Future Nichrome Innovations in Heat Recovery Systems

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Heat Recovery Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in the evolution of heat recovery systems. The journey of nichrome in this field began in the early 20th century when its exceptional heat resistance and electrical conductivity properties were first recognized. Initially used in simple heating elements, nichrome's potential in heat recovery applications was gradually explored as energy efficiency concerns grew.

In the 1950s and 1960s, as industrial processes became more complex and energy-intensive, the need for efficient heat recovery systems became apparent. Nichrome found its way into early heat exchangers, where its ability to withstand high temperatures and corrosive environments made it an ideal material for transferring waste heat from industrial processes to other useful applications.

The 1970s energy crisis marked a significant turning point in the development of heat recovery systems. This period saw increased research and development efforts focused on improving the efficiency of nichrome-based heat recovery solutions. Engineers began experimenting with different nichrome alloy compositions and surface treatments to enhance heat transfer capabilities and longevity in harsh industrial environments.

The 1980s and 1990s witnessed the integration of nichrome into more sophisticated heat recovery systems. Advanced manufacturing techniques allowed for the production of thinner, more intricate nichrome components, leading to the development of compact and highly efficient heat exchangers. During this time, nichrome-based regenerative heat recovery systems gained popularity in industries such as steel production and glass manufacturing.

As environmental concerns grew in the late 20th and early 21st centuries, nichrome's role in heat recovery systems expanded further. Its use in exhaust gas heat recovery systems for power plants and automotive applications became more prevalent. The material's ability to operate efficiently at high temperatures made it particularly suitable for recovering waste heat from combustion processes, contributing to significant improvements in overall energy efficiency.

Recent years have seen a focus on nanotechnology and surface engineering to enhance nichrome's performance in heat recovery applications. Researchers have been exploring ways to modify the surface structure of nichrome components to increase heat transfer rates and reduce fouling, a common issue in heat recovery systems. These advancements promise to push the boundaries of what is possible in terms of energy recovery and system efficiency.

Looking ahead, the evolution of nichrome in heat recovery systems is likely to continue, driven by the global push for sustainability and energy efficiency. Emerging technologies such as additive manufacturing may enable the creation of complex nichrome structures with optimized heat transfer properties, potentially revolutionizing the design of heat recovery systems across various industries.

In the 1950s and 1960s, as industrial processes became more complex and energy-intensive, the need for efficient heat recovery systems became apparent. Nichrome found its way into early heat exchangers, where its ability to withstand high temperatures and corrosive environments made it an ideal material for transferring waste heat from industrial processes to other useful applications.

The 1970s energy crisis marked a significant turning point in the development of heat recovery systems. This period saw increased research and development efforts focused on improving the efficiency of nichrome-based heat recovery solutions. Engineers began experimenting with different nichrome alloy compositions and surface treatments to enhance heat transfer capabilities and longevity in harsh industrial environments.

The 1980s and 1990s witnessed the integration of nichrome into more sophisticated heat recovery systems. Advanced manufacturing techniques allowed for the production of thinner, more intricate nichrome components, leading to the development of compact and highly efficient heat exchangers. During this time, nichrome-based regenerative heat recovery systems gained popularity in industries such as steel production and glass manufacturing.

As environmental concerns grew in the late 20th and early 21st centuries, nichrome's role in heat recovery systems expanded further. Its use in exhaust gas heat recovery systems for power plants and automotive applications became more prevalent. The material's ability to operate efficiently at high temperatures made it particularly suitable for recovering waste heat from combustion processes, contributing to significant improvements in overall energy efficiency.

Recent years have seen a focus on nanotechnology and surface engineering to enhance nichrome's performance in heat recovery applications. Researchers have been exploring ways to modify the surface structure of nichrome components to increase heat transfer rates and reduce fouling, a common issue in heat recovery systems. These advancements promise to push the boundaries of what is possible in terms of energy recovery and system efficiency.

