Heat Sink Design Optimization Using Advanced Simulation Techniques

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Optimization Goals

Thermal management has evolved significantly over the past decades, driven by the increasing power densities and miniaturization trends across various industries. In the 1960s and 1970s, thermal management primarily relied on natural convection and simple heat sink designs. The 1980s saw the introduction of forced convection cooling systems, while the 1990s brought liquid cooling solutions for high-performance applications. The early 2000s marked the beginning of advanced computational methods for thermal analysis, though these were limited by computational power and algorithm efficiency.

The past decade has witnessed a paradigm shift in heat sink design methodologies, moving from empirical approaches to sophisticated simulation-based optimization techniques. This transition has been fueled by advancements in computational fluid dynamics (CFD), finite element analysis (FEA), and machine learning algorithms, enabling more accurate predictions of thermal behavior under various operating conditions.

Current thermal management challenges stem from the exponential increase in power densities, particularly in electronics, aerospace, and automotive industries. Modern processors can generate heat fluxes exceeding 100 W/cm², pushing conventional cooling solutions to their limits. Additionally, the trend toward more compact and lightweight designs creates spatial constraints that further complicate thermal management strategies.

The primary optimization goals for heat sink design using advanced simulation techniques include maximizing heat dissipation efficiency while minimizing material usage, weight, and spatial footprint. Specific objectives encompass reducing thermal resistance by at least 20-30% compared to conventional designs, achieving uniform temperature distribution to eliminate hotspots, and minimizing pressure drop in fluid-based cooling systems to reduce pumping power requirements.

Another critical goal is developing multi-physics simulation capabilities that can simultaneously account for thermal, structural, and electromagnetic interactions, providing a more holistic approach to heat sink design. This integration aims to address the complex interdependencies between thermal performance and other system parameters.

Looking forward, the industry is moving toward real-time simulation capabilities that can adapt to changing thermal loads and environmental conditions, enabling dynamic optimization of cooling systems. The ultimate vision is to create self-optimizing thermal management solutions that can automatically adjust their configuration based on operational demands, representing a significant leap from traditional static designs to adaptive thermal management systems.

The past decade has witnessed a paradigm shift in heat sink design methodologies, moving from empirical approaches to sophisticated simulation-based optimization techniques. This transition has been fueled by advancements in computational fluid dynamics (CFD), finite element analysis (FEA), and machine learning algorithms, enabling more accurate predictions of thermal behavior under various operating conditions.

Current thermal management challenges stem from the exponential increase in power densities, particularly in electronics, aerospace, and automotive industries. Modern processors can generate heat fluxes exceeding 100 W/cm², pushing conventional cooling solutions to their limits. Additionally, the trend toward more compact and lightweight designs creates spatial constraints that further complicate thermal management strategies.

The primary optimization goals for heat sink design using advanced simulation techniques include maximizing heat dissipation efficiency while minimizing material usage, weight, and spatial footprint. Specific objectives encompass reducing thermal resistance by at least 20-30% compared to conventional designs, achieving uniform temperature distribution to eliminate hotspots, and minimizing pressure drop in fluid-based cooling systems to reduce pumping power requirements.

Another critical goal is developing multi-physics simulation capabilities that can simultaneously account for thermal, structural, and electromagnetic interactions, providing a more holistic approach to heat sink design. This integration aims to address the complex interdependencies between thermal performance and other system parameters.

Looking forward, the industry is moving toward real-time simulation capabilities that can adapt to changing thermal loads and environmental conditions, enabling dynamic optimization of cooling systems. The ultimate vision is to create self-optimizing thermal management solutions that can automatically adjust their configuration based on operational demands, representing a significant leap from traditional static designs to adaptive thermal management systems.

Market Analysis for Advanced Heat Sink Solutions

The global market for advanced heat sink solutions is experiencing robust growth, driven primarily by the increasing thermal management demands across multiple industries. The market size was valued at approximately $3.5 billion in 2022 and is projected to reach $5.2 billion by 2027, representing a compound annual growth rate (CAGR) of 8.3%. This growth trajectory is significantly influenced by the rapid expansion of data centers, telecommunications infrastructure, and high-performance computing applications.

