Membrane Capacitive Deionization: Principles And Industrial Applications

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MCDI Technology Background and Objectives

Membrane Capacitive Deionization (MCDI) emerged in the early 2000s as an evolution of Capacitive Deionization (CDI) technology, representing a significant advancement in electrochemical water treatment methods. The fundamental principle behind MCDI involves the application of an electrical potential difference across two electrodes, typically made of porous carbon materials, to remove ionic species from water through electrosorption. The distinctive feature of MCDI is the incorporation of ion-exchange membranes positioned in front of the electrodes, which substantially enhances salt removal efficiency and reduces energy consumption compared to conventional CDI systems.

The historical development of MCDI technology can be traced back to the 1960s when the basic concept of CDI was first introduced. However, it wasn't until the early 21st century that researchers began integrating ion-exchange membranes into CDI systems, marking the birth of MCDI. This innovation addressed several limitations of traditional CDI, particularly the co-ion expulsion phenomenon that significantly reduced efficiency in earlier systems.

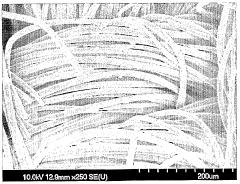

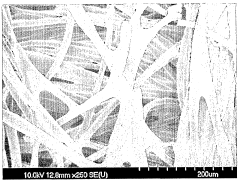

The technological evolution of MCDI has been characterized by continuous improvements in electrode materials, membrane properties, and system design. Carbon-based materials with high specific surface area, such as activated carbon, carbon aerogels, and more recently, graphene and carbon nanotubes, have been extensively investigated to enhance the electrosorption capacity. Concurrently, advances in ion-exchange membrane technology have focused on improving selectivity, reducing electrical resistance, and enhancing durability under various operating conditions.

The primary objective of MCDI technology development is to establish a sustainable, energy-efficient, and cost-effective method for water desalination and selective ion removal. Unlike conventional desalination technologies such as reverse osmosis (RO) and thermal distillation, MCDI offers distinct advantages for treating brackish water with lower salinity levels, typically below 10,000 mg/L total dissolved solids (TDS). The technology aims to achieve higher water recovery rates while consuming less energy, particularly for applications where moderate desalination is required.

Current research and development efforts in MCDI are directed toward several key goals: enhancing energy efficiency through improved materials and operational strategies; increasing salt removal capacity and selectivity for specific ions; extending system lifespan through better fouling resistance; and scaling up the technology for industrial applications. Additionally, there is growing interest in developing hybrid systems that combine MCDI with other treatment technologies to address complex water quality challenges.

As global water scarcity intensifies and the demand for sustainable water treatment solutions grows, MCDI technology is positioned to play an increasingly important role in various sectors, including municipal water treatment, industrial wastewater reclamation, and specialized applications in the food, pharmaceutical, and semiconductor industries.

The historical development of MCDI technology can be traced back to the 1960s when the basic concept of CDI was first introduced. However, it wasn't until the early 21st century that researchers began integrating ion-exchange membranes into CDI systems, marking the birth of MCDI. This innovation addressed several limitations of traditional CDI, particularly the co-ion expulsion phenomenon that significantly reduced efficiency in earlier systems.

The technological evolution of MCDI has been characterized by continuous improvements in electrode materials, membrane properties, and system design. Carbon-based materials with high specific surface area, such as activated carbon, carbon aerogels, and more recently, graphene and carbon nanotubes, have been extensively investigated to enhance the electrosorption capacity. Concurrently, advances in ion-exchange membrane technology have focused on improving selectivity, reducing electrical resistance, and enhancing durability under various operating conditions.

The primary objective of MCDI technology development is to establish a sustainable, energy-efficient, and cost-effective method for water desalination and selective ion removal. Unlike conventional desalination technologies such as reverse osmosis (RO) and thermal distillation, MCDI offers distinct advantages for treating brackish water with lower salinity levels, typically below 10,000 mg/L total dissolved solids (TDS). The technology aims to achieve higher water recovery rates while consuming less energy, particularly for applications where moderate desalination is required.

Current research and development efforts in MCDI are directed toward several key goals: enhancing energy efficiency through improved materials and operational strategies; increasing salt removal capacity and selectivity for specific ions; extending system lifespan through better fouling resistance; and scaling up the technology for industrial applications. Additionally, there is growing interest in developing hybrid systems that combine MCDI with other treatment technologies to address complex water quality challenges.

