Why Heat Sink Design Optimization Improves Device Reliability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Sink Technology Evolution and Objectives

Heat sink technology has evolved significantly over the past several decades, transitioning from simple metal plates to sophisticated thermal management solutions. The earliest heat sinks, developed in the 1960s, were basic aluminum extrusions with minimal surface area. As electronic devices became more powerful and compact in the 1970s and 1980s, heat sink designs incorporated fins to increase surface area for better heat dissipation, marking the first major evolution in this technology.

The 1990s witnessed the introduction of copper as a heat sink material, offering superior thermal conductivity compared to aluminum. This period also saw the development of heat pipes, which utilize phase change principles to transfer heat more efficiently from the source to the dissipation area. The early 2000s brought significant advancements with the integration of active cooling components such as fans and liquid cooling systems, creating hybrid solutions for high-performance computing environments.

Recent technological trends have focused on miniaturization and efficiency improvements. Micro-channel heat sinks, developed in the last decade, feature extremely fine channels that maximize surface area while maintaining compact dimensions. Additionally, advanced manufacturing techniques like 3D printing have enabled complex geometries previously impossible to produce, optimizing fluid flow and heat transfer characteristics.

The primary objective of heat sink design optimization is to maximize thermal efficiency while minimizing space requirements, weight, and cost. This balance is crucial as electronic devices continue to increase in power density while decreasing in size. Specific technical goals include reducing thermal resistance, minimizing the temperature gradient across components, and ensuring uniform heat distribution to prevent hotspots that can lead to premature component failure.

Another critical objective is to develop heat sink solutions that operate effectively in various environmental conditions, from consumer electronics in homes to industrial equipment in harsh settings. This adaptability requires innovative approaches to material selection, geometry design, and integration with other cooling technologies.

Looking forward, the evolution of heat sink technology aims to address emerging challenges in quantum computing, artificial intelligence hardware, and next-generation mobile devices. These applications demand unprecedented thermal management capabilities to ensure reliability and performance. Research is increasingly focused on bio-inspired designs, nanomaterials, and smart thermal management systems that can dynamically adjust to changing thermal loads, representing the next frontier in heat sink technology development.

The 1990s witnessed the introduction of copper as a heat sink material, offering superior thermal conductivity compared to aluminum. This period also saw the development of heat pipes, which utilize phase change principles to transfer heat more efficiently from the source to the dissipation area. The early 2000s brought significant advancements with the integration of active cooling components such as fans and liquid cooling systems, creating hybrid solutions for high-performance computing environments.

Recent technological trends have focused on miniaturization and efficiency improvements. Micro-channel heat sinks, developed in the last decade, feature extremely fine channels that maximize surface area while maintaining compact dimensions. Additionally, advanced manufacturing techniques like 3D printing have enabled complex geometries previously impossible to produce, optimizing fluid flow and heat transfer characteristics.

The primary objective of heat sink design optimization is to maximize thermal efficiency while minimizing space requirements, weight, and cost. This balance is crucial as electronic devices continue to increase in power density while decreasing in size. Specific technical goals include reducing thermal resistance, minimizing the temperature gradient across components, and ensuring uniform heat distribution to prevent hotspots that can lead to premature component failure.

Another critical objective is to develop heat sink solutions that operate effectively in various environmental conditions, from consumer electronics in homes to industrial equipment in harsh settings. This adaptability requires innovative approaches to material selection, geometry design, and integration with other cooling technologies.

Looking forward, the evolution of heat sink technology aims to address emerging challenges in quantum computing, artificial intelligence hardware, and next-generation mobile devices. These applications demand unprecedented thermal management capabilities to ensure reliability and performance. Research is increasingly focused on bio-inspired designs, nanomaterials, and smart thermal management systems that can dynamically adjust to changing thermal loads, representing the next frontier in heat sink technology development.

Market Demand for Thermal Management Solutions

The thermal management solutions market is experiencing unprecedented growth driven by the increasing power density and miniaturization of electronic devices across multiple industries. Current market analysis indicates that the global thermal management market is projected to reach $16.2 billion by 2026, growing at a CAGR of 8.2% from 2021. This robust growth is primarily fueled by the rapid expansion of data centers, telecommunications infrastructure, and the automotive electronics sector.