Looking ahead, the evolution of nichrome in heat recovery systems is likely to continue, driven by the global push for sustainability and energy efficiency. Emerging technologies such as additive manufacturing may enable the creation of complex nichrome structures with optimized heat transfer properties, potentially revolutionizing the design of heat recovery systems across various industries.

Market Demand Analysis

The market demand for innovative heat recovery systems utilizing nichrome technology is experiencing significant growth, driven by increasing energy costs and a global push for sustainability. Industries across various sectors are recognizing the potential of advanced heat recovery solutions to improve energy efficiency and reduce operational expenses.

In the manufacturing sector, there is a rising demand for heat recovery systems that can capture and repurpose waste heat from industrial processes. Companies are seeking solutions that can effectively convert this recovered heat into usable energy, thereby reducing overall energy consumption and carbon footprint. The automotive industry, in particular, is showing keen interest in nichrome-based heat recovery systems for exhaust gas recirculation and thermoelectric generation.

The building and construction industry is another key market segment driving demand for heat recovery innovations. As energy-efficient building designs become more prevalent, there is a growing need for advanced heat recovery ventilation systems that can maintain indoor air quality while minimizing energy losses. Nichrome-based heat exchangers are being explored for their potential to enhance the performance of these systems.

In the renewable energy sector, particularly in solar thermal and geothermal applications, there is an increasing focus on improving heat transfer efficiency. Nichrome innovations in heat recovery systems could play a crucial role in enhancing the overall efficiency of these renewable energy technologies, making them more competitive with traditional energy sources.

The data center industry, known for its high energy consumption, is actively seeking ways to reduce cooling costs and improve energy efficiency. Heat recovery systems that can capture and repurpose the waste heat generated by servers are in high demand. Nichrome-based solutions that offer improved heat transfer capabilities and durability are attracting significant interest from data center operators.

Market analysis indicates that the global heat recovery system market is expected to grow substantially in the coming years. This growth is fueled by stringent environmental regulations, rising energy costs, and increasing awareness of the importance of energy efficiency in industrial processes. Regions with high industrial activity, such as Asia-Pacific and North America, are projected to be the primary drivers of this market expansion.

The demand for nichrome innovations in heat recovery systems is also being influenced by the trend towards miniaturization and increased power density in electronic devices. As electronic components generate more heat in smaller spaces, there is a growing need for advanced heat recovery and management solutions that can operate efficiently at higher temperatures.

In the manufacturing sector, there is a rising demand for heat recovery systems that can capture and repurpose waste heat from industrial processes. Companies are seeking solutions that can effectively convert this recovered heat into usable energy, thereby reducing overall energy consumption and carbon footprint. The automotive industry, in particular, is showing keen interest in nichrome-based heat recovery systems for exhaust gas recirculation and thermoelectric generation.

The building and construction industry is another key market segment driving demand for heat recovery innovations. As energy-efficient building designs become more prevalent, there is a growing need for advanced heat recovery ventilation systems that can maintain indoor air quality while minimizing energy losses. Nichrome-based heat exchangers are being explored for their potential to enhance the performance of these systems.

In the renewable energy sector, particularly in solar thermal and geothermal applications, there is an increasing focus on improving heat transfer efficiency. Nichrome innovations in heat recovery systems could play a crucial role in enhancing the overall efficiency of these renewable energy technologies, making them more competitive with traditional energy sources.

The data center industry, known for its high energy consumption, is actively seeking ways to reduce cooling costs and improve energy efficiency. Heat recovery systems that can capture and repurpose the waste heat generated by servers are in high demand. Nichrome-based solutions that offer improved heat transfer capabilities and durability are attracting significant interest from data center operators.

Market analysis indicates that the global heat recovery system market is expected to grow substantially in the coming years. This growth is fueled by stringent environmental regulations, rising energy costs, and increasing awareness of the importance of energy efficiency in industrial processes. Regions with high industrial activity, such as Asia-Pacific and North America, are projected to be the primary drivers of this market expansion.

