How Will PU–MXene Hybrids Enhance EMI Shielding?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU-MXene EMI Shielding Background and Objectives

Electromagnetic interference (EMI) shielding has become increasingly critical in modern electronics and communications systems. As devices become more compact and powerful, the need for effective EMI shielding materials has grown exponentially. In this context, the development of PU-MXene hybrids represents a significant advancement in the field of EMI shielding technology.

MXenes, a class of two-dimensional transition metal carbides and nitrides, have emerged as promising materials for EMI shielding due to their unique electrical and mechanical properties. When combined with polyurethane (PU), a versatile polymer known for its flexibility and durability, the resulting hybrids offer a synergistic blend of properties that can potentially revolutionize EMI shielding applications.

The primary objective of exploring PU-MXene hybrids for EMI shielding is to address the limitations of current shielding materials. Traditional metal-based shields, while effective, are often heavy, prone to corrosion, and difficult to integrate into complex designs. Polymer-based composites, on the other hand, typically lack the conductivity required for high-performance shielding. PU-MXene hybrids aim to bridge this gap by offering lightweight, flexible, and highly conductive materials that can be easily molded into various shapes and sizes.

The development of PU-MXene hybrids for EMI shielding is driven by several key technological trends. First, the miniaturization of electronic devices demands thinner and more efficient shielding materials. Second, the proliferation of wireless technologies and the impending rollout of 5G networks necessitate advanced EMI shielding solutions to prevent signal interference. Lastly, the growing emphasis on sustainable and environmentally friendly materials has spurred interest in alternatives to traditional metal-based shields.

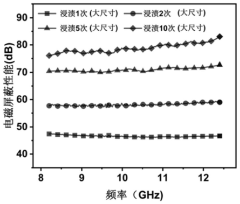

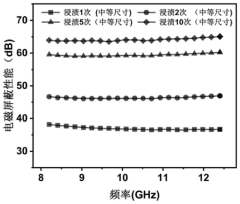

Research into PU-MXene hybrids for EMI shielding aims to achieve several specific goals. These include enhancing the overall shielding effectiveness across a wide frequency range, improving the mechanical properties of the composite materials, and developing scalable manufacturing processes for commercial applications. Additionally, researchers are exploring ways to optimize the dispersion of MXene sheets within the PU matrix to maximize conductivity and shielding performance.

The potential applications of PU-MXene hybrids extend beyond traditional electronics. These materials could find use in aerospace and automotive industries, where lightweight and effective EMI shielding is crucial. Moreover, the flexibility and moldability of PU-MXene composites make them attractive for wearable technology and smart textiles, where EMI shielding needs to be integrated seamlessly into fabric-like materials.

As research in this field progresses, it is expected that PU-MXene hybrids will play a significant role in addressing the growing challenges of electromagnetic compatibility in an increasingly connected world. The development of these advanced materials represents a convergence of materials science, nanotechnology, and electrical engineering, highlighting the interdisciplinary nature of modern technological advancements.

MXenes, a class of two-dimensional transition metal carbides and nitrides, have emerged as promising materials for EMI shielding due to their unique electrical and mechanical properties. When combined with polyurethane (PU), a versatile polymer known for its flexibility and durability, the resulting hybrids offer a synergistic blend of properties that can potentially revolutionize EMI shielding applications.

The primary objective of exploring PU-MXene hybrids for EMI shielding is to address the limitations of current shielding materials. Traditional metal-based shields, while effective, are often heavy, prone to corrosion, and difficult to integrate into complex designs. Polymer-based composites, on the other hand, typically lack the conductivity required for high-performance shielding. PU-MXene hybrids aim to bridge this gap by offering lightweight, flexible, and highly conductive materials that can be easily molded into various shapes and sizes.

The development of PU-MXene hybrids for EMI shielding is driven by several key technological trends. First, the miniaturization of electronic devices demands thinner and more efficient shielding materials. Second, the proliferation of wireless technologies and the impending rollout of 5G networks necessitate advanced EMI shielding solutions to prevent signal interference. Lastly, the growing emphasis on sustainable and environmentally friendly materials has spurred interest in alternatives to traditional metal-based shields.

Research into PU-MXene hybrids for EMI shielding aims to achieve several specific goals. These include enhancing the overall shielding effectiveness across a wide frequency range, improving the mechanical properties of the composite materials, and developing scalable manufacturing processes for commercial applications. Additionally, researchers are exploring ways to optimize the dispersion of MXene sheets within the PU matrix to maximize conductivity and shielding performance.

The potential applications of PU-MXene hybrids extend beyond traditional electronics. These materials could find use in aerospace and automotive industries, where lightweight and effective EMI shielding is crucial. Moreover, the flexibility and moldability of PU-MXene composites make them attractive for wearable technology and smart textiles, where EMI shielding needs to be integrated seamlessly into fabric-like materials.

As research in this field progresses, it is expected that PU-MXene hybrids will play a significant role in addressing the growing challenges of electromagnetic compatibility in an increasingly connected world. The development of these advanced materials represents a convergence of materials science, nanotechnology, and electrical engineering, highlighting the interdisciplinary nature of modern technological advancements.

Market Analysis for Advanced EMI Shielding Materials

The market for advanced EMI shielding materials, particularly PU-MXene hybrids, is experiencing significant growth driven by the increasing demand for electronic devices and the need for effective electromagnetic interference (EMI) protection. As the global electronics industry continues to expand, the EMI shielding market is projected to grow substantially in the coming years.

The proliferation of wireless technologies, including 5G networks, IoT devices, and high-speed electronics, has created a pressing need for advanced EMI shielding solutions. PU-MXene hybrids offer a promising alternative to traditional shielding materials due to their unique combination of properties, including high conductivity, flexibility, and lightweight nature.

In the automotive sector, the transition towards electric and autonomous vehicles is driving the demand for EMI shielding materials. These vehicles incorporate numerous electronic components and sensors that require protection from electromagnetic interference to ensure optimal performance and safety. PU-MXene hybrids are well-positioned to address this growing market segment.

The aerospace and defense industries also represent significant opportunities for advanced EMI shielding materials. With the increasing use of composite materials in aircraft construction and the integration of sophisticated electronic systems, there is a growing need for lightweight and effective EMI shielding solutions. PU-MXene hybrids offer potential advantages in terms of weight reduction and enhanced protection.

Consumer electronics remain a key driver of the EMI shielding market. As devices become smaller, more powerful, and increasingly interconnected, the need for effective EMI shielding becomes critical. PU-MXene