As global water scarcity intensifies and the demand for sustainable water treatment solutions grows, MCDI technology is positioned to play an increasingly important role in various sectors, including municipal water treatment, industrial wastewater reclamation, and specialized applications in the food, pharmaceutical, and semiconductor industries.

Market Analysis for Water Desalination Solutions

The global water desalination market is experiencing robust growth, driven by increasing water scarcity and rising demand for clean water across industrial, municipal, and agricultural sectors. Currently valued at approximately 17.7 billion USD in 2022, the market is projected to reach 32.1 billion USD by 2030, growing at a CAGR of 7.8% during the forecast period.

Membrane Capacitive Deionization (MCDI) technology is positioned within a competitive landscape dominated by traditional desalination methods. Reverse Osmosis (RO) continues to lead with roughly 65% market share due to its established infrastructure and proven reliability. Thermal desalination methods, including Multi-Stage Flash (MSF) and Multiple Effect Distillation (MED), account for approximately 25% of the market, particularly in energy-rich regions like the Middle East.

MCDI currently occupies a niche segment (estimated at 2-3% of the market) but demonstrates significant growth potential, especially for brackish water treatment applications where its energy efficiency advantages are most pronounced. Market analysis indicates that MCDI solutions can achieve up to 30-40% energy savings compared to RO when treating low to medium salinity water.

Regional market distribution shows the Middle East and North Africa (MENA) region leading with 48% of global desalination capacity, followed by Asia-Pacific (21%), North America (11%), Europe (10%), and other regions (10%). However, MCDI adoption patterns differ, with higher implementation rates in regions facing moderate salinity challenges rather than extreme seawater desalination needs.

Customer segmentation reveals three primary markets for MCDI technology: municipal water utilities seeking cost-effective brackish water treatment solutions; industrial users requiring specialized water purification for manufacturing processes; and small to medium-scale applications in remote or resource-constrained environments where energy efficiency is paramount.

Pricing analysis indicates that while MCDI systems typically require higher initial capital investment than conventional ion exchange systems, they offer competitive total cost of ownership due to lower operational expenses, reduced chemical usage, and longer membrane lifespans. The average payback period for MCDI installations ranges from 3-5 years depending on application scale and local energy costs.

Market barriers include limited awareness of MCDI benefits among potential end-users, technical challenges in scaling up systems for large municipal applications, and competition from established desalination technologies with extensive installation bases and proven track records.

Membrane Capacitive Deionization (MCDI) technology is positioned within a competitive landscape dominated by traditional desalination methods. Reverse Osmosis (RO) continues to lead with roughly 65% market share due to its established infrastructure and proven reliability. Thermal desalination methods, including Multi-Stage Flash (MSF) and Multiple Effect Distillation (MED), account for approximately 25% of the market, particularly in energy-rich regions like the Middle East.

MCDI currently occupies a niche segment (estimated at 2-3% of the market) but demonstrates significant growth potential, especially for brackish water treatment applications where its energy efficiency advantages are most pronounced. Market analysis indicates that MCDI solutions can achieve up to 30-40% energy savings compared to RO when treating low to medium salinity water.

Regional market distribution shows the Middle East and North Africa (MENA) region leading with 48% of global desalination capacity, followed by Asia-Pacific (21%), North America (11%), Europe (10%), and other regions (10%). However, MCDI adoption patterns differ, with higher implementation rates in regions facing moderate salinity challenges rather than extreme seawater desalination needs.

Customer segmentation reveals three primary markets for MCDI technology: municipal water utilities seeking cost-effective brackish water treatment solutions; industrial users requiring specialized water purification for manufacturing processes; and small to medium-scale applications in remote or resource-constrained environments where energy efficiency is paramount.

Pricing analysis indicates that while MCDI systems typically require higher initial capital investment than conventional ion exchange systems, they offer competitive total cost of ownership due to lower operational expenses, reduced chemical usage, and longer membrane lifespans. The average payback period for MCDI installations ranges from 3-5 years depending on application scale and local energy costs.

Market barriers include limited awareness of MCDI benefits among potential end-users, technical challenges in scaling up systems for large municipal applications, and competition from established desalination technologies with extensive installation bases and proven track records.

