Hybrid CDI Systems For Heavy Metal Removal From Wastewater

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid CDI Technology Background and Objectives

Capacitive Deionization (CDI) technology has evolved significantly over the past three decades as a promising electrochemical method for water treatment. Initially developed in the 1960s, CDI has undergone substantial refinement, particularly in the last decade, with the emergence of hybrid systems specifically designed for heavy metal removal from wastewater. The fundamental principle of CDI involves applying an electrical potential difference between two electrodes to adsorb charged ions from water, making it particularly suitable for removing ionic contaminants such as heavy metals.

The evolution of traditional CDI to hybrid CDI systems represents a critical technological advancement in addressing the limitations of conventional water treatment methods. Hybrid CDI integrates capacitive deionization with complementary technologies such as membrane filtration, ion exchange materials, or advanced electrode materials to enhance removal efficiency, selectivity, and operational stability. This technological convergence aims to overcome the inherent limitations of standalone CDI systems, particularly when targeting complex heavy metal contamination scenarios.

The primary objective of hybrid CDI technology development is to create more efficient, cost-effective, and sustainable solutions for heavy metal removal from industrial wastewater, mining effluents, and contaminated groundwater. Specific technical goals include achieving higher removal rates for priority heavy metals such as lead, cadmium, chromium, and mercury, while simultaneously reducing energy consumption and operational costs compared to conventional treatment methods like chemical precipitation or reverse osmosis.

Current research trajectories in hybrid CDI technology focus on several key areas: development of novel electrode materials with enhanced adsorption capacity and selectivity for heavy metals; integration of ion-selective membranes to improve separation efficiency; incorporation of redox-active materials to enable faradaic reactions alongside capacitive processes; and optimization of system architecture and operational parameters to maximize performance under varying influent conditions.

The technological progression of hybrid CDI systems aligns with growing global concerns regarding water security and increasingly stringent environmental regulations on industrial discharges. As water scarcity intensifies and awareness of heavy metal toxicity increases, the demand for advanced treatment technologies capable of addressing these challenges grows proportionally. Hybrid CDI represents a promising response to these trends, offering potential advantages in terms of operational flexibility, reduced chemical usage, and lower waste generation compared to conventional treatment approaches.

Future development of hybrid CDI technology is expected to focus on scalability, long-term operational stability, and integration with renewable energy sources to further enhance sustainability credentials. The ultimate goal is to establish hybrid CDI as a mainstream technology for heavy metal removal across diverse applications, from centralized industrial wastewater treatment to decentralized point-of-use systems in remote or resource-constrained environments.

The evolution of traditional CDI to hybrid CDI systems represents a critical technological advancement in addressing the limitations of conventional water treatment methods. Hybrid CDI integrates capacitive deionization with complementary technologies such as membrane filtration, ion exchange materials, or advanced electrode materials to enhance removal efficiency, selectivity, and operational stability. This technological convergence aims to overcome the inherent limitations of standalone CDI systems, particularly when targeting complex heavy metal contamination scenarios.

The primary objective of hybrid CDI technology development is to create more efficient, cost-effective, and sustainable solutions for heavy metal removal from industrial wastewater, mining effluents, and contaminated groundwater. Specific technical goals include achieving higher removal rates for priority heavy metals such as lead, cadmium, chromium, and mercury, while simultaneously reducing energy consumption and operational costs compared to conventional treatment methods like chemical precipitation or reverse osmosis.

Current research trajectories in hybrid CDI technology focus on several key areas: development of novel electrode materials with enhanced adsorption capacity and selectivity for heavy metals; integration of ion-selective membranes to improve separation efficiency; incorporation of redox-active materials to enable faradaic reactions alongside capacitive processes; and optimization of system architecture and operational parameters to maximize performance under varying influent conditions.

The technological progression of hybrid CDI systems aligns with growing global concerns regarding water security and increasingly stringent environmental regulations on industrial discharges. As water scarcity intensifies and awareness of heavy metal toxicity increases, the demand for advanced treatment technologies capable of addressing these challenges grows proportionally. Hybrid CDI represents a promising response to these trends, offering potential advantages in terms of operational flexibility, reduced chemical usage, and lower waste generation compared to conventional treatment approaches.

