How Did PU Functionalization Evolve for Drug Eluting Devices?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Functionalization Evolution and Objectives

Polyurethane (PU) functionalization for drug-eluting devices has undergone significant evolution over the past few decades. This technological advancement has been driven by the increasing demand for more effective and controlled drug delivery systems in medical applications. The journey of PU functionalization began with simple surface modifications and has progressed to sophisticated molecular-level alterations.

In the early stages, researchers focused on enhancing the biocompatibility of PU surfaces to improve their interaction with biological systems. This was primarily achieved through physical and chemical surface treatments, such as plasma treatment and grafting of hydrophilic polymers. These initial efforts laid the foundation for more advanced functionalization techniques.

As the field progressed, the emphasis shifted towards creating PU materials with controlled drug release properties. This led to the development of various strategies for incorporating drugs into the PU matrix. Early approaches involved simple drug dispersion within the polymer, but this often resulted in burst release profiles and limited control over drug elution rates.

The next significant milestone in PU functionalization was the introduction of covalent bonding techniques. Researchers began to explore methods for chemically attaching drug molecules or pro-drug moieties directly to the PU backbone. This approach allowed for more precise control over drug release kinetics and improved the long-term stability of drug-eluting devices.

Recent advancements have focused on creating "smart" PU materials that can respond to specific stimuli or environmental cues. These include pH-responsive, temperature-sensitive, and enzyme-degradable PU systems. Such functionalized materials offer the potential for targeted and on-demand drug release, significantly enhancing the efficacy and safety of drug-eluting devices.

The evolution of PU functionalization has also seen a shift towards more sustainable and biocompatible approaches. There is growing interest in utilizing bio-based polyols and isocyanates in PU synthesis, as well as incorporating naturally derived molecules for functionalization. This trend aligns with the broader goals of developing environmentally friendly and biocompatible medical devices.

Looking forward, the objectives of PU functionalization for drug-eluting devices are multifaceted. Researchers aim to develop PU materials with even greater control over drug release profiles, improved long-term stability, and enhanced biocompatibility. There is also a push towards multi-functional PU systems that can simultaneously elute multiple drugs or combine drug delivery with other therapeutic functions.

In the early stages, researchers focused on enhancing the biocompatibility of PU surfaces to improve their interaction with biological systems. This was primarily achieved through physical and chemical surface treatments, such as plasma treatment and grafting of hydrophilic polymers. These initial efforts laid the foundation for more advanced functionalization techniques.

As the field progressed, the emphasis shifted towards creating PU materials with controlled drug release properties. This led to the development of various strategies for incorporating drugs into the PU matrix. Early approaches involved simple drug dispersion within the polymer, but this often resulted in burst release profiles and limited control over drug elution rates.

The next significant milestone in PU functionalization was the introduction of covalent bonding techniques. Researchers began to explore methods for chemically attaching drug molecules or pro-drug moieties directly to the PU backbone. This approach allowed for more precise control over drug release kinetics and improved the long-term stability of drug-eluting devices.

Recent advancements have focused on creating "smart" PU materials that can respond to specific stimuli or environmental cues. These include pH-responsive, temperature-sensitive, and enzyme-degradable PU systems. Such functionalized materials offer the potential for targeted and on-demand drug release, significantly enhancing the efficacy and safety of drug-eluting devices.

The evolution of PU functionalization has also seen a shift towards more sustainable and biocompatible approaches. There is growing interest in utilizing bio-based polyols and isocyanates in PU synthesis, as well as incorporating naturally derived molecules for functionalization. This trend aligns with the broader goals of developing environmentally friendly and biocompatible medical devices.

Looking forward, the objectives of PU functionalization for drug-eluting devices are multifaceted. Researchers aim to develop PU materials with even greater control over drug release profiles, improved long-term stability, and enhanced biocompatibility. There is also a push towards multi-functional PU systems that can simultaneously elute multiple drugs or combine drug delivery with other therapeutic functions.

Market Demand Analysis

The market demand for drug-eluting devices utilizing functionalized polyurethane (PU) has experienced significant growth over the past decade. This surge is primarily driven by the increasing prevalence of chronic diseases, such as cardiovascular disorders and diabetes, which require long-term drug delivery solutions. The global drug-eluting devices market, encompassing stents, implants, and other medical devices, has shown a steady compound annual growth rate (CAGR) of 5-7% in recent years.

