation. This property enhances the longevity and reliability of nichrome components in harsh environments.Expand Specific Solutions05 Thermal expansion characteristics

The thermal expansion coefficient of nichrome is an important consideration in applications where dimensional stability is crucial. Understanding and accounting for thermal expansion helps in designing components that maintain their shape and function across temperature variations.Expand Specific Solutions

Key Players in Nichrome 3D Printing Industry

The thermal applications of Nichrome in 3D printing represent an emerging field with significant potential for growth. The market is in its early stages, characterized by ongoing research and development efforts. While the exact market size is not yet well-defined, it is expected to expand as the technology matures. Companies like Thermwood Corp., Bond high performance 3D technology BV, and Xian Bright Laser Technologies Co., Ltd. are at the forefront of this technology, developing innovative solutions for high-temperature 3D printing applications. The involvement of established players such as 3M Innovative Properties Co. and Jabil, Inc. suggests growing interest in the commercial potential of Nichrome-based 3D printing technologies. However, the technology is still evolving, with ongoing efforts to optimize material properties and printing processes for various industrial applications.

3M Innovative Properties Co.

Technical Solution: 3M has developed a novel approach to thermal management in 3D printing using Nichrome-based heating elements. Their technology incorporates thin Nichrome films as part of a multi-layer composite material that can be directly 3D printed. This allows for the creation of embedded heating elements within the printed structure itself. The Nichrome layers are precisely deposited using a modified fused deposition modeling (FDM) process, enabling the production of parts with integrated thermal control capabilities[3]. 3M's method includes a proprietary insulation layer to prevent thermal interference between adjacent Nichrome elements, allowing for complex thermal gradients within a single printed part[4].

Strengths: Enables creation of parts with integrated heating elements, allows for complex thermal gradients. Weaknesses: Requires specialized printing equipment and materials, potentially limiting widespread adoption.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed a high-performance polymer composite material incorporating Nichrome particles for use in 3D printing applications requiring thermal management. Their material, known as KetaSpire® PEEK NT1, combines polyetheretherketone (PEEK) with finely dispersed Nichrome particles. This composite offers excellent thermal conductivity and electrical resistivity, making it suitable for applications where heat generation or dissipation is crucial. The material can be processed using selective laser sintering (SLS) or fused filament fabrication (FFF) 3D printing techniques[5]. Solvay's approach allows for the creation of complex geometries with inherent thermal properties, eliminating the need for separate heating elements in some applications[6].

Strengths: Combines thermal properties of Nichrome with the mechanical strength of PEEK, suitable for high-performance applications. Weaknesses: Higher material cost compared to standard 3D printing filaments, requires specialized printing equipment.

Innovative Nichrome Applications in Additive Manufacturing

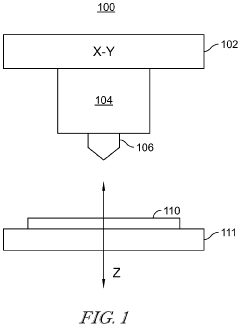

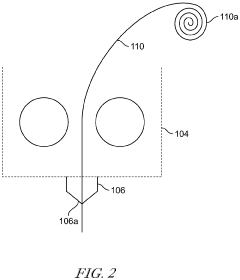

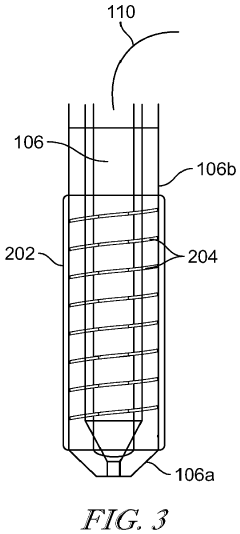

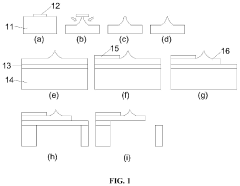

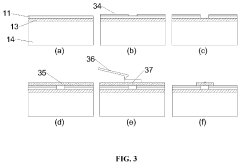

Apparatus, system and method of operating an additive manufacturing nozzle

PatentActiveEP4275818A2

Innovation

- A 3D printer nozzle design featuring a sheath with embedded wire coils, such as nichrome wire coils, that provide improved thermal control and energy efficiency, allowing for precise heating and cooling management.

