Fouling Mechanisms And Cleaning Strategies In CDI Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CDI Fouling Background and Research Objectives

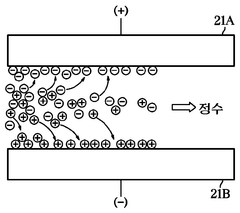

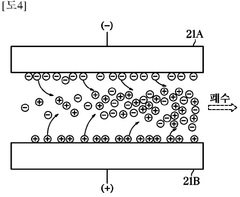

Capacitive deionization (CDI) has emerged as a promising technology for water desalination and purification over the past two decades. This electrochemical separation process utilizes porous carbon electrodes to remove ions from water through the application of an electrical potential difference. Unlike conventional desalination technologies such as reverse osmosis, CDI operates at low pressure and voltage, offering significant energy efficiency advantages for treating brackish water with low to moderate salinity.

Fouling in CDI systems represents a critical challenge that severely impacts long-term operational stability and economic viability. The accumulation of contaminants on electrode surfaces and within porous structures leads to diminished ion removal capacity, increased energy consumption, and shortened system lifespan. Despite its significance, fouling mechanisms in CDI have received considerably less research attention compared to membrane-based technologies, creating a substantial knowledge gap in the field.

The evolution of CDI technology has progressed through several generations, from conventional CDI to membrane-assisted variants and more recently, flow-electrode systems. Each iteration has attempted to address inherent limitations, including fouling susceptibility. Historical data indicates that fouling-related performance degradation can reduce CDI efficiency by 20-50% within weeks of operation in real-world applications, highlighting the urgency of developing effective mitigation strategies.

Current research objectives in CDI fouling focus on three primary dimensions: mechanistic understanding, preventive strategies, and remediation techniques. First, elucidating the fundamental mechanisms of organic, inorganic, and biological fouling at the molecular and system levels is essential for developing targeted solutions. This includes investigating the interactions between foulants and electrode materials under various operational conditions.

Second, developing innovative electrode materials and surface modifications that inherently resist fouling represents a promising preventive approach. This includes exploring hydrophilic coatings, antimicrobial surface treatments, and novel carbon architectures that minimize foulant adhesion while maintaining electrosorption capacity.

Third, establishing optimized cleaning protocols and regeneration methods for fouled electrodes is crucial for extending system lifespan. This encompasses chemical, physical, and electrochemical cleaning strategies that effectively remove accumulated foulants without degrading electrode performance over multiple cycles.

The ultimate goal of this research is to develop a comprehensive fouling management framework for CDI systems that enables reliable long-term operation in diverse water treatment applications. By addressing these objectives, CDI technology can overcome current limitations and fulfill its potential as a sustainable alternative to conventional desalination methods, particularly for decentralized applications and regions with limited resources.

Fouling in CDI systems represents a critical challenge that severely impacts long-term operational stability and economic viability. The accumulation of contaminants on electrode surfaces and within porous structures leads to diminished ion removal capacity, increased energy consumption, and shortened system lifespan. Despite its significance, fouling mechanisms in CDI have received considerably less research attention compared to membrane-based technologies, creating a substantial knowledge gap in the field.

The evolution of CDI technology has progressed through several generations, from conventional CDI to membrane-assisted variants and more recently, flow-electrode systems. Each iteration has attempted to address inherent limitations, including fouling susceptibility. Historical data indicates that fouling-related performance degradation can reduce CDI efficiency by 20-50% within weeks of operation in real-world applications, highlighting the urgency of developing effective mitigation strategies.

Current research objectives in CDI fouling focus on three primary dimensions: mechanistic understanding, preventive strategies, and remediation techniques. First, elucidating the fundamental mechanisms of organic, inorganic, and biological fouling at the molecular and system levels is essential for developing targeted solutions. This includes investigating the interactions between foulants and electrode materials under various operational conditions.

Second, developing innovative electrode materials and surface modifications that inherently resist fouling represents a promising preventive approach. This includes exploring hydrophilic coatings, antimicrobial surface treatments, and novel carbon architectures that minimize foulant adhesion while maintaining electrosorption capacity.

Third, establishing optimized cleaning protocols and regeneration methods for fouled electrodes is crucial for extending system lifespan. This encompasses chemical, physical, and electrochemical cleaning strategies that effectively remove accumulated foulants without degrading electrode performance over multiple cycles.

The ultimate goal of this research is to develop a comprehensive fouling management framework for CDI systems that enables reliable long-term operation in diverse water treatment applications. By addressing these objectives, CDI technology can overcome current limitations and fulfill its potential as a sustainable alternative to conventional desalination methods, particularly for decentralized applications and regions with limited resources.

Market Analysis of CDI Technology Applications

The Capacitive Deionization (CDI) technology market has witnessed significant growth in recent years, driven by increasing water scarcity concerns and the need for energy-efficient desalination solutions. The global CDI market was valued at approximately $32 million in 2022 and is projected to reach $89 million by 2028, representing a compound annual growth rate (CAGR) of 18.6% during the forecast period.

The industrial sector currently dominates CDI technology applications, accounting for nearly 45% of the market share. This is primarily due to the technology's effectiveness in treating industrial wastewater and process water, where selective ion removal capabilities provide substantial cost advantages over conventional technologies. Industries such as electronics manufacturing, pharmaceuticals, and food processing are increasingly adopting CDI systems for their specific water treatment requirements.