Cardiovascular applications, particularly drug-eluting stents, represent the largest segment of this market. The rising incidence of coronary artery disease and the growing aging population have fueled the demand for these devices. Additionally, the orthopedic sector has witnessed substantial growth in drug-eluting implants, driven by the increasing number of joint replacement surgeries and the need for infection prevention.

The oncology field has also contributed to the market expansion, with a growing interest in localized drug delivery systems for cancer treatment. This trend is expected to continue as personalized medicine gains traction and targeted therapies become more prevalent.

Geographically, North America and Europe dominate the market due to advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, attributed to improving healthcare access and rising disposable incomes.

The market demand is further propelled by the advantages offered by PU functionalization in drug-eluting devices. These benefits include enhanced biocompatibility, improved drug release kinetics, and the ability to tailor surface properties for specific therapeutic applications. As a result, healthcare providers and patients are increasingly favoring these advanced devices over traditional alternatives.

Regulatory bodies' growing acceptance of drug-eluting devices has also positively impacted market demand. The FDA and EMA have established clearer guidelines for the approval of these devices, streamlining the path to market for manufacturers and encouraging innovation in the field.

Looking ahead, the market for PU-functionalized drug-eluting devices is projected to continue its upward trajectory. Factors such as the increasing focus on minimally invasive procedures, the rise of combination devices, and the ongoing research into novel drug delivery mechanisms are expected to drive further growth. Moreover, the potential applications of these devices in emerging fields like regenerative medicine and tissue engineering present exciting opportunities for market expansion in the coming years.

Cardiovascular applications, particularly drug-eluting stents, represent the largest segment of this market. The rising incidence of coronary artery disease and the growing aging population have fueled the demand for these devices. Additionally, the orthopedic sector has witnessed substantial growth in drug-eluting implants, driven by the increasing number of joint replacement surgeries and the need for infection prevention.

The oncology field has also contributed to the market expansion, with a growing interest in localized drug delivery systems for cancer treatment. This trend is expected to continue as personalized medicine gains traction and targeted therapies become more prevalent.

Geographically, North America and Europe dominate the market due to advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, attributed to improving healthcare access and rising disposable incomes.

The market demand is further propelled by the advantages offered by PU functionalization in drug-eluting devices. These benefits include enhanced biocompatibility, improved drug release kinetics, and the ability to tailor surface properties for specific therapeutic applications. As a result, healthcare providers and patients are increasingly favoring these advanced devices over traditional alternatives.

Regulatory bodies' growing acceptance of drug-eluting devices has also positively impacted market demand. The FDA and EMA have established clearer guidelines for the approval of these devices, streamlining the path to market for manufacturers and encouraging innovation in the field.

Looking ahead, the market for PU-functionalized drug-eluting devices is projected to continue its upward trajectory. Factors such as the increasing focus on minimally invasive procedures, the rise of combination devices, and the ongoing research into novel drug delivery mechanisms are expected to drive further growth. Moreover, the potential applications of these devices in emerging fields like regenerative medicine and tissue engineering present exciting opportunities for market expansion in the coming years.

Current Challenges in Drug Eluting Devices

Drug eluting devices have revolutionized medical treatments, particularly in cardiovascular interventions. However, several challenges persist in this field, hindering the full potential of these devices. One of the primary concerns is the long-term biocompatibility of the materials used. While polyurethane (PU) has been widely adopted due to its versatility, ensuring its prolonged compatibility with biological tissues remains a significant hurdle.

The controlled release of drugs from these devices presents another major challenge. Achieving a consistent and sustained drug release profile over extended periods is crucial for optimal therapeutic outcomes. Current technologies often struggle to maintain steady drug concentrations, leading to potential under- or over-dosing scenarios. This issue is particularly pronounced in devices intended for long-term implantation.

The degradation of polymer matrices used in drug eluting devices is a complex issue that researchers continue to grapple with. As these matrices break down, they can potentially release harmful byproducts or alter the drug release kinetics. Balancing the degradation rate with the desired drug release profile remains a delicate and often unpredictable process.

Another significant challenge lies in the limited drug-loading capacity of current materials. This constraint restricts the types and quantities of drugs that can be effectively incorporated into the devices. Enhancing the drug-loading capacity without compromising the mechanical properties or biocompatibility of the device is an ongoing area of research.

The potential for adverse biological responses, such as inflammation or thrombosis, continues to be a concern with drug eluting devices. Despite advancements in surface functionalization techniques, completely eliminating these risks remains elusive. The complex interplay between the device material, the eluted drug, and the biological environment presents a multifaceted challenge.