Consumer electronics continues to be the largest application segment, accounting for nearly 35% of the total market share. The miniaturization trend in electronic devices, coupled with increasing processing power, has created substantial demand for efficient thermal management solutions. Smartphones, tablets, and laptops are key contributors to this segment's dominance.

The automotive sector represents the fastest-growing market segment, with an estimated CAGR of 12.7% through 2027. This acceleration is primarily attributed to the rising adoption of electric vehicles and advanced driver-assistance systems (ADAS), both requiring sophisticated thermal management to ensure optimal performance and longevity of electronic components.

Geographically, Asia-Pacific leads the market with approximately 42% share, followed by North America (28%) and Europe (21%). China and Taiwan dominate the manufacturing landscape, while significant R&D investments are concentrated in the United States, Germany, and Japan. The regional distribution closely mirrors the global electronics manufacturing ecosystem.

Industry analysis reveals a fragmented competitive landscape with over 200 manufacturers globally. However, the top ten players control approximately 65% of the market share. Recent market trends indicate increasing demand for customized thermal solutions tailored to specific applications rather than generic offerings.

Customer preferences are evolving toward lightweight, high-efficiency heat sinks with minimal space requirements. The willingness to pay premium prices for advanced thermal solutions has increased by 15% over the past three years, particularly in high-value applications such as medical devices, aerospace, and military equipment.

Market forecasts suggest that liquid cooling solutions will gain significant traction, potentially capturing 18% of the total heat sink market by 2025, up from 11% in 2022. This shift is driven by the limitations of traditional air cooling in managing extreme thermal loads in next-generation computing and power electronics applications.

Consumer electronics continues to be the largest application segment, accounting for nearly 35% of the total market share. The miniaturization trend in electronic devices, coupled with increasing processing power, has created substantial demand for efficient thermal management solutions. Smartphones, tablets, and laptops are key contributors to this segment's dominance.

The automotive sector represents the fastest-growing market segment, with an estimated CAGR of 12.7% through 2027. This acceleration is primarily attributed to the rising adoption of electric vehicles and advanced driver-assistance systems (ADAS), both requiring sophisticated thermal management to ensure optimal performance and longevity of electronic components.

Geographically, Asia-Pacific leads the market with approximately 42% share, followed by North America (28%) and Europe (21%). China and Taiwan dominate the manufacturing landscape, while significant R&D investments are concentrated in the United States, Germany, and Japan. The regional distribution closely mirrors the global electronics manufacturing ecosystem.

Industry analysis reveals a fragmented competitive landscape with over 200 manufacturers globally. However, the top ten players control approximately 65% of the market share. Recent market trends indicate increasing demand for customized thermal solutions tailored to specific applications rather than generic offerings.

Customer preferences are evolving toward lightweight, high-efficiency heat sinks with minimal space requirements. The willingness to pay premium prices for advanced thermal solutions has increased by 15% over the past three years, particularly in high-value applications such as medical devices, aerospace, and military equipment.

Market forecasts suggest that liquid cooling solutions will gain significant traction, potentially capturing 18% of the total heat sink market by 2025, up from 11% in 2022. This shift is driven by the limitations of traditional air cooling in managing extreme thermal loads in next-generation computing and power electronics applications.

Current Simulation Techniques and Limitations

Current heat sink design optimization relies heavily on computational fluid dynamics (CFD) and finite element analysis (FEA) simulations. These techniques have evolved significantly over the past decade, allowing engineers to model complex thermal behaviors with increasing accuracy. Traditional CFD approaches utilize Reynolds-Averaged Navier-Stokes (RANS) equations to simulate fluid flow and heat transfer around heat sink geometries, while FEA methods focus on conduction within the solid components.

Despite these advancements, current simulation techniques face several critical limitations. Computational resource requirements remain substantial, with high-fidelity simulations often requiring hours or days to complete even on powerful workstations. This creates a bottleneck in the iterative design process, limiting the number of design variations that can be practically evaluated within project timeframes.