The demand for nichrome innovations in heat recovery systems is also being influenced by the trend towards miniaturization and increased power density in electronic devices. As electronic components generate more heat in smaller spaces, there is a growing need for advanced heat recovery and management solutions that can operate efficiently at higher temperatures.

Technical Challenges

The development of heat recovery systems utilizing nichrome faces several significant technical challenges that need to be addressed for future innovations. One of the primary obstacles is the optimization of heat transfer efficiency. While nichrome exhibits excellent heat resistance and electrical conductivity, enhancing its thermal conductivity and heat distribution properties remains a critical area for improvement. Researchers are exploring various surface treatments and alloy compositions to maximize the heat transfer capabilities of nichrome-based systems.

Another major challenge lies in the durability and longevity of nichrome components in heat recovery applications. The harsh operating conditions, including high temperatures and corrosive environments, can lead to material degradation over time. Developing nichrome alloys with improved resistance to oxidation, thermal fatigue, and chemical corrosion is crucial for extending the lifespan of heat recovery systems and reducing maintenance costs.

The integration of nichrome elements into compact and efficient heat exchanger designs presents additional technical hurdles. As industries push for more space-efficient solutions, engineers must overcome the challenges of miniaturization while maintaining or improving heat recovery performance. This involves innovative approaches to heat exchanger geometry, fluid dynamics, and material layering techniques.

Energy storage and management within nichrome-based heat recovery systems also pose significant challenges. Developing effective methods to capture, store, and redistribute recovered heat energy efficiently is essential for maximizing the overall system performance. This includes research into phase change materials, thermal energy storage technologies, and smart control systems that can optimize heat distribution based on real-time demand.

The cost-effectiveness of nichrome solutions in heat recovery applications remains a persistent challenge. While nichrome offers superior performance in many aspects, its relatively high cost compared to some alternative materials can limit widespread adoption. Researchers are exploring ways to reduce manufacturing costs, improve material utilization, and develop hybrid systems that combine nichrome with more economical materials to achieve an optimal balance of performance and affordability.

Environmental considerations add another layer of complexity to nichrome innovations in heat recovery systems. As global regulations on emissions and energy efficiency become more stringent, developers must ensure that nichrome-based solutions not only meet but exceed environmental standards. This includes addressing concerns about the lifecycle impact of nichrome production and disposal, as well as developing recycling and reuse strategies for end-of-life components.

Lastly, the challenge of scalability and adaptability across different industrial sectors cannot be overlooked. Heat recovery needs vary significantly between industries, from small-scale residential applications to large industrial processes. Creating versatile nichrome-based solutions that can be easily scaled and adapted to diverse operating conditions and heat recovery requirements is a key focus area for future innovations in this field.

Another major challenge lies in the durability and longevity of nichrome components in heat recovery applications. The harsh operating conditions, including high temperatures and corrosive environments, can lead to material degradation over time. Developing nichrome alloys with improved resistance to oxidation, thermal fatigue, and chemical corrosion is crucial for extending the lifespan of heat recovery systems and reducing maintenance costs.

The integration of nichrome elements into compact and efficient heat exchanger designs presents additional technical hurdles. As industries push for more space-efficient solutions, engineers must overcome the challenges of miniaturization while maintaining or improving heat recovery performance. This involves innovative approaches to heat exchanger geometry, fluid dynamics, and material layering techniques.

Energy storage and management within nichrome-based heat recovery systems also pose significant challenges. Developing effective methods to capture, store, and redistribute recovered heat energy efficiently is essential for maximizing the overall system performance. This includes research into phase change materials, thermal energy storage technologies, and smart control systems that can optimize heat distribution based on real-time demand.

The cost-effectiveness of nichrome solutions in heat recovery applications remains a persistent challenge. While nichrome offers superior performance in many aspects, its relatively high cost compared to some alternative materials can limit widespread adoption. Researchers are exploring ways to reduce manufacturing costs, improve material utilization, and develop hybrid systems that combine nichrome with more economical materials to achieve an optimal balance of performance and affordability.