Manufacturing consistency and scalability pose additional hurdles in the development of drug eluting devices. Ensuring uniform drug distribution and consistent release profiles across large-scale production batches is technically demanding. This challenge is further compounded by the need to meet stringent regulatory requirements for medical devices.

Lastly, the development of drug eluting devices for diverse medical applications beyond cardiovascular interventions faces unique challenges. Each application, whether in orthopedics, ophthalmology, or other fields, presents distinct requirements in terms of drug selection, release kinetics, and device design. Adapting PU functionalization techniques to these varied contexts while maintaining efficacy and safety remains a significant challenge in the field.

The controlled release of drugs from these devices presents another major challenge. Achieving a consistent and sustained drug release profile over extended periods is crucial for optimal therapeutic outcomes. Current technologies often struggle to maintain steady drug concentrations, leading to potential under- or over-dosing scenarios. This issue is particularly pronounced in devices intended for long-term implantation.

The degradation of polymer matrices used in drug eluting devices is a complex issue that researchers continue to grapple with. As these matrices break down, they can potentially release harmful byproducts or alter the drug release kinetics. Balancing the degradation rate with the desired drug release profile remains a delicate and often unpredictable process.

Another significant challenge lies in the limited drug-loading capacity of current materials. This constraint restricts the types and quantities of drugs that can be effectively incorporated into the devices. Enhancing the drug-loading capacity without compromising the mechanical properties or biocompatibility of the device is an ongoing area of research.

The potential for adverse biological responses, such as inflammation or thrombosis, continues to be a concern with drug eluting devices. Despite advancements in surface functionalization techniques, completely eliminating these risks remains elusive. The complex interplay between the device material, the eluted drug, and the biological environment presents a multifaceted challenge.

Manufacturing consistency and scalability pose additional hurdles in the development of drug eluting devices. Ensuring uniform drug distribution and consistent release profiles across large-scale production batches is technically demanding. This challenge is further compounded by the need to meet stringent regulatory requirements for medical devices.

Lastly, the development of drug eluting devices for diverse medical applications beyond cardiovascular interventions faces unique challenges. Each application, whether in orthopedics, ophthalmology, or other fields, presents distinct requirements in terms of drug selection, release kinetics, and device design. Adapting PU functionalization techniques to these varied contexts while maintaining efficacy and safety remains a significant challenge in the field.

Current PU Functionalization Techniques

01 Polyurethane functionalization for controlled drug release

Polyurethane can be functionalized to control drug elution rates. This involves modifying the polymer structure to incorporate drug molecules or create specific binding sites. The functionalization can be achieved through various methods such as chemical modification, surface treatment, or incorporation of functional groups. This approach allows for tailored drug release profiles and improved biocompatibility.- Polyurethane functionalization for controlled drug release: Polyurethane can be functionalized to control drug elution rates. This involves modifying the polymer structure to incorporate drug-binding sites or create porous networks that allow for sustained release of therapeutic agents. The functionalization can be achieved through various methods such as chemical modification, surface treatment, or incorporation of specific functional groups.

- Drug-eluting polyurethane coatings for medical devices: Polyurethane coatings can be formulated to incorporate and release drugs over time. These coatings are often applied to medical devices such as stents, catheters, or implants to provide localized drug delivery. The drug release profile can be tailored by adjusting the polyurethane composition, crosslinking density, and drug loading.

- Nanocomposite polyurethane systems for drug delivery: Nanocomposite polyurethane systems can be developed by incorporating nanoparticles or nanostructures into the polymer matrix. These nanocomposites can enhance drug loading capacity, improve mechanical properties, and provide better control over drug release kinetics. Various types of nanoparticles, such as silica, clay, or carbon nanotubes, can be used to create these advanced drug delivery systems.

- Biodegradable polyurethane for drug elution: Biodegradable polyurethanes can be designed to break down over time while releasing encapsulated drugs. This approach is particularly useful for implantable drug delivery systems or tissue engineering applications. The degradation rate and drug release profile can be tuned by adjusting the polyurethane chemistry, incorporating hydrolyzable segments, or using enzyme-sensitive linkages.

- Stimuli-responsive polyurethane drug delivery systems: Polyurethane-based drug delivery systems can be engineered to respond to specific stimuli such as pH, temperature, or light. These smart materials can release drugs in a controlled manner in response to environmental cues or external triggers. This approach allows for targeted and on-demand drug release, improving therapeutic efficacy and reducing side effects.

