Heat Sink Design Optimization in High Performance Computing Systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Objectives

Thermal management in high-performance computing (HPC) systems has evolved significantly over the past decades, driven by the continuous increase in processing power and the corresponding rise in heat generation. In the early days of computing, passive cooling methods such as natural convection were sufficient for maintaining acceptable operating temperatures. However, as transistor densities increased following Moore's Law, thermal management quickly became a critical engineering challenge.

The 1980s marked the widespread adoption of active cooling solutions, primarily utilizing fans and basic heat sinks. By the 1990s, as processor speeds exceeded 1 GHz, more sophisticated approaches emerged, including copper heat sinks with optimized fin designs and the introduction of heat pipes for more efficient heat transfer from hotspots.

The early 2000s witnessed a paradigm shift with the industry's move toward multi-core architectures, partly motivated by thermal constraints that limited further increases in clock speeds. This period saw the development of advanced thermal interface materials (TIMs) and the integration of liquid cooling solutions in high-end systems.

Recent years have brought revolutionary approaches to thermal management, including direct liquid cooling, two-phase cooling systems, and immersion cooling technologies. These innovations have been essential for supporting the extreme computational demands of artificial intelligence workloads and exascale computing initiatives.

The primary objective of modern heat sink design optimization in HPC systems is to maintain component temperatures below critical thresholds while minimizing the energy consumption of cooling systems, which can represent up to 40% of a data center's total power usage. Additional goals include reducing acoustic noise, enhancing reliability through temperature uniformity, and developing compact solutions to accommodate increasing power densities.

Future thermal management strategies aim to achieve zero-impact cooling, where the energy required for cooling approaches zero through innovations in materials science, design optimization, and integration with facility-level thermal management. Research objectives also include developing adaptive cooling systems that dynamically respond to workload variations and exploring novel materials with superior thermal properties, such as graphene and diamond-based composites.

The evolution of thermal management technologies continues to be driven by sustainability concerns, with growing emphasis on waste heat recovery and reuse. This holistic approach considers not only the immediate cooling requirements but also the broader environmental impact of HPC operations, aligning with global initiatives for carbon-neutral computing.

The 1980s marked the widespread adoption of active cooling solutions, primarily utilizing fans and basic heat sinks. By the 1990s, as processor speeds exceeded 1 GHz, more sophisticated approaches emerged, including copper heat sinks with optimized fin designs and the introduction of heat pipes for more efficient heat transfer from hotspots.

The early 2000s witnessed a paradigm shift with the industry's move toward multi-core architectures, partly motivated by thermal constraints that limited further increases in clock speeds. This period saw the development of advanced thermal interface materials (TIMs) and the integration of liquid cooling solutions in high-end systems.

Recent years have brought revolutionary approaches to thermal management, including direct liquid cooling, two-phase cooling systems, and immersion cooling technologies. These innovations have been essential for supporting the extreme computational demands of artificial intelligence workloads and exascale computing initiatives.

The primary objective of modern heat sink design optimization in HPC systems is to maintain component temperatures below critical thresholds while minimizing the energy consumption of cooling systems, which can represent up to 40% of a data center's total power usage. Additional goals include reducing acoustic noise, enhancing reliability through temperature uniformity, and developing compact solutions to accommodate increasing power densities.

Future thermal management strategies aim to achieve zero-impact cooling, where the energy required for cooling approaches zero through innovations in materials science, design optimization, and integration with facility-level thermal management. Research objectives also include developing adaptive cooling systems that dynamically respond to workload variations and exploring novel materials with superior thermal properties, such as graphene and diamond-based composites.

The evolution of thermal management technologies continues to be driven by sustainability concerns, with growing emphasis on waste heat recovery and reuse. This holistic approach considers not only the immediate cooling requirements but also the broader environmental impact of HPC operations, aligning with global initiatives for carbon-neutral computing.

Market Demand for Advanced Cooling Solutions

The global market for advanced cooling solutions in high-performance computing (HPC) systems has experienced substantial growth, driven primarily by the increasing power density and computational demands of modern data centers. As processing capabilities continue to advance according to Moore's Law, thermal management has become a critical bottleneck in system design and performance optimization.

Market research indicates that the data center cooling market is projected to reach $20 billion by 2025, with liquid cooling solutions showing the fastest growth segment at approximately 15% CAGR. This acceleration is directly correlated with the proliferation of AI workloads, which typically generate 2-3 times more heat than traditional computing applications due to their intensive computational requirements.