MCDI Technical Challenges and Global Development Status

Membrane Capacitive Deionization (MCDI) technology has witnessed significant advancements globally, yet continues to face several technical challenges that impede its widespread industrial adoption. The primary technical hurdle remains the development of electrode materials with optimal performance characteristics. Current carbon-based electrodes often suffer from limited ion adsorption capacity, inadequate stability during repeated charge-discharge cycles, and insufficient selectivity for target ions in complex water matrices.

Energy efficiency represents another critical challenge, as MCDI systems typically require external power sources to drive the deionization process. Research efforts are focused on reducing energy consumption through improved cell design, enhanced electrode materials, and optimized operational parameters. The energy recovery during discharge cycles remains suboptimal in many existing systems, limiting the overall efficiency of the technology.

Membrane fouling and scaling present persistent operational challenges, particularly when treating water with high organic content or elevated hardness levels. These phenomena reduce system performance over time and necessitate frequent maintenance or replacement of components, increasing operational costs and downtime. Current anti-fouling strategies have shown limited long-term effectiveness in industrial settings.

From a global development perspective, MCDI technology has gained significant traction in research institutions across North America, Europe, and East Asia. The United States leads in fundamental research and patent filings, with major contributions from universities and national laboratories. China has emerged as a rapidly growing center for MCDI development, with substantial government investment supporting both academic research and industrial applications.

European countries, particularly Germany and the Netherlands, have focused on specialized applications and system integration aspects. South Korea and Singapore have established themselves as important hubs for MCDI innovation in Asia, with strong industry-academia collaboration models driving commercialization efforts.

The technology readiness level (TRL) varies significantly across different applications. For brackish water desalination, MCDI has reached TRL 7-8 with several commercial installations operational. However, for more complex applications such as industrial wastewater treatment or selective ion removal, the technology remains at TRL 4-6, with pilot demonstrations showing promise but requiring further optimization for full-scale implementation.

Recent technological breakthroughs include the development of novel composite electrodes incorporating nanomaterials, advanced ion-exchange membranes with enhanced selectivity, and intelligent control systems that optimize operational parameters in real-time. These innovations are gradually addressing the existing limitations and expanding the potential application scope of MCDI technology.

Energy efficiency represents another critical challenge, as MCDI systems typically require external power sources to drive the deionization process. Research efforts are focused on reducing energy consumption through improved cell design, enhanced electrode materials, and optimized operational parameters. The energy recovery during discharge cycles remains suboptimal in many existing systems, limiting the overall efficiency of the technology.

Membrane fouling and scaling present persistent operational challenges, particularly when treating water with high organic content or elevated hardness levels. These phenomena reduce system performance over time and necessitate frequent maintenance or replacement of components, increasing operational costs and downtime. Current anti-fouling strategies have shown limited long-term effectiveness in industrial settings.

From a global development perspective, MCDI technology has gained significant traction in research institutions across North America, Europe, and East Asia. The United States leads in fundamental research and patent filings, with major contributions from universities and national laboratories. China has emerged as a rapidly growing center for MCDI development, with substantial government investment supporting both academic research and industrial applications.

European countries, particularly Germany and the Netherlands, have focused on specialized applications and system integration aspects. South Korea and Singapore have established themselves as important hubs for MCDI innovation in Asia, with strong industry-academia collaboration models driving commercialization efforts.

The technology readiness level (TRL) varies significantly across different applications. For brackish water desalination, MCDI has reached TRL 7-8 with several commercial installations operational. However, for more complex applications such as industrial wastewater treatment or selective ion removal, the technology remains at TRL 4-6, with pilot demonstrations showing promise but requiring further optimization for full-scale implementation.

Recent technological breakthroughs include the development of novel composite electrodes incorporating nanomaterials, advanced ion-exchange membranes with enhanced selectivity, and intelligent control systems that optimize operational parameters in real-time. These innovations are gradually addressing the existing limitations and expanding the potential application scope of MCDI technology.

Current MCDI System Designs and Operational Principles

01 Electrode materials for membrane capacitive deionization

Various electrode materials can be used in membrane capacitive deionization systems to improve performance. These materials include carbon-based electrodes, such as activated carbon, carbon nanotubes, and graphene, which offer high surface area and conductivity. Modified electrode materials with enhanced adsorption capacity and selectivity can significantly improve the efficiency of ion removal from water. The electrode material selection directly impacts the deionization capacity, energy efficiency, and operational lifespan of the system.- Electrode materials for membrane capacitive deionization: Various electrode materials can be used in membrane capacitive deionization systems to improve performance. These materials include carbon-based electrodes, such as activated carbon, carbon nanotubes, and graphene, which offer high surface area and conductivity. Modified electrode materials with enhanced adsorption capacity and selectivity can significantly improve the efficiency of ion removal from water. The electrode material selection directly impacts the deionization capacity, energy efficiency, and operational lifetime of the system.

