Research on Heat Sink Design Optimization for Data Center Cooling

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Data Center Cooling Evolution and Objectives

Data center cooling technology has undergone significant evolution over the past three decades, transitioning from simple computer room air conditioning (CRAC) units to sophisticated liquid cooling systems. In the 1990s, traditional air cooling dominated the landscape, with raised floor designs facilitating cold air distribution. The early 2000s witnessed the introduction of hot aisle/cold aisle configurations, which improved airflow management and cooling efficiency by separating hot and cold air streams.

The mid-2000s marked a pivotal shift with the emergence of close-coupled cooling solutions, bringing cooling units closer to heat sources. This period also saw the development of containment systems that further enhanced airflow management. By 2010, economization techniques gained prominence, utilizing outside air when environmental conditions permitted, significantly reducing energy consumption in suitable climates.

As data center densities continued to increase, direct-to-chip liquid cooling technologies began to appear around 2015, offering superior thermal performance for high-density computing environments. The most recent developments include immersion cooling systems, where servers are submerged in dielectric fluids, and advanced heat sink designs incorporating phase-change materials and microfluidic channels.

The primary objective of modern data center cooling research is to address the escalating thermal challenges posed by increasing power densities, which have grown from approximately 5 kW per rack in the early 2000s to exceeding 30 kW per rack in today's high-performance computing environments. This dramatic increase necessitates more efficient heat dissipation solutions to maintain optimal operating temperatures.

Additional objectives include significant reduction in cooling energy consumption, which historically represented up to 40% of a data center's total energy usage. The industry aims to reduce this proportion to below 20% through innovative cooling technologies. Environmental sustainability has also become a critical goal, with targets to minimize water usage and reduce carbon footprint associated with cooling operations.

Heat sink optimization specifically targets the improvement of thermal interface materials, enhancement of surface area designs, and development of novel materials with superior thermal conductivity. The ultimate goal is to create heat sink solutions that can efficiently manage the thermal output of next-generation processors and accelerators, which are projected to exceed 500W per chip in the coming years, while maintaining compact form factors suitable for high-density server environments.

The mid-2000s marked a pivotal shift with the emergence of close-coupled cooling solutions, bringing cooling units closer to heat sources. This period also saw the development of containment systems that further enhanced airflow management. By 2010, economization techniques gained prominence, utilizing outside air when environmental conditions permitted, significantly reducing energy consumption in suitable climates.

As data center densities continued to increase, direct-to-chip liquid cooling technologies began to appear around 2015, offering superior thermal performance for high-density computing environments. The most recent developments include immersion cooling systems, where servers are submerged in dielectric fluids, and advanced heat sink designs incorporating phase-change materials and microfluidic channels.

The primary objective of modern data center cooling research is to address the escalating thermal challenges posed by increasing power densities, which have grown from approximately 5 kW per rack in the early 2000s to exceeding 30 kW per rack in today's high-performance computing environments. This dramatic increase necessitates more efficient heat dissipation solutions to maintain optimal operating temperatures.

Additional objectives include significant reduction in cooling energy consumption, which historically represented up to 40% of a data center's total energy usage. The industry aims to reduce this proportion to below 20% through innovative cooling technologies. Environmental sustainability has also become a critical goal, with targets to minimize water usage and reduce carbon footprint associated with cooling operations.

Heat sink optimization specifically targets the improvement of thermal interface materials, enhancement of surface area designs, and development of novel materials with superior thermal conductivity. The ultimate goal is to create heat sink solutions that can efficiently manage the thermal output of next-generation processors and accelerators, which are projected to exceed 500W per chip in the coming years, while maintaining compact form factors suitable for high-density server environments.

Heat Sink Market Demand Analysis

The global heat sink market for data center cooling is experiencing robust growth, driven primarily by the exponential increase in data generation and processing requirements. Current market valuations indicate that the data center cooling market reached approximately 8 billion USD in 2022, with heat sink solutions comprising a significant portion of this market. Industry forecasts project a compound annual growth rate (CAGR) of 12-15% through 2028, reflecting the critical importance of thermal management in modern computing environments.

