Heat Sink Design Optimization for Automotive Electronic Systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive Thermal Management Background and Objectives

Thermal management has emerged as a critical challenge in the automotive industry, particularly with the rapid evolution of electronic systems in modern vehicles. The historical progression of automotive electronics has seen a dramatic increase in complexity and power density, transitioning from basic engine control units in the 1970s to today's sophisticated systems that include advanced driver assistance systems (ADAS), infotainment platforms, and electric powertrain components. This evolution has intensified heat generation concerns, necessitating more effective thermal management solutions.

The automotive operating environment presents unique thermal challenges compared to consumer electronics, with temperature ranges spanning from -40°C to 125°C in under-hood applications. Vehicles must function reliably across diverse climatic conditions while enduring vibration, shock, and exposure to contaminants. These factors significantly complicate thermal management strategies for automotive electronic systems.

Heat sinks represent a fundamental passive cooling technology in this domain, serving as the primary interface between heat-generating components and the ambient environment. Their optimization directly impacts system reliability, performance, and longevity. Industry data indicates that approximately 55% of electronic failures in automotive applications are temperature-related, underscoring the critical importance of effective thermal management.

Current industry trends are driving the need for advanced heat sink solutions. The electrification of vehicles has introduced high-power components that generate substantial heat, while the miniaturization of electronic modules has increased power density. Simultaneously, consumer expectations for vehicle performance and reliability continue to rise, creating a complex set of requirements for thermal engineers.

The primary objective of heat sink design optimization is to maximize thermal efficiency while minimizing weight, space requirements, and cost—factors particularly crucial in automotive applications. Secondary objectives include ensuring manufacturability at scale, maintaining compatibility with existing assembly processes, and meeting increasingly stringent environmental regulations regarding materials usage.

This technical research aims to comprehensively evaluate current heat sink technologies in automotive electronic systems, identify key performance bottlenecks, and explore innovative design approaches that could significantly improve thermal management capabilities. The ultimate goal is to develop optimization methodologies that balance thermal performance with practical automotive design constraints, potentially establishing new industry benchmarks for electronic cooling solutions in next-generation vehicles.

The automotive operating environment presents unique thermal challenges compared to consumer electronics, with temperature ranges spanning from -40°C to 125°C in under-hood applications. Vehicles must function reliably across diverse climatic conditions while enduring vibration, shock, and exposure to contaminants. These factors significantly complicate thermal management strategies for automotive electronic systems.

Heat sinks represent a fundamental passive cooling technology in this domain, serving as the primary interface between heat-generating components and the ambient environment. Their optimization directly impacts system reliability, performance, and longevity. Industry data indicates that approximately 55% of electronic failures in automotive applications are temperature-related, underscoring the critical importance of effective thermal management.

Current industry trends are driving the need for advanced heat sink solutions. The electrification of vehicles has introduced high-power components that generate substantial heat, while the miniaturization of electronic modules has increased power density. Simultaneously, consumer expectations for vehicle performance and reliability continue to rise, creating a complex set of requirements for thermal engineers.

The primary objective of heat sink design optimization is to maximize thermal efficiency while minimizing weight, space requirements, and cost—factors particularly crucial in automotive applications. Secondary objectives include ensuring manufacturability at scale, maintaining compatibility with existing assembly processes, and meeting increasingly stringent environmental regulations regarding materials usage.

This technical research aims to comprehensively evaluate current heat sink technologies in automotive electronic systems, identify key performance bottlenecks, and explore innovative design approaches that could significantly improve thermal management capabilities. The ultimate goal is to develop optimization methodologies that balance thermal performance with practical automotive design constraints, potentially establishing new industry benchmarks for electronic cooling solutions in next-generation vehicles.

Market Demand Analysis for Advanced Cooling Solutions

The automotive electronics market is experiencing unprecedented growth, with the global market value projected to reach $382 billion by 2026, growing at a CAGR of 7.3%. This expansion is directly driving demand for advanced thermal management solutions, particularly sophisticated heat sink designs. As vehicles incorporate more electronic components for autonomous driving, infotainment systems, and electrification, the heat dissipation requirements have increased exponentially.

Industry research indicates that approximately 55% of electronic failures in automotive systems are temperature-related, highlighting the critical importance of effective cooling solutions. The transition to electric vehicles has further intensified this demand, as power electronics in EVs generate significantly more heat than traditional combustion engine control units. Battery management systems alone require cooling solutions capable of handling temperature variations between -40°C and 85°C while maintaining optimal performance.

Consumer expectations for vehicle reliability have reached all-time highs, with surveys showing that 78% of consumers consider electronic system reliability a key factor in purchasing decisions. This consumer pressure translates directly to OEM requirements for thermal solutions with longer lifespans and higher performance metrics.

The market for automotive cooling solutions is segmented by vehicle type, with passenger vehicles representing the largest segment at 65% of market share. However, commercial vehicles are showing the fastest growth rate at 9.2% annually, driven by electrification of delivery fleets and increased electronics in logistics management systems.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, followed by Europe (28%) and North America (22%). China's aggressive push toward electric vehicle production has created a particularly strong demand center for advanced cooling technologies, with local production of thermal management components growing at 12% annually.