Accuracy challenges persist, particularly at the interface between fluid and solid domains where complex phenomena like boundary layer development and transition flows occur. Most commercial simulation packages struggle to accurately capture these effects without extensive mesh refinement, which further increases computational demands. Additionally, turbulence modeling remains an approximation science, with different models producing varying results for the same heat sink geometry.

Multi-physics integration represents another significant limitation. While thermal-fluid simulations have matured, their integration with structural, vibrational, and electromagnetic analyses remains cumbersome in most simulation environments. This siloed approach prevents holistic optimization that accounts for all relevant physical phenomena simultaneously.

Parameterization and automation capabilities in current simulation tools often lack the flexibility needed for true design exploration. Many tools require manual setup for each design iteration, making broad design space exploration prohibitively time-consuming. While some advanced tools offer design of experiments (DOE) capabilities, these typically require significant expertise to implement effectively.

Validation methodologies also present challenges, with simulation results frequently showing discrepancies when compared to physical prototypes. These discrepancies stem from idealized boundary conditions, material property assumptions, and manufacturing variations that are difficult to account for in simulation environments.

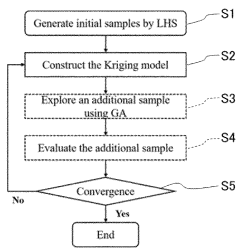

Emerging techniques like reduced-order modeling (ROM) and machine learning-enhanced simulations show promise in addressing some of these limitations, but remain in early adoption phases within the heat sink design community. These approaches aim to maintain accuracy while dramatically reducing computational requirements, potentially enabling real-time design optimization that current techniques cannot support.

Despite these advancements, current simulation techniques face several critical limitations. Computational resource requirements remain substantial, with high-fidelity simulations often requiring hours or days to complete even on powerful workstations. This creates a bottleneck in the iterative design process, limiting the number of design variations that can be practically evaluated within project timeframes.

Accuracy challenges persist, particularly at the interface between fluid and solid domains where complex phenomena like boundary layer development and transition flows occur. Most commercial simulation packages struggle to accurately capture these effects without extensive mesh refinement, which further increases computational demands. Additionally, turbulence modeling remains an approximation science, with different models producing varying results for the same heat sink geometry.

Multi-physics integration represents another significant limitation. While thermal-fluid simulations have matured, their integration with structural, vibrational, and electromagnetic analyses remains cumbersome in most simulation environments. This siloed approach prevents holistic optimization that accounts for all relevant physical phenomena simultaneously.

Parameterization and automation capabilities in current simulation tools often lack the flexibility needed for true design exploration. Many tools require manual setup for each design iteration, making broad design space exploration prohibitively time-consuming. While some advanced tools offer design of experiments (DOE) capabilities, these typically require significant expertise to implement effectively.

Validation methodologies also present challenges, with simulation results frequently showing discrepancies when compared to physical prototypes. These discrepancies stem from idealized boundary conditions, material property assumptions, and manufacturing variations that are difficult to account for in simulation environments.

Emerging techniques like reduced-order modeling (ROM) and machine learning-enhanced simulations show promise in addressing some of these limitations, but remain in early adoption phases within the heat sink design community. These approaches aim to maintain accuracy while dramatically reducing computational requirements, potentially enabling real-time design optimization that current techniques cannot support.