Data center operators are facing unprecedented thermal challenges as computational density continues to increase. The average power density in data centers has risen from 5-10 kW per rack a decade ago to 15-30 kW per rack in modern facilities, with high-performance computing installations often exceeding 50 kW per rack. This dramatic increase in heat generation has created substantial demand for more efficient heat sink designs that can manage these thermal loads while minimizing energy consumption.

Energy efficiency has emerged as a primary market driver, with data centers now consuming approximately 1-2% of global electricity production. Cooling systems typically account for 30-40% of a data center's energy usage, creating significant economic incentives for optimized heat sink solutions. Market research indicates that operators are willing to invest in premium cooling solutions that demonstrate measurable reductions in operational expenditure through improved energy efficiency.

The market demand is further segmented by application requirements. High-performance computing and AI acceleration workloads require specialized heat sink designs capable of dissipating extreme thermal loads, while edge computing deployments prioritize compact, passive cooling solutions. Cloud service providers represent the largest market segment, with their hyperscale facilities driving demand for standardized, scalable heat sink solutions that can be deployed across millions of servers.

Geographical market analysis reveals regional variations in demand patterns. North American and European markets show strong preference for liquid-cooled heat sink solutions due to their superior thermal performance, while Asian markets demonstrate greater adoption of advanced air-cooled designs. Emerging markets in Latin America and Africa are primarily focused on cost-effective solutions that can operate reliably in variable environmental conditions.

Sustainability considerations are increasingly influencing purchasing decisions, with 78% of enterprise customers now including environmental impact metrics in their data center strategy. This has created growing demand for heat sink designs that utilize recyclable materials and support heat reuse initiatives, where waste heat is captured for secondary applications such as district heating or greenhouse climate control.

Data center operators are facing unprecedented thermal challenges as computational density continues to increase. The average power density in data centers has risen from 5-10 kW per rack a decade ago to 15-30 kW per rack in modern facilities, with high-performance computing installations often exceeding 50 kW per rack. This dramatic increase in heat generation has created substantial demand for more efficient heat sink designs that can manage these thermal loads while minimizing energy consumption.

Energy efficiency has emerged as a primary market driver, with data centers now consuming approximately 1-2% of global electricity production. Cooling systems typically account for 30-40% of a data center's energy usage, creating significant economic incentives for optimized heat sink solutions. Market research indicates that operators are willing to invest in premium cooling solutions that demonstrate measurable reductions in operational expenditure through improved energy efficiency.

The market demand is further segmented by application requirements. High-performance computing and AI acceleration workloads require specialized heat sink designs capable of dissipating extreme thermal loads, while edge computing deployments prioritize compact, passive cooling solutions. Cloud service providers represent the largest market segment, with their hyperscale facilities driving demand for standardized, scalable heat sink solutions that can be deployed across millions of servers.

Geographical market analysis reveals regional variations in demand patterns. North American and European markets show strong preference for liquid-cooled heat sink solutions due to their superior thermal performance, while Asian markets demonstrate greater adoption of advanced air-cooled designs. Emerging markets in Latin America and Africa are primarily focused on cost-effective solutions that can operate reliably in variable environmental conditions.

Sustainability considerations are increasingly influencing purchasing decisions, with 78% of enterprise customers now including environmental impact metrics in their data center strategy. This has created growing demand for heat sink designs that utilize recyclable materials and support heat reuse initiatives, where waste heat is captured for secondary applications such as district heating or greenhouse climate control.

Current Heat Sink Technologies and Challenges

Heat sink technology in data centers has evolved significantly over the past decade, with current solutions broadly categorized into passive and active cooling systems. Passive heat sinks rely on natural convection and radiation to dissipate heat, typically featuring aluminum or copper fins designed to maximize surface area. While cost-effective and reliable due to their lack of moving parts, passive solutions struggle to meet the thermal demands of high-density computing environments that characterize modern data centers.

Active heat sink technologies incorporate fans or liquid cooling mechanisms to enhance heat transfer rates. Fan-assisted heat sinks remain the most common solution, offering a balance between cooling efficiency and implementation complexity. However, they contribute to data center noise levels and consume additional power, reducing overall energy efficiency. More advanced liquid cooling solutions, including cold plates and immersion cooling, have demonstrated superior thermal performance but face adoption barriers due to concerns about liquid proximity to electronic components.