02 Drug-eluting polyurethane coatings for medical devices

Polyurethane coatings can be formulated to incorporate and release drugs over time. These coatings are applied to medical devices such as stents, catheters, or implants to provide localized drug delivery. The drug elution characteristics can be controlled by adjusting the polyurethane composition, coating thickness, and drug loading. This approach enhances the therapeutic efficacy of medical devices while reducing systemic side effects.Expand Specific Solutions03 Nanocomposite polyurethane systems for drug delivery

Nanocomposite polyurethane systems can be developed for enhanced drug elution properties. These systems incorporate nanoparticles or nanostructures within the polyurethane matrix, creating a more complex and controllable drug release mechanism. The nanocomposites can improve drug loading capacity, provide sustained release, and offer additional functionalities such as targeted delivery or stimuli-responsive release.Expand Specific Solutions04 Biodegradable polyurethane for drug elution

Biodegradable polyurethane formulations can be designed for drug elution applications. These materials gradually break down in the body, releasing the incorporated drugs over time. The degradation rate can be tuned by adjusting the polymer composition and structure, allowing for controlled drug release profiles. This approach is particularly useful for long-term drug delivery systems and tissue engineering applications.Expand Specific Solutions05 Surface modification of polyurethane for improved drug elution

Surface modification techniques can be applied to polyurethane to enhance drug elution properties. These methods include plasma treatment, grafting of functional groups, or creation of porous structures on the polymer surface. Modified surfaces can improve drug loading capacity, control release kinetics, and enhance the interaction between the polymer and drug molecules. This approach allows for fine-tuning of drug elution characteristics without significantly altering the bulk properties of the polyurethane.Expand Specific Solutions

Key Players in PU Functionalization

The evolution of PU functionalization for drug-eluting devices has progressed significantly, reflecting a maturing industry with substantial market potential. The market is in a growth phase, driven by increasing demand for advanced medical technologies. Key players like Medtronic Vascular, Inc., Terumo Corp., and Abbott Cardiovascular Systems, Inc. have made significant strides in developing sophisticated drug-eluting technologies. The technical maturity varies, with established companies demonstrating advanced capabilities, while newer entrants like Glaukos Corp. and EyePoint Pharmaceuticals, Inc. are introducing innovative approaches. Academic institutions such as Sichuan University and Harvard College are contributing to fundamental research, pushing the boundaries of PU functionalization techniques. This collaborative ecosystem of industry leaders, emerging companies, and research institutions is driving rapid advancements in the field.

Terumo Corp.

Technical Solution: Terumo has developed the Ultimaster Tansei DES, which uses a bioresorbable polymer coating. The polymer gradually degrades over 3-4 months, releasing sirolimus to prevent restenosis. After drug elution, the polymer is fully absorbed, leaving a bare-metal stent. Terumo has also explored unique abluminal gradient coating technology, where the drug concentration is higher on the outer surface of the stent, allowing for more efficient drug delivery to the vessel wall.

Strengths: Innovative bioresorbable polymer technology with targeted drug delivery. Weaknesses: Relatively newer player in the DES market compared to some competitors.

Medtronic, Inc.

Technical Solution: Medtronic has developed advanced drug-eluting stents with polymer coatings that allow for controlled release of drugs. Their Resolute Onyx DES uses a biocompatible polymer that enhances drug delivery and reduces inflammation. The stent's core wire technology allows for thinner struts while maintaining radial strength. Medtronic has also explored bioresorbable polymer coatings that dissolve over time, leaving only the bare-metal stent behind after drug elution is complete.

Strengths: Industry leader with extensive R&D capabilities and clinical data. Weaknesses: Potential for long-term polymer-related complications.

Key Innovations in PU Functionalization

Porous silicon drug-eluting particles

PatentActiveUS20170128464A1

Innovation

- Biodegradable drug-eluting particles made from porous silicon, featuring a reservoir within a porous silicon body with an agent-permeable seal, allowing for controlled and sustained release of the agent, which then biodegrades into innocuous by-products, eliminating the need for surgical removal.