Municipal water treatment represents the second-largest application segment, with approximately 30% market share. The growing emphasis on sustainable water management practices in urban areas has accelerated the adoption of CDI technology for drinking water production, particularly in regions facing brackish water challenges. Several pilot projects in North America and Europe have demonstrated CDI's potential for municipal-scale implementation.

Geographically, North America leads the CDI technology market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). The Asia-Pacific region is expected to witness the fastest growth rate of 22.3% during the forecast period, driven by rapid industrialization, increasing water pollution concerns, and supportive government initiatives in countries like China, India, and South Korea.

From an end-user perspective, the market segmentation reveals interesting patterns. Large enterprises account for 65% of CDI system installations, while small and medium enterprises (SMEs) represent 35%. However, the adoption rate among SMEs is growing faster, indicating increasing accessibility and cost-effectiveness of CDI technology.

The fouling mechanisms in CDI systems present both challenges and opportunities for market players. The development of advanced cleaning strategies has emerged as a key differentiator among technology providers. Companies offering CDI systems with effective anti-fouling features and simplified maintenance protocols are gaining competitive advantage, commanding premium pricing of 15-20% above market averages.

Market analysts predict that innovations addressing fouling issues could potentially expand the CDI market by an additional $40-50 million by 2030, particularly in challenging water treatment applications where conventional technologies struggle with fouling-related performance degradation.

The industrial sector currently dominates CDI technology applications, accounting for nearly 45% of the market share. This is primarily due to the technology's effectiveness in treating industrial wastewater and process water, where selective ion removal capabilities provide substantial cost advantages over conventional technologies. Industries such as electronics manufacturing, pharmaceuticals, and food processing are increasingly adopting CDI systems for their specific water treatment requirements.

Municipal water treatment represents the second-largest application segment, with approximately 30% market share. The growing emphasis on sustainable water management practices in urban areas has accelerated the adoption of CDI technology for drinking water production, particularly in regions facing brackish water challenges. Several pilot projects in North America and Europe have demonstrated CDI's potential for municipal-scale implementation.

Geographically, North America leads the CDI technology market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). The Asia-Pacific region is expected to witness the fastest growth rate of 22.3% during the forecast period, driven by rapid industrialization, increasing water pollution concerns, and supportive government initiatives in countries like China, India, and South Korea.

From an end-user perspective, the market segmentation reveals interesting patterns. Large enterprises account for 65% of CDI system installations, while small and medium enterprises (SMEs) represent 35%. However, the adoption rate among SMEs is growing faster, indicating increasing accessibility and cost-effectiveness of CDI technology.

The fouling mechanisms in CDI systems present both challenges and opportunities for market players. The development of advanced cleaning strategies has emerged as a key differentiator among technology providers. Companies offering CDI systems with effective anti-fouling features and simplified maintenance protocols are gaining competitive advantage, commanding premium pricing of 15-20% above market averages.

Market analysts predict that innovations addressing fouling issues could potentially expand the CDI market by an additional $40-50 million by 2030, particularly in challenging water treatment applications where conventional technologies struggle with fouling-related performance degradation.

Current Challenges in CDI Fouling Prevention

Despite significant advancements in Capacitive Deionization (CDI) technology, fouling prevention remains one of the most critical challenges hindering widespread industrial adoption. The accumulation of organic matter, inorganic precipitates, and microbial growth on electrode surfaces progressively degrades system performance, reducing ion removal efficiency and operational lifespan. Current prevention strategies often fail to address the complex, multi-faceted nature of fouling mechanisms in real-world applications.

A primary challenge lies in developing electrode materials that maintain high ion adsorption capacity while simultaneously exhibiting anti-fouling properties. Conventional carbon-based electrodes with high surface area are particularly susceptible to organic fouling due to their hydrophobic nature and surface functional groups that promote irreversible adsorption of organic compounds. Recent attempts to incorporate hydrophilic coatings have shown promise but often compromise electrical conductivity and ion transport kinetics.

The dynamic nature of fouling presents another significant obstacle. Fouling mechanisms evolve throughout operational cycles, with initial stages dominated by physical adsorption followed by more complex biological fouling as systems mature. This temporal evolution makes it difficult to implement single-approach prevention strategies, necessitating adaptive, multi-stage solutions that current technologies struggle to provide.

Scale-up challenges further complicate fouling prevention efforts. Laboratory-scale prevention techniques often fail when implemented in industrial settings due to differences in flow dynamics, electrode configurations, and operational parameters. The heterogeneous distribution of fouling across large-scale electrode arrays creates localized performance degradation that can rapidly propagate throughout the system.

Energy efficiency considerations create additional constraints for prevention strategies. Many current anti-fouling approaches, such as periodic polarity reversal or high-voltage cleaning pulses, significantly increase energy consumption, undermining one of CDI's primary advantages as an energy-efficient desalination technology. Finding the optimal balance between fouling prevention and energy efficiency remains elusive.

Real-time monitoring and predictive maintenance capabilities are notably underdeveloped. Current systems typically lack sophisticated sensors and algorithms capable of detecting early-stage fouling before performance degradation becomes significant. This reactive rather than proactive approach to fouling management results in unnecessary downtime and increased operational costs.