Enterprise customers are increasingly prioritizing cooling efficiency as energy costs continue to represent 40-50% of data center operational expenses. A recent industry survey revealed that 78% of data center operators consider thermal management a top-three priority for infrastructure investments, with 65% actively exploring advanced heat sink technologies and alternative cooling methodologies.

The demand landscape shows distinct segmentation across different computing sectors. Hyperscale cloud providers demonstrate the highest demand for innovative cooling solutions, followed by high-performance computing research facilities and financial services with high-frequency trading operations. These sectors share common requirements for cooling solutions that can handle extreme heat loads while maintaining reliability and minimizing space utilization.

Geographically, North America leads the market demand with approximately 40% share, followed by Asia-Pacific at 30%, which is experiencing the fastest growth rate due to rapid data center expansion in China, Singapore, and Japan. European markets show particular interest in environmentally sustainable cooling technologies, driven by stringent energy efficiency regulations and corporate sustainability goals.

Customer requirements are evolving beyond simple thermal performance metrics. Key demand drivers now include energy efficiency (measured in PUE - Power Usage Effectiveness), space optimization capabilities, noise reduction, reliability metrics (MTBF), and increasingly, environmental sustainability factors such as water usage effectiveness and carbon footprint considerations.

The market shows strong correlation between cooling solution adoption and total cost of ownership (TCO) benefits. Solutions that demonstrate 20-30% improvement in cooling efficiency typically achieve market penetration 2-3 times faster than those with marginal improvements, highlighting the economic sensitivity of this market segment despite its technical nature.

Market research indicates that the data center cooling market is projected to reach $20 billion by 2025, with liquid cooling solutions showing the fastest growth segment at approximately 15% CAGR. This acceleration is directly correlated with the proliferation of AI workloads, which typically generate 2-3 times more heat than traditional computing applications due to their intensive computational requirements.

Enterprise customers are increasingly prioritizing cooling efficiency as energy costs continue to represent 40-50% of data center operational expenses. A recent industry survey revealed that 78% of data center operators consider thermal management a top-three priority for infrastructure investments, with 65% actively exploring advanced heat sink technologies and alternative cooling methodologies.

The demand landscape shows distinct segmentation across different computing sectors. Hyperscale cloud providers demonstrate the highest demand for innovative cooling solutions, followed by high-performance computing research facilities and financial services with high-frequency trading operations. These sectors share common requirements for cooling solutions that can handle extreme heat loads while maintaining reliability and minimizing space utilization.

Geographically, North America leads the market demand with approximately 40% share, followed by Asia-Pacific at 30%, which is experiencing the fastest growth rate due to rapid data center expansion in China, Singapore, and Japan. European markets show particular interest in environmentally sustainable cooling technologies, driven by stringent energy efficiency regulations and corporate sustainability goals.

Customer requirements are evolving beyond simple thermal performance metrics. Key demand drivers now include energy efficiency (measured in PUE - Power Usage Effectiveness), space optimization capabilities, noise reduction, reliability metrics (MTBF), and increasingly, environmental sustainability factors such as water usage effectiveness and carbon footprint considerations.

The market shows strong correlation between cooling solution adoption and total cost of ownership (TCO) benefits. Solutions that demonstrate 20-30% improvement in cooling efficiency typically achieve market penetration 2-3 times faster than those with marginal improvements, highlighting the economic sensitivity of this market segment despite its technical nature.

Current Heat Sink Technologies and Limitations

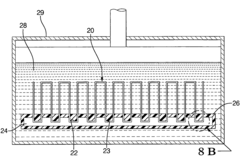

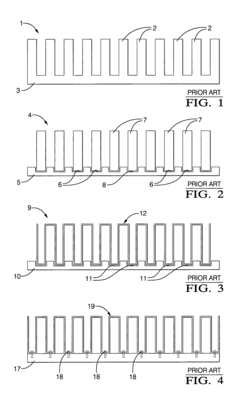

Heat sink technology in high-performance computing (HPC) systems has evolved significantly over the past decades, yet continues to face substantial challenges as computational demands increase. Current mainstream heat sink solutions primarily fall into four categories: passive air-cooled, active air-cooled, liquid-cooled, and emerging technologies such as phase-change materials and immersion cooling.