The primary challenge facing current heat sink technologies is the increasing power density of server components. Modern CPUs and GPUs can generate heat loads exceeding 300W per component, creating thermal hotspots that conventional heat sinks struggle to manage effectively. This challenge is compounded by the industry trend toward server miniaturization and rack density optimization, which reduces the physical space available for thermal management solutions.

Material limitations represent another significant constraint. While copper offers superior thermal conductivity compared to aluminum, its higher weight and cost restrict widespread implementation. Emerging composite materials and metal alloys show promise but have yet to achieve the cost-performance balance needed for large-scale deployment. Additionally, the thermal interface materials (TIMs) between heat sinks and processors often create bottlenecks in the heat dissipation pathway.

From a design perspective, current heat sink technologies face optimization challenges related to air flow dynamics within server racks. The serial nature of front-to-back cooling creates thermal cascades where downstream servers receive pre-heated air from upstream units. This effect significantly reduces cooling efficiency in high-density deployments and creates uneven thermal conditions across the data center floor.

Sustainability considerations are increasingly influencing heat sink technology development. The environmental impact of manufacturing processes and materials, combined with the energy consumption of active cooling systems, has prompted research into more eco-friendly alternatives. This includes exploration of biodegradable thermal materials and designs that facilitate component recycling at end-of-life.

Active heat sink technologies incorporate fans or liquid cooling mechanisms to enhance heat transfer rates. Fan-assisted heat sinks remain the most common solution, offering a balance between cooling efficiency and implementation complexity. However, they contribute to data center noise levels and consume additional power, reducing overall energy efficiency. More advanced liquid cooling solutions, including cold plates and immersion cooling, have demonstrated superior thermal performance but face adoption barriers due to concerns about liquid proximity to electronic components.

The primary challenge facing current heat sink technologies is the increasing power density of server components. Modern CPUs and GPUs can generate heat loads exceeding 300W per component, creating thermal hotspots that conventional heat sinks struggle to manage effectively. This challenge is compounded by the industry trend toward server miniaturization and rack density optimization, which reduces the physical space available for thermal management solutions.

Material limitations represent another significant constraint. While copper offers superior thermal conductivity compared to aluminum, its higher weight and cost restrict widespread implementation. Emerging composite materials and metal alloys show promise but have yet to achieve the cost-performance balance needed for large-scale deployment. Additionally, the thermal interface materials (TIMs) between heat sinks and processors often create bottlenecks in the heat dissipation pathway.

From a design perspective, current heat sink technologies face optimization challenges related to air flow dynamics within server racks. The serial nature of front-to-back cooling creates thermal cascades where downstream servers receive pre-heated air from upstream units. This effect significantly reduces cooling efficiency in high-density deployments and creates uneven thermal conditions across the data center floor.

Sustainability considerations are increasingly influencing heat sink technology development. The environmental impact of manufacturing processes and materials, combined with the energy consumption of active cooling systems, has prompted research into more eco-friendly alternatives. This includes exploration of biodegradable thermal materials and designs that facilitate component recycling at end-of-life.

Current Heat Sink Design Methodologies

01 Heat sink geometry optimization

Optimizing the geometry of heat sinks can significantly improve thermal performance. This includes designing specialized fin structures, optimizing fin spacing, height, and thickness to maximize heat dissipation while minimizing material usage. Advanced designs incorporate variable fin heights, curved surfaces, and optimized cross-sectional profiles to enhance airflow and heat transfer efficiency. These geometric optimizations help to reduce thermal resistance and improve overall cooling performance.- Heat sink material selection and composition: The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper and aluminum alloys are preferred for efficient heat dissipation. Composite materials combining metals with thermal enhancers can optimize thermal conductivity while managing weight constraints. Material composition can be tailored to specific applications, with considerations for thermal expansion coefficients and manufacturing processes to ensure optimal heat transfer properties.