Finally, the diversity of water compositions encountered in practical applications demands customizable prevention strategies that can adapt to varying foulant types and concentrations. Current one-size-fits-all approaches fail to address the unique fouling challenges presented by different water sources, limiting CDI application across diverse geographical and industrial contexts.

A primary challenge lies in developing electrode materials that maintain high ion adsorption capacity while simultaneously exhibiting anti-fouling properties. Conventional carbon-based electrodes with high surface area are particularly susceptible to organic fouling due to their hydrophobic nature and surface functional groups that promote irreversible adsorption of organic compounds. Recent attempts to incorporate hydrophilic coatings have shown promise but often compromise electrical conductivity and ion transport kinetics.

The dynamic nature of fouling presents another significant obstacle. Fouling mechanisms evolve throughout operational cycles, with initial stages dominated by physical adsorption followed by more complex biological fouling as systems mature. This temporal evolution makes it difficult to implement single-approach prevention strategies, necessitating adaptive, multi-stage solutions that current technologies struggle to provide.

Scale-up challenges further complicate fouling prevention efforts. Laboratory-scale prevention techniques often fail when implemented in industrial settings due to differences in flow dynamics, electrode configurations, and operational parameters. The heterogeneous distribution of fouling across large-scale electrode arrays creates localized performance degradation that can rapidly propagate throughout the system.

Energy efficiency considerations create additional constraints for prevention strategies. Many current anti-fouling approaches, such as periodic polarity reversal or high-voltage cleaning pulses, significantly increase energy consumption, undermining one of CDI's primary advantages as an energy-efficient desalination technology. Finding the optimal balance between fouling prevention and energy efficiency remains elusive.

Real-time monitoring and predictive maintenance capabilities are notably underdeveloped. Current systems typically lack sophisticated sensors and algorithms capable of detecting early-stage fouling before performance degradation becomes significant. This reactive rather than proactive approach to fouling management results in unnecessary downtime and increased operational costs.

Finally, the diversity of water compositions encountered in practical applications demands customizable prevention strategies that can adapt to varying foulant types and concentrations. Current one-size-fits-all approaches fail to address the unique fouling challenges presented by different water sources, limiting CDI application across diverse geographical and industrial contexts.

Established Cleaning Methodologies for CDI Systems

01 Anti-fouling electrode materials for CDI systems

Specialized electrode materials can be used in capacitive deionization systems to reduce fouling. These materials include carbon-based electrodes with modified surface properties, composite electrodes with anti-fouling coatings, and electrodes with specific pore structures that minimize the accumulation of foulants. By incorporating these materials, the operational efficiency and lifespan of CDI systems can be significantly improved, reducing maintenance requirements and operational costs.- Fouling prevention mechanisms in CDI systems: Various mechanisms can be implemented in CDI systems to prevent fouling, which occurs when contaminants accumulate on electrode surfaces. These mechanisms include specialized electrode coatings, surface modifications, and pre-treatment processes that reduce the adhesion of foulants. By implementing these preventive measures, the operational efficiency and lifespan of CDI systems can be significantly improved, reducing maintenance requirements and downtime.

- Electrode materials resistant to fouling: Specific electrode materials can be engineered to resist fouling in CDI systems. These materials include modified carbon-based electrodes, composite materials, and nanomaterials with anti-fouling properties. The selection of appropriate electrode materials is crucial for maintaining the performance of CDI systems over extended periods, particularly in applications involving water with high organic content or suspended solids that are prone to causing fouling issues.

- Cleaning and regeneration methods for fouled CDI systems: When fouling occurs in CDI systems, various cleaning and regeneration methods can be employed to restore performance. These methods include chemical cleaning protocols, polarity reversal techniques, and physical cleaning processes. Regular maintenance using these cleaning approaches helps to extend the operational lifetime of CDI systems and maintain their deionization efficiency, particularly in challenging water treatment applications.

- Flow design optimization to minimize fouling: The design of flow patterns within CDI systems can significantly impact fouling tendencies. Optimized flow configurations can reduce dead zones where foulants accumulate, enhance shear forces that prevent deposition, and improve the distribution of water across electrode surfaces. These design considerations include channel geometry, flow rate control, and the implementation of turbulence-inducing features that help maintain clean electrode surfaces during operation.

- Monitoring and control systems for fouling detection: Advanced monitoring and control systems can be implemented to detect fouling in CDI systems before performance is significantly impacted. These systems utilize parameters such as electrical resistance, flow rate changes, and pressure differentials to identify the onset of fouling. Early detection allows for timely intervention, such as initiating cleaning cycles or adjusting operational parameters, thereby maintaining optimal system performance and extending maintenance intervals.