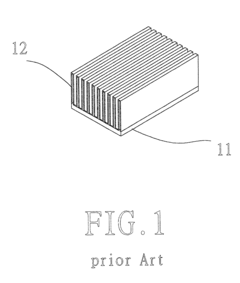

Passive air-cooled heat sinks remain the most widely deployed solution due to their reliability, cost-effectiveness, and absence of moving parts. These typically feature aluminum or copper fins designed to maximize surface area for heat dissipation. However, they have reached thermal efficiency plateaus, with limited capacity to handle heat loads exceeding 150-200W/cm², significantly constraining their application in next-generation HPC systems.

Active air-cooled solutions incorporate fans to enhance convective heat transfer, improving cooling efficiency by 30-40% compared to passive alternatives. Modern designs feature variable-speed fans and optimized airflow channels. Nevertheless, these systems generate noise, consume additional power, and introduce reliability concerns due to mechanical components. Their cooling capacity typically maxes out at 250-300W/cm², insufficient for the projected thermal demands of future HPC architectures.

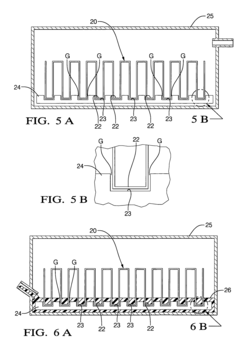

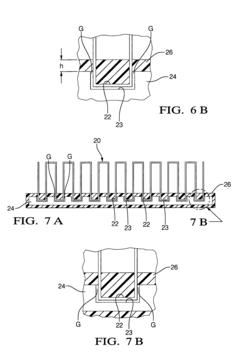

Liquid cooling technologies have gained significant traction, offering thermal conductivity 20-30 times greater than air-based solutions. Cold plate designs, where coolant flows through channels in direct contact with heat-generating components, can manage heat loads up to 500-700W/cm². However, implementation challenges include system complexity, potential for leakage, maintenance requirements, and substantially higher costs—typically 3-5 times that of air-cooled alternatives.

Emerging technologies show promise but face adoption barriers. Two-phase cooling systems utilizing the latent heat of vaporization can theoretically handle heat fluxes exceeding 1000W/cm². Immersion cooling, where components are submerged in dielectric fluid, offers exceptional thermal performance but requires complete system redesign and raises concerns regarding fluid degradation and maintenance.

A critical limitation across all current technologies is thermal interface material (TIM) performance. The thermal resistance at the interface between heat sources and heat sinks creates bottlenecks, with even advanced metal-based TIMs introducing thermal resistance that can account for 30-50% of the total thermal resistance in the cooling path.

Miniaturization trends in HPC components further complicate heat sink design, creating hotspots with extreme power densities that exceed the capabilities of uniform cooling solutions. Additionally, current designs struggle with transient thermal loads characteristic of modern workloads, where rapid power fluctuations can cause thermal cycling and reliability issues.

Passive air-cooled heat sinks remain the most widely deployed solution due to their reliability, cost-effectiveness, and absence of moving parts. These typically feature aluminum or copper fins designed to maximize surface area for heat dissipation. However, they have reached thermal efficiency plateaus, with limited capacity to handle heat loads exceeding 150-200W/cm², significantly constraining their application in next-generation HPC systems.

Active air-cooled solutions incorporate fans to enhance convective heat transfer, improving cooling efficiency by 30-40% compared to passive alternatives. Modern designs feature variable-speed fans and optimized airflow channels. Nevertheless, these systems generate noise, consume additional power, and introduce reliability concerns due to mechanical components. Their cooling capacity typically maxes out at 250-300W/cm², insufficient for the projected thermal demands of future HPC architectures.

Liquid cooling technologies have gained significant traction, offering thermal conductivity 20-30 times greater than air-based solutions. Cold plate designs, where coolant flows through channels in direct contact with heat-generating components, can manage heat loads up to 500-700W/cm². However, implementation challenges include system complexity, potential for leakage, maintenance requirements, and substantially higher costs—typically 3-5 times that of air-cooled alternatives.

Emerging technologies show promise but face adoption barriers. Two-phase cooling systems utilizing the latent heat of vaporization can theoretically handle heat fluxes exceeding 1000W/cm². Immersion cooling, where components are submerged in dielectric fluid, offers exceptional thermal performance but requires complete system redesign and raises concerns regarding fluid degradation and maintenance.