Consumer electronics represent a significant demand driver, with smartphones, tablets, and laptops requiring increasingly sophisticated thermal solutions to maintain performance while reducing form factors. The average smartphone now generates 30% more heat than models from five years ago, creating urgent demand for advanced cooling technologies that can fit within increasingly compact designs.

Industrial applications constitute another major market segment, with manufacturing equipment, power electronics, and industrial computing systems requiring reliable thermal management to ensure operational continuity and prevent costly downtime. Studies show that equipment failures due to thermal issues cost industrial operations an estimated $5 billion annually in lost productivity and replacement costs.

The automotive sector presents perhaps the fastest-growing demand segment, particularly with the rapid adoption of electric vehicles. EV battery thermal management systems are critical for ensuring battery longevity, safety, and optimal charging performance. Market research indicates that the automotive thermal management subsector is growing at 9.7% annually, outpacing the broader market.

Healthcare and medical devices represent an emerging but rapidly expanding market for thermal solutions, with sensitive diagnostic equipment and implantable devices requiring precise temperature control to ensure accuracy and patient safety. This sector is expected to grow at 11.3% annually through 2026.

Geographically, Asia-Pacific dominates the demand landscape, accounting for approximately 42% of global market share, driven by the concentration of electronics manufacturing and rapid technological adoption. North America follows at 28%, with particularly strong demand from data center operations and aerospace applications.

Customer requirements are increasingly focused on solutions that not only provide effective cooling but also contribute to overall energy efficiency and sustainability goals. A recent industry survey revealed that 76% of procurement decision-makers now consider energy efficiency a primary factor when selecting thermal management components, reflecting broader corporate environmental initiatives and operational cost concerns.

Consumer electronics represent a significant demand driver, with smartphones, tablets, and laptops requiring increasingly sophisticated thermal solutions to maintain performance while reducing form factors. The average smartphone now generates 30% more heat than models from five years ago, creating urgent demand for advanced cooling technologies that can fit within increasingly compact designs.

Industrial applications constitute another major market segment, with manufacturing equipment, power electronics, and industrial computing systems requiring reliable thermal management to ensure operational continuity and prevent costly downtime. Studies show that equipment failures due to thermal issues cost industrial operations an estimated $5 billion annually in lost productivity and replacement costs.

The automotive sector presents perhaps the fastest-growing demand segment, particularly with the rapid adoption of electric vehicles. EV battery thermal management systems are critical for ensuring battery longevity, safety, and optimal charging performance. Market research indicates that the automotive thermal management subsector is growing at 9.7% annually, outpacing the broader market.

Healthcare and medical devices represent an emerging but rapidly expanding market for thermal solutions, with sensitive diagnostic equipment and implantable devices requiring precise temperature control to ensure accuracy and patient safety. This sector is expected to grow at 11.3% annually through 2026.

Geographically, Asia-Pacific dominates the demand landscape, accounting for approximately 42% of global market share, driven by the concentration of electronics manufacturing and rapid technological adoption. North America follows at 28%, with particularly strong demand from data center operations and aerospace applications.

Customer requirements are increasingly focused on solutions that not only provide effective cooling but also contribute to overall energy efficiency and sustainability goals. A recent industry survey revealed that 76% of procurement decision-makers now consider energy efficiency a primary factor when selecting thermal management components, reflecting broader corporate environmental initiatives and operational cost concerns.

Current Challenges in Heat Sink Design

Despite significant advancements in thermal management technologies, heat sink design continues to face numerous challenges that limit optimal performance and device reliability. One of the most persistent issues is the fundamental trade-off between size constraints and thermal dissipation requirements. As electronic devices become increasingly compact while processing power grows exponentially, designers must achieve greater cooling efficiency within smaller form factors. This spatial limitation often forces compromises that reduce thermal performance and ultimately impact device longevity.

Material selection presents another significant challenge. Traditional aluminum and copper heat sinks offer good thermal conductivity but add considerable weight to devices. Advanced materials like graphene, carbon nanotubes, and metal matrix composites show promising thermal properties but remain costly for mass production and present manufacturing complexity. The industry continues to search for the optimal balance between thermal performance, weight, cost, and manufacturability.