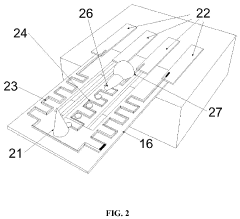

Self-packing three-arm thermal scanning probe for micro-nano manufacturing

PatentActiveUS20240002220A1

Innovation

- A self-packing three-arm thermal scanning probe with gradient density nichrome heating electrodes, where the transportation cantilever beam has a sparse S-shaped nichrome heating electrode to create a continuous temperature gradient, and S-shaped nichrome heating electrodes on printing cantilever beams maintain the polymer in a liquid state, enabling continuous printing.

Material Safety and Handling Considerations

When exploring thermal applications of Nichrome in 3D printing, material safety and handling considerations are paramount. Nichrome, an alloy primarily composed of nickel and chromium, requires careful management due to its unique properties and potential hazards.

Proper storage of Nichrome wire or powder is essential. It should be kept in a cool, dry environment away from moisture and corrosive substances. Sealed containers are recommended to prevent oxidation and contamination. Labeling should clearly indicate the material's composition and any associated risks.

Personal protective equipment (PPE) is crucial when handling Nichrome. Operators should wear safety glasses, heat-resistant gloves, and appropriate respiratory protection, especially when working with Nichrome powder. Long-sleeved clothing and closed-toe shoes are also advisable to minimize skin exposure.

During the 3D printing process, adequate ventilation is necessary to mitigate potential fume exposure. Local exhaust ventilation or fume hoods should be employed to capture and remove any airborne particles or vapors generated during heating. Regular air quality monitoring in the workspace is recommended to ensure safe operating conditions.

Nichrome can reach high temperatures rapidly when electrically heated. Operators must be trained in proper handling techniques to avoid burns or accidental ignition of surrounding materials. Implementing thermal barriers and using insulated tools can help prevent accidental contact with heated Nichrome components.

Proper disposal of Nichrome waste is critical. Unused material and printing byproducts should be collected in designated containers and disposed of according to local regulations for metal waste. Recycling options should be explored where possible to minimize environmental impact.

Emergency protocols must be established and communicated to all personnel working with Nichrome. This includes procedures for addressing potential fires, spills, or accidental exposure. Readily accessible fire extinguishers suitable for metal fires should be available in the work area.

Regular training and safety briefings should be conducted to ensure all staff are aware of the potential hazards and proper handling procedures for Nichrome in 3D printing applications. Documentation of safety protocols and material safety data sheets (MSDS) should be easily accessible to all personnel.

By implementing these safety and handling considerations, the risks associated with using Nichrome in 3D printing can be effectively managed, allowing for the safe exploration and development of its thermal applications in additive manufacturing processes.

Proper storage of Nichrome wire or powder is essential. It should be kept in a cool, dry environment away from moisture and corrosive substances. Sealed containers are recommended to prevent oxidation and contamination. Labeling should clearly indicate the material's composition and any associated risks.

Personal protective equipment (PPE) is crucial when handling Nichrome. Operators should wear safety glasses, heat-resistant gloves, and appropriate respiratory protection, especially when working with Nichrome powder. Long-sleeved clothing and closed-toe shoes are also advisable to minimize skin exposure.

During the 3D printing process, adequate ventilation is necessary to mitigate potential fume exposure. Local exhaust ventilation or fume hoods should be employed to capture and remove any airborne particles or vapors generated during heating. Regular air quality monitoring in the workspace is recommended to ensure safe operating conditions.

Nichrome can reach high temperatures rapidly when electrically heated. Operators must be trained in proper handling techniques to avoid burns or accidental ignition of surrounding materials. Implementing thermal barriers and using insulated tools can help prevent accidental contact with heated Nichrome components.

Proper disposal of Nichrome waste is critical. Unused material and printing byproducts should be collected in designated containers and disposed of according to local regulations for metal waste. Recycling options should be explored where possible to minimize environmental impact.

Emergency protocols must be established and communicated to all personnel working with Nichrome. This includes procedures for addressing potential fires, spills, or accidental exposure. Readily accessible fire extinguishers suitable for metal fires should be available in the work area.

Regular training and safety briefings should be conducted to ensure all staff are aware of the potential hazards and proper handling procedures for Nichrome in 3D printing applications. Documentation of safety protocols and material safety data sheets (MSDS) should be easily accessible to all personnel.

By implementing these safety and handling considerations, the risks associated with using Nichrome in 3D printing can be effectively managed, allowing for the safe exploration and development of its thermal applications in additive manufacturing processes.