Drug-eluting films

PatentInactiveUS20120027833A1

Innovation

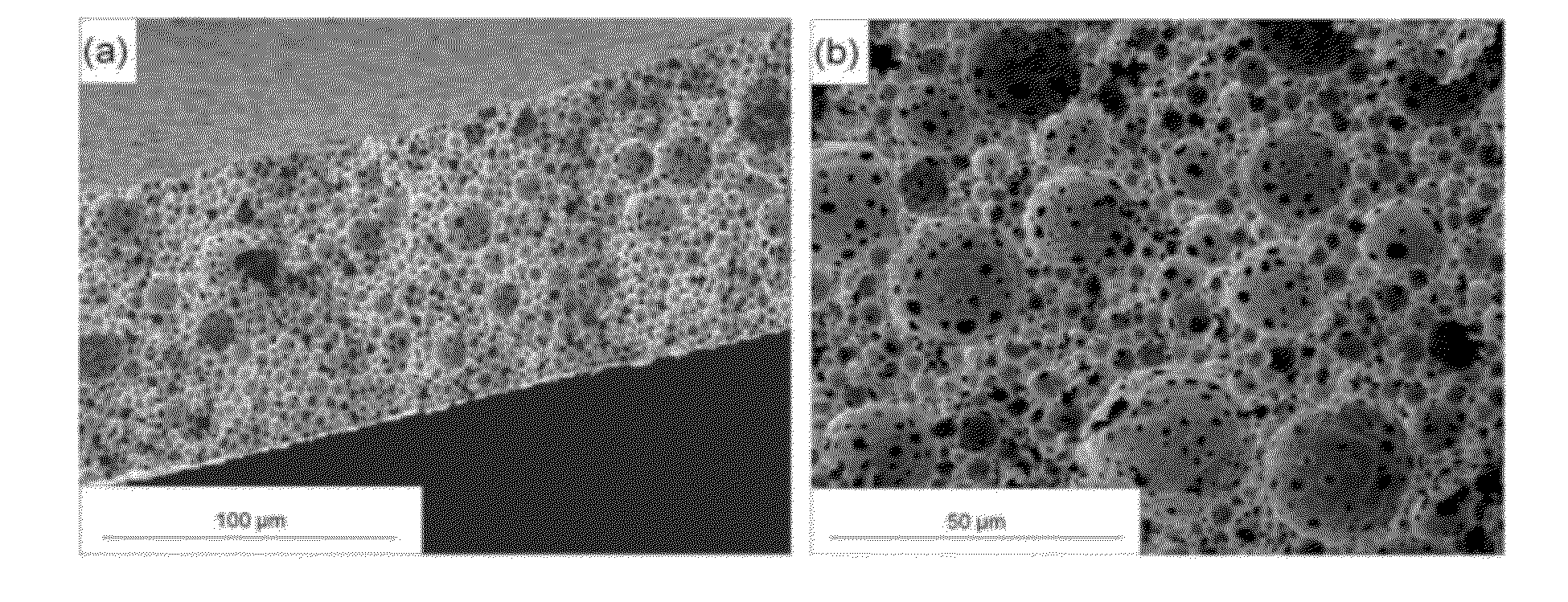

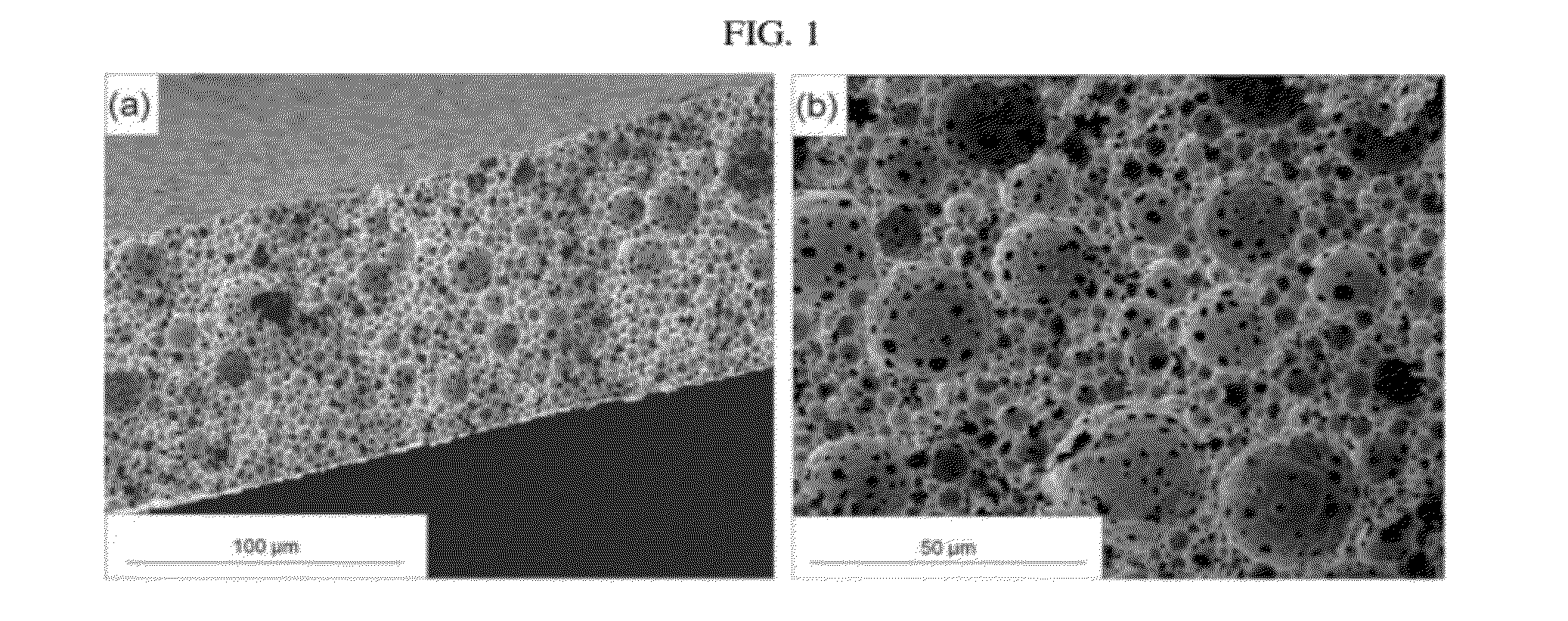

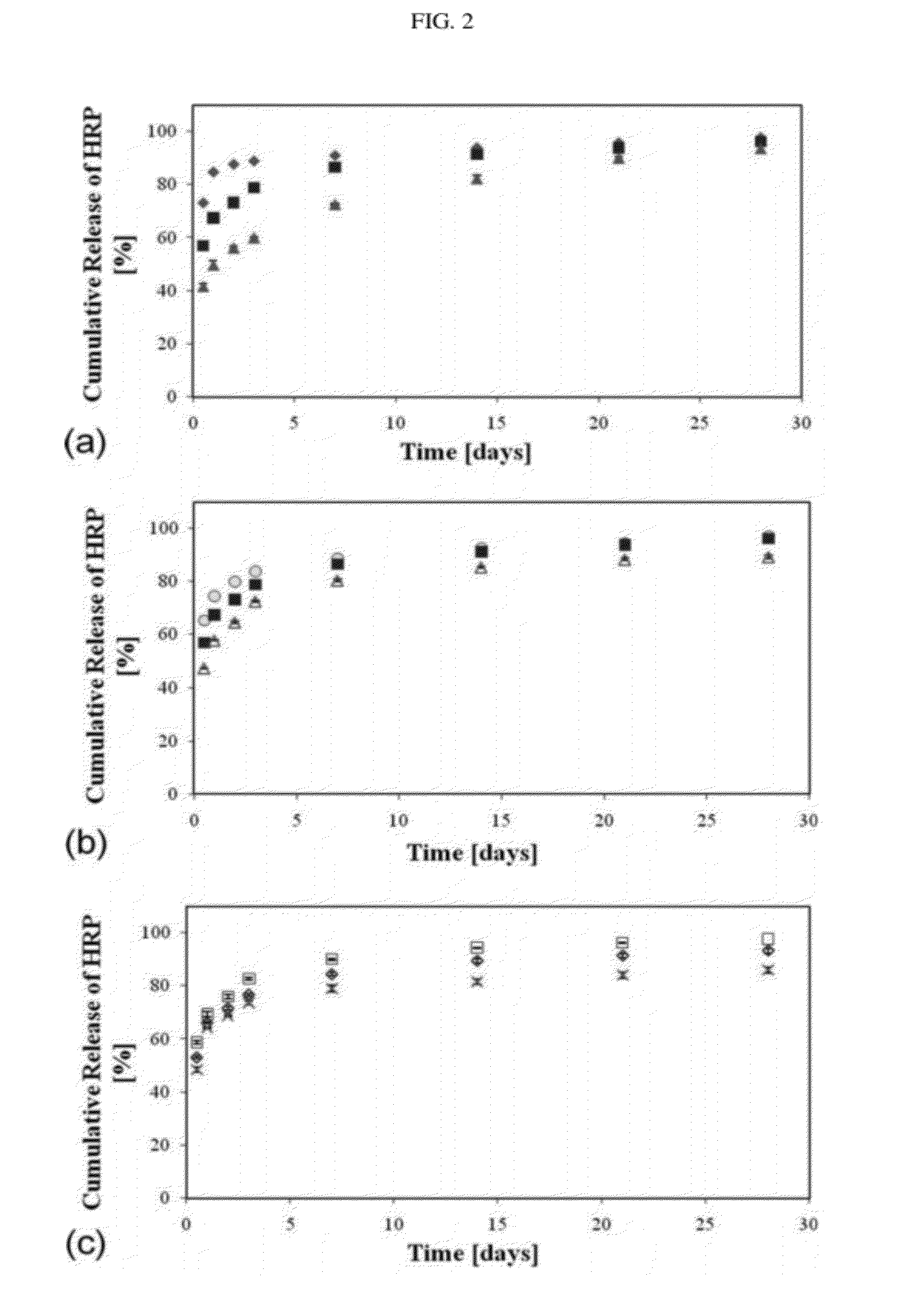

- The development of polymeric porous films prepared by freeze-drying inverted emulsions, where the composition, concentration, and homogenization parameters of the polymer and surfactant are optimized to control the release profile, allowing for high or low burst release of bioactive agents, and incorporating sensitive agents in the aqueous phase to prevent exposure to harsh solvents.

Regulatory Landscape

The regulatory landscape for drug-eluting devices incorporating functionalized polyurethane (PU) has evolved significantly over the years, reflecting the growing complexity and sophistication of these medical technologies. Initially, regulatory bodies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) approached these devices primarily from a materials safety perspective, focusing on the biocompatibility of PU and its potential degradation products.

As the field progressed, regulatory frameworks expanded to encompass the drug-eluting aspect of these devices. This shift necessitated a more comprehensive evaluation process, considering both the device's physical properties and its pharmacological effects. Regulatory agencies began requiring manufacturers to provide detailed data on drug release kinetics, long-term stability, and the potential for adverse interactions between the drug and the functionalized PU matrix.