Future development of hybrid CDI technology is expected to focus on scalability, long-term operational stability, and integration with renewable energy sources to further enhance sustainability credentials. The ultimate goal is to establish hybrid CDI as a mainstream technology for heavy metal removal across diverse applications, from centralized industrial wastewater treatment to decentralized point-of-use systems in remote or resource-constrained environments.

Market Analysis for Heavy Metal Wastewater Treatment

The global market for heavy metal wastewater treatment is experiencing significant growth, driven by increasing industrial activities and stringent environmental regulations. Currently valued at approximately $6.5 billion, this market is projected to reach $9.8 billion by 2027, with a compound annual growth rate of 8.2%. The Asia-Pacific region dominates the market share at 35%, followed by North America (28%) and Europe (25%), reflecting the concentration of industrial activities and regulatory pressures in these regions.

Industries contributing most significantly to heavy metal wastewater include mining (32% of market demand), electroplating (24%), battery manufacturing (18%), and chemical processing (15%). These sectors generate wastewater containing various heavy metals including lead, mercury, cadmium, chromium, and arsenic, creating substantial demand for effective treatment solutions.

The market for Hybrid Capacitive Deionization (CDI) systems specifically is emerging as a high-growth segment, currently representing about 7% of the total heavy metal treatment market but expanding at 12.3% annually. This accelerated growth is attributed to CDI's lower energy consumption compared to traditional methods like reverse osmosis and ion exchange, with potential operational cost savings of 30-40%.

Customer segmentation reveals three primary buyer categories: large industrial corporations (55% of market revenue), municipal water treatment facilities (30%), and small to medium enterprises (15%). The purchasing decisions increasingly prioritize total cost of ownership rather than initial capital expenditure, with recovery efficiency and operational costs becoming key differentiators.

Price sensitivity varies significantly by region and industry. While developing markets remain highly price-sensitive, developed economies show willingness to invest in premium solutions that offer higher efficiency and lower long-term operational costs. The average implementation cost for industrial-scale hybrid CDI systems ranges from $150,000 to $750,000, depending on capacity and customization requirements.

Market barriers include high initial capital costs, technological complexity requiring specialized knowledge, and competition from established technologies with lower upfront costs. However, regulatory drivers are creating strong market pull, with environmental compliance penalties increasing by an average of 15% annually in major industrial nations.

The competitive landscape features both established water treatment corporations and innovative technology startups. Major players include Evoqua Water Technologies, Veolia, Suez, and Pentair, while emerging specialists in hybrid CDI technology such as Voltea, EST Water, and Idropan have secured significant venture capital funding totaling $285 million in the past three years.

Industries contributing most significantly to heavy metal wastewater include mining (32% of market demand), electroplating (24%), battery manufacturing (18%), and chemical processing (15%). These sectors generate wastewater containing various heavy metals including lead, mercury, cadmium, chromium, and arsenic, creating substantial demand for effective treatment solutions.

The market for Hybrid Capacitive Deionization (CDI) systems specifically is emerging as a high-growth segment, currently representing about 7% of the total heavy metal treatment market but expanding at 12.3% annually. This accelerated growth is attributed to CDI's lower energy consumption compared to traditional methods like reverse osmosis and ion exchange, with potential operational cost savings of 30-40%.

Customer segmentation reveals three primary buyer categories: large industrial corporations (55% of market revenue), municipal water treatment facilities (30%), and small to medium enterprises (15%). The purchasing decisions increasingly prioritize total cost of ownership rather than initial capital expenditure, with recovery efficiency and operational costs becoming key differentiators.

Price sensitivity varies significantly by region and industry. While developing markets remain highly price-sensitive, developed economies show willingness to invest in premium solutions that offer higher efficiency and lower long-term operational costs. The average implementation cost for industrial-scale hybrid CDI systems ranges from $150,000 to $750,000, depending on capacity and customization requirements.

Market barriers include high initial capital costs, technological complexity requiring specialized knowledge, and competition from established technologies with lower upfront costs. However, regulatory drivers are creating strong market pull, with environmental compliance penalties increasing by an average of 15% annually in major industrial nations.

The competitive landscape features both established water treatment corporations and innovative technology startups. Major players include Evoqua Water Technologies, Veolia, Suez, and Pentair, while emerging specialists in hybrid CDI technology such as Voltea, EST Water, and Idropan have secured significant venture capital funding totaling $285 million in the past three years.