Environmental Impact of Nichrome in 3D Printing

The environmental impact of Nichrome in 3D printing is a crucial aspect to consider as this technology gains prominence in various industries. Nichrome, an alloy of nickel and chromium, is widely used in 3D printing applications due to its excellent thermal properties and resistance to corrosion. However, its utilization raises several environmental concerns that warrant careful examination.

One of the primary environmental issues associated with Nichrome in 3D printing is the potential release of harmful particles during the printing process. When heated, Nichrome can emit fine particulate matter and potentially toxic fumes, which may pose risks to both human health and the environment if not properly managed. These emissions can contribute to air pollution and may require specialized filtration systems to mitigate their impact.

The production of Nichrome itself also has environmental implications. Mining and refining nickel and chromium, the primary components of Nichrome, can lead to significant ecological disturbances, including habitat destruction, soil erosion, and water pollution. The energy-intensive processes involved in alloy production further contribute to greenhouse gas emissions and climate change concerns.

Waste management is another critical environmental consideration in the use of Nichrome for 3D printing. As 3D printing technologies advance, the volume of waste generated from failed prints, support structures, and obsolete parts increases. Nichrome, being a metal alloy, presents challenges in recycling and disposal. Improper handling of Nichrome waste can lead to soil and water contamination, necessitating the development of effective recycling and disposal protocols.

The durability and corrosion resistance of Nichrome can be viewed as both an advantage and a potential environmental concern. While these properties contribute to the longevity of 3D-printed objects, potentially reducing waste, they also mean that Nichrome products may persist in the environment for extended periods if not properly managed at the end of their lifecycle.

Energy consumption during the 3D printing process using Nichrome is another environmental factor to consider. The high melting point of Nichrome requires significant energy input, which can increase the carbon footprint of 3D printing operations if not sourced from renewable energy.

To address these environmental challenges, research and development efforts are focusing on several areas. These include improving the efficiency of Nichrome use in 3D printing to reduce waste, developing more environmentally friendly alloy alternatives, and enhancing recycling technologies for metal 3D printing waste. Additionally, the implementation of closed-loop systems and advanced filtration technologies in 3D printing facilities can help mitigate the release of harmful emissions.

As the adoption of 3D printing with Nichrome continues to grow, it is essential to balance the technological benefits with environmental responsibility. This requires ongoing assessment of the environmental impact, development of sustainable practices, and collaboration between industry stakeholders, researchers, and policymakers to ensure that the advancement of 3D printing technology does not come at the cost of environmental degradation.

One of the primary environmental issues associated with Nichrome in 3D printing is the potential release of harmful particles during the printing process. When heated, Nichrome can emit fine particulate matter and potentially toxic fumes, which may pose risks to both human health and the environment if not properly managed. These emissions can contribute to air pollution and may require specialized filtration systems to mitigate their impact.

The production of Nichrome itself also has environmental implications. Mining and refining nickel and chromium, the primary components of Nichrome, can lead to significant ecological disturbances, including habitat destruction, soil erosion, and water pollution. The energy-intensive processes involved in alloy production further contribute to greenhouse gas emissions and climate change concerns.

Waste management is another critical environmental consideration in the use of Nichrome for 3D printing. As 3D printing technologies advance, the volume of waste generated from failed prints, support structures, and obsolete parts increases. Nichrome, being a metal alloy, presents challenges in recycling and disposal. Improper handling of Nichrome waste can lead to soil and water contamination, necessitating the development of effective recycling and disposal protocols.

The durability and corrosion resistance of Nichrome can be viewed as both an advantage and a potential environmental concern. While these properties contribute to the longevity of 3D-printed objects, potentially reducing waste, they also mean that Nichrome products may persist in the environment for extended periods if not properly managed at the end of their lifecycle.

Energy consumption during the 3D printing process using Nichrome is another environmental factor to consider. The high melting point of Nichrome requires significant energy input, which can increase the carbon footprint of 3D printing operations if not sourced from renewable energy.

To address these environmental challenges, research and development efforts are focusing on several areas. These include improving the efficiency of Nichrome use in 3D printing to reduce waste, developing more environmentally friendly alloy alternatives, and enhancing recycling technologies for metal 3D printing waste. Additionally, the implementation of closed-loop systems and advanced filtration technologies in 3D printing facilities can help mitigate the release of harmful emissions.

As the adoption of 3D printing with Nichrome continues to grow, it is essential to balance the technological benefits with environmental responsibility. This requires ongoing assessment of the environmental impact, development of sustainable practices, and collaboration between industry stakeholders, researchers, and policymakers to ensure that the advancement of 3D printing technology does not come at the cost of environmental degradation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!