Material innovation is reshaping market dynamics, with aluminum-silicon carbide composites gaining traction due to their superior thermal conductivity and reduced weight. The lightweight materials segment is growing at 10.5% annually, reflecting automotive manufacturers' dual focus on thermal efficiency and vehicle weight reduction to improve overall energy efficiency.

Regulatory factors are also driving market growth, with stringent emissions standards and safety regulations requiring more sophisticated electronic control systems that, in turn, demand more effective cooling solutions. The European Union's Euro 7 standards and similar regulations worldwide are indirectly expanding the market for advanced heat sink technologies as manufacturers seek to ensure compliance and reliability of increasingly complex electronic systems.

Industry research indicates that approximately 55% of electronic failures in automotive systems are temperature-related, highlighting the critical importance of effective cooling solutions. The transition to electric vehicles has further intensified this demand, as power electronics in EVs generate significantly more heat than traditional combustion engine control units. Battery management systems alone require cooling solutions capable of handling temperature variations between -40°C and 85°C while maintaining optimal performance.

Consumer expectations for vehicle reliability have reached all-time highs, with surveys showing that 78% of consumers consider electronic system reliability a key factor in purchasing decisions. This consumer pressure translates directly to OEM requirements for thermal solutions with longer lifespans and higher performance metrics.

The market for automotive cooling solutions is segmented by vehicle type, with passenger vehicles representing the largest segment at 65% of market share. However, commercial vehicles are showing the fastest growth rate at 9.2% annually, driven by electrification of delivery fleets and increased electronics in logistics management systems.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, followed by Europe (28%) and North America (22%). China's aggressive push toward electric vehicle production has created a particularly strong demand center for advanced cooling technologies, with local production of thermal management components growing at 12% annually.

Material innovation is reshaping market dynamics, with aluminum-silicon carbide composites gaining traction due to their superior thermal conductivity and reduced weight. The lightweight materials segment is growing at 10.5% annually, reflecting automotive manufacturers' dual focus on thermal efficiency and vehicle weight reduction to improve overall energy efficiency.

Regulatory factors are also driving market growth, with stringent emissions standards and safety regulations requiring more sophisticated electronic control systems that, in turn, demand more effective cooling solutions. The European Union's Euro 7 standards and similar regulations worldwide are indirectly expanding the market for advanced heat sink technologies as manufacturers seek to ensure compliance and reliability of increasingly complex electronic systems.

Current Heat Sink Technologies and Challenges

Heat sink technology in automotive electronic systems has evolved significantly over the past decade, with current designs primarily categorized into passive and active cooling solutions. Passive heat sinks rely on natural convection and radiation, utilizing materials with high thermal conductivity such as aluminum and copper. These traditional designs, while reliable, often struggle to meet the increasing thermal demands of modern automotive electronics, particularly in confined spaces with limited airflow.

Active cooling solutions incorporate fans or liquid cooling systems to enhance heat dissipation. Fan-assisted heat sinks have become common in automotive applications where space constraints permit, offering improved cooling efficiency compared to passive designs. However, they introduce additional failure points, noise concerns, and power consumption requirements that must be carefully managed in automotive environments.

The industry currently faces several critical challenges in heat sink design optimization. Miniaturization of electronic components has led to higher power densities, creating thermal hotspots that are difficult to manage with conventional heat sink geometries. The trend toward more compact electronic control units (ECUs) further exacerbates this issue, limiting the physical space available for thermal management solutions.

Material limitations present another significant challenge. While aluminum remains the predominant material due to its cost-effectiveness and reasonable thermal properties, its thermal conductivity (approximately 200-250 W/m·K) falls short of what next-generation automotive electronics require. Copper offers superior thermal conductivity (around 400 W/m·K) but adds considerable weight and cost, making it impractical for many applications.

Manufacturing constraints also impact heat sink effectiveness. Traditional manufacturing methods like extrusion and die-casting limit the complexity of fin structures and channel designs that can be achieved. This restricts the optimization of surface area and airflow patterns, which are critical factors in heat dissipation efficiency.

Emerging technologies such as phase-change materials (PCMs) and vapor chambers are being explored to address these limitations. PCMs can absorb large amounts of heat during phase transition, helping to manage transient thermal loads common in automotive applications. Vapor chambers provide more uniform heat distribution across the base of the heat sink, reducing thermal resistance and hotspots.

The automotive industry's shift toward electric and autonomous vehicles introduces additional thermal management challenges. Power electronics in electric vehicles generate significant heat during charging and discharging cycles, while the computational hardware required for autonomous driving features creates new cooling demands that current heat sink technologies struggle to address efficiently and reliably.

Active cooling solutions incorporate fans or liquid cooling systems to enhance heat dissipation. Fan-assisted heat sinks have become common in automotive applications where space constraints permit, offering improved cooling efficiency compared to passive designs. However, they introduce additional failure points, noise concerns, and power consumption requirements that must be carefully managed in automotive environments.