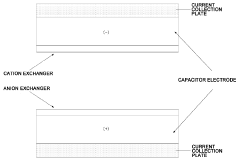

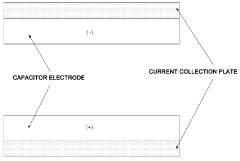

- Membrane configurations and designs: Different membrane configurations and designs can be employed in capacitive deionization systems to enhance performance. Ion-exchange membranes, including cation and anion exchange membranes, can be strategically positioned to improve ion selectivity and reduce energy consumption. Flow-through and flow-between architectures affect the system's hydraulic performance and deionization efficiency. Advanced membrane designs with optimized pore structures and surface properties can minimize fouling and enhance the system's operational stability.

- System operation and control strategies: Effective operation and control strategies are crucial for optimizing membrane capacitive deionization performance. These include voltage control methods, charging/discharging cycles, flow rate management, and regeneration protocols. Advanced control algorithms can be implemented to maximize salt removal while minimizing energy consumption. Real-time monitoring and adaptive control systems can respond to changes in feed water quality and adjust operational parameters accordingly, ensuring consistent performance across varying conditions.

- Energy recovery and efficiency improvements: Energy recovery and efficiency improvement techniques are essential for making membrane capacitive deionization economically viable. These include energy recovery during the discharge phase, optimized power management systems, and reduced internal resistance designs. Hybrid systems that combine capacitive deionization with other technologies can achieve better energy utilization. Novel circuit designs and power electronics solutions can significantly reduce the energy consumption per volume of treated water, making the technology more competitive with conventional desalination methods.

- Novel applications and integrated systems: Membrane capacitive deionization technology can be applied in various novel applications and integrated systems beyond conventional water desalination. These include selective ion removal for resource recovery, integration with renewable energy sources, hybrid systems combining multiple water treatment technologies, and specialized applications in industrial wastewater treatment. The technology can be scaled for different applications, from point-of-use systems to large-scale industrial installations, and can be tailored for specific contaminant removal requirements in different sectors.

02 Membrane configurations and modifications

Different membrane configurations and modifications can enhance the performance of capacitive deionization systems. Ion-exchange membranes, including cation and anion exchange membranes, can be strategically placed to improve ion selectivity and reduce co-ion repulsion effects. Composite membranes with specialized coatings or functional groups can enhance ion transport while minimizing fouling. The membrane structure, thickness, and charge density are critical parameters that affect the overall system efficiency and energy consumption.Expand Specific Solutions03 System design and operational parameters

The design and operational parameters of membrane capacitive deionization systems significantly impact performance. Factors such as cell architecture, flow configuration, applied voltage, and operational cycling time influence deionization efficiency. Advanced system designs incorporate optimized flow channels, electrode spacing, and current collectors to minimize internal resistance and maximize ion removal. Operational strategies like voltage swing, constant current operation, or pulsed electric fields can be employed to enhance salt removal capacity and energy efficiency while extending the system's operational lifetime.Expand Specific Solutions04 Energy recovery and efficiency improvements

Energy recovery techniques and efficiency improvements are crucial for making membrane capacitive deionization economically viable. Methods include energy recovery during the discharge phase, optimized power management systems, and integration with renewable energy sources. Advanced circuit designs can capture and reuse energy that would otherwise be wasted during the deionization cycle. Hybrid systems combining capacitive deionization with other technologies can also improve overall energy efficiency and reduce operational costs while maintaining high water recovery rates.Expand Specific Solutions05 Novel applications and specialized treatments

Membrane capacitive deionization technology has expanded beyond simple desalination to include specialized applications. These include selective removal of specific ions like heavy metals or nutrients, treatment of industrial wastewater, and integration into decentralized water treatment systems. Modified systems can target particular contaminants through electrode or membrane functionalization. The technology is also being adapted for resource recovery applications, where valuable ions are captured for reuse rather than simply removed as waste, creating more sustainable water treatment processes.Expand Specific Solutions