State-of-the-Art Heat Sink Design Methodologies

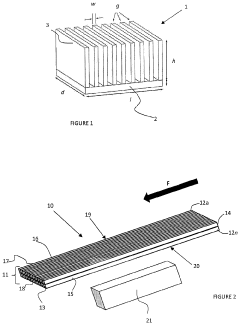

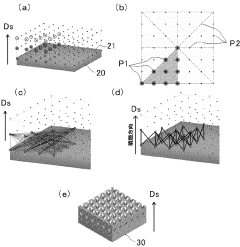

01 Heat sink geometry optimization

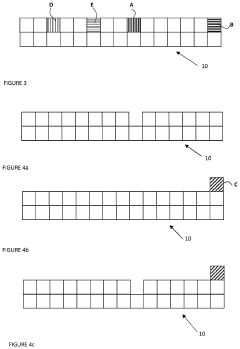

Optimizing the geometry of heat sinks can significantly improve thermal performance. This includes designing specialized fin structures, optimizing fin spacing, height, and thickness to maximize heat dissipation while minimizing material usage. Advanced designs may incorporate variable fin heights, curved surfaces, or asymmetrical patterns to direct airflow and enhance convection cooling. These geometric optimizations can lead to more efficient heat transfer and reduced thermal resistance.- Heat sink geometry optimization: Optimizing the geometry of heat sinks can significantly improve thermal performance. This includes designing specialized fin structures, optimizing fin spacing, height, and thickness to maximize heat dissipation while minimizing material usage. Advanced designs incorporate variable fin heights, curved surfaces, and customized shapes that enhance airflow and increase surface area for heat transfer, resulting in more efficient cooling solutions for electronic components.

- Material selection and composition for heat sinks: The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper, aluminum alloys, and composite materials are commonly used. Advanced heat sink designs incorporate novel materials such as metal matrix composites, phase change materials, and thermally enhanced polymers. Material selection considers factors including thermal conductivity, weight, cost, manufacturability, and compatibility with the application environment to achieve optimal thermal management.

- Surface treatment and coating technologies: Surface treatments and coatings can enhance heat sink performance by improving thermal radiation properties and protecting against environmental factors. Techniques include anodizing, micro-texturing, black oxide treatments, and application of specialized thermal coatings. These treatments can increase surface emissivity, reduce thermal resistance at interfaces, improve corrosion resistance, and enhance the overall heat dissipation efficiency of the heat sink system.

- Integration of advanced cooling technologies: Modern heat sink designs often incorporate advanced cooling technologies to enhance thermal performance. These include heat pipes, vapor chambers, liquid cooling channels, thermoelectric coolers, and phase change materials. Hybrid cooling solutions combine multiple technologies to address high heat flux applications. The integration of these technologies with traditional heat sinks creates more effective thermal management systems capable of handling increasing power densities in electronic devices.

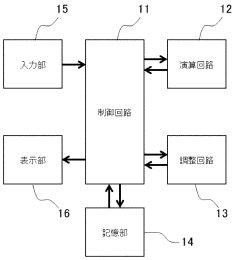

- Computational methods for heat sink design: Advanced computational methods are employed to optimize heat sink designs before physical prototyping. These include computational fluid dynamics (CFD) simulations, finite element analysis, topology optimization algorithms, and machine learning approaches. These tools enable engineers to predict thermal performance, analyze airflow patterns, identify hotspots, and iteratively optimize designs. Simulation-driven design processes reduce development time and cost while producing more efficient heat sink solutions.

02 Material selection and composition for heat sinks

The choice of materials significantly impacts heat sink performance. High thermal conductivity materials like copper, aluminum, and their alloys are commonly used. Composite materials combining metals with ceramics or carbon-based materials can offer improved thermal properties while reducing weight. Advanced material treatments and coatings can enhance surface properties for better heat dissipation. Material selection must balance thermal performance with considerations of weight, cost, manufacturability, and environmental factors.Expand Specific Solutions03 Integration of phase change materials and heat pipes

Incorporating phase change materials (PCMs) and heat pipes into heat sink designs can significantly enhance thermal management. Heat pipes utilize the evaporation and condensation of working fluids to transfer heat efficiently across distances. PCMs absorb and release thermal energy during phase transitions, helping to buffer temperature fluctuations. These technologies can be integrated into traditional heat sink structures to create hybrid cooling solutions that offer improved performance for applications with variable heat loads or space constraints.Expand Specific Solutions04 Computational methods for heat sink optimization

Advanced computational methods are employed to optimize heat sink designs. Computational Fluid Dynamics (CFD) simulations model airflow and heat transfer to predict thermal performance. Finite Element Analysis (FEA) evaluates structural integrity and thermal stress. Machine learning algorithms and genetic algorithms can rapidly explore design variations to identify optimal configurations. These computational approaches reduce development time and costs by minimizing physical prototyping while enabling more complex and efficient heat sink designs.Expand Specific Solutions05 Specialized heat sinks for electronic applications