The industry currently faces several critical challenges in heat sink design optimization. Miniaturization of electronic components has led to higher power densities, creating thermal hotspots that are difficult to manage with conventional heat sink geometries. The trend toward more compact electronic control units (ECUs) further exacerbates this issue, limiting the physical space available for thermal management solutions.

Material limitations present another significant challenge. While aluminum remains the predominant material due to its cost-effectiveness and reasonable thermal properties, its thermal conductivity (approximately 200-250 W/m·K) falls short of what next-generation automotive electronics require. Copper offers superior thermal conductivity (around 400 W/m·K) but adds considerable weight and cost, making it impractical for many applications.

Manufacturing constraints also impact heat sink effectiveness. Traditional manufacturing methods like extrusion and die-casting limit the complexity of fin structures and channel designs that can be achieved. This restricts the optimization of surface area and airflow patterns, which are critical factors in heat dissipation efficiency.

Emerging technologies such as phase-change materials (PCMs) and vapor chambers are being explored to address these limitations. PCMs can absorb large amounts of heat during phase transition, helping to manage transient thermal loads common in automotive applications. Vapor chambers provide more uniform heat distribution across the base of the heat sink, reducing thermal resistance and hotspots.

The automotive industry's shift toward electric and autonomous vehicles introduces additional thermal management challenges. Power electronics in electric vehicles generate significant heat during charging and discharging cycles, while the computational hardware required for autonomous driving features creates new cooling demands that current heat sink technologies struggle to address efficiently and reliably.

Current Heat Sink Design Methodologies

01 Heat sink geometry optimization

Optimizing the physical geometry of heat sinks can significantly improve thermal performance. This includes designing specialized fin structures, optimizing fin spacing, height, and thickness to maximize surface area while minimizing air flow resistance. Advanced designs incorporate variable fin heights, curved surfaces, and customized shapes that enhance heat dissipation based on specific thermal loads and space constraints.- Heat sink geometry optimization: Optimizing the geometry of heat sinks can significantly improve thermal performance. This includes designing specific fin shapes, spacing, and arrangements to maximize heat dissipation. Advanced designs may incorporate variable fin heights, curved surfaces, or asymmetric patterns to enhance airflow and heat transfer efficiency. Computational fluid dynamics (CFD) analysis is often used to determine optimal geometrical configurations for specific thermal requirements.

- Material selection and composition for heat sinks: The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper, aluminum, and their alloys are commonly used. Composite materials combining metals with ceramics or carbon-based materials can provide enhanced thermal properties while reducing weight. Material treatments and coatings can further improve surface properties for better heat dissipation. The selection process considers thermal conductivity, weight, cost, and manufacturing constraints.

- Advanced cooling techniques integration: Modern heat sink designs incorporate advanced cooling techniques beyond passive dissipation. These include phase-change materials, liquid cooling channels, vapor chambers, and thermoelectric elements. Hybrid cooling solutions combine multiple methods to handle high heat loads in compact spaces. Some designs integrate microchannels or porous media to increase surface area and enhance convective heat transfer. These techniques are particularly valuable in high-performance computing and power electronics applications.

- Manufacturing methods for optimized heat sinks: Advanced manufacturing techniques enable the production of complex heat sink designs that were previously impossible. Additive manufacturing (3D printing) allows for intricate internal structures and optimized geometries. Other methods include die-casting, extrusion, forging, and CNC machining, each offering different advantages in terms of precision, cost, and scalability. The manufacturing process selection impacts the final thermal performance and is often optimized based on production volume and application requirements.

- Thermal interface optimization: The interface between heat sources and heat sinks significantly affects overall thermal performance. Optimizing this interface involves selecting appropriate thermal interface materials (TIMs) such as thermal greases, pads, or phase-change materials. Surface preparation techniques like polishing or micro-texturing can reduce thermal contact resistance. Some designs incorporate direct bonding or soldering to eliminate interface resistance. Pressure application methods and mounting techniques are also critical for maintaining consistent thermal contact over the device lifetime.

02 Material selection and composition

The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper, aluminum alloys, and composite materials are commonly used. Advanced heat sinks may incorporate phase-change materials, metal matrix composites, or thermally enhanced polymers to optimize weight, cost, and thermal performance. Material selection must balance thermal properties with manufacturing constraints, weight requirements, and cost considerations.Expand Specific Solutions03 Surface treatment and coating technologies

Surface treatments and coatings can enhance heat sink performance by improving thermal radiation properties and protecting against corrosion. Techniques include anodizing, black oxide coating, nickel plating, and application of specialized thermal interface materials. These treatments can increase surface emissivity, improve contact with heat sources, and extend the operational lifespan of heat sinks in harsh environments.Expand Specific Solutions04 Integration with active cooling systems

Combining passive heat sinks with active cooling components creates hybrid thermal management solutions. These designs incorporate fans, liquid cooling channels, thermoelectric coolers, or heat pipes to enhance heat transfer. Smart integration allows for dynamic thermal management that responds to changing heat loads, optimizing energy consumption while maintaining effective cooling performance.Expand Specific Solutions05 Computational modeling and simulation techniques

Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) enable precise optimization of heat sink designs before physical prototyping. These simulation techniques allow engineers to predict thermal performance, identify hotspots, optimize airflow patterns, and evaluate design variations efficiently. Machine learning algorithms are increasingly being applied to generate novel heat sink geometries that outperform traditional designs by identifying non-intuitive optimization opportunities.Expand Specific Solutions

Key Players in Automotive Thermal Solution Industry

The automotive heat sink design optimization market is currently in a growth phase, with increasing demand driven by the electrification trend in vehicles. The global market size is expanding rapidly, expected to reach several billion dollars by 2025 as electronic content in vehicles continues to rise. From a technological maturity perspective, the field shows varying levels of advancement among key players. Industry leaders like Robert Bosch, Continental Automotive, and ZF Friedrichshafen have established sophisticated thermal management solutions, while specialized companies such as Diabatix are pioneering AI-driven optimization approaches. Asian manufacturers including BYD, Samsung Electronics, and Mitsubishi Electric are gaining competitive advantage through vertical integration of electronics manufacturing. The competitive landscape is further shaped by semiconductor giants like Intel who bring advanced materials expertise, while traditional tier-1 suppliers focus on system-level thermal management integration.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced liquid cooling heat sink solutions for automotive power electronics, particularly for electric vehicle inverters and control units. Their design incorporates micro-channel cooling technology with optimized flow distribution to maximize heat transfer efficiency. The system features a multi-layer structure with integrated temperature sensors for real-time thermal management. Bosch's heat sinks utilize aluminum-silicon carbide (AlSiC) composite materials that provide excellent thermal conductivity (180-200 W/m·K) while maintaining lower weight compared to traditional copper solutions. Their designs incorporate computational fluid dynamics (CFD) simulation to optimize coolant flow patterns, achieving up to 30% improved thermal performance compared to conventional designs while maintaining pressure drops below critical thresholds for automotive pump systems.

Strengths: Industry-leading thermal efficiency with proven reliability in harsh automotive environments; comprehensive design approach integrating materials science and fluid dynamics; extensive manufacturing capabilities ensuring consistent quality. Weaknesses: Higher production costs compared to simpler cooling solutions; requires integration with vehicle cooling systems which increases complexity; performance advantages diminish in less demanding thermal applications.

Continental Automotive Technologies GmbH

Technical Solution: Continental has pioneered phase-change material (PCM) enhanced heat sink technology for automotive electronics, particularly for power modules in hybrid and electric vehicles. Their solution combines traditional aluminum heat sinks with strategically embedded PCM pockets that absorb thermal energy during peak loads and release it during lower demand periods. This approach effectively dampens thermal cycling, which is critical for extending component lifespan in automotive applications. Continental's designs feature optimized fin geometries with variable spacing and heights based on computational thermal analysis, achieving thermal resistance values as low as 0.2°C/W for high-power applications. The company has also developed specialized surface treatments that increase the effective heat transfer area by up to 40% through micro-texturing processes, while maintaining manufacturability at automotive production volumes.

Strengths: Excellent thermal transient management particularly suited to variable load profiles in automotive applications; proven durability in field conditions; integration with vehicle thermal management systems. Weaknesses: Higher complexity in manufacturing compared to conventional heat sinks; PCM components have limited lifetime under extreme temperature cycling; requires more space than some competing solutions.