Manufacturing precision significantly impacts heat sink effectiveness. Even minor imperfections in the contact surface between the heat sink and heat source can create air gaps that dramatically reduce thermal transfer efficiency. These microscopic imperfections, often invisible to the naked eye, can increase thermal resistance by up to 30%, negating the benefits of otherwise well-designed cooling solutions.

Complex airflow dynamics further complicate heat sink design. Optimizing fin geometry, spacing, and orientation requires sophisticated computational fluid dynamics modeling. Many designs that appear theoretically sound perform poorly in real-world applications due to unexpected airflow patterns, turbulence, or dead zones where heat accumulates. This disconnect between simulation and reality often leads to suboptimal thermal management.

Power density variations across components create hotspots that standard heat sink designs struggle to address. Modern processors and other high-performance components generate heat unevenly, with certain areas producing significantly more thermal energy than others. Conventional uniform heat sink designs fail to adequately manage these concentrated heat sources, leading to localized overheating despite acceptable average temperatures.

Environmental factors add another layer of complexity. Heat sinks must perform reliably across varying ambient temperatures, humidity levels, and altitudes. Designs optimized for controlled laboratory conditions often underperform in real-world environments where these factors fluctuate. Additionally, dust accumulation between fins progressively degrades thermal performance over time, a factor frequently overlooked during initial design phases.

Cost constraints often force compromises in heat sink design that impact long-term reliability. While more complex designs with vapor chambers or heat pipes offer superior performance, their higher manufacturing costs limit widespread adoption, particularly in consumer electronics where price sensitivity drives design decisions.

Material selection presents another significant challenge. Traditional aluminum and copper heat sinks offer good thermal conductivity but add considerable weight to devices. Advanced materials like graphene, carbon nanotubes, and metal matrix composites show promising thermal properties but remain costly for mass production and present manufacturing complexity. The industry continues to search for the optimal balance between thermal performance, weight, cost, and manufacturability.

Manufacturing precision significantly impacts heat sink effectiveness. Even minor imperfections in the contact surface between the heat sink and heat source can create air gaps that dramatically reduce thermal transfer efficiency. These microscopic imperfections, often invisible to the naked eye, can increase thermal resistance by up to 30%, negating the benefits of otherwise well-designed cooling solutions.

Complex airflow dynamics further complicate heat sink design. Optimizing fin geometry, spacing, and orientation requires sophisticated computational fluid dynamics modeling. Many designs that appear theoretically sound perform poorly in real-world applications due to unexpected airflow patterns, turbulence, or dead zones where heat accumulates. This disconnect between simulation and reality often leads to suboptimal thermal management.

Power density variations across components create hotspots that standard heat sink designs struggle to address. Modern processors and other high-performance components generate heat unevenly, with certain areas producing significantly more thermal energy than others. Conventional uniform heat sink designs fail to adequately manage these concentrated heat sources, leading to localized overheating despite acceptable average temperatures.

Environmental factors add another layer of complexity. Heat sinks must perform reliably across varying ambient temperatures, humidity levels, and altitudes. Designs optimized for controlled laboratory conditions often underperform in real-world environments where these factors fluctuate. Additionally, dust accumulation between fins progressively degrades thermal performance over time, a factor frequently overlooked during initial design phases.

Cost constraints often force compromises in heat sink design that impact long-term reliability. While more complex designs with vapor chambers or heat pipes offer superior performance, their higher manufacturing costs limit widespread adoption, particularly in consumer electronics where price sensitivity drives design decisions.

Contemporary Heat Sink Design Methodologies

01 Heat sink material selection for reliability

The choice of materials for heat sinks significantly impacts their reliability. Materials with high thermal conductivity, such as copper and aluminum alloys, are preferred for efficient heat dissipation. The material should also have good mechanical strength to withstand thermal cycling and physical stress. Additionally, materials resistant to corrosion and oxidation ensure longer operational life in various environmental conditions. The proper selection of heat sink materials balances thermal performance, weight considerations, and long-term reliability.- Material selection for heat sink reliability: The choice of materials significantly impacts heat sink reliability. Materials with high thermal conductivity, such as copper and aluminum alloys, improve heat dissipation efficiency. Corrosion-resistant materials extend the operational lifespan of heat sinks in harsh environments. Composite materials can provide both thermal performance and mechanical stability, enhancing overall reliability under various operating conditions.

- Thermal interface material optimization: Thermal interface materials (TIMs) play a crucial role in heat sink reliability by ensuring efficient heat transfer between the heat source and the heat sink. Optimizing TIM properties such as thermal conductivity, thickness, and long-term stability can significantly improve heat dissipation performance. Advanced TIMs that resist degradation over time, thermal cycling, and mechanical stress contribute to sustained heat sink reliability throughout the product lifecycle.

- Structural design for enhanced reliability: The structural design of heat sinks directly impacts their reliability. Fin geometry, spacing, and orientation affect thermal performance and resistance to mechanical stresses. Designs that minimize thermal expansion issues and prevent vibration-induced failures improve long-term reliability. Integrated mounting mechanisms that maintain consistent contact pressure without causing mechanical stress on components ensure reliable thermal performance over time.

- Cooling system integration and redundancy: Integrating heat sinks into comprehensive cooling systems with redundant features enhances overall reliability. Hybrid cooling approaches combining passive and active cooling methods provide fail-safe operation. Systems with multiple fans or cooling paths ensure continued operation if one component fails. Intelligent thermal management systems that adjust cooling performance based on operating conditions help maintain optimal temperatures and prevent thermal-related failures.

- Testing and quality assurance methods: Rigorous testing and quality assurance protocols are essential for ensuring heat sink reliability. Thermal cycling tests evaluate performance under varying temperature conditions. Accelerated aging tests predict long-term reliability. Vibration and shock testing ensures mechanical stability in challenging environments. Advanced simulation techniques help identify potential failure points before manufacturing, while statistical process control during production maintains consistent quality and reliability.

02 Thermal interface material optimization

The reliability of heat sinks depends significantly on the thermal interface materials (TIMs) used between the heat source and the heat sink. Optimizing these materials reduces thermal resistance and improves heat transfer efficiency. Advanced TIMs include phase-change materials, thermal greases, adhesives, and metal-based compounds that maintain performance over time. Proper application techniques and thickness control are essential to prevent air gaps and ensure consistent thermal conductivity throughout the operational life of the device, enhancing overall heat sink reliability.Expand Specific Solutions03 Heat sink design for thermal stress management

The design of heat sinks plays a crucial role in managing thermal stress and ensuring reliability. Features such as fin geometry, spacing, and orientation affect heat dissipation efficiency. Designs that accommodate thermal expansion and contraction reduce mechanical stress on components. Advanced designs incorporate variable fin density, curved surfaces, and strategic mounting points to optimize airflow and heat distribution. Computational fluid dynamics simulations help predict thermal behavior and identify potential failure points, allowing for design improvements that enhance long-term reliability.Expand Specific Solutions04 Cooling system integration for enhanced reliability

Integrating heat sinks with complementary cooling systems significantly improves reliability. Combinations of passive and active cooling methods, such as fans, liquid cooling, or heat pipes, create redundancy and enhance thermal management. Proper integration considers airflow patterns, system pressure drops, and potential failure modes. Smart cooling systems with temperature sensors and variable-speed fans can adjust cooling capacity based on thermal load, preventing overheating during peak operations while conserving energy during lower demand periods, thus extending the operational life of electronic components.Expand Specific Solutions05 Environmental and operational testing for reliability validation

Comprehensive testing protocols are essential for validating heat sink reliability under various conditions. These include thermal cycling tests, humidity exposure, vibration testing, and accelerated life testing. Environmental chambers simulate extreme operating conditions to identify potential failure modes. Thermal imaging and temperature sensors monitor performance during testing. Statistical analysis of test data helps establish reliability metrics and predict service life. Implementing standardized testing procedures ensures consistent quality and performance across different manufacturing batches, ultimately improving the long-term reliability of heat sink solutions.Expand Specific Solutions

Leading Heat Sink Manufacturers and Competitors

Heat sink design optimization is evolving rapidly in a maturing market estimated at $3.5-4 billion globally, with projected annual growth of 5-7%. The competitive landscape features established industrial giants like Siemens AG, Samsung Electronics, and Robert Bosch alongside specialized thermal management companies. Technical innovation is accelerating as companies respond to increasing device miniaturization and power density challenges. Industry leaders including Huawei Technologies, Furukawa Electric, and GLOBALFOUNDRIES are advancing solutions through computational fluid dynamics, novel materials integration, and AI-optimized designs. The market is transitioning from standardized solutions toward customized thermal management systems that significantly enhance device reliability through improved heat dissipation efficiency, reduced thermal resistance, and extended component lifespan.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced heat sink solutions incorporating bionic designs inspired by natural cooling systems. Their technology utilizes vapor chamber cooling with ultra-thin microchannels that increase surface area by up to 40% compared to traditional designs. The company implements computational fluid dynamics (CFD) simulations to optimize airflow patterns and heat distribution, resulting in thermal resistance reduction of approximately 30%. Huawei's heat sinks feature composite materials combining copper cores with aluminum fins, optimizing both thermal conductivity and weight. Their designs incorporate phase-change materials (PCMs) that absorb heat during peak loads and release it during lower demand periods, effectively managing temperature fluctuations. Additionally, Huawei employs AI-driven thermal management systems that dynamically adjust cooling performance based on real-time device usage patterns and environmental conditions.

Strengths: Superior thermal efficiency through bionic design principles and advanced materials; comprehensive simulation-based optimization approach; integration with intelligent thermal management systems. Weaknesses: Higher manufacturing costs compared to conventional solutions; increased complexity requiring specialized production facilities; potential reliability concerns with newer composite materials under extended use conditions.

Siemens AG

Technical Solution: Siemens has developed comprehensive heat sink optimization solutions through their digital twin technology, which creates virtual models that simulate thermal behavior with over 95% accuracy compared to physical prototypes. Their approach incorporates generative design algorithms that explore thousands of possible heat sink configurations to identify optimal geometries based on specific thermal requirements and space constraints. Siemens utilizes advanced additive manufacturing techniques to produce complex heat sink structures with internal cooling channels that would be impossible to create using traditional manufacturing methods, improving thermal efficiency by up to 35%. Their thermal management systems integrate with industrial IoT platforms, enabling predictive maintenance based on thermal performance degradation patterns. Siemens has pioneered hybrid cooling solutions that combine passive heat sinks with microfluidic cooling channels, particularly effective for high-power density applications like industrial drives and power electronics. Their designs incorporate thermal expansion compensation mechanisms that maintain optimal thermal contact under varying temperature conditions.

Strengths: Unparalleled simulation capabilities through digital twin technology; ability to manufacture highly complex optimized geometries; comprehensive integration with industrial IoT ecosystems. Weaknesses: Solutions often require significant upfront investment in design and simulation infrastructure; higher complexity in implementation compared to standard cooling solutions; specialized expertise required for optimal deployment.

Key Innovations in Thermal Interface Materials

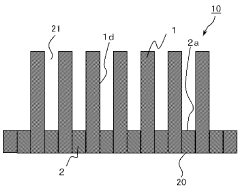

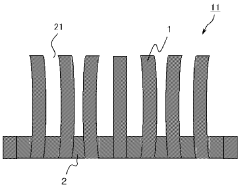

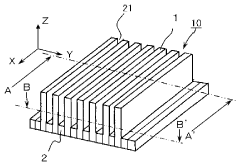

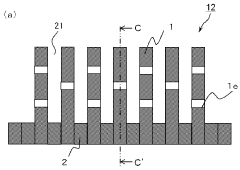

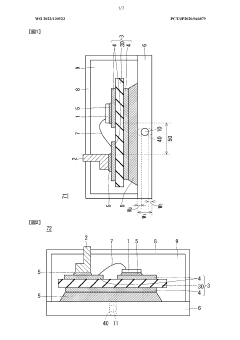

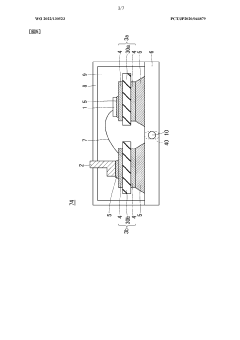

Heat sink and electronic component device provided with said heat sink

PatentWO2013115285A1

Innovation

- A heat sink design comprising multiple first plate-shaped bodies with a second plate-shaped body of lower height stacked between them, creating a fluid flow path, allowing for adjustable dimensions and enhanced heat dissipation characteristics through turbulence promotion and material selection for improved reliability.

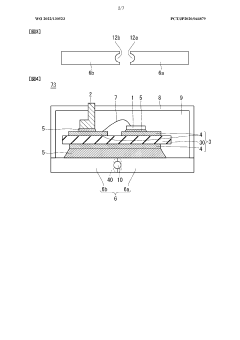

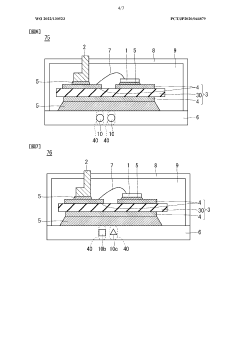

Semiconductor device, power conversion device, and mobile body

PatentWO2022130523A1

Innovation

- A semiconductor device design featuring a heat sink with a narrowed portion between the regions where the semiconductor element and the metal electrode are bonded, which suppresses heat transmission to the joint, improving reliability by using a heat sink with a narrower width in the thickness direction and potentially filling the narrowed area with a substance of lower thermal conductivity, such as air or resin.

Environmental Impact of Heat Sink Materials

The environmental impact of heat sink materials represents a critical consideration in sustainable technology development. Traditional heat sink materials such as aluminum and copper, while effective for thermal management, carry significant environmental footprints throughout their lifecycle. The extraction of these metals involves energy-intensive mining operations that contribute to habitat destruction, water pollution, and greenhouse gas emissions. Aluminum production particularly requires substantial electricity, with the global aluminum industry accounting for approximately 1% of worldwide carbon emissions.

Manufacturing processes for heat sinks further compound environmental concerns through high energy consumption and the generation of toxic byproducts. Chemical treatments and surface finishing techniques often employ hazardous substances that require careful disposal to prevent environmental contamination. The carbon footprint of heat sink production extends beyond manufacturing to include transportation logistics across global supply chains.

Recent industry trends show increasing adoption of eco-friendly alternatives and recycled materials. Recycled aluminum and copper heat sinks can reduce energy requirements by up to 95% and 85% respectively compared to virgin material production. Emerging composite materials incorporating graphene, carbon fiber, and phase-change materials offer promising thermal performance with potentially lower environmental impacts, though comprehensive lifecycle assessments remain limited.

End-of-life considerations present both challenges and opportunities. While metal heat sinks are theoretically highly recyclable, practical recovery rates are hampered by complex product designs that impede disassembly and material separation. The electronic waste stream containing heat sinks continues to grow at approximately 3-5% annually, creating urgent need for improved recycling infrastructure and design-for-disassembly approaches.

Regulatory frameworks increasingly influence material selection decisions. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations restrict certain materials and treatments in electronic components. Similarly, the Electronic Product Environmental Assessment Tool (EPEAT) and other green certification programs incentivize manufacturers to consider environmental impacts throughout product lifecycles.

Forward-looking heat sink design optimization must balance thermal performance requirements with environmental sustainability. This necessitates holistic approaches incorporating lifecycle assessment methodologies to quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life management. Such comprehensive evaluation enables meaningful comparisons between material choices and design alternatives to support environmentally responsible thermal management solutions.

Manufacturing processes for heat sinks further compound environmental concerns through high energy consumption and the generation of toxic byproducts. Chemical treatments and surface finishing techniques often employ hazardous substances that require careful disposal to prevent environmental contamination. The carbon footprint of heat sink production extends beyond manufacturing to include transportation logistics across global supply chains.

Recent industry trends show increasing adoption of eco-friendly alternatives and recycled materials. Recycled aluminum and copper heat sinks can reduce energy requirements by up to 95% and 85% respectively compared to virgin material production. Emerging composite materials incorporating graphene, carbon fiber, and phase-change materials offer promising thermal performance with potentially lower environmental impacts, though comprehensive lifecycle assessments remain limited.

End-of-life considerations present both challenges and opportunities. While metal heat sinks are theoretically highly recyclable, practical recovery rates are hampered by complex product designs that impede disassembly and material separation. The electronic waste stream containing heat sinks continues to grow at approximately 3-5% annually, creating urgent need for improved recycling infrastructure and design-for-disassembly approaches.

Regulatory frameworks increasingly influence material selection decisions. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations restrict certain materials and treatments in electronic components. Similarly, the Electronic Product Environmental Assessment Tool (EPEAT) and other green certification programs incentivize manufacturers to consider environmental impacts throughout product lifecycles.

Forward-looking heat sink design optimization must balance thermal performance requirements with environmental sustainability. This necessitates holistic approaches incorporating lifecycle assessment methodologies to quantify environmental impacts from raw material extraction through manufacturing, use, and end-of-life management. Such comprehensive evaluation enables meaningful comparisons between material choices and design alternatives to support environmentally responsible thermal management solutions.

Cost-Performance Analysis of Advanced Cooling Solutions

When evaluating advanced cooling solutions for electronic devices, cost-performance analysis becomes a critical factor in decision-making processes. The implementation of optimized heat sink designs requires careful consideration of both initial investment and long-term operational benefits. Traditional cooling methods often represent lower upfront costs but may lead to increased expenses over time due to reduced device reliability and higher maintenance requirements.

Advanced cooling solutions such as vapor chambers, liquid cooling systems, and phase-change materials typically demand higher initial investments compared to conventional heat sinks. For instance, vapor chamber technology can cost 30-50% more than traditional heat sinks but offers thermal resistance improvements of up to 20-30%. This performance enhancement directly translates to extended device lifespan and reduced failure rates, creating significant long-term value.

The return on investment (ROI) calculation for advanced cooling solutions must incorporate multiple factors beyond the immediate purchase price. These include energy efficiency improvements, reduced warranty claims, decreased downtime, and extended product lifecycles. Studies indicate that properly optimized cooling systems can reduce overall energy consumption by 5-15% in data center environments, representing substantial operational savings over a 3-5 year period.

Manufacturing scalability also plays a crucial role in the cost-performance equation. While cutting-edge cooling technologies may initially carry premium pricing due to specialized production processes, costs typically decrease as manufacturing techniques mature and production volumes increase. Industry data suggests that manufacturing costs for advanced heat sink designs can decrease by 15-25% when moving from prototype to mass production phases.

Material selection represents another significant cost-performance variable. While copper offers superior thermal conductivity compared to aluminum (385 W/m·K versus 205 W/m·K), it comes at approximately 3-4 times the cost. Hybrid solutions combining aluminum bases with copper inserts at critical thermal junction points often provide an optimal balance between performance and cost-effectiveness.

The total cost of ownership (TCO) model provides the most comprehensive framework for evaluating cooling solution investments. This approach factors in initial acquisition costs, installation expenses, operational efficiency, maintenance requirements, and end-of-life considerations. When properly analyzed, advanced cooling solutions frequently demonstrate superior TCO metrics despite higher upfront costs, particularly in high-performance computing, telecommunications, and industrial applications where device reliability directly impacts business operations.

Advanced cooling solutions such as vapor chambers, liquid cooling systems, and phase-change materials typically demand higher initial investments compared to conventional heat sinks. For instance, vapor chamber technology can cost 30-50% more than traditional heat sinks but offers thermal resistance improvements of up to 20-30%. This performance enhancement directly translates to extended device lifespan and reduced failure rates, creating significant long-term value.

The return on investment (ROI) calculation for advanced cooling solutions must incorporate multiple factors beyond the immediate purchase price. These include energy efficiency improvements, reduced warranty claims, decreased downtime, and extended product lifecycles. Studies indicate that properly optimized cooling systems can reduce overall energy consumption by 5-15% in data center environments, representing substantial operational savings over a 3-5 year period.

Manufacturing scalability also plays a crucial role in the cost-performance equation. While cutting-edge cooling technologies may initially carry premium pricing due to specialized production processes, costs typically decrease as manufacturing techniques mature and production volumes increase. Industry data suggests that manufacturing costs for advanced heat sink designs can decrease by 15-25% when moving from prototype to mass production phases.

Material selection represents another significant cost-performance variable. While copper offers superior thermal conductivity compared to aluminum (385 W/m·K versus 205 W/m·K), it comes at approximately 3-4 times the cost. Hybrid solutions combining aluminum bases with copper inserts at critical thermal junction points often provide an optimal balance between performance and cost-effectiveness.

The total cost of ownership (TCO) model provides the most comprehensive framework for evaluating cooling solution investments. This approach factors in initial acquisition costs, installation expenses, operational efficiency, maintenance requirements, and end-of-life considerations. When properly analyzed, advanced cooling solutions frequently demonstrate superior TCO metrics despite higher upfront costs, particularly in high-performance computing, telecommunications, and industrial applications where device reliability directly impacts business operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!