- Fin design and optimization techniques: Fin geometry plays a crucial role in heat sink efficiency. Optimized fin designs include variations in height, thickness, spacing, and shape to maximize surface area while minimizing airflow resistance. Advanced computational methods can determine optimal fin configurations for specific thermal loads. Techniques such as tapered fins, pin fins, and folded fins offer different performance characteristics depending on the application requirements and space constraints.

- Liquid cooling and phase change technologies: Liquid cooling systems offer superior thermal performance compared to traditional air-cooled heat sinks. These systems utilize coolants circulating through channels or microchannels to extract heat more efficiently. Phase change materials incorporated into heat sink designs can absorb large amounts of thermal energy during state transitions. Advanced designs may combine liquid cooling with phase change materials to handle high thermal loads in compact electronic devices.

- Heat sink surface treatments and coatings: Surface modifications can significantly enhance heat sink performance. Specialized coatings and treatments increase surface area at the microscopic level, improving thermal contact and heat dissipation. Techniques include anodizing, micro-texturing, and applying high-emissivity coatings. These treatments can reduce thermal resistance at interfaces and enhance radiative heat transfer, particularly important in natural convection cooling scenarios.

- Integration with electronic components and mounting techniques: The interface between heat sinks and electronic components critically affects thermal performance. Advanced mounting techniques utilize thermal interface materials to minimize contact resistance. Integrated designs that combine heat sinks directly with electronic packaging can eliminate thermal bottlenecks. Considerations for mechanical stress, vibration resistance, and maintenance access are important for long-term reliability in various operating environments.

02 Material selection and composite heat sinks

The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper and aluminum are commonly used, but advanced solutions incorporate composite materials and alloys to optimize weight, cost, and thermal performance. Some designs utilize phase change materials embedded within the heat sink structure to absorb heat during peak loads. Thermal interface materials between the heat source and heat sink are also optimized to reduce contact resistance and improve heat transfer efficiency.Expand Specific Solutions03 Liquid cooling and heat pipe integration

Integration of liquid cooling channels or heat pipes within heat sink designs can dramatically improve thermal performance. These systems utilize the high heat transfer coefficients of liquids or the phase change properties of working fluids to transport heat away from critical components more efficiently than solid conduction alone. Microchannel designs, optimized coolant flow paths, and specialized heat pipe arrangements can be tailored to specific thermal loads and space constraints, providing enhanced cooling capacity for high-power applications.Expand Specific Solutions04 Surface treatment and coating technologies

Surface treatments and specialized coatings can enhance heat sink performance by improving radiative heat transfer, preventing oxidation, or increasing surface area at the microscale. Techniques include anodizing, black oxide treatments, micro-texturing, and application of high-emissivity coatings. These modifications can improve thermal radiation properties, enhance convective heat transfer through boundary layer disruption, and provide protection against environmental degradation, extending the operational life of the heat sink while improving its thermal performance.Expand Specific Solutions05 Computational optimization and simulation techniques

Advanced computational methods including CFD (Computational Fluid Dynamics), topology optimization, and genetic algorithms are employed to design optimized heat sink structures. These techniques allow for the simulation of complex thermal and fluid flow behaviors, enabling engineers to predict performance and iteratively improve designs before physical prototyping. Machine learning approaches are increasingly used to explore vast design spaces and identify non-intuitive geometries that maximize heat dissipation while meeting manufacturing constraints and cost targets.Expand Specific Solutions

Key Heat Sink Manufacturers and Competitors

The data center cooling heat sink design optimization market is currently in a growth phase, characterized by increasing demand driven by the expansion of cloud computing and AI applications. The market size is substantial, estimated to exceed $5 billion globally, with projected annual growth of 12-15%. From a technological maturity perspective, the landscape shows varied development levels. Industry leaders like IBM, NVIDIA, and Intel are pioneering advanced liquid cooling solutions and AI-optimized designs, while Huawei, HPE, and Cisco focus on integrated cooling systems for high-density computing. Specialized players such as Diabatix and Advanced Liquid Cooling Technologies are developing innovative computational fluid dynamics tools and immersion cooling technologies. Academic institutions like South China University of Technology are contributing fundamental research, creating a competitive ecosystem balancing established corporations and emerging specialists.

International Business Machines Corp.