Critical Patents and Innovations in Heat Sink Technology

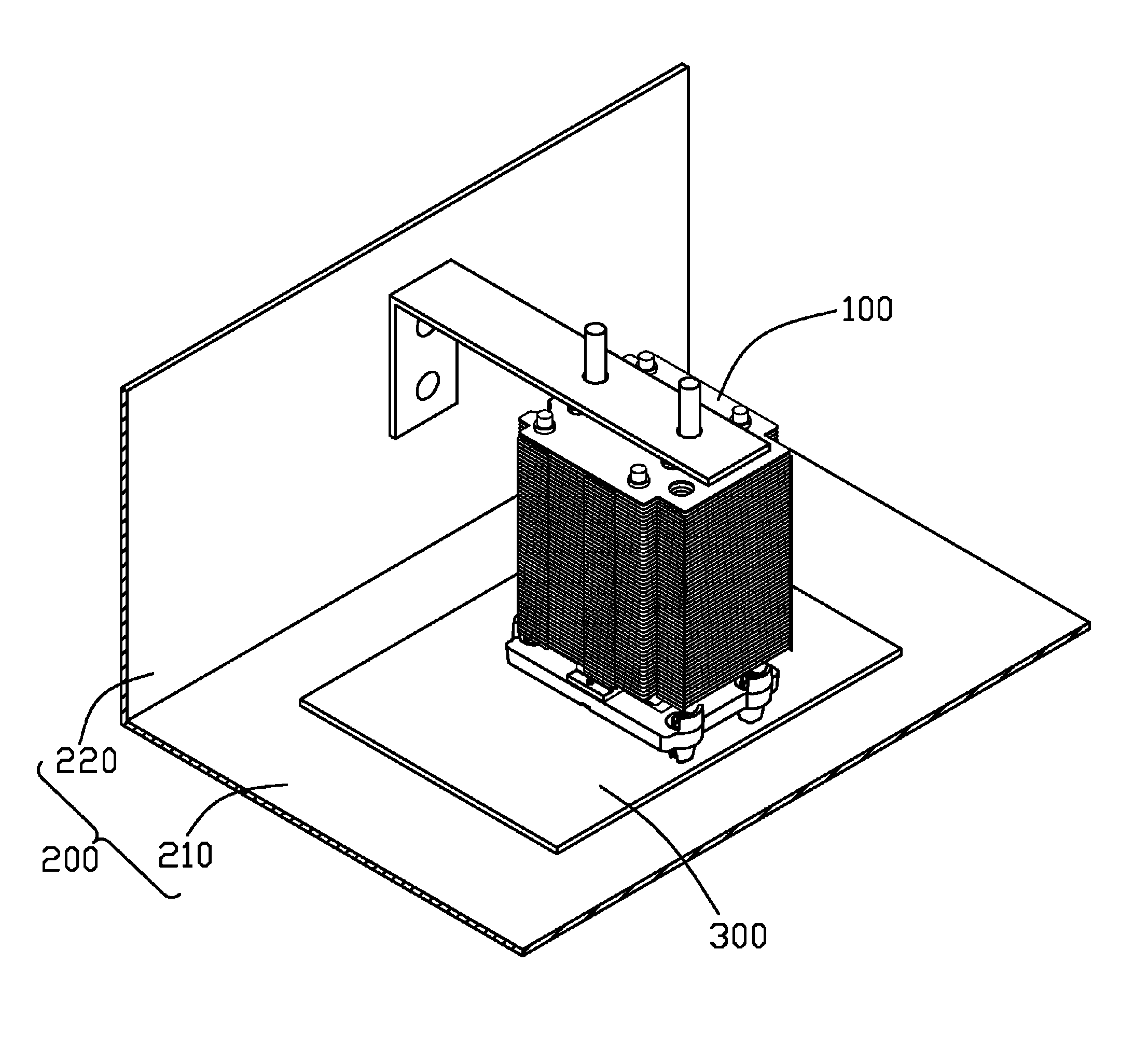

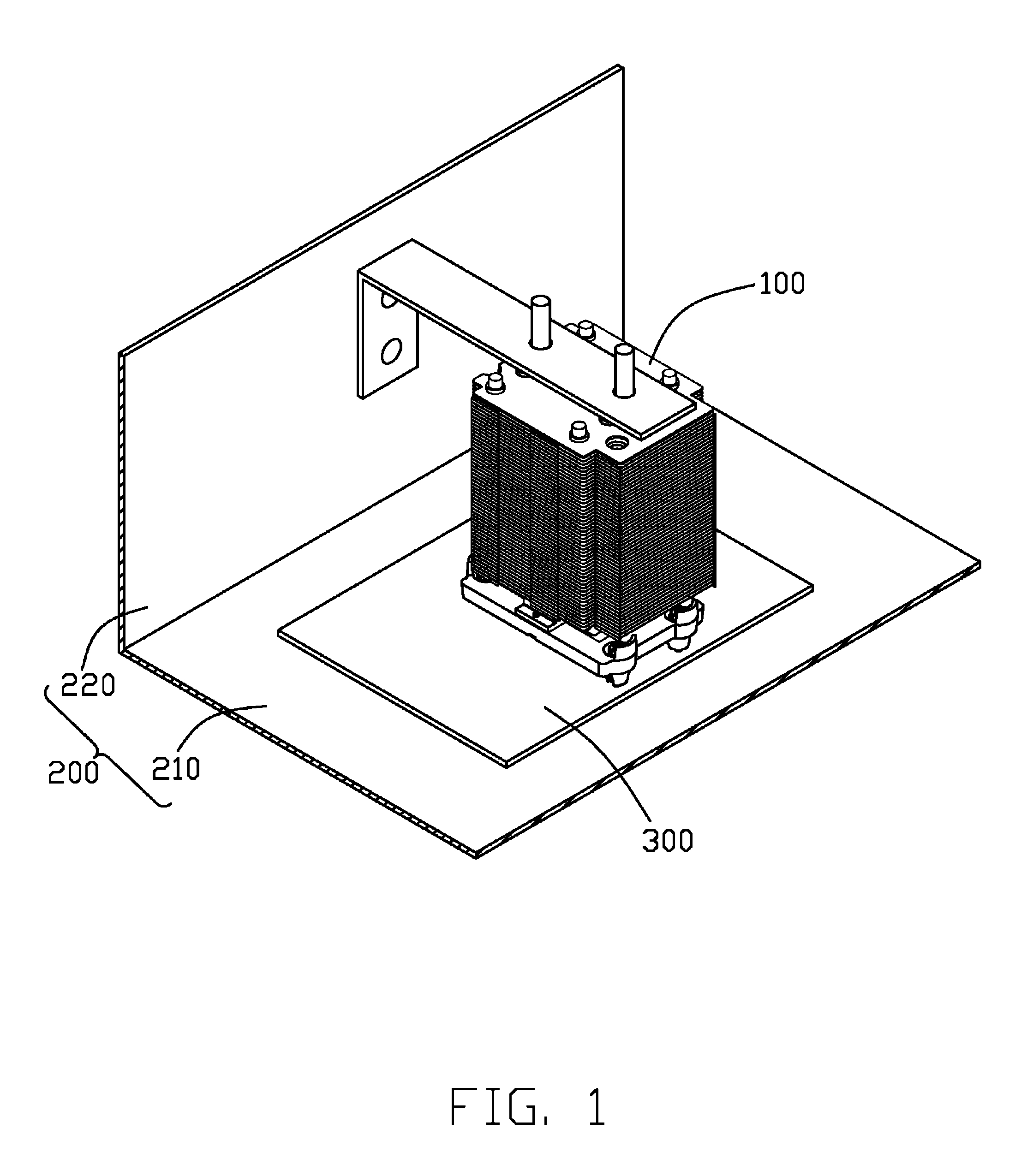

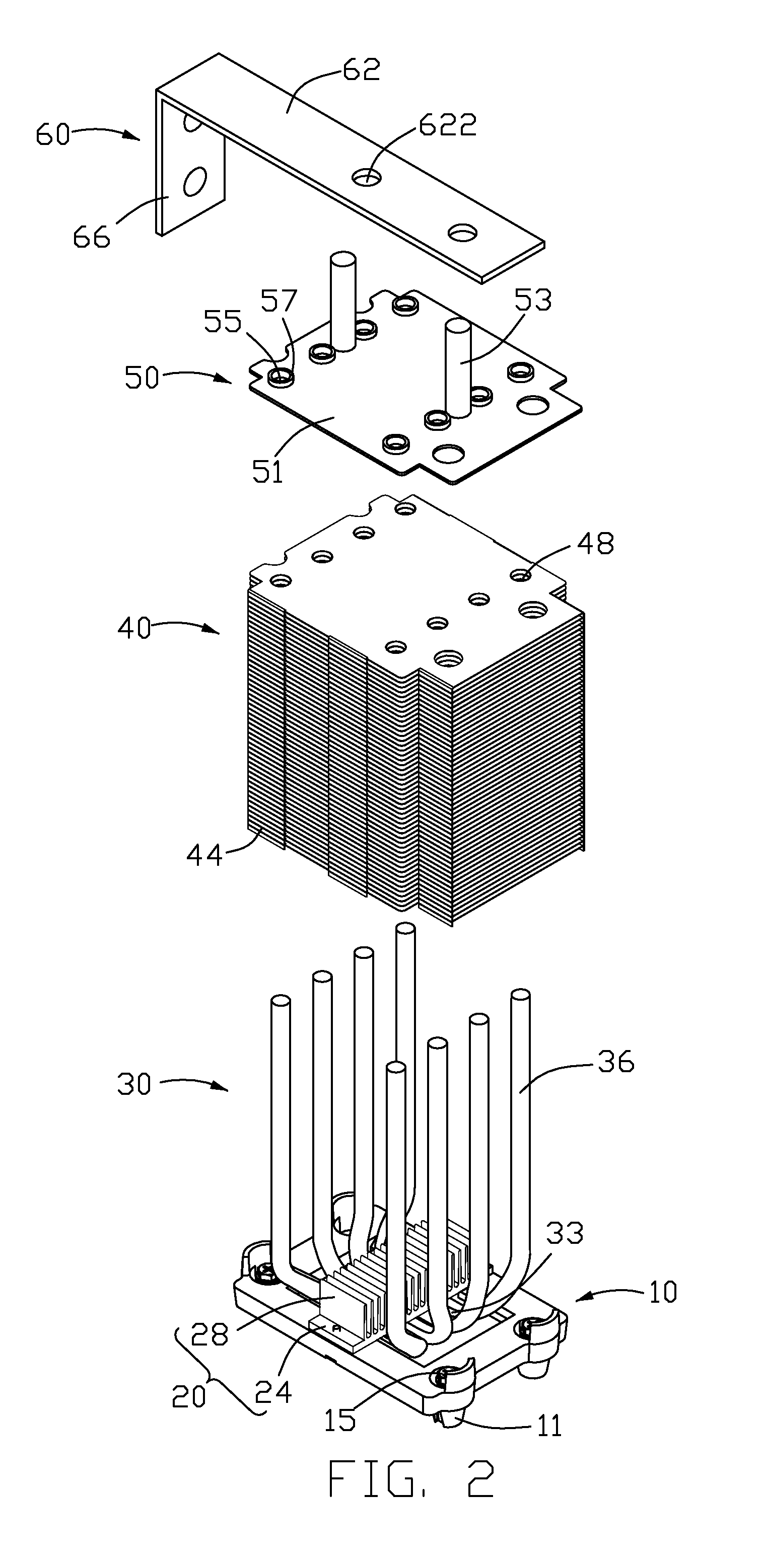

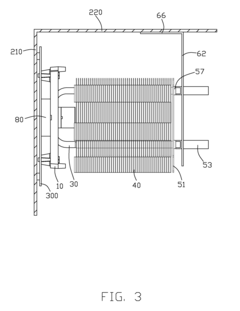

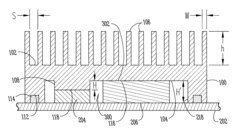

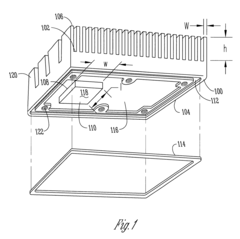

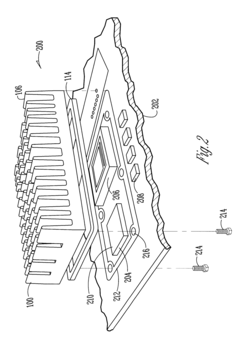

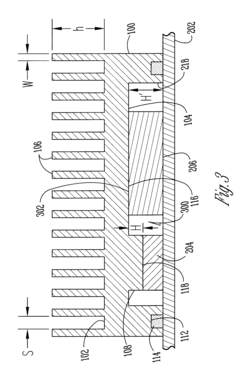

Electronic system with a heat sink assembly

PatentInactiveUS7764500B2

Innovation

- A heat sink assembly is designed with a holding member that connects the second end to the enclosure, distributing the weight and reducing the shearing force by supporting both ends of the assembly within the enclosure.

Integrated heat sink for different size components with EMI suppression features

PatentInactiveUS6577504B1

Innovation

- An integrated heat sink with a first face featuring high-aspect-ratio cooling fins and a second face with a pedestal for thermal coupling to components of different heights, along with a groove and gasket for EMI shielding, forming a Faraday cage to suppress electromagnetic interference.

Material Science Advancements for Thermal Management

Recent advancements in material science have revolutionized thermal management solutions for automotive electronic systems. Traditional aluminum and copper heat sinks are increasingly being supplemented or replaced by novel materials with superior thermal properties. Graphene, with its exceptional thermal conductivity of up to 5,000 W/mK, represents a significant leap forward compared to copper's 400 W/mK. Research indicates that graphene-enhanced composites can improve thermal dissipation by 25-40% in automotive power electronics applications.