Leading Companies and Research Institutions in MCDI Field

Membrane Capacitive Deionization (MCDI) technology is currently in a growth phase, transitioning from early adoption to commercial implementation. The global market is expanding rapidly, estimated at approximately $25-30 million with projected annual growth of 15-20% through 2030. Technologically, MCDI is approaching maturity with significant advancements from key players. Companies like Voltea BV and Kurita Water Industries lead commercial applications, while research institutions such as MIT, University of Kentucky, and Qingdao University of Science & Technology drive innovation. Samsung Electronics and Robert Bosch GmbH are leveraging their manufacturing expertise to scale the technology. Chinese entities like Jiangsu Xinyi Zhongao and Shanghai Najing Technology are emerging as significant competitors, particularly in industrial water treatment applications where MCDI offers energy-efficient alternatives to traditional desalination methods.

Voltea BV

Technical Solution: Voltea has pioneered commercial Membrane Capacitive Deionization (MCDI) systems through their CapDI© technology. Their approach utilizes ion-exchange membranes placed in front of porous carbon electrodes to enhance salt removal efficiency. When voltage is applied, cations and anions are attracted to oppositely charged electrodes, passing through the ion-selective membranes and becoming temporarily stored in the electrode's electric double layer. This design achieves up to 90% water recovery rates while consuming 30-70% less energy compared to reverse osmosis systems for brackish water desalination. Voltea's modular systems can be scaled from point-of-use applications to industrial installations with flow rates exceeding 100 m³/h. Their technology incorporates automated self-cleaning cycles through polarity reversal, which significantly reduces maintenance requirements and extends system lifespan.

Strengths: Superior energy efficiency for brackish water treatment; high water recovery rates; modular scalability; reduced chemical usage; automated self-cleaning capability. Weaknesses: Limited effectiveness for high-salinity waters; requires stable power supply; higher initial capital investment compared to conventional technologies; performance dependent on feed water composition.

University of Kentucky Research Foundation

Technical Solution: The University of Kentucky Research Foundation has developed advanced MCDI systems focusing on selective ion removal capabilities. Their research has produced novel composite electrode materials incorporating activated carbon with metal oxide nanoparticles that enhance specific ion selectivity while maintaining high capacitance. These electrodes demonstrate 40-50% improved adsorption capacity for target ions compared to conventional carbon electrodes. Their patented flow-through electrode configuration allows for treatment of waters with higher suspended solids content without significant fouling issues. The foundation has also pioneered the integration of redox-active materials within MCDI electrodes to enable Faradaic reactions alongside capacitive deionization, effectively increasing salt removal capacity by up to 60% in laboratory tests. Their systems incorporate intelligent control algorithms that optimize operational parameters based on influent water quality, maximizing energy efficiency.

Strengths: Enhanced ion selectivity capabilities; superior fouling resistance; higher salt removal capacity through hybrid mechanisms; intelligent control systems for optimization. Weaknesses: Technology remains primarily at research/pilot scale; higher manufacturing complexity; potential durability concerns with novel materials; limited long-term operational data from field applications.

Key Patents and Scientific Breakthroughs in MCDI

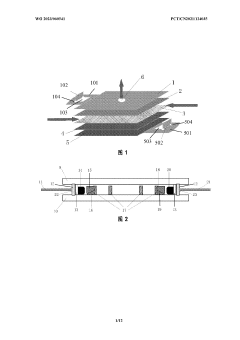

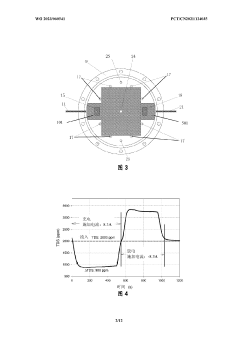

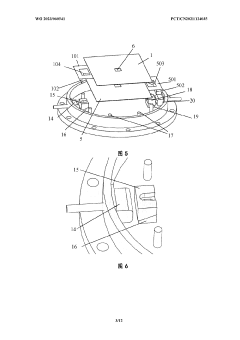

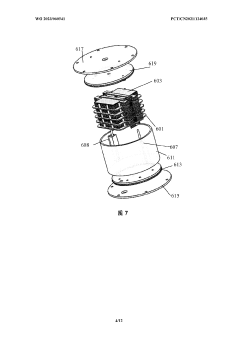

Membrane capacitive deionization electrode assembly, housing structure, module and liquid treatment method

PatentWO2023060541A1

Innovation

- Using membrane capacitive deionization technology (MCDI), through flexible anion electrodes and cation electrodes, exchange membrane components and their shell structures, a membrane capacitive deionization electrode assembly and module is designed to adsorb and separate anions and cations in seawater. Reduce energy consumption and secondary pollution.