Heat sinks designed for specific electronic applications feature tailored characteristics to address unique cooling challenges. For high-power electronics, heat sinks may incorporate active cooling elements like fans or liquid cooling channels. In compact devices, low-profile heat sinks with high-density fins maximize surface area within space constraints. For LED applications, heat sinks often integrate optical and thermal functions. These specialized designs consider factors such as airflow direction, mounting constraints, and thermal interface materials to optimize performance in their intended applications.Expand Specific Solutions

Leading Companies in Thermal Simulation Industry

The heat sink design optimization market is currently in a growth phase, with increasing demand driven by the need for efficient thermal management in electronics and power systems. The global market size is estimated to exceed $2 billion, expanding at a CAGR of 6-8% due to miniaturization trends and higher power densities. Leading players include established industrial giants like Siemens AG, Robert Bosch, and IBM, who leverage their extensive R&D capabilities, alongside specialized thermal solution providers such as Diabatix NV, which offers advanced AI-driven optimization software. The technology maturity varies significantly, with traditional companies like Furukawa Electric and Mitsubishi Electric focusing on material innovations, while newer entrants like Huawei Digital Power and ZTE are integrating computational fluid dynamics and machine learning to revolutionize simulation-based design approaches.

Diabatix NV

Technical Solution: Diabatix has developed ColdStream, an AI-powered generative design platform specifically for thermal management solutions. Their approach combines computational fluid dynamics (CFD) with topology optimization algorithms to create highly efficient heat sink designs. The platform utilizes machine learning to rapidly iterate through thousands of design possibilities, considering parameters such as material properties, flow conditions, and spatial constraints. Diabatix's technology can reduce the thermal design cycle from weeks to hours while achieving up to 30% better thermal performance compared to traditional designs. Their simulation techniques incorporate multi-physics modeling that simultaneously accounts for heat transfer, fluid dynamics, and structural integrity, enabling holistic optimization of heat sink performance.

Strengths: Significantly faster design cycle (reduction from weeks to hours); superior thermal performance (up to 30% improvement); AI-driven approach that continuously improves with more data. Weaknesses: Requires substantial computational resources; may have higher initial implementation costs; relies on quality of input data for accurate simulations.

Siemens AG

Technical Solution: Siemens has developed Simcenter, a comprehensive thermal simulation platform that integrates advanced heat sink optimization capabilities. Their solution employs a multi-fidelity approach combining 1D, 3D CFD (Computational Fluid Dynamics), and FEA (Finite Element Analysis) simulations to address thermal challenges across various scales. Siemens' technology incorporates digital twins for heat sink design, allowing engineers to virtually test multiple design iterations before physical prototyping. Their platform features parametric optimization algorithms that can automatically adjust fin geometry, spacing, material distribution, and orientation to maximize heat dissipation while minimizing material usage and pressure drop. Siemens has demonstrated up to 25% improvement in thermal performance while reducing material costs by 15-20% through their simulation-driven optimization approach.

Strengths: Comprehensive multi-physics simulation capabilities; seamless integration with broader product development workflows; extensive material libraries and validated simulation models. Weaknesses: Complex software ecosystem with steep learning curve; higher licensing costs compared to specialized solutions; may require significant computing infrastructure for large-scale optimizations.

Critical Simulation Algorithms and Models

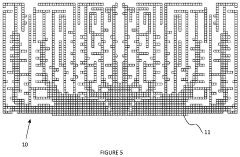

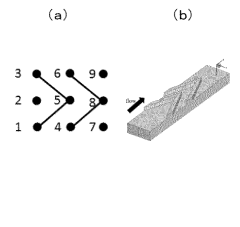

Heatsink configuration generation

PatentPendingUS20230169233A1

Innovation

- A method involving a computer-executed process that generates a heatsink configuration by iteratively removing and adding tessellated rods based on thermal evaluation parameters, allowing for the creation of non-parameterizable geometries that optimize thermal performance without relying on adjoint solutions or optimizers, using a combination of additive and subtractive techniques.