02 Operational strategies to mitigate fouling in CDI systems

Various operational strategies can be implemented to reduce fouling in capacitive deionization systems. These include optimized voltage cycling, polarity reversal techniques, pulsed electric field application, and controlled flow dynamics. By adjusting operational parameters such as current density, flow rate, and charge/discharge cycles, the accumulation of foulants on electrode surfaces can be minimized, thereby extending the effective operational time between cleaning cycles.Expand Specific Solutions03 Cleaning and regeneration methods for fouled CDI electrodes

Effective cleaning and regeneration methods are essential for maintaining the performance of CDI systems affected by fouling. These methods include chemical cleaning with specific agents that dissolve or detach foulants, physical cleaning techniques such as backwashing or air scouring, and electrochemical regeneration processes that utilize controlled current or voltage to remove accumulated contaminants from electrode surfaces. Regular implementation of these cleaning protocols can restore system performance and extend the operational lifetime of CDI units.Expand Specific Solutions04 Membrane and spacer designs to reduce fouling

Advanced membrane and spacer designs play a crucial role in minimizing fouling in CDI systems. Ion-exchange membranes with anti-fouling properties, specialized spacer configurations that promote turbulent flow, and hybrid membrane-electrode assemblies can significantly reduce the accumulation of foulants. These designs enhance mass transfer, reduce concentration polarization, and create unfavorable conditions for foulant attachment, thereby improving the overall performance and longevity of CDI systems.Expand Specific Solutions05 Monitoring and predictive maintenance systems for fouling detection

Advanced monitoring and predictive maintenance systems can be implemented to detect and address fouling in CDI systems before it significantly impacts performance. These systems utilize real-time sensors, electrical impedance measurements, pressure drop monitoring, and machine learning algorithms to identify early signs of fouling. By detecting fouling at its initial stages, appropriate interventions can be implemented promptly, optimizing cleaning schedules and minimizing performance degradation and energy consumption.Expand Specific Solutions

Leading Organizations in CDI Technology Research

Capacitive Deionization (CDI) technology is currently in a growth phase, with the market expected to expand significantly due to increasing water scarcity concerns. The global CDI market is projected to reach approximately $2-3 billion by 2027, growing at a CAGR of 8-10%. Technologically, CDI systems are advancing from early commercial adoption to mainstream implementation, with fouling mechanisms representing a critical challenge. Leading players like Ecolab, Samsung Electronics, and LG Electronics are developing advanced anti-fouling strategies, while research institutions such as MIT and Worcester Polytechnic Institute are pioneering novel cleaning approaches. Chinese companies including Sinopec and Hwatsing Technology are rapidly entering the market with cost-effective solutions. The competitive landscape shows a mix of established water treatment corporations and technology innovators focusing on membrane improvements and automated cleaning systems to address scaling, organic fouling, and biofouling challenges.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a comprehensive CDI fouling management system that combines specialized chemical treatments with advanced monitoring technology. Their approach utilizes proprietary anti-scaling compounds that selectively target inorganic precipitates common in CDI systems, particularly calcium carbonate and silica deposits. The company's technology incorporates real-time fouling detection sensors that monitor electrical resistance changes across electrodes, triggering automated cleaning cycles before performance degradation occurs. Ecolab's cleaning strategy employs a multi-phase approach: first applying a low-pH solution to dissolve inorganic scale, followed by specialized surfactants to remove organic foulants, and finally a disinfection phase to prevent biofouling. Their research has demonstrated that this integrated approach can extend CDI operational cycles by 40-60% compared to conventional cleaning methods, while reducing cleaning chemical consumption by approximately 30%. Ecolab has also developed specific protocols for different water sources, optimizing cleaning frequency and chemistry based on influent water quality parameters.

Strengths: Extensive commercial experience in water treatment applications; comprehensive approach combining chemical, monitoring and automation technologies; customizable solutions for different water qualities and system configurations. Weaknesses: Chemical-intensive approach may have higher operational costs; potential environmental concerns with chemical discharge; requires regular consumable replenishment.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Laboratory has developed advanced computational modeling and experimental validation techniques to understand and address CDI fouling mechanisms at a fundamental level. Their approach combines molecular dynamics simulations with in-situ characterization methods to visualize and quantify fouling processes in real-time. This has led to the development of flow-optimized electrode architectures that minimize dead zones and concentration polarization effects that accelerate fouling. LLNL researchers have pioneered hierarchical carbon electrode structures with controlled macro, meso, and micropores that demonstrate superior fouling resistance while maintaining high capacitance. Their cleaning strategy incorporates pulsed electric field treatments at optimized frequencies that can dislodge foulants without damaging electrode structures. LLNL has also developed novel carbon-based composite electrodes incorporating antimicrobial nanomaterials that inhibit biofouling without compromising electrochemical performance. Their research demonstrates these approaches can extend operational cycles by 200-300% before intensive cleaning is required, while maintaining consistent desalination performance. The laboratory has also developed predictive models that can optimize cleaning schedules based on water quality parameters and operational conditions.

Strengths: Cutting-edge research capabilities and fundamental understanding of fouling mechanisms; advanced materials science expertise; sophisticated modeling capabilities for optimization. Weaknesses: Solutions may be at earlier technology readiness levels; potential challenges in scaling laboratory approaches to commercial systems; may require significant adaptation for specific applications.