Current Challenges in Heavy Metal Removal Technologies

Despite significant advancements in wastewater treatment technologies, heavy metal removal continues to face substantial technical challenges. Conventional methods such as chemical precipitation, ion exchange, and adsorption suffer from inherent limitations when addressing complex industrial effluents containing multiple heavy metal contaminants at varying concentrations. These traditional approaches often require large quantities of chemicals, generate secondary waste streams, and demonstrate reduced efficiency when treating low concentration pollutants.

Capacitive Deionization (CDI) technology has emerged as a promising alternative, but standalone CDI systems encounter several obstacles when targeting heavy metals. The selectivity of standard carbon electrodes remains insufficient for preferential removal of toxic metals like lead, cadmium, and mercury in the presence of competing ions. Additionally, electrode fouling and performance degradation occur rapidly when processing real industrial wastewaters containing organic compounds and suspended solids.

Hybrid CDI systems, while offering theoretical advantages by combining multiple removal mechanisms, face integration challenges that limit their practical implementation. The synergistic operation of different components (electrodes, membranes, and functional materials) requires precise engineering that has not been fully optimized. Current hybrid configurations often experience reduced energy efficiency due to increased system complexity and resistance at material interfaces.

Scale-up represents another significant hurdle for hybrid CDI technologies. Laboratory-scale systems demonstrating excellent heavy metal removal often fail to maintain performance when scaled to industrial capacities. Flow distribution, pressure drop issues, and uneven current distribution in larger systems compromise treatment effectiveness and operational stability.

The economic viability of hybrid CDI systems remains questionable due to high material costs, particularly for specialized electrodes and ion-selective membranes. Manufacturing processes for advanced electrode materials with heavy metal selectivity are not yet standardized for mass production, resulting in prohibitive costs for full-scale implementation.

Operational challenges include the management of pH fluctuations during treatment cycles, which can significantly impact heavy metal removal efficiency and potentially cause re-release of captured contaminants. Furthermore, the regeneration of hybrid CDI systems after heavy metal saturation presents technical difficulties in recovering valuable metals while maintaining electrode performance over multiple cycles.

Regulatory compliance presents an additional challenge, as discharge standards for heavy metals continue to become more stringent globally. Current hybrid CDI technologies struggle to consistently achieve these ultra-low concentration targets across varying influent conditions, limiting their adoption by industries facing strict environmental regulations.

Capacitive Deionization (CDI) technology has emerged as a promising alternative, but standalone CDI systems encounter several obstacles when targeting heavy metals. The selectivity of standard carbon electrodes remains insufficient for preferential removal of toxic metals like lead, cadmium, and mercury in the presence of competing ions. Additionally, electrode fouling and performance degradation occur rapidly when processing real industrial wastewaters containing organic compounds and suspended solids.

Hybrid CDI systems, while offering theoretical advantages by combining multiple removal mechanisms, face integration challenges that limit their practical implementation. The synergistic operation of different components (electrodes, membranes, and functional materials) requires precise engineering that has not been fully optimized. Current hybrid configurations often experience reduced energy efficiency due to increased system complexity and resistance at material interfaces.

Scale-up represents another significant hurdle for hybrid CDI technologies. Laboratory-scale systems demonstrating excellent heavy metal removal often fail to maintain performance when scaled to industrial capacities. Flow distribution, pressure drop issues, and uneven current distribution in larger systems compromise treatment effectiveness and operational stability.

The economic viability of hybrid CDI systems remains questionable due to high material costs, particularly for specialized electrodes and ion-selective membranes. Manufacturing processes for advanced electrode materials with heavy metal selectivity are not yet standardized for mass production, resulting in prohibitive costs for full-scale implementation.

Operational challenges include the management of pH fluctuations during treatment cycles, which can significantly impact heavy metal removal efficiency and potentially cause re-release of captured contaminants. Furthermore, the regeneration of hybrid CDI systems after heavy metal saturation presents technical difficulties in recovering valuable metals while maintaining electrode performance over multiple cycles.

Regulatory compliance presents an additional challenge, as discharge standards for heavy metals continue to become more stringent globally. Current hybrid CDI technologies struggle to consistently achieve these ultra-low concentration targets across varying influent conditions, limiting their adoption by industries facing strict environmental regulations.