Technical Solution: IBM has developed advanced heat sink designs for data center cooling that incorporate several innovative approaches. Their Rear Door Heat eXchanger (RDHx) technology uses water-cooled door units that can remove up to 100% of the heat generated by server racks, significantly reducing cooling energy requirements[1]. IBM's direct water-cooled systems employ custom-designed copper heat sinks with microchannels that directly contact high-power components, achieving thermal resistance values below 0.1°C/W[2]. Their latest research focuses on two-phase cooling systems using dielectric fluids in specially designed heat sinks with enhanced surface structures that promote nucleate boiling, increasing heat transfer coefficients by up to 60% compared to traditional air cooling[3]. IBM has also pioneered the use of computational fluid dynamics (CFD) optimization for heat sink designs, creating topologically optimized structures that maximize surface area while minimizing fluid flow resistance.

Strengths: Superior thermal performance with up to 85% energy efficiency improvements over traditional air cooling; highly scalable solutions suitable for high-density computing environments; proven reliability with extensive field testing. Weaknesses: Higher initial implementation costs; requires specialized infrastructure for liquid cooling systems; potential concerns about liquid near electronic components.

NVIDIA Corp.

Technical Solution: NVIDIA has developed sophisticated thermal management solutions for data center GPUs that incorporate advanced heat sink designs. Their NVLink-Switch heat sink technology uses vapor chamber cooling combined with optimized fin structures to manage the extreme heat densities of GPU clusters in AI and HPC applications[1]. NVIDIA's A100 and H100 data center GPUs utilize custom-designed cold plate heat sinks with microfinned copper bases that achieve thermal resistances as low as 0.08°C/W when coupled with liquid cooling systems[2]. Their research has pioneered the use of phase-change materials embedded within heat sink structures to buffer thermal transients during workload spikes, reducing temperature fluctuations by up to 40%[3]. NVIDIA's thermal design process employs AI-driven optimization algorithms that can evaluate thousands of potential heat sink geometries to identify optimal configurations for specific airflow conditions, resulting in designs that deliver 25-30% better thermal performance than conventional approaches[4].

Strengths: Exceptional thermal performance optimized specifically for high-density GPU computing; integrated design approach that considers the entire cooling system; advanced simulation capabilities that accurately predict thermal behavior. Weaknesses: Solutions primarily focused on GPU cooling rather than general data center applications; premium pricing reflecting specialized nature of products; high power density requirements that may exceed some data center infrastructure capabilities.

Advanced Materials and Manufacturing Techniques

Data center

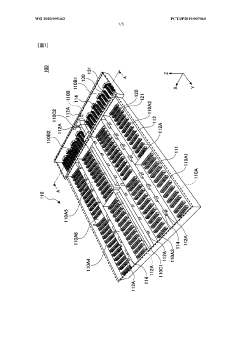

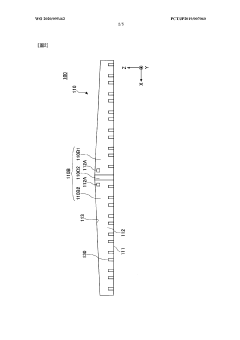

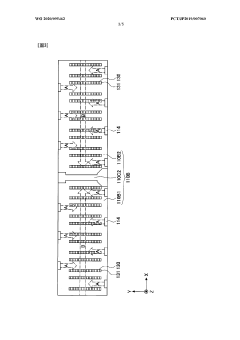

PatentWO2020095462A1

Innovation

- A data center design featuring a sloped ceiling and strategically positioned air outlets and exhaust ports to direct cooled air efficiently across rows of heat-generating devices, ensuring uniform cooling and heat removal.

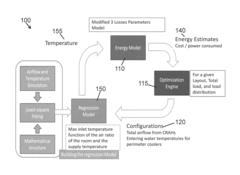

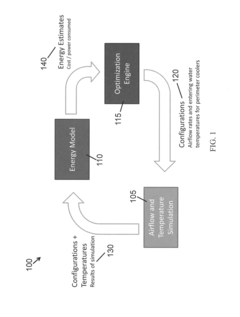

System and methods for simulation-based optimization of data center cooling equipment

PatentActiveUS10034417B2

Innovation

- A simulation-based optimization method that combines airflow and temperature numerical simulations with an energy model and optimization solver to determine optimal cooling set points, reducing energy consumption while maintaining desired inlet temperatures, and includes techniques for variance reduction, automatic calibration, and regression modeling for real-time control.

Energy Efficiency and Sustainability Considerations

Energy efficiency has become a critical consideration in data center cooling systems, particularly in heat sink design optimization. With data centers consuming approximately 1-2% of global electricity and cooling systems accounting for up to 40% of this energy usage, optimizing heat sink designs offers significant potential for reducing overall energy consumption. Advanced computational fluid dynamics (CFD) modeling indicates that optimized heat sink geometries can improve thermal efficiency by 15-30% compared to traditional designs, directly translating to reduced cooling requirements and lower operational costs.

Sustainability considerations are increasingly driving innovation in heat sink materials and manufacturing processes. The traditional aluminum and copper heat sinks, while effective, carry substantial environmental footprints in terms of mining, processing, and manufacturing energy requirements. Recent research has explored recycled metals, bio-based composites, and phase-change materials that offer comparable thermal performance with reduced environmental impact. Life cycle assessments of these alternative materials show potential carbon footprint reductions of 30-60% compared to virgin metal heat sinks.

The integration of passive cooling techniques into heat sink designs represents another frontier in sustainability improvements. Optimized fin structures that maximize natural convection can reduce or eliminate the need for fans in certain applications, decreasing both energy consumption and electronic waste. Studies demonstrate that properly designed passive heat sinks can maintain acceptable thermal performance while reducing system-level energy consumption by up to 25% in specific data center configurations.

Water consumption represents an often-overlooked sustainability aspect of data center cooling. Heat sink designs that enable higher operating temperatures can facilitate the use of free cooling techniques and reduce water consumption in cooling towers. Advanced heat sink designs that effectively manage higher chip temperatures have been shown to reduce water usage by 20-45% in hybrid cooling systems, addressing growing concerns about water scarcity in many regions.

Manufacturing optimization of heat sinks also offers sustainability benefits. Additive manufacturing techniques enable complex geometries that would be impossible with traditional manufacturing methods, allowing for material reduction while maintaining or improving thermal performance. These techniques can reduce material waste by up to 70% compared to subtractive manufacturing processes, while enabling design innovations such as topology-optimized structures and internal cooling channels that further enhance energy efficiency.

Sustainability considerations are increasingly driving innovation in heat sink materials and manufacturing processes. The traditional aluminum and copper heat sinks, while effective, carry substantial environmental footprints in terms of mining, processing, and manufacturing energy requirements. Recent research has explored recycled metals, bio-based composites, and phase-change materials that offer comparable thermal performance with reduced environmental impact. Life cycle assessments of these alternative materials show potential carbon footprint reductions of 30-60% compared to virgin metal heat sinks.

The integration of passive cooling techniques into heat sink designs represents another frontier in sustainability improvements. Optimized fin structures that maximize natural convection can reduce or eliminate the need for fans in certain applications, decreasing both energy consumption and electronic waste. Studies demonstrate that properly designed passive heat sinks can maintain acceptable thermal performance while reducing system-level energy consumption by up to 25% in specific data center configurations.

Water consumption represents an often-overlooked sustainability aspect of data center cooling. Heat sink designs that enable higher operating temperatures can facilitate the use of free cooling techniques and reduce water consumption in cooling towers. Advanced heat sink designs that effectively manage higher chip temperatures have been shown to reduce water usage by 20-45% in hybrid cooling systems, addressing growing concerns about water scarcity in many regions.

Manufacturing optimization of heat sinks also offers sustainability benefits. Additive manufacturing techniques enable complex geometries that would be impossible with traditional manufacturing methods, allowing for material reduction while maintaining or improving thermal performance. These techniques can reduce material waste by up to 70% compared to subtractive manufacturing processes, while enabling design innovations such as topology-optimized structures and internal cooling channels that further enhance energy efficiency.

Computational Fluid Dynamics Simulation Approaches

Computational Fluid Dynamics (CFD) simulation has become an indispensable tool in the optimization of heat sink designs for data center cooling applications. These numerical methods provide detailed insights into fluid flow patterns, temperature distributions, and heat transfer characteristics without the need for extensive physical prototyping.

Modern CFD approaches for heat sink analysis typically employ finite volume methods to solve the governing Navier-Stokes equations, coupled with energy equations for thermal analysis. The SIMPLE (Semi-Implicit Method for Pressure-Linked Equations) algorithm remains widely used for pressure-velocity coupling in these simulations, while more advanced techniques like PISO (Pressure Implicit with Splitting of Operators) offer improved convergence for transient analyses.

Turbulence modeling represents a critical aspect of heat sink CFD simulations. The k-ε and k-ω SST (Shear Stress Transport) models have demonstrated particular efficacy for data center cooling applications, with the latter providing superior performance in predicting flow separation and reattachment around heat sink fins. For more complex geometries, Large Eddy Simulation (LES) approaches offer enhanced accuracy at the cost of significantly higher computational requirements.

Mesh generation strategies significantly impact simulation accuracy and efficiency. Adaptive mesh refinement techniques have proven valuable for heat sink optimization, allowing higher resolution in regions of steep gradients while maintaining computational economy elsewhere. Boundary layer meshing with appropriate y+ values ensures accurate capture of near-wall phenomena critical to heat transfer performance.

Commercial CFD packages including ANSYS Fluent, COMSOL Multiphysics, and Siemens Star-CCM+ dominate the industry landscape, while open-source alternatives like OpenFOAM have gained traction for research applications. Recent developments in GPU acceleration have dramatically reduced simulation times, enabling more extensive design space exploration and optimization studies.

Conjugate heat transfer modeling, which simultaneously solves for conduction within solid components and convection in fluid regions, has become standard practice for comprehensive heat sink analysis. This approach eliminates the need for assumed boundary conditions at solid-fluid interfaces, resulting in more accurate temperature predictions.

Validation methodologies typically involve comparison with experimental data from wind tunnel testing or operational data centers. Particle Image Velocimetry (PIV) and infrared thermography provide valuable experimental benchmarks for CFD model validation, establishing confidence in simulation results before implementation in production environments.

Modern CFD approaches for heat sink analysis typically employ finite volume methods to solve the governing Navier-Stokes equations, coupled with energy equations for thermal analysis. The SIMPLE (Semi-Implicit Method for Pressure-Linked Equations) algorithm remains widely used for pressure-velocity coupling in these simulations, while more advanced techniques like PISO (Pressure Implicit with Splitting of Operators) offer improved convergence for transient analyses.

Turbulence modeling represents a critical aspect of heat sink CFD simulations. The k-ε and k-ω SST (Shear Stress Transport) models have demonstrated particular efficacy for data center cooling applications, with the latter providing superior performance in predicting flow separation and reattachment around heat sink fins. For more complex geometries, Large Eddy Simulation (LES) approaches offer enhanced accuracy at the cost of significantly higher computational requirements.

Mesh generation strategies significantly impact simulation accuracy and efficiency. Adaptive mesh refinement techniques have proven valuable for heat sink optimization, allowing higher resolution in regions of steep gradients while maintaining computational economy elsewhere. Boundary layer meshing with appropriate y+ values ensures accurate capture of near-wall phenomena critical to heat transfer performance.

Commercial CFD packages including ANSYS Fluent, COMSOL Multiphysics, and Siemens Star-CCM+ dominate the industry landscape, while open-source alternatives like OpenFOAM have gained traction for research applications. Recent developments in GPU acceleration have dramatically reduced simulation times, enabling more extensive design space exploration and optimization studies.

Conjugate heat transfer modeling, which simultaneously solves for conduction within solid components and convection in fluid regions, has become standard practice for comprehensive heat sink analysis. This approach eliminates the need for assumed boundary conditions at solid-fluid interfaces, resulting in more accurate temperature predictions.

Validation methodologies typically involve comparison with experimental data from wind tunnel testing or operational data centers. Particle Image Velocimetry (PIV) and infrared thermography provide valuable experimental benchmarks for CFD model validation, establishing confidence in simulation results before implementation in production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!