Critical Patents in Anti-Fouling CDI Technology

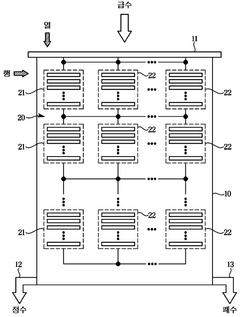

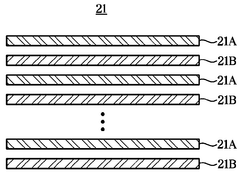

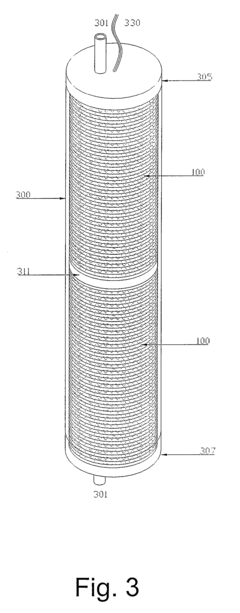

Water treatment apparatus and method for controlling same

PatentWO2025009677A1

Innovation

- A water treatment device with a housing containing series-connected electrode cells and variable resistors in parallel, controlled by a power supply unit and a control unit to maintain equal voltage across all electrode cells, preventing overcurrent and allowing continuous operation even with failed cells.