Fabrication method for capacitor electrode

PatentWO2010101338A1

Innovation

- A capacitor electrode fabrication method involving a thin base polymer layer formed using the spraying method, onto which a cation or anion exchanger is applied, reducing system resistance and enhancing ion removal efficiency.

Environmental Impact and Sustainability Assessment

Membrane Capacitive Deionization (MCDI) technology demonstrates significant environmental advantages compared to conventional desalination methods. The process operates at low voltage (typically 1.2-1.8V), resulting in substantially reduced energy consumption—approximately 0.5-1.5 kWh/m³ for brackish water treatment, which is 30-50% lower than reverse osmosis systems processing similar water sources. This energy efficiency directly translates to reduced carbon emissions when powered by conventional energy sources.

The technology's chemical footprint is notably minimal, as MCDI requires no chemical additives for normal operation, unlike conventional ion exchange systems that demand regular regeneration with acids and bases. This characteristic eliminates the environmental burden associated with chemical production, transportation, and disposal of spent regenerants.

Waste stream management represents another environmental advantage of MCDI systems. The technology produces a concentrated brine stream that is typically 80-90% smaller in volume compared to reverse osmosis systems, significantly reducing discharge challenges. Furthermore, the intermittent nature of the discharge allows for more controlled release strategies that minimize ecological impact on receiving water bodies.

From a life cycle perspective, MCDI membranes demonstrate extended operational lifespans of 3-5 years under proper maintenance conditions, compared to 1-3 years for conventional RO membranes. This longevity reduces material consumption and waste generation associated with membrane replacement. The carbon-based electrodes used in MCDI systems can potentially be recycled or repurposed at end-of-life, further enhancing sustainability metrics.

Water recovery rates for MCDI typically range from 80-95%, significantly higher than the 50-75% commonly achieved in reverse osmosis systems. This efficiency reduces overall water withdrawal requirements and supports water conservation objectives in water-stressed regions.

When integrated with renewable energy sources such as solar photovoltaics, MCDI systems can achieve near-zero carbon operation due to their low voltage requirements and operational flexibility. Several pilot projects have demonstrated successful solar-powered MCDI installations that can operate effectively even with variable power input, eliminating the need for extensive energy storage systems.

Material sustainability considerations reveal that while ion exchange membranes currently rely on petroleum-based polymers, research into bio-based alternatives shows promising results. Recent developments in membrane materials derived from modified cellulose and chitosan demonstrate comparable performance while reducing dependence on fossil fuel resources.

The technology's chemical footprint is notably minimal, as MCDI requires no chemical additives for normal operation, unlike conventional ion exchange systems that demand regular regeneration with acids and bases. This characteristic eliminates the environmental burden associated with chemical production, transportation, and disposal of spent regenerants.

Waste stream management represents another environmental advantage of MCDI systems. The technology produces a concentrated brine stream that is typically 80-90% smaller in volume compared to reverse osmosis systems, significantly reducing discharge challenges. Furthermore, the intermittent nature of the discharge allows for more controlled release strategies that minimize ecological impact on receiving water bodies.

From a life cycle perspective, MCDI membranes demonstrate extended operational lifespans of 3-5 years under proper maintenance conditions, compared to 1-3 years for conventional RO membranes. This longevity reduces material consumption and waste generation associated with membrane replacement. The carbon-based electrodes used in MCDI systems can potentially be recycled or repurposed at end-of-life, further enhancing sustainability metrics.

Water recovery rates for MCDI typically range from 80-95%, significantly higher than the 50-75% commonly achieved in reverse osmosis systems. This efficiency reduces overall water withdrawal requirements and supports water conservation objectives in water-stressed regions.

When integrated with renewable energy sources such as solar photovoltaics, MCDI systems can achieve near-zero carbon operation due to their low voltage requirements and operational flexibility. Several pilot projects have demonstrated successful solar-powered MCDI installations that can operate effectively even with variable power input, eliminating the need for extensive energy storage systems.