Existing Hybrid CDI Solutions for Heavy Metal Removal

01 Electrode materials for enhanced heavy metal removal

Specialized electrode materials can significantly improve the efficiency of heavy metal removal in hybrid CDI systems. These materials include carbon-based electrodes modified with functional groups, metal oxides, or conductive polymers that have high affinity for heavy metal ions. The enhanced adsorption capacity and selectivity of these electrodes enable more effective capture of heavy metals such as lead, cadmium, and arsenic from contaminated water sources.- Electrode materials for enhanced heavy metal removal: Advanced electrode materials can significantly improve the efficiency of heavy metal removal in hybrid CDI systems. These materials include carbon-based electrodes modified with functional groups, metal oxides, or conductive polymers that have high adsorption capacity for heavy metal ions. The incorporation of these specialized materials enhances the selectivity and capacity for heavy metal ions such as lead, cadmium, arsenic, and mercury, while maintaining good electrical conductivity for the capacitive deionization process.

- Integration of electrochemical processes with CDI: Hybrid CDI systems that integrate electrochemical processes with traditional capacitive deionization offer improved heavy metal removal capabilities. These systems combine the principles of electrosorption with electrochemical reactions such as reduction, oxidation, or precipitation to enhance the removal efficiency of heavy metals. The synergistic effect of these combined processes allows for more complete removal of heavy metal contaminants from water, even at low concentrations, and can reduce energy consumption compared to conventional methods.

- Membrane-assisted hybrid CDI systems: Incorporating ion-exchange membranes into CDI systems creates membrane-assisted hybrid configurations that enhance heavy metal removal efficiency. These membranes can be cation-exchange, anion-exchange, or bipolar types that selectively allow certain ions to pass while blocking others. The integration of these membranes with CDI electrodes improves the selectivity for heavy metal ions, prevents co-ion adsorption, increases charge efficiency, and reduces energy consumption during the deionization and regeneration cycles.

- Flow-through and flow-by CDI configurations: Different flow configurations in hybrid CDI systems can optimize heavy metal removal performance. Flow-through designs allow water to pass directly through porous electrode materials, maximizing contact between heavy metal ions and adsorption sites. Flow-by configurations direct water parallel to electrode surfaces, which can be advantageous for certain applications. These design variations can be tailored to specific heavy metal contaminants and water conditions, affecting parameters such as pressure drop, energy consumption, and removal efficiency.

- Regeneration and system optimization techniques: Effective regeneration methods and system optimization techniques are crucial for sustainable operation of hybrid CDI systems for heavy metal removal. These include optimized voltage application protocols, polarity reversal techniques, chemical regeneration methods, and integrated cleaning processes. Advanced control systems can monitor performance parameters and automatically adjust operating conditions to maintain optimal heavy metal removal efficiency while minimizing energy consumption and extending electrode lifespan.

02 Integration of membrane technology with CDI

Hybrid CDI systems that incorporate ion-exchange membranes or other selective membranes can achieve superior heavy metal removal performance. These membrane-assisted CDI systems prevent co-ion effects and enhance ion selectivity, resulting in higher removal efficiency for specific heavy metal ions. The integration of membrane technology also reduces energy consumption and extends the operational lifetime of the electrodes by preventing electrode fouling.Expand Specific Solutions03 Flow-through electrode configurations

Flow-through electrode configurations in hybrid CDI systems allow for more efficient heavy metal removal compared to traditional flow-by designs. In these systems, water flows directly through porous electrodes rather than between them, increasing the contact area between the contaminated water and the electrode surface. This configuration enhances mass transfer rates, reduces diffusion limitations, and improves the overall kinetics of heavy metal ion adsorption.Expand Specific Solutions04 Combination of electrochemical processes with CDI

Hybrid systems that combine CDI with other electrochemical processes such as electrocoagulation, electrooxidation, or electroreduction demonstrate enhanced heavy metal removal capabilities. These combined approaches leverage synergistic effects between different electrochemical mechanisms to address a wider range of heavy metal contaminants. The integration of multiple electrochemical processes also enables the treatment of complex wastewaters containing various heavy metals at different concentrations.Expand Specific Solutions05 Energy recovery and operational optimization