Environmental considerations add another layer of complexity to nichrome innovations in heat recovery systems. As global regulations on emissions and energy efficiency become more stringent, developers must ensure that nichrome-based solutions not only meet but exceed environmental standards. This includes addressing concerns about the lifecycle impact of nichrome production and disposal, as well as developing recycling and reuse strategies for end-of-life components.

Lastly, the challenge of scalability and adaptability across different industrial sectors cannot be overlooked. Heat recovery needs vary significantly between industries, from small-scale residential applications to large industrial processes. Creating versatile nichrome-based solutions that can be easily scaled and adapted to diverse operating conditions and heat recovery requirements is a key focus area for future innovations in this field.

Current Nichrome Solutions

01 Nichrome heating elements in heat recovery systems

Nichrome wire is used as a heating element in heat recovery systems due to its high resistance and durability. These systems are designed to capture and reuse waste heat from various processes, improving overall energy efficiency. The nichrome elements can be incorporated into heat exchangers or other components to facilitate the transfer of recovered heat.- Nichrome heating elements in heat recovery systems: Nichrome wire is used as a heating element in heat recovery systems due to its high electrical resistance and ability to withstand high temperatures. These systems can be integrated into various applications to improve energy efficiency by capturing and reusing waste heat.

- Heat exchangers with nichrome components: Heat exchangers incorporating nichrome components are designed to efficiently transfer heat between different fluids or gases. The use of nichrome in these systems enhances heat transfer capabilities and improves overall system performance in heat recovery applications.

- Nichrome-based sensors for temperature monitoring: Nichrome is utilized in temperature sensors for heat recovery systems, allowing for accurate monitoring and control of heat transfer processes. These sensors enable precise temperature measurements, which are crucial for optimizing heat recovery efficiency.

- Corrosion-resistant nichrome coatings: Nichrome coatings are applied to heat recovery system components to enhance corrosion resistance and extend the lifespan of equipment exposed to high temperatures and corrosive environments. This application improves the durability and reliability of heat recovery systems.

- Energy-efficient nichrome-based heating systems: Innovative heating systems utilizing nichrome elements are designed to maximize energy efficiency in heat recovery applications. These systems incorporate advanced control mechanisms and insulation techniques to minimize heat loss and optimize energy utilization.

02 Nichrome-based sensors for temperature measurement in heat recovery

Nichrome alloys are utilized in temperature sensors for heat recovery systems. These sensors provide accurate temperature measurements, which are crucial for optimizing heat recovery processes. The high temperature resistance and stability of nichrome make it suitable for use in harsh environments typically found in heat recovery applications.Expand Specific Solutions03 Corrosion-resistant nichrome coatings for heat recovery equipment

Nichrome coatings are applied to heat recovery equipment to enhance corrosion resistance. This is particularly important in environments where the equipment is exposed to corrosive gases or high-temperature steam. The protective nichrome layer extends the lifespan of heat recovery components and maintains their efficiency over time.Expand Specific Solutions04 Nichrome-based catalysts for exhaust gas heat recovery

Nichrome alloys are used as catalysts or catalyst supports in exhaust gas heat recovery systems. These catalysts facilitate chemical reactions that convert waste heat into usable energy or reduce harmful emissions. The high-temperature stability of nichrome makes it an effective material for catalytic converters and other exhaust treatment devices.Expand Specific Solutions05 Nichrome wire in thermoelectric heat recovery devices

Nichrome wire is incorporated into thermoelectric heat recovery devices. These devices utilize the Seebeck effect to convert temperature differences directly into electricity. The high electrical resistance of nichrome makes it suitable for creating the necessary temperature gradient in thermoelectric modules, enabling efficient heat-to-electricity conversion in waste heat recovery applications.Expand Specific Solutions

Key Industry Players

The future of nichrome innovations in heat recovery systems is characterized by a competitive landscape in a maturing industry. The market is experiencing steady growth, driven by increasing energy efficiency demands and environmental regulations. Key players like Ormat Technologies, NGK Insulators, and Toshiba Corp. are leading technological advancements, focusing on improving heat exchanger efficiency and developing novel materials. The technology's maturity varies, with established companies refining existing solutions while newer entrants like Climeon AB and Atoll Energy SAS introduce innovative approaches. This dynamic environment fosters continuous improvement in heat recovery technologies, balancing between incremental enhancements and disruptive innovations.