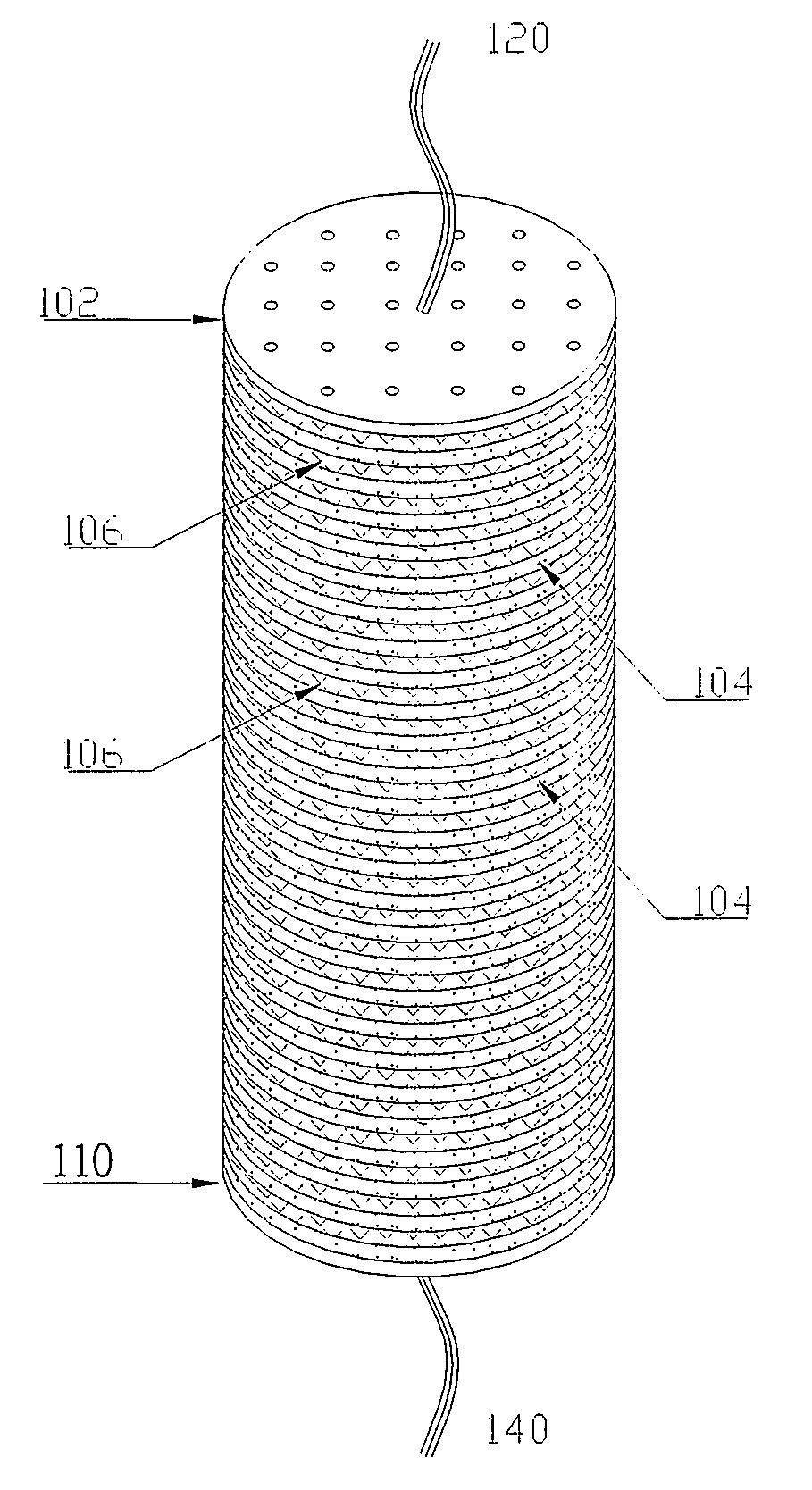

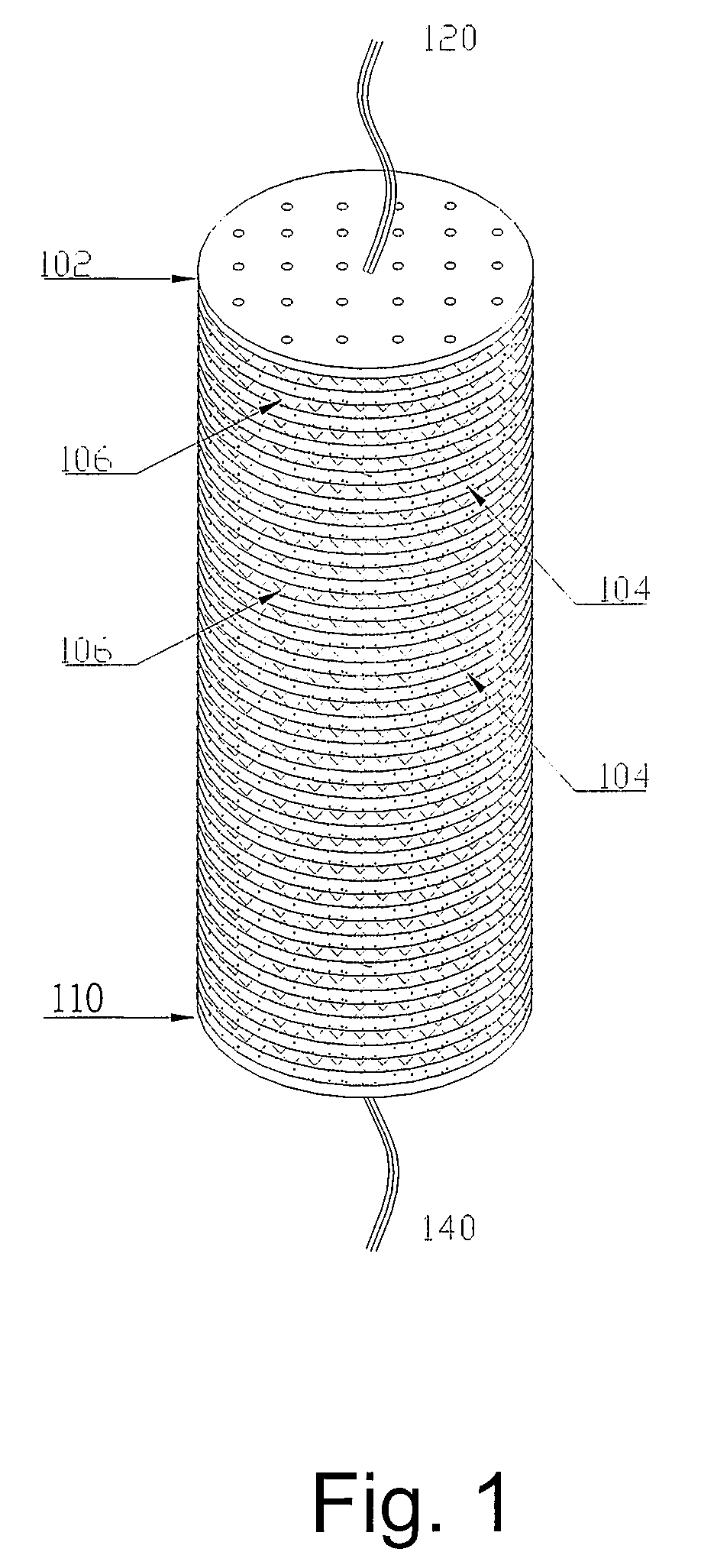

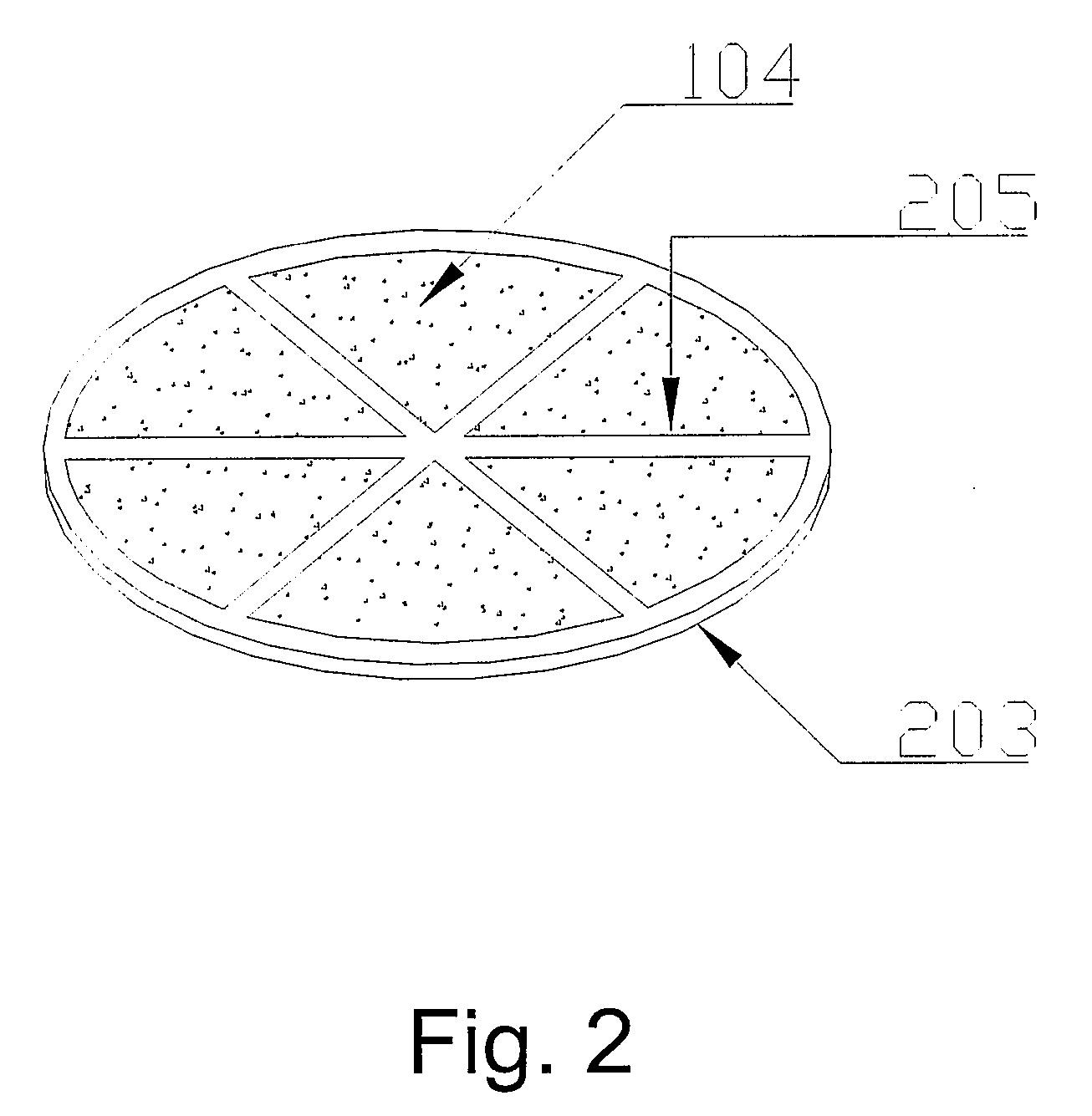

Capacitive deionization system for water treatment

PatentInactiveUS20080198531A1

Innovation

- The use of prefabricated electrodes with high surface area materials like activated carbon or carbon nanotubes, embedded in sealing members to prevent leakage, and a regeneration method involving supercapacitors for efficient energy recovery and electrode reuse.

Environmental Impact of CDI Cleaning Chemicals

The cleaning chemicals used in Capacitive Deionization (CDI) systems have significant environmental implications that must be carefully considered. Traditional cleaning agents such as strong acids, bases, and oxidizing agents can pose substantial ecological risks when discharged into water bodies. These chemicals may alter aquatic pH levels, disrupt ecosystem balance, and potentially harm sensitive aquatic organisms. For instance, chlorine-based cleaners can form harmful disinfection by-products when reacting with organic matter in natural water systems.

The environmental footprint of CDI cleaning processes extends beyond direct aquatic impacts. The production, transportation, and disposal of these chemicals contribute to carbon emissions and resource depletion. Many conventional cleaning agents require energy-intensive manufacturing processes and utilize non-renewable resources as feedstock, further exacerbating their environmental burden.

Regulatory frameworks worldwide are increasingly restricting the use and discharge of potentially harmful cleaning chemicals. The European Water Framework Directive, the U.S. Clean Water Act, and similar regulations in other regions impose stringent limits on chemical discharges, compelling CDI operators to adopt more environmentally responsible cleaning approaches. Non-compliance can result in substantial penalties and reputational damage for organizations.