Advanced energy recovery systems and operational optimization strategies can significantly improve the efficiency and sustainability of hybrid CDI systems for heavy metal removal. These include energy recovery during electrode discharge, optimized voltage cycling, and smart control systems that adjust operational parameters based on influent water quality. Such improvements reduce energy consumption, operational costs, and environmental footprint while maintaining high heavy metal removal performance.Expand Specific Solutions

Leading Companies in Wastewater Treatment Industry

The hybrid capacitive deionization (CDI) systems for heavy metal removal from wastewater market is in a growth phase, with increasing adoption driven by stricter environmental regulations. The global market size is expanding rapidly as industries seek cost-effective treatment solutions. Technologically, the field shows varying maturity levels, with academic institutions like Nankai University, Peking University, and Tongji University leading fundamental research, while companies such as Samsung Electronics, LG Electronics, and Mitsubishi Electric are advancing commercial applications. Korean research organizations (KIGAM, KICT) have made significant contributions to system optimization. Chinese environmental firms like Zhejiang Zezhong and Xi'an Jinzang are developing specialized membrane technologies, positioning themselves as emerging players in this competitive landscape that bridges academic innovation and industrial implementation.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed an advanced hybrid CDI system incorporating modified carbon electrodes with metal oxide nanoparticles for enhanced heavy metal adsorption. Their technology combines electrosorption principles with specific ion selectivity through surface functionalization. The system utilizes a flow-through electrode configuration with optimized pore structure that maximizes contact between wastewater and electrode surfaces. Research shows removal efficiencies exceeding 95% for lead, cadmium, and chromium ions at relatively low energy consumption (0.1-0.3 kWh/m³). Their approach incorporates regeneration cycles using polarity reversal techniques that maintain electrode performance over hundreds of operational cycles while minimizing secondary waste generation. The university has also pioneered integration of renewable energy sources to power CDI systems, making them suitable for remote applications.

Strengths: Superior heavy metal selectivity through specialized electrode modifications; excellent regeneration capabilities with minimal performance degradation; energy-efficient operation suitable for decentralized applications. Weaknesses: Higher initial manufacturing costs compared to conventional treatments; potential membrane fouling in complex industrial wastewaters; requires precise control systems for optimal performance.

Shaanxi University of Science & Technology

Technical Solution: Shaanxi University of Science & Technology has developed an advanced hybrid CDI system that combines capacitive deionization with biosorption mechanisms for heavy metal removal from wastewater. Their innovative approach incorporates biochar-derived electrodes functionalized with specific microbial communities that enhance heavy metal binding through both physical adsorption and biological sequestration processes. The system employs a unique pulsed-power operation strategy that optimizes energy efficiency while preventing microbial inactivation. Laboratory and pilot-scale demonstrations show removal efficiencies exceeding 95% for cadmium, lead, and zinc from mining effluents with complex matrices. The university has pioneered electrode manufacturing techniques using agricultural waste materials, significantly reducing production costs while providing additional carbon sequestration benefits. Their system features a self-regenerating capability where controlled biofilm development and detachment cycles maintain long-term performance without frequent electrode replacement. The technology incorporates specialized ion-selective membranes that enhance separation efficiency while reducing energy requirements by approximately 35% compared to conventional CDI systems.

Strengths: Unique bio-electrochemical approach provides cost-effective treatment; sustainable electrode materials from agricultural waste; self-regenerating capabilities reduce maintenance requirements. Weaknesses: Biological components may be sensitive to extreme pH or toxic compounds; potential for inconsistent performance under variable influent conditions; longer startup periods required for biofilm establishment.