Carbon-based materials including carbon nanotubes (CNTs) and diamond-like carbon coatings have emerged as promising alternatives. CNTs exhibit directional thermal conductivity exceeding 3,000 W/mK, while maintaining lightweight properties critical for automotive applications where weight reduction directly impacts vehicle efficiency. These materials are being integrated into hybrid solutions that combine traditional metals with advanced carbon structures.

Phase change materials (PCMs) represent another breakthrough in thermal management. These materials absorb and release thermal energy during phase transitions, effectively acting as thermal buffers during peak load conditions. Automotive-grade PCMs with transition temperatures between 70-120°C are particularly valuable for managing thermal spikes in power electronics, extending component lifespan by maintaining more consistent operating temperatures.

Ceramic-metal composites (cermets) and metal matrix composites (MMCs) offer customizable thermal properties by combining the high thermal conductivity of metals with the temperature stability of ceramics. Aluminum silicon carbide (AlSiC), with thermal conductivity of 180-200 W/mK and a coefficient of thermal expansion closely matching semiconductor materials, has become particularly valuable for power electronics packaging in electric vehicle applications.

3D-printed lattice structures using these advanced materials represent the cutting edge of heat sink design. These structures enable previously impossible geometries that maximize surface area while optimizing fluid dynamics. Research demonstrates that topology-optimized lattice structures can improve thermal performance by up to 30% compared to traditional designs while using 40% less material.