The emergence of combination products, which integrate drugs, devices, and/or biological components, further complicated the regulatory landscape. In response, agencies like the FDA established specialized offices to handle these hybrid products, recognizing the need for expertise spanning multiple regulatory domains. This led to the development of more nuanced guidelines for premarket approval and post-market surveillance of drug-eluting devices.

International harmonization efforts, such as the International Medical Device Regulators Forum (IMDRF), have played a crucial role in standardizing regulatory approaches across different regions. These initiatives have helped streamline the approval process for manufacturers seeking to market their PU-based drug-eluting devices globally, while maintaining high standards of safety and efficacy.

Recent regulatory trends have focused on personalized medicine and adaptive clinical trial designs. This has implications for PU functionalization in drug-eluting devices, as regulators now expect manufacturers to demonstrate how their technologies can be tailored to specific patient populations or adapted based on real-world performance data.

Additionally, there has been an increased emphasis on post-market surveillance and real-world evidence collection. Regulatory bodies now require more robust long-term monitoring of drug-eluting devices to ensure their continued safety and effectiveness after market approval. This has led to the implementation of advanced tracking systems and the development of comprehensive registries for these devices.

As the field progressed, regulatory frameworks expanded to encompass the drug-eluting aspect of these devices. This shift necessitated a more comprehensive evaluation process, considering both the device's physical properties and its pharmacological effects. Regulatory agencies began requiring manufacturers to provide detailed data on drug release kinetics, long-term stability, and the potential for adverse interactions between the drug and the functionalized PU matrix.

The emergence of combination products, which integrate drugs, devices, and/or biological components, further complicated the regulatory landscape. In response, agencies like the FDA established specialized offices to handle these hybrid products, recognizing the need for expertise spanning multiple regulatory domains. This led to the development of more nuanced guidelines for premarket approval and post-market surveillance of drug-eluting devices.

International harmonization efforts, such as the International Medical Device Regulators Forum (IMDRF), have played a crucial role in standardizing regulatory approaches across different regions. These initiatives have helped streamline the approval process for manufacturers seeking to market their PU-based drug-eluting devices globally, while maintaining high standards of safety and efficacy.

Recent regulatory trends have focused on personalized medicine and adaptive clinical trial designs. This has implications for PU functionalization in drug-eluting devices, as regulators now expect manufacturers to demonstrate how their technologies can be tailored to specific patient populations or adapted based on real-world performance data.