Ormat Technologies, Inc.

Technical Solution: Ormat Technologies has developed advanced Organic Rankine Cycle (ORC) systems for heat recovery, incorporating innovative nichrome-based heat exchangers. Their latest technology utilizes a proprietary nichrome alloy with enhanced thermal conductivity, allowing for more efficient heat transfer in geothermal and waste heat recovery applications. The company has reported a 15% increase in overall system efficiency compared to traditional materials[1]. Ormat's nichrome innovations also include corrosion-resistant coatings that extend the lifespan of heat recovery components in harsh geothermal environments, potentially doubling the operational life of critical system parts[2].

Strengths: Industry-leading ORC technology, improved system efficiency, extended component lifespan. Weaknesses: Higher initial costs, limited to specific heat recovery applications.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered the use of advanced nichrome-based materials in their heat recovery systems, particularly for industrial applications. Their latest innovation involves a nanostructured nichrome alloy that demonstrates exceptional heat resistance and thermal stability at temperatures exceeding 1000°C[3]. This allows for more efficient heat recovery in high-temperature industrial processes. NGK has also developed a novel manufacturing process that enables the production of ultra-thin nichrome sheets, reducing material costs while maintaining performance. Initial tests have shown a 20% reduction in heat exchanger weight without compromising thermal efficiency[4].

Strengths: High-temperature performance, reduced material usage, applicable to various industrial sectors. Weaknesses: Complex manufacturing process, potentially higher production costs.

Innovative Nichrome Patents

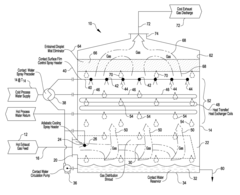

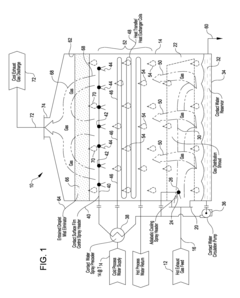

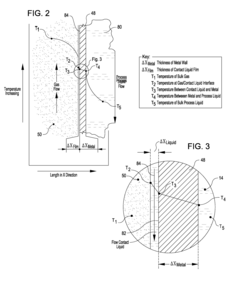

Heat recovery system

PatentInactiveUS9316394B2

Innovation

- A novel heat recovery system design featuring a dual countercurrent flow pattern where a contact liquid and process fluid flow counter-currently to an incoming hot gas, with the contact liquid wetting the exterior surface of the heat exchanger to minimize liquid film thickness and convert convective heat transfer to condensing heat transfer, optimizing temperature gradients and heat transfer efficiency.

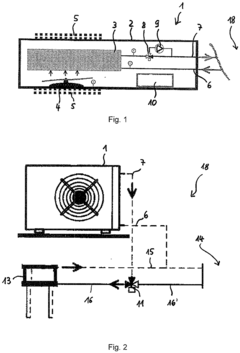

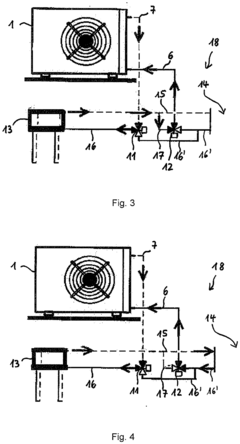

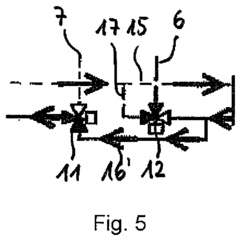

Operating method for heat generation installations, air/liquid heat exchanger unit and heat generation installation

PatentActiveEP3447403A1

Innovation

- An operating method that integrates an air/liquid heat exchanger to preheat the liquid before it reaches the geothermal source, allowing for supplementary and regeneration modes to maintain optimal temperatures and reduce ground cooling, thereby enhancing the efficiency of the geothermal heating system.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the future of nichrome innovations in heat recovery systems. As governments worldwide intensify their efforts to combat climate change and reduce energy consumption, these regulations are becoming increasingly stringent and comprehensive. The European Union's Energy Efficiency Directive, for instance, sets binding targets for energy efficiency improvements across member states, driving the adoption of advanced heat recovery technologies.