A critical limitation across all current technologies is thermal interface material (TIM) performance. The thermal resistance at the interface between heat sources and heat sinks creates bottlenecks, with even advanced metal-based TIMs introducing thermal resistance that can account for 30-50% of the total thermal resistance in the cooling path.

Miniaturization trends in HPC components further complicate heat sink design, creating hotspots with extreme power densities that exceed the capabilities of uniform cooling solutions. Additionally, current designs struggle with transient thermal loads characteristic of modern workloads, where rapid power fluctuations can cause thermal cycling and reliability issues.

Contemporary Heat Sink Design Methodologies

01 Material selection for heat sink optimization

The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper and aluminum alloys are preferred for efficient heat dissipation. Composite materials and metal matrix composites can provide enhanced thermal properties while maintaining structural integrity. Material selection must balance thermal performance with other factors such as weight, cost, and manufacturability to achieve optimal heat sink designs.- Heat sink geometry optimization: Optimizing the physical structure and geometry of heat sinks can significantly improve thermal performance. This includes designing specialized fin shapes, optimizing fin spacing, and creating innovative structural configurations that maximize surface area while minimizing airflow resistance. Advanced geometric designs can enhance heat dissipation efficiency by improving convection and conduction pathways, resulting in better overall thermal management for electronic components.

- Material selection and composition for heat sinks: The choice of materials plays a crucial role in heat sink performance. High thermal conductivity materials like copper, aluminum alloys, and composite materials can significantly improve heat dissipation. Advanced material compositions, including metal matrix composites and phase-change materials, offer enhanced thermal properties. Material selection must balance thermal performance with other considerations such as weight, cost, manufacturability, and compatibility with the application environment.

- Liquid cooling and phase change heat sink systems: Liquid cooling systems and phase change materials provide superior thermal management compared to traditional air-cooled heat sinks. These systems utilize the high heat capacity of liquids or the latent heat of phase transitions to absorb and transfer heat away from critical components. Designs may incorporate microchannels, heat pipes, vapor chambers, or immersion cooling techniques to efficiently manage high heat loads in compact spaces, making them ideal for high-performance computing and power electronics applications.

- Integration of heat sinks with electronic components: Optimizing the integration between heat sinks and electronic components is essential for effective thermal management. This includes improving thermal interface materials, reducing contact resistance, and designing application-specific mounting solutions. Advanced integration techniques focus on minimizing the thermal resistance path from heat source to heat sink, ensuring proper pressure distribution, and accommodating thermal expansion differences. These approaches enable more efficient heat transfer and better overall system performance.

- Computational methods for heat sink design: Computational fluid dynamics (CFD) and thermal simulation techniques are increasingly used to optimize heat sink designs before physical prototyping. These methods enable engineers to predict airflow patterns, temperature distributions, and overall thermal performance under various operating conditions. Advanced algorithms, including topology optimization and machine learning approaches, can generate novel heat sink geometries that outperform traditional designs. Computational methods significantly reduce development time and cost while improving the final thermal solution.

02 Geometric design and fin optimization

The geometric configuration of heat sinks significantly affects thermal performance. Optimized fin designs, including variations in fin height, thickness, spacing, and shape (straight, curved, or pin fins), can maximize surface area while minimizing airflow resistance. Advanced computational methods are used to determine optimal fin arrangements that balance heat dissipation with pressure drop considerations. Innovative fin geometries can create turbulent flow patterns that enhance convective heat transfer.Expand Specific Solutions03 Liquid cooling and phase change technologies

Advanced heat sink designs incorporate liquid cooling systems and phase change materials to handle high heat loads. These systems utilize the high heat capacity of liquids and the latent heat of phase transitions to achieve superior thermal management. Microchannels, heat pipes, and vapor chambers embedded within heat sinks facilitate efficient heat transport from hot spots to larger dissipation areas. These technologies are particularly valuable for high-power electronic applications where traditional air cooling is insufficient.Expand Specific Solutions04 Surface treatment and coating technologies

Surface modifications and specialized coatings can enhance heat sink performance. Techniques such as anodizing, micro-texturing, and applying high-emissivity coatings improve radiative and convective heat transfer. Hydrophilic or hydrophobic surface treatments can optimize performance in specific operating environments. These surface enhancements can significantly improve thermal efficiency without altering the basic heat sink structure or increasing its size.Expand Specific Solutions05 Integration with electronic systems and thermal management