Recent research has focused on developing environmentally benign alternatives for CDI system cleaning. Bio-based surfactants derived from renewable resources show promising cleaning efficacy while being biodegradable. Enzymatic cleaners that specifically target organic foulants offer another green alternative, as they operate under mild conditions and decompose into harmless compounds after use. Physical cleaning methods such as ultrasonic cleaning and electro-hydraulic shock waves are also gaining attention as chemical-free approaches.

Life cycle assessment (LCA) studies comparing conventional and green cleaning strategies reveal significant differences in environmental impact. While traditional chemical cleaners may offer immediate cost advantages, their environmental externalities often outweigh these benefits when considering the complete life cycle. Green cleaning alternatives typically demonstrate superior performance in categories such as aquatic toxicity, eutrophication potential, and human health impacts.

The transition toward environmentally responsible cleaning practices in CDI systems aligns with broader sustainability goals and circular economy principles. By minimizing harmful chemical usage, optimizing cleaning frequencies, and implementing chemical recovery systems, CDI operators can significantly reduce their environmental footprint while maintaining system performance. This approach not only addresses immediate environmental concerns but also positions CDI technology as a truly sustainable water treatment solution for the future.

The environmental footprint of CDI cleaning processes extends beyond direct aquatic impacts. The production, transportation, and disposal of these chemicals contribute to carbon emissions and resource depletion. Many conventional cleaning agents require energy-intensive manufacturing processes and utilize non-renewable resources as feedstock, further exacerbating their environmental burden.

Regulatory frameworks worldwide are increasingly restricting the use and discharge of potentially harmful cleaning chemicals. The European Water Framework Directive, the U.S. Clean Water Act, and similar regulations in other regions impose stringent limits on chemical discharges, compelling CDI operators to adopt more environmentally responsible cleaning approaches. Non-compliance can result in substantial penalties and reputational damage for organizations.