Nano-engineered surface treatments have also emerged as a complementary approach to material selection. Hydrophobic and hydrophilic coatings can enhance condensation heat transfer in two-phase cooling systems, while nano-textured surfaces increase effective surface area without changing the macro dimensions of heat sink components. These surface modifications have demonstrated 15-20% improvements in heat transfer coefficients in automotive cooling applications.

Carbon-based materials including carbon nanotubes (CNTs) and diamond-like carbon coatings have emerged as promising alternatives. CNTs exhibit directional thermal conductivity exceeding 3,000 W/mK, while maintaining lightweight properties critical for automotive applications where weight reduction directly impacts vehicle efficiency. These materials are being integrated into hybrid solutions that combine traditional metals with advanced carbon structures.

Phase change materials (PCMs) represent another breakthrough in thermal management. These materials absorb and release thermal energy during phase transitions, effectively acting as thermal buffers during peak load conditions. Automotive-grade PCMs with transition temperatures between 70-120°C are particularly valuable for managing thermal spikes in power electronics, extending component lifespan by maintaining more consistent operating temperatures.

Ceramic-metal composites (cermets) and metal matrix composites (MMCs) offer customizable thermal properties by combining the high thermal conductivity of metals with the temperature stability of ceramics. Aluminum silicon carbide (AlSiC), with thermal conductivity of 180-200 W/mK and a coefficient of thermal expansion closely matching semiconductor materials, has become particularly valuable for power electronics packaging in electric vehicle applications.