Optimized heat sink designs consider the entire thermal management system, including integration with electronic components and cooling mechanisms. This approach involves strategic placement of heat sinks relative to heat sources, airflow paths, and other system components. Advanced designs incorporate thermal interface materials to minimize contact resistance and may feature adaptive elements that respond to changing thermal loads. System-level optimization ensures efficient heat dissipation while meeting space constraints and reliability requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The heat sink design optimization market in high-performance computing is currently in a growth phase, with increasing demand driven by rising computational densities and thermal challenges. The market is characterized by a mix of established players and specialized innovators. Major technology corporations like IBM, Intel, and Siemens dominate with comprehensive thermal management portfolios, while specialized firms such as Diabatix offer cutting-edge computational fluid dynamics solutions. Asian manufacturers including Hon Hai Precision (Foxconn), Huawei, and Samsung provide scale and manufacturing expertise. The technology landscape spans from traditional passive cooling to advanced liquid cooling and computational design optimization, with companies increasingly leveraging AI for thermal simulation. As data centers and high-performance computing continue expanding, this sector is projected to grow significantly, with innovation focused on energy efficiency and performance optimization.

International Business Machines Corp.

Technical Solution: IBM has pioneered advanced heat sink designs for high-performance computing systems through their Thermal Conduction Module (TCM) technology and subsequent innovations. Their current approach focuses on microfluidic cooling systems that utilize a network of microchannels directly integrated into silicon chips. This technology employs a closed-loop system where coolant flows through microscopic channels etched directly into the back of the silicon chip, allowing heat removal at the source. IBM's "hot water cooling" technology enables data centers to operate with coolant temperatures up to 45°C, significantly reducing energy consumption compared to traditional air cooling methods. Their Rear Door Heat eXchanger (RDHx) technology captures up to 85% of server heat output and can handle heat loads exceeding 100 kW per rack. Additionally, IBM has developed two-phase immersion cooling systems where servers are submerged in dielectric fluid that changes from liquid to vapor to efficiently remove heat.

Strengths: Direct on-chip cooling provides superior thermal performance with minimal thermal resistance; integrated approach reduces system complexity; supports extreme computing densities. Weaknesses: Higher implementation costs compared to traditional solutions; requires specialized maintenance expertise; potential reliability concerns with liquid cooling near electronic components.

Diabatix NV

Technical Solution: Diabatix has revolutionized heat sink design optimization through their AI-driven computational fluid dynamics (CFD) platform called ColdStream. This platform employs generative design algorithms and machine learning to automatically create optimized heat sink designs that significantly outperform traditional designs. Their approach begins with defining the thermal problem constraints and performance targets, after which their AI algorithms explore thousands of possible design iterations to identify optimal geometries that would be impossible to conceive through conventional engineering methods. Diabatix's technology can reduce thermal resistance by up to 30-40% compared to traditional designs, while simultaneously reducing material usage by creating complex, nature-inspired structures with enhanced surface area and optimized fluid flow paths. The platform considers manufacturing constraints during the design process, ensuring that the resulting heat sinks can be produced using existing manufacturing methods like CNC machining, die casting, or additive manufacturing. Their recent innovations include multi-material optimization and topology optimization for liquid-cooled cold plates.

Strengths: AI-driven approach discovers non-intuitive geometries with superior performance; automated workflow reduces design time from weeks to hours; designs are optimized for specific manufacturing processes. Weaknesses: Requires significant computational resources; complex geometries may increase manufacturing costs; relatively new technology with limited long-term performance data in field conditions.

Critical Patents in Thermal Management Innovation

Method of making high performance heat sinks

PatentInactiveUS7537151B2

Innovation

- A method utilizing cold isostatic pressing (CIP) with a localized hermetical seal material applied at the fin-to-base plate interfaces, allowing for plastic deformation and intimate mechanical bonding without distortion, and subsequent diffusion bonding for enhanced thermal performance.