Recent research has focused on developing environmentally benign alternatives for CDI system cleaning. Bio-based surfactants derived from renewable resources show promising cleaning efficacy while being biodegradable. Enzymatic cleaners that specifically target organic foulants offer another green alternative, as they operate under mild conditions and decompose into harmless compounds after use. Physical cleaning methods such as ultrasonic cleaning and electro-hydraulic shock waves are also gaining attention as chemical-free approaches.

Life cycle assessment (LCA) studies comparing conventional and green cleaning strategies reveal significant differences in environmental impact. While traditional chemical cleaners may offer immediate cost advantages, their environmental externalities often outweigh these benefits when considering the complete life cycle. Green cleaning alternatives typically demonstrate superior performance in categories such as aquatic toxicity, eutrophication potential, and human health impacts.

The transition toward environmentally responsible cleaning practices in CDI systems aligns with broader sustainability goals and circular economy principles. By minimizing harmful chemical usage, optimizing cleaning frequencies, and implementing chemical recovery systems, CDI operators can significantly reduce their environmental footprint while maintaining system performance. This approach not only addresses immediate environmental concerns but also positions CDI technology as a truly sustainable water treatment solution for the future.

Cost-Benefit Analysis of CDI Maintenance Strategies

Implementing effective maintenance strategies for Capacitive Deionization (CDI) systems requires a thorough cost-benefit analysis to optimize operational efficiency and economic viability. The direct costs associated with CDI maintenance include replacement materials (electrodes, membranes, spacers), cleaning chemicals, labor, and system downtime. These expenses vary significantly based on fouling severity, system size, and cleaning frequency. For instance, chemical cleaning protocols may cost between $0.05-0.15 per cubic meter of treated water, while electrode replacement can represent 15-30% of total operational costs over a system's lifecycle.

Preventive maintenance strategies, though requiring initial investment, demonstrate superior long-term economic returns compared to reactive approaches. Data from industrial implementations indicates that scheduled maintenance protocols can reduce unexpected system failures by up to 65% and extend electrode lifespan by 30-45%. The implementation of real-time monitoring systems, while adding $5,000-15,000 to initial capital expenditure, typically delivers ROI within 12-18 months through optimized cleaning cycles and reduced chemical consumption.

Energy efficiency represents a critical factor in the maintenance equation. Fouled CDI systems may experience 20-40% increased energy consumption, translating to significant operational cost escalation. Regular maintenance can maintain energy efficiency within 5-10% of optimal performance, yielding substantial savings for large-scale operations where energy costs often constitute 30-45% of operational expenses.

Water recovery rates also factor prominently in cost-benefit calculations. Optimized maintenance schedules can improve recovery rates by 8-15%, reducing intake water requirements and associated costs. This improvement becomes particularly significant in water-scarce regions where source water acquisition represents a substantial expense.

Lifecycle analysis reveals that integrated maintenance approaches combining mechanical, chemical, and electrical cleaning methods deliver the most favorable cost-benefit ratio. Such integrated strategies typically increase system lifespan by 3-5 years while reducing total maintenance costs by 20-30% compared to single-method approaches. The implementation of automated cleaning systems, though requiring capital investment of $20,000-50,000 depending on scale, demonstrates payback periods of 2-4 years through labor reduction and optimization of cleaning parameters.

Environmental compliance costs must also factor into maintenance strategy selection. Proper handling and disposal of cleaning chemicals and replaced components can add 5-15% to maintenance budgets but mitigates regulatory risks and potential penalties that could otherwise exceed $100,000 per violation in stringent regulatory environments.

Preventive maintenance strategies, though requiring initial investment, demonstrate superior long-term economic returns compared to reactive approaches. Data from industrial implementations indicates that scheduled maintenance protocols can reduce unexpected system failures by up to 65% and extend electrode lifespan by 30-45%. The implementation of real-time monitoring systems, while adding $5,000-15,000 to initial capital expenditure, typically delivers ROI within 12-18 months through optimized cleaning cycles and reduced chemical consumption.

Energy efficiency represents a critical factor in the maintenance equation. Fouled CDI systems may experience 20-40% increased energy consumption, translating to significant operational cost escalation. Regular maintenance can maintain energy efficiency within 5-10% of optimal performance, yielding substantial savings for large-scale operations where energy costs often constitute 30-45% of operational expenses.

Water recovery rates also factor prominently in cost-benefit calculations. Optimized maintenance schedules can improve recovery rates by 8-15%, reducing intake water requirements and associated costs. This improvement becomes particularly significant in water-scarce regions where source water acquisition represents a substantial expense.

Lifecycle analysis reveals that integrated maintenance approaches combining mechanical, chemical, and electrical cleaning methods deliver the most favorable cost-benefit ratio. Such integrated strategies typically increase system lifespan by 3-5 years while reducing total maintenance costs by 20-30% compared to single-method approaches. The implementation of automated cleaning systems, though requiring capital investment of $20,000-50,000 depending on scale, demonstrates payback periods of 2-4 years through labor reduction and optimization of cleaning parameters.

Environmental compliance costs must also factor into maintenance strategy selection. Proper handling and disposal of cleaning chemicals and replaced components can add 5-15% to maintenance budgets but mitigates regulatory risks and potential penalties that could otherwise exceed $100,000 per violation in stringent regulatory environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!