Additionally, there has been an increased emphasis on post-market surveillance and real-world evidence collection. Regulatory bodies now require more robust long-term monitoring of drug-eluting devices to ensure their continued safety and effectiveness after market approval. This has led to the implementation of advanced tracking systems and the development of comprehensive registries for these devices.

Biocompatibility Considerations

Biocompatibility is a critical consideration in the evolution of polyurethane (PU) functionalization for drug-eluting devices. As these devices are designed to interact directly with biological systems, ensuring their safety and efficacy is paramount. The development of biocompatible PU materials has been a key focus in the field of biomaterials and medical device engineering.

Early PU functionalization efforts primarily concentrated on improving the material's surface properties to reduce protein adsorption and platelet adhesion. This was achieved through techniques such as grafting hydrophilic polymers onto the PU surface or incorporating bioactive molecules. These modifications aimed to minimize the foreign body response and reduce the risk of thrombosis, which are crucial factors in the long-term performance of implantable devices.

As research progressed, more sophisticated approaches to enhancing biocompatibility emerged. One significant advancement was the development of PU materials with controlled degradation rates. This allowed for the creation of drug-eluting devices that could gradually break down and be absorbed by the body over time, reducing the risk of long-term complications associated with permanent implants.

The incorporation of anti-inflammatory agents and growth factors into the PU matrix became another important strategy for improving biocompatibility. These bioactive molecules could be released in a controlled manner, promoting tissue healing and integration while minimizing the inflammatory response. This approach not only enhanced the overall performance of drug-eluting devices but also expanded their potential applications in various medical fields.

Recent advancements in PU functionalization have focused on creating "smart" materials that can respond to specific biological stimuli. These biomimetic PUs can adapt their properties based on changes in the local environment, such as pH or temperature fluctuations. This dynamic behavior allows for more precise control over drug release and improved integration with surrounding tissues, further enhancing biocompatibility.

Nanotechnology has also played a significant role in improving the biocompatibility of PU-based drug-eluting devices. The incorporation of nanoparticles or nanostructured surfaces has been shown to enhance cell adhesion, proliferation, and differentiation. These nanoscale modifications can mimic the natural extracellular matrix, providing a more favorable environment for tissue integration and reducing the risk of adverse reactions.

As the field continues to evolve, researchers are exploring new avenues for enhancing biocompatibility, such as the development of biohybrid materials that combine synthetic PUs with natural biomolecules. These innovative approaches aim to create drug-eluting devices that not only avoid harmful interactions with biological systems but actively promote healing and tissue regeneration.

Early PU functionalization efforts primarily concentrated on improving the material's surface properties to reduce protein adsorption and platelet adhesion. This was achieved through techniques such as grafting hydrophilic polymers onto the PU surface or incorporating bioactive molecules. These modifications aimed to minimize the foreign body response and reduce the risk of thrombosis, which are crucial factors in the long-term performance of implantable devices.

As research progressed, more sophisticated approaches to enhancing biocompatibility emerged. One significant advancement was the development of PU materials with controlled degradation rates. This allowed for the creation of drug-eluting devices that could gradually break down and be absorbed by the body over time, reducing the risk of long-term complications associated with permanent implants.

The incorporation of anti-inflammatory agents and growth factors into the PU matrix became another important strategy for improving biocompatibility. These bioactive molecules could be released in a controlled manner, promoting tissue healing and integration while minimizing the inflammatory response. This approach not only enhanced the overall performance of drug-eluting devices but also expanded their potential applications in various medical fields.

Recent advancements in PU functionalization have focused on creating "smart" materials that can respond to specific biological stimuli. These biomimetic PUs can adapt their properties based on changes in the local environment, such as pH or temperature fluctuations. This dynamic behavior allows for more precise control over drug release and improved integration with surrounding tissues, further enhancing biocompatibility.

Nanotechnology has also played a significant role in improving the biocompatibility of PU-based drug-eluting devices. The incorporation of nanoparticles or nanostructured surfaces has been shown to enhance cell adhesion, proliferation, and differentiation. These nanoscale modifications can mimic the natural extracellular matrix, providing a more favorable environment for tissue integration and reducing the risk of adverse reactions.

As the field continues to evolve, researchers are exploring new avenues for enhancing biocompatibility, such as the development of biohybrid materials that combine synthetic PUs with natural biomolecules. These innovative approaches aim to create drug-eluting devices that not only avoid harmful interactions with biological systems but actively promote healing and tissue regeneration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!