In the United States, the Department of Energy's appliance and equipment standards program continues to evolve, pushing manufacturers to develop more efficient heat recovery systems. These regulations often include specific performance requirements for heat exchangers and thermal management components, directly impacting the design and application of nichrome-based solutions.

The implementation of energy labeling schemes and minimum energy performance standards (MEPS) in various countries has created a competitive landscape where manufacturers strive to achieve higher efficiency ratings. This regulatory environment has spurred innovation in nichrome alloy compositions and manufacturing techniques, aiming to enhance the material's heat transfer properties and durability under high-temperature conditions.

Emerging economies, such as China and India, are also rapidly adopting and enforcing energy efficiency regulations. These markets present significant opportunities for nichrome-based heat recovery systems, as industries seek to comply with new standards while optimizing their energy consumption. The regulations in these countries often focus on industrial processes and power generation, areas where nichrome's heat-resistant properties are particularly valuable.

Building codes and standards are another critical aspect of energy efficiency regulations affecting nichrome innovations. Many jurisdictions now require the integration of heat recovery ventilation systems in new constructions, creating a growing market for nichrome-based heat exchangers and related components. These regulations often specify minimum heat recovery efficiencies, driving the development of more advanced nichrome alloys and heat exchanger designs.

The automotive industry is also subject to increasingly strict fuel efficiency and emissions standards, indirectly influencing nichrome innovations in vehicle heat recovery systems. Regulations such as the Corporate Average Fuel Economy (CAFE) standards in the US and similar measures in other countries are pushing automakers to explore advanced thermal management solutions, including those utilizing nichrome components.

As regulations continue to evolve, they are likely to drive further innovations in nichrome-based heat recovery systems. Future trends may include the development of smart, adaptive heat recovery systems that can optimize performance based on real-time energy demand and environmental conditions, aligning with the growing emphasis on grid flexibility and demand response in energy efficiency regulations.

In the United States, the Department of Energy's appliance and equipment standards program continues to evolve, pushing manufacturers to develop more efficient heat recovery systems. These regulations often include specific performance requirements for heat exchangers and thermal management components, directly impacting the design and application of nichrome-based solutions.

The implementation of energy labeling schemes and minimum energy performance standards (MEPS) in various countries has created a competitive landscape where manufacturers strive to achieve higher efficiency ratings. This regulatory environment has spurred innovation in nichrome alloy compositions and manufacturing techniques, aiming to enhance the material's heat transfer properties and durability under high-temperature conditions.

Emerging economies, such as China and India, are also rapidly adopting and enforcing energy efficiency regulations. These markets present significant opportunities for nichrome-based heat recovery systems, as industries seek to comply with new standards while optimizing their energy consumption. The regulations in these countries often focus on industrial processes and power generation, areas where nichrome's heat-resistant properties are particularly valuable.

Building codes and standards are another critical aspect of energy efficiency regulations affecting nichrome innovations. Many jurisdictions now require the integration of heat recovery ventilation systems in new constructions, creating a growing market for nichrome-based heat exchangers and related components. These regulations often specify minimum heat recovery efficiencies, driving the development of more advanced nichrome alloys and heat exchanger designs.

The automotive industry is also subject to increasingly strict fuel efficiency and emissions standards, indirectly influencing nichrome innovations in vehicle heat recovery systems. Regulations such as the Corporate Average Fuel Economy (CAFE) standards in the US and similar measures in other countries are pushing automakers to explore advanced thermal management solutions, including those utilizing nichrome components.