3D-printed lattice structures using these advanced materials represent the cutting edge of heat sink design. These structures enable previously impossible geometries that maximize surface area while optimizing fluid dynamics. Research demonstrates that topology-optimized lattice structures can improve thermal performance by up to 30% compared to traditional designs while using 40% less material.

Nano-engineered surface treatments have also emerged as a complementary approach to material selection. Hydrophobic and hydrophilic coatings can enhance condensation heat transfer in two-phase cooling systems, while nano-textured surfaces increase effective surface area without changing the macro dimensions of heat sink components. These surface modifications have demonstrated 15-20% improvements in heat transfer coefficients in automotive cooling applications.

Environmental Impact and Sustainability Considerations

The environmental impact of heat sink design in automotive electronic systems has become increasingly significant as the industry faces stricter sustainability regulations and growing consumer awareness. Traditional heat sink manufacturing processes often involve energy-intensive methods and materials with considerable carbon footprints. Aluminum, the most commonly used heat sink material, requires substantial energy during extraction and processing, generating approximately 10-12 kg of CO2 per kg of aluminum produced. Copper, while offering superior thermal conductivity, has an even higher environmental impact during production.

Material selection represents a critical sustainability consideration in heat sink design optimization. Recent innovations have focused on recycled aluminum and copper alloys, which can reduce the carbon footprint by 60-80% compared to virgin materials. Additionally, composite materials incorporating natural thermal conductors like graphite or carbon-based materials offer promising alternatives with lower environmental impacts while maintaining adequate thermal performance.

Manufacturing processes also significantly influence the sustainability profile of heat sink solutions. Traditional subtractive manufacturing methods generate substantial material waste, with some processes wasting up to 30% of raw materials. Advanced manufacturing techniques such as additive manufacturing can reduce material waste to less than 5% while enabling more complex geometries that optimize thermal performance with less material. Precision die casting has also evolved to minimize material usage while maintaining structural integrity.

End-of-life considerations represent another crucial aspect of environmental impact assessment. Designing heat sinks for disassembly and material recovery can significantly improve their lifecycle sustainability. Modular designs that allow for component replacement rather than complete system disposal can extend product lifespans by 40-60%. Furthermore, implementing design principles that facilitate material separation at end-of-life can increase recycling rates from the current industry average of 30% to potentially over 85%.

Energy efficiency during operation constitutes perhaps the most significant environmental consideration. Optimized heat sink designs that improve thermal management can reduce the overall energy consumption of automotive electronic systems by 5-15%. This operational efficiency translates to reduced vehicle fuel consumption or extended range in electric vehicles, multiplying the environmental benefits throughout the product lifecycle. Passive cooling solutions that minimize or eliminate the need for active cooling components further reduce energy requirements and associated emissions.

Water usage in manufacturing processes presents another environmental challenge. Traditional heat sink production can consume 20-40 liters of water per unit. Implementing closed-loop water systems and dry machining techniques can reduce water consumption by up to 90%, significantly decreasing the water footprint of heat sink production while also preventing potential water pollution from manufacturing byproducts.

Material selection represents a critical sustainability consideration in heat sink design optimization. Recent innovations have focused on recycled aluminum and copper alloys, which can reduce the carbon footprint by 60-80% compared to virgin materials. Additionally, composite materials incorporating natural thermal conductors like graphite or carbon-based materials offer promising alternatives with lower environmental impacts while maintaining adequate thermal performance.

Manufacturing processes also significantly influence the sustainability profile of heat sink solutions. Traditional subtractive manufacturing methods generate substantial material waste, with some processes wasting up to 30% of raw materials. Advanced manufacturing techniques such as additive manufacturing can reduce material waste to less than 5% while enabling more complex geometries that optimize thermal performance with less material. Precision die casting has also evolved to minimize material usage while maintaining structural integrity.

End-of-life considerations represent another crucial aspect of environmental impact assessment. Designing heat sinks for disassembly and material recovery can significantly improve their lifecycle sustainability. Modular designs that allow for component replacement rather than complete system disposal can extend product lifespans by 40-60%. Furthermore, implementing design principles that facilitate material separation at end-of-life can increase recycling rates from the current industry average of 30% to potentially over 85%.

Energy efficiency during operation constitutes perhaps the most significant environmental consideration. Optimized heat sink designs that improve thermal management can reduce the overall energy consumption of automotive electronic systems by 5-15%. This operational efficiency translates to reduced vehicle fuel consumption or extended range in electric vehicles, multiplying the environmental benefits throughout the product lifecycle. Passive cooling solutions that minimize or eliminate the need for active cooling components further reduce energy requirements and associated emissions.

Water usage in manufacturing processes presents another environmental challenge. Traditional heat sink production can consume 20-40 liters of water per unit. Implementing closed-loop water systems and dry machining techniques can reduce water consumption by up to 90%, significantly decreasing the water footprint of heat sink production while also preventing potential water pollution from manufacturing byproducts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!