Material sustainability considerations reveal that while ion exchange membranes currently rely on petroleum-based polymers, research into bio-based alternatives shows promising results. Recent developments in membrane materials derived from modified cellulose and chitosan demonstrate comparable performance while reducing dependence on fossil fuel resources.

Cost-Benefit Analysis of MCDI Implementation

Implementing Membrane Capacitive Deionization (MCDI) technology requires careful economic evaluation to determine its viability across different industrial applications. Initial capital expenditure for MCDI systems ranges from $50,000 to $500,000 depending on treatment capacity, with larger industrial installations at the higher end of this spectrum. This investment includes membrane electrode assemblies, power supply systems, hydraulic components, and control systems.

Operational costs present a more favorable picture compared to traditional desalination technologies. MCDI systems typically consume 0.1-0.5 kWh per cubic meter of treated water, representing a 30-70% energy reduction compared to reverse osmosis for brackish water applications. Maintenance costs average 3-5% of capital costs annually, primarily for membrane replacement every 2-5 years and electrode maintenance.

The economic benefits of MCDI implementation extend beyond direct operational savings. Water recovery rates of 80-95% significantly reduce waste stream management costs. For industrial applications treating process water, the improved quality of treated water can extend equipment lifespan by reducing scaling and corrosion, generating additional savings of 5-15% in equipment maintenance costs.

Return on investment timelines vary by application scale and water quality requirements. Small to medium industrial installations typically achieve ROI within 3-5 years, while larger systems may see returns in 2-3 years due to economies of scale. Industries with high-value processes where water quality directly impacts product quality, such as pharmaceuticals or microelectronics, may realize ROI in as little as 18 months.

Environmental cost benefits, though harder to quantify directly, include reduced chemical usage (70-90% less than conventional ion exchange systems) and lower carbon footprint from energy savings. These factors increasingly translate to tangible financial benefits as environmental regulations tighten and carbon pricing mechanisms expand globally.

Sensitivity analysis reveals that MCDI economics are most affected by energy costs, feed water salinity, and required treatment capacity. The technology shows optimal cost-effectiveness for brackish water with total dissolved solids between 1,000-10,000 mg/L. Beyond this range, hybrid systems combining MCDI with other technologies may provide better economic outcomes.

Future cost trajectories appear promising, with membrane and electrode material advancements expected to reduce capital costs by 15-25% over the next five years while simultaneously improving energy efficiency by an additional 10-20%. These improvements will further enhance the already compelling economic case for MCDI adoption across diverse industrial applications.

Operational costs present a more favorable picture compared to traditional desalination technologies. MCDI systems typically consume 0.1-0.5 kWh per cubic meter of treated water, representing a 30-70% energy reduction compared to reverse osmosis for brackish water applications. Maintenance costs average 3-5% of capital costs annually, primarily for membrane replacement every 2-5 years and electrode maintenance.

The economic benefits of MCDI implementation extend beyond direct operational savings. Water recovery rates of 80-95% significantly reduce waste stream management costs. For industrial applications treating process water, the improved quality of treated water can extend equipment lifespan by reducing scaling and corrosion, generating additional savings of 5-15% in equipment maintenance costs.

Return on investment timelines vary by application scale and water quality requirements. Small to medium industrial installations typically achieve ROI within 3-5 years, while larger systems may see returns in 2-3 years due to economies of scale. Industries with high-value processes where water quality directly impacts product quality, such as pharmaceuticals or microelectronics, may realize ROI in as little as 18 months.

Environmental cost benefits, though harder to quantify directly, include reduced chemical usage (70-90% less than conventional ion exchange systems) and lower carbon footprint from energy savings. These factors increasingly translate to tangible financial benefits as environmental regulations tighten and carbon pricing mechanisms expand globally.

Sensitivity analysis reveals that MCDI economics are most affected by energy costs, feed water salinity, and required treatment capacity. The technology shows optimal cost-effectiveness for brackish water with total dissolved solids between 1,000-10,000 mg/L. Beyond this range, hybrid systems combining MCDI with other technologies may provide better economic outcomes.

Future cost trajectories appear promising, with membrane and electrode material advancements expected to reduce capital costs by 15-25% over the next five years while simultaneously improving energy efficiency by an additional 10-20%. These improvements will further enhance the already compelling economic case for MCDI adoption across diverse industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!