As regulations continue to evolve, they are likely to drive further innovations in nichrome-based heat recovery systems. Future trends may include the development of smart, adaptive heat recovery systems that can optimize performance based on real-time energy demand and environmental conditions, aligning with the growing emphasis on grid flexibility and demand response in energy efficiency regulations.

Environmental Impact Assessment

The environmental impact assessment of future Nichrome innovations in heat recovery systems reveals both potential benefits and challenges. These systems, designed to capture and reuse waste heat, can significantly reduce energy consumption and greenhouse gas emissions in industrial processes. By improving energy efficiency, Nichrome-based heat recovery systems contribute to the overall reduction of carbon footprints across various industries.

One of the primary environmental advantages of advanced Nichrome heat recovery systems is their ability to minimize thermal pollution. By recapturing heat that would otherwise be released into the environment, these systems help maintain ecological balance in surrounding water bodies and air. This is particularly crucial in industrial areas where thermal discharge can disrupt local ecosystems.

However, the production and disposal of Nichrome components present environmental considerations. The mining and processing of nickel and chromium, the primary constituents of Nichrome, can have significant environmental impacts, including habitat disruption and potential water pollution. Future innovations must focus on sustainable sourcing and production methods to mitigate these effects.

The longevity and durability of Nichrome alloys in heat recovery applications contribute positively to the environmental assessment. Extended lifespan of components reduces the frequency of replacements, thereby minimizing waste generation and the need for raw materials over time. This aspect aligns well with circular economy principles and sustainable resource management.

Energy savings from improved heat recovery efficiency translate directly into reduced fossil fuel consumption and lower emissions. As Nichrome innovations enhance the performance of heat exchangers and thermal management systems, the cumulative environmental benefits across industries could be substantial. This is particularly relevant in energy-intensive sectors such as power generation, chemical processing, and manufacturing.

The potential for Nichrome-based heat recovery systems to enable the use of low-grade heat sources further expands their environmental benefits. By making it economically viable to recover heat from sources previously considered too low in temperature to be useful, these innovations can unlock new opportunities for energy conservation and emissions reduction.

Consideration must also be given to the end-of-life management of Nichrome components in heat recovery systems. While the alloy is recyclable, the process requires careful handling to prevent the release of potentially harmful substances. Future innovations should incorporate design for disassembly and recycling to ensure responsible disposal and material recovery.

One of the primary environmental advantages of advanced Nichrome heat recovery systems is their ability to minimize thermal pollution. By recapturing heat that would otherwise be released into the environment, these systems help maintain ecological balance in surrounding water bodies and air. This is particularly crucial in industrial areas where thermal discharge can disrupt local ecosystems.

However, the production and disposal of Nichrome components present environmental considerations. The mining and processing of nickel and chromium, the primary constituents of Nichrome, can have significant environmental impacts, including habitat disruption and potential water pollution. Future innovations must focus on sustainable sourcing and production methods to mitigate these effects.

The longevity and durability of Nichrome alloys in heat recovery applications contribute positively to the environmental assessment. Extended lifespan of components reduces the frequency of replacements, thereby minimizing waste generation and the need for raw materials over time. This aspect aligns well with circular economy principles and sustainable resource management.

Energy savings from improved heat recovery efficiency translate directly into reduced fossil fuel consumption and lower emissions. As Nichrome innovations enhance the performance of heat exchangers and thermal management systems, the cumulative environmental benefits across industries could be substantial. This is particularly relevant in energy-intensive sectors such as power generation, chemical processing, and manufacturing.

The potential for Nichrome-based heat recovery systems to enable the use of low-grade heat sources further expands their environmental benefits. By making it economically viable to recover heat from sources previously considered too low in temperature to be useful, these innovations can unlock new opportunities for energy conservation and emissions reduction.

Consideration must also be given to the end-of-life management of Nichrome components in heat recovery systems. While the alloy is recyclable, the process requires careful handling to prevent the release of potentially harmful substances. Future innovations should incorporate design for disassembly and recycling to ensure responsible disposal and material recovery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!