Key Patents and Research in Hybrid CDI Technology

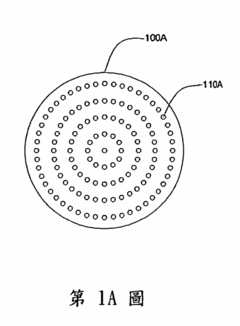

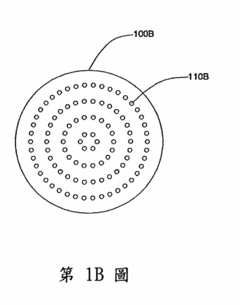

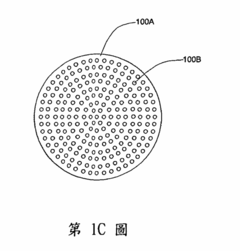

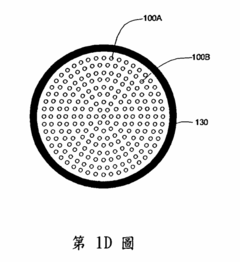

Capacitive deionization using hybrid polar electrodes

PatentInactiveTW200942494A

Innovation

- A hybrid flow-through capacitor module incorporating both unipolar and bipolar electrodes, optimized fluid dynamics through perforated electrode plates, and supercapacitors for energy recovery, enabling balanced operating voltage and current while reducing energy costs and cycle times.

Environmental Regulations and Compliance Standards

The global regulatory landscape for wastewater treatment has become increasingly stringent, particularly regarding heavy metal contamination. The European Union's Water Framework Directive (2000/60/EC) establishes comprehensive guidelines for water protection and management, with specific provisions for heavy metal concentration limits. This framework is complemented by the Industrial Emissions Directive (2010/75/EU), which mandates the implementation of Best Available Techniques (BAT) for industrial wastewater treatment. These regulations have set maximum allowable concentrations for cadmium, lead, mercury, and chromium at levels as low as 0.05-0.5 mg/L, depending on the specific metal and application.

In the United States, the Environmental Protection Agency (EPA) enforces the Clean Water Act, which includes the National Pollutant Discharge Elimination System (NPDES) permit program. This program regulates point source discharges and has established effluent limitation guidelines for various industries. The Resource Conservation and Recovery Act (RCRA) further governs hazardous waste management, including heavy metal-contaminated wastewater. Recent amendments have reduced permissible levels of hexavalent chromium to 0.1 mg/L and lead to 0.015 mg/L in drinking water systems.

Asian countries have also strengthened their regulatory frameworks. China's Water Pollution Prevention and Control Law, revised in 2018, has introduced more stringent standards for heavy metal discharge, with particular focus on industries such as mining, metallurgy, and electronics manufacturing. Similarly, Japan's Water Pollution Control Law sets comprehensive standards for effluent quality, with specific provisions for heavy metals that are among the strictest globally.

International standards such as ISO 14001 for environmental management systems provide frameworks for organizations to identify and control their environmental impact, including wastewater discharge. The World Health Organization's guidelines for drinking water quality, though not legally binding, serve as important reference points for many national regulations, particularly in developing countries where regulatory frameworks may be less developed.

Compliance with these regulations presents significant challenges for industries, particularly those with high water usage or heavy metal processing. Non-compliance can result in substantial penalties, including fines ranging from thousands to millions of dollars, operational restrictions, and reputational damage. This regulatory pressure has become a primary driver for the adoption of advanced treatment technologies like Hybrid Capacitive Deionization (CDI) systems, which offer efficient heavy metal removal capabilities while potentially reducing operational costs compared to traditional treatment methods.

In the United States, the Environmental Protection Agency (EPA) enforces the Clean Water Act, which includes the National Pollutant Discharge Elimination System (NPDES) permit program. This program regulates point source discharges and has established effluent limitation guidelines for various industries. The Resource Conservation and Recovery Act (RCRA) further governs hazardous waste management, including heavy metal-contaminated wastewater. Recent amendments have reduced permissible levels of hexavalent chromium to 0.1 mg/L and lead to 0.015 mg/L in drinking water systems.

Asian countries have also strengthened their regulatory frameworks. China's Water Pollution Prevention and Control Law, revised in 2018, has introduced more stringent standards for heavy metal discharge, with particular focus on industries such as mining, metallurgy, and electronics manufacturing. Similarly, Japan's Water Pollution Control Law sets comprehensive standards for effluent quality, with specific provisions for heavy metals that are among the strictest globally.

International standards such as ISO 14001 for environmental management systems provide frameworks for organizations to identify and control their environmental impact, including wastewater discharge. The World Health Organization's guidelines for drinking water quality, though not legally binding, serve as important reference points for many national regulations, particularly in developing countries where regulatory frameworks may be less developed.