Heat sink design method and heat sink design program

PatentActiveJP2022161593A

Innovation

- A heat sink design method using a 3D structure composed of edges connecting three-dimensional nodes, optimized through graph theory, group search-based optimization algorithms, and response surface methods to enhance heat dissipation and reduce material costs.

Materials Innovation for Next-Generation Heat Sinks

The evolution of heat sink materials has reached a critical juncture where traditional materials can no longer meet the increasing thermal demands of modern electronic systems. Aluminum and copper, while historically dominant in heat sink applications, are approaching their theoretical limits in terms of thermal conductivity and weight-to-performance ratios. This necessitates exploration of novel materials that can provide superior thermal management capabilities for next-generation devices.

Advanced composite materials represent one of the most promising directions for heat sink innovation. Carbon-based composites, particularly those incorporating graphene and carbon nanotubes, demonstrate thermal conductivity values exceeding 2000 W/m·K—significantly surpassing copper's 400 W/m·K. These materials offer the additional advantage of reduced weight, making them ideal for applications where both thermal performance and weight constraints are critical considerations.

Metal matrix composites (MMCs) combining aluminum or copper matrices with high-conductivity reinforcements such as silicon carbide or diamond particles have shown remarkable improvements in thermal performance. Recent research indicates that aluminum-diamond composites can achieve thermal conductivity values up to 600 W/m·K while maintaining reasonable manufacturing costs for specialized applications. These materials effectively address the thermal expansion mismatch issues that often plague traditional heat sink designs.

Phase change materials (PCMs) integrated into heat sink structures represent another innovative approach. These materials absorb excess heat during peak operation by changing phase, typically from solid to liquid, and release it during lower power operation cycles. This capability enables more consistent temperature profiles and prevents thermal spikes that can damage sensitive electronic components. Recent developments in microencapsulation techniques have significantly improved the stability and lifespan of PCM-enhanced heat sinks.

Additive manufacturing technologies have revolutionized the potential for material customization in heat sink design. Multi-material 3D printing now enables the creation of functionally graded materials with spatially varying thermal properties, optimized for specific heat flow paths. This approach allows engineers to place high-conductivity materials precisely where thermal management is most critical, while using less expensive or lighter materials elsewhere.

Ceramic-based materials with enhanced thermal properties, such as aluminum nitride and boron nitride, offer excellent electrical insulation alongside good thermal conductivity. These materials are particularly valuable in applications where electrical isolation is as important as thermal management. Recent breakthroughs in sintering techniques have improved the thermal conductivity of these ceramics while reducing manufacturing costs.

Advanced composite materials represent one of the most promising directions for heat sink innovation. Carbon-based composites, particularly those incorporating graphene and carbon nanotubes, demonstrate thermal conductivity values exceeding 2000 W/m·K—significantly surpassing copper's 400 W/m·K. These materials offer the additional advantage of reduced weight, making them ideal for applications where both thermal performance and weight constraints are critical considerations.

Metal matrix composites (MMCs) combining aluminum or copper matrices with high-conductivity reinforcements such as silicon carbide or diamond particles have shown remarkable improvements in thermal performance. Recent research indicates that aluminum-diamond composites can achieve thermal conductivity values up to 600 W/m·K while maintaining reasonable manufacturing costs for specialized applications. These materials effectively address the thermal expansion mismatch issues that often plague traditional heat sink designs.

Phase change materials (PCMs) integrated into heat sink structures represent another innovative approach. These materials absorb excess heat during peak operation by changing phase, typically from solid to liquid, and release it during lower power operation cycles. This capability enables more consistent temperature profiles and prevents thermal spikes that can damage sensitive electronic components. Recent developments in microencapsulation techniques have significantly improved the stability and lifespan of PCM-enhanced heat sinks.

Additive manufacturing technologies have revolutionized the potential for material customization in heat sink design. Multi-material 3D printing now enables the creation of functionally graded materials with spatially varying thermal properties, optimized for specific heat flow paths. This approach allows engineers to place high-conductivity materials precisely where thermal management is most critical, while using less expensive or lighter materials elsewhere.