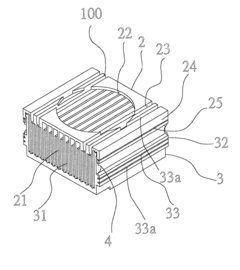

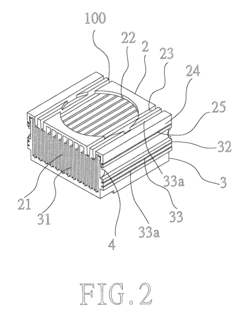

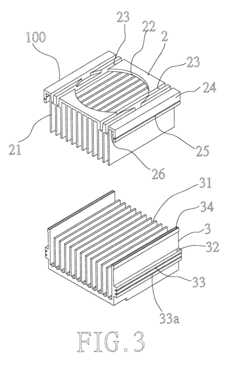

Heat sink

PatentInactiveUS20020024796A1

Innovation

- A heat sink design comprising a bottom unit with parallel upright fins and a top unit with parallel bottom fins, secured together by hook plates and mounting grooves, allowing for enhanced engagement and increased heat dissipation area, along with provisions for fan mounting to improve cooling efficiency.

Material Science Advancements for Thermal Solutions

The evolution of material science has revolutionized thermal management solutions for high-performance computing systems. Traditional materials like aluminum and copper, while effective, have reached their physical limitations in dissipating the extreme heat generated by modern processors. Recent advancements in composite materials have introduced metal matrix composites (MMCs) that combine the thermal conductivity of metals with the lightweight properties of ceramics, offering up to 25% better thermal performance than conventional materials.

Graphene-based materials represent a significant breakthrough, exhibiting thermal conductivity values exceeding 5000 W/m·K, compared to copper's 400 W/m·K. Research from MIT and Stanford University demonstrates that graphene-enhanced heat sinks can reduce operating temperatures by up to 30% in high-load computing environments. These materials allow for thinner, more efficient heat sink designs that address the space constraints in compact computing systems.

Phase change materials (PCMs) have emerged as another innovative solution, absorbing thermal energy during state transitions. When integrated into heat sink designs, PCMs can buffer temperature spikes during computational bursts, maintaining more consistent operating temperatures. Recent implementations show that PCM-enhanced heat sinks can extend the duration of peak performance in HPC systems by 40-60% before thermal throttling occurs.

Diamond-copper composites represent the cutting edge of thermal interface materials, combining diamond's exceptional thermal conductivity (2000 W/m·K) with copper's manufacturability. Though currently expensive, these composites are becoming viable for specialized applications where thermal performance justifies the cost premium. Industry projections suggest a 30% cost reduction within the next five years as manufacturing processes mature.

Additive manufacturing has enabled the development of novel microstructured materials with engineered thermal properties. 3D-printed lattice structures with variable density can create optimized thermal gradients that direct heat flow more efficiently than homogeneous materials. These structures can improve thermal dissipation by up to 35% compared to traditional heat sink designs while reducing material usage by 20-40%.

Nanofluids and micro-channel cooling solutions incorporate advanced materials science principles to enhance liquid cooling efficiency. By suspending nanoparticles in traditional coolants, thermal conductivity can be increased by 15-40%, depending on particle composition and concentration. These solutions are particularly promising for the next generation of exascale computing systems where traditional air cooling approaches physical limitations.

Graphene-based materials represent a significant breakthrough, exhibiting thermal conductivity values exceeding 5000 W/m·K, compared to copper's 400 W/m·K. Research from MIT and Stanford University demonstrates that graphene-enhanced heat sinks can reduce operating temperatures by up to 30% in high-load computing environments. These materials allow for thinner, more efficient heat sink designs that address the space constraints in compact computing systems.

Phase change materials (PCMs) have emerged as another innovative solution, absorbing thermal energy during state transitions. When integrated into heat sink designs, PCMs can buffer temperature spikes during computational bursts, maintaining more consistent operating temperatures. Recent implementations show that PCM-enhanced heat sinks can extend the duration of peak performance in HPC systems by 40-60% before thermal throttling occurs.

Diamond-copper composites represent the cutting edge of thermal interface materials, combining diamond's exceptional thermal conductivity (2000 W/m·K) with copper's manufacturability. Though currently expensive, these composites are becoming viable for specialized applications where thermal performance justifies the cost premium. Industry projections suggest a 30% cost reduction within the next five years as manufacturing processes mature.

Additive manufacturing has enabled the development of novel microstructured materials with engineered thermal properties. 3D-printed lattice structures with variable density can create optimized thermal gradients that direct heat flow more efficiently than homogeneous materials. These structures can improve thermal dissipation by up to 35% compared to traditional heat sink designs while reducing material usage by 20-40%.

Nanofluids and micro-channel cooling solutions incorporate advanced materials science principles to enhance liquid cooling efficiency. By suspending nanoparticles in traditional coolants, thermal conductivity can be increased by 15-40%, depending on particle composition and concentration. These solutions are particularly promising for the next generation of exascale computing systems where traditional air cooling approaches physical limitations.

Environmental Impact of Cooling Technologies

The environmental impact of cooling technologies in high-performance computing (HPC) systems has become increasingly significant as data centers continue to expand globally. Traditional cooling methods, particularly air cooling with heat sinks, contribute substantially to the carbon footprint of computing infrastructure. Current estimates indicate that cooling systems account for approximately 30-40% of a data center's total energy consumption, highlighting the urgent need for more sustainable approaches.

Liquid cooling technologies offer promising environmental benefits compared to conventional air cooling. Studies demonstrate that direct liquid cooling can reduce energy consumption by 20-50%, depending on implementation specifics and operational conditions. This translates to significant reductions in greenhouse gas emissions, with some advanced implementations achieving carbon footprint reductions of up to 30% compared to traditional cooling methods.

Material selection for heat sinks also presents important environmental considerations. Conventional aluminum and copper heat sinks, while effective thermal conductors, involve energy-intensive mining and manufacturing processes. The extraction and processing of these metals generate substantial environmental impacts, including habitat destruction, water pollution, and high carbon emissions. Recent life cycle assessments indicate that the production phase of traditional heat sink materials accounts for approximately 70% of their total environmental impact.

Emerging sustainable alternatives include recycled metals, carbon-based composites, and phase-change materials that offer reduced environmental footprints. Particularly promising are bio-inspired designs that maximize cooling efficiency while minimizing material usage. These innovations can reduce raw material requirements by up to 40% while maintaining or even improving thermal performance.

Water consumption represents another critical environmental concern, especially for data centers employing water-based cooling systems. A typical 1MW data center using evaporative cooling can consume 7-8 million gallons of water annually. This substantial water footprint becomes particularly problematic in regions experiencing water scarcity. Advanced closed-loop systems and waterless cooling technologies are being developed to address this challenge, potentially reducing water consumption by 80-90%.

The end-of-life management of cooling technologies presents additional environmental challenges. Most conventional heat sinks and cooling components have limited recycling pathways, contributing to electronic waste streams. Designing for disassembly and incorporating easily recyclable materials can significantly improve the environmental profile of cooling systems throughout their complete lifecycle.

Liquid cooling technologies offer promising environmental benefits compared to conventional air cooling. Studies demonstrate that direct liquid cooling can reduce energy consumption by 20-50%, depending on implementation specifics and operational conditions. This translates to significant reductions in greenhouse gas emissions, with some advanced implementations achieving carbon footprint reductions of up to 30% compared to traditional cooling methods.

Material selection for heat sinks also presents important environmental considerations. Conventional aluminum and copper heat sinks, while effective thermal conductors, involve energy-intensive mining and manufacturing processes. The extraction and processing of these metals generate substantial environmental impacts, including habitat destruction, water pollution, and high carbon emissions. Recent life cycle assessments indicate that the production phase of traditional heat sink materials accounts for approximately 70% of their total environmental impact.

Emerging sustainable alternatives include recycled metals, carbon-based composites, and phase-change materials that offer reduced environmental footprints. Particularly promising are bio-inspired designs that maximize cooling efficiency while minimizing material usage. These innovations can reduce raw material requirements by up to 40% while maintaining or even improving thermal performance.

Water consumption represents another critical environmental concern, especially for data centers employing water-based cooling systems. A typical 1MW data center using evaporative cooling can consume 7-8 million gallons of water annually. This substantial water footprint becomes particularly problematic in regions experiencing water scarcity. Advanced closed-loop systems and waterless cooling technologies are being developed to address this challenge, potentially reducing water consumption by 80-90%.

The end-of-life management of cooling technologies presents additional environmental challenges. Most conventional heat sinks and cooling components have limited recycling pathways, contributing to electronic waste streams. Designing for disassembly and incorporating easily recyclable materials can significantly improve the environmental profile of cooling systems throughout their complete lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!