Compliance with these regulations presents significant challenges for industries, particularly those with high water usage or heavy metal processing. Non-compliance can result in substantial penalties, including fines ranging from thousands to millions of dollars, operational restrictions, and reputational damage. This regulatory pressure has become a primary driver for the adoption of advanced treatment technologies like Hybrid Capacitive Deionization (CDI) systems, which offer efficient heavy metal removal capabilities while potentially reducing operational costs compared to traditional treatment methods.

Cost-Benefit Analysis of Hybrid CDI Implementation

The implementation of Hybrid Capacitive Deionization (CDI) systems for heavy metal removal from wastewater requires careful economic evaluation to justify investment decisions. Initial capital expenditure for hybrid CDI systems typically ranges from $50,000 to $500,000 depending on treatment capacity and configuration complexity, with larger industrial-scale installations at the higher end of this spectrum. These systems integrate conventional CDI with complementary technologies such as ion exchange membranes or electrochemical processes, increasing initial costs but potentially offering superior long-term economics.

Operational expenses for hybrid CDI systems are notably lower than conventional treatment methods, with energy consumption averaging 0.1-0.5 kWh per cubic meter of treated water. This represents a 30-60% reduction compared to reverse osmosis systems. Maintenance costs typically account for 5-8% of the initial capital investment annually, primarily for electrode replacement and membrane cleaning.

The economic benefits of hybrid CDI implementation extend beyond direct operational savings. Treatment efficiency for heavy metals such as lead, cadmium, and chromium regularly exceeds 95%, reducing downstream processing requirements and associated costs. The selective removal capability of hybrid CDI systems also enables potential recovery of valuable metals from wastewater streams, creating secondary revenue opportunities that can offset implementation costs.

Regulatory compliance represents another significant economic factor. With increasingly stringent discharge regulations worldwide, hybrid CDI systems provide a technical solution that consistently meets or exceeds regulatory standards, avoiding potential non-compliance penalties that can range from thousands to millions of dollars depending on jurisdiction and violation severity.

The payback period for hybrid CDI systems typically ranges from 3-7 years, with smaller installations generally requiring longer periods to achieve return on investment. This timeline is influenced by factors including wastewater characteristics, treatment volume, energy costs, and regulatory requirements. Case studies from the chemical manufacturing sector demonstrate payback periods as short as 2.5 years when replacing conventional precipitation methods.

Life-cycle assessment indicates that hybrid CDI systems maintain operational efficiency for 8-12 years before requiring significant refurbishment, providing favorable total cost of ownership compared to alternative technologies. When factoring in externalities such as environmental impact reduction and resource recovery potential, the cost-benefit ratio improves further, particularly for industries facing strict environmental compliance requirements or operating in water-scarce regions.

Operational expenses for hybrid CDI systems are notably lower than conventional treatment methods, with energy consumption averaging 0.1-0.5 kWh per cubic meter of treated water. This represents a 30-60% reduction compared to reverse osmosis systems. Maintenance costs typically account for 5-8% of the initial capital investment annually, primarily for electrode replacement and membrane cleaning.

The economic benefits of hybrid CDI implementation extend beyond direct operational savings. Treatment efficiency for heavy metals such as lead, cadmium, and chromium regularly exceeds 95%, reducing downstream processing requirements and associated costs. The selective removal capability of hybrid CDI systems also enables potential recovery of valuable metals from wastewater streams, creating secondary revenue opportunities that can offset implementation costs.

Regulatory compliance represents another significant economic factor. With increasingly stringent discharge regulations worldwide, hybrid CDI systems provide a technical solution that consistently meets or exceeds regulatory standards, avoiding potential non-compliance penalties that can range from thousands to millions of dollars depending on jurisdiction and violation severity.

The payback period for hybrid CDI systems typically ranges from 3-7 years, with smaller installations generally requiring longer periods to achieve return on investment. This timeline is influenced by factors including wastewater characteristics, treatment volume, energy costs, and regulatory requirements. Case studies from the chemical manufacturing sector demonstrate payback periods as short as 2.5 years when replacing conventional precipitation methods.

Life-cycle assessment indicates that hybrid CDI systems maintain operational efficiency for 8-12 years before requiring significant refurbishment, providing favorable total cost of ownership compared to alternative technologies. When factoring in externalities such as environmental impact reduction and resource recovery potential, the cost-benefit ratio improves further, particularly for industries facing strict environmental compliance requirements or operating in water-scarce regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!