Ceramic-based materials with enhanced thermal properties, such as aluminum nitride and boron nitride, offer excellent electrical insulation alongside good thermal conductivity. These materials are particularly valuable in applications where electrical isolation is as important as thermal management. Recent breakthroughs in sintering techniques have improved the thermal conductivity of these ceramics while reducing manufacturing costs.

Energy Efficiency and Sustainability Considerations

The optimization of heat sink designs through advanced simulation techniques must inherently address energy efficiency and sustainability considerations, as these factors have become critical in modern engineering practices. Energy efficiency in heat sink design directly impacts the overall power consumption of electronic systems, with more efficient thermal management solutions reducing the need for active cooling mechanisms such as fans, which consume additional power.

From a sustainability perspective, material selection plays a crucial role in heat sink design optimization. Traditional heat sinks often utilize aluminum and copper due to their excellent thermal conductivity. However, the extraction and processing of these materials have significant environmental footprints. Advanced simulation techniques now enable engineers to explore alternative materials with lower environmental impact while maintaining thermal performance, including recycled metals, composite materials, and novel alloys specifically designed for thermal applications.

Life cycle assessment (LCA) has emerged as a valuable methodology when incorporated into heat sink design simulations. By analyzing the environmental impact from raw material extraction through manufacturing, use, and eventual disposal, engineers can make informed decisions that balance thermal performance with sustainability goals. Simulation tools that integrate LCA data provide a comprehensive view of a design's environmental impact beyond mere thermal efficiency metrics.

Manufacturing processes for heat sinks also present opportunities for energy conservation. Advanced simulations can optimize designs for manufacturing techniques that require less energy input, such as additive manufacturing or precision die casting, compared to traditional subtractive manufacturing methods. These simulations can predict material waste and energy consumption during production, allowing engineers to select the most sustainable manufacturing approach.

The longevity of heat sink solutions represents another critical sustainability factor. Simulations that account for thermal cycling, corrosion resistance, and mechanical stress over time help design heat sinks with extended operational lifespans. This reduces the frequency of replacement and associated resource consumption, particularly important in applications where heat sinks are integrated into systems with long expected service lives.

Weight optimization through simulation also contributes to sustainability in transportation applications. Lighter heat sink designs in vehicles, aircraft, and portable electronics reduce overall weight, decreasing fuel consumption and associated emissions. Advanced simulations can identify the minimum material required while maintaining thermal performance, creating lightweight yet effective thermal management solutions.

From a sustainability perspective, material selection plays a crucial role in heat sink design optimization. Traditional heat sinks often utilize aluminum and copper due to their excellent thermal conductivity. However, the extraction and processing of these materials have significant environmental footprints. Advanced simulation techniques now enable engineers to explore alternative materials with lower environmental impact while maintaining thermal performance, including recycled metals, composite materials, and novel alloys specifically designed for thermal applications.

Life cycle assessment (LCA) has emerged as a valuable methodology when incorporated into heat sink design simulations. By analyzing the environmental impact from raw material extraction through manufacturing, use, and eventual disposal, engineers can make informed decisions that balance thermal performance with sustainability goals. Simulation tools that integrate LCA data provide a comprehensive view of a design's environmental impact beyond mere thermal efficiency metrics.

Manufacturing processes for heat sinks also present opportunities for energy conservation. Advanced simulations can optimize designs for manufacturing techniques that require less energy input, such as additive manufacturing or precision die casting, compared to traditional subtractive manufacturing methods. These simulations can predict material waste and energy consumption during production, allowing engineers to select the most sustainable manufacturing approach.

The longevity of heat sink solutions represents another critical sustainability factor. Simulations that account for thermal cycling, corrosion resistance, and mechanical stress over time help design heat sinks with extended operational lifespans. This reduces the frequency of replacement and associated resource consumption, particularly important in applications where heat sinks are integrated into systems with long expected service lives.

Weight optimization through simulation also contributes to sustainability in transportation applications. Lighter heat sink designs in vehicles, aircraft, and portable electronics reduce overall weight, decreasing fuel consumption and associated emissions. Advanced simulations can identify the minimum material required while maintaining thermal performance, creating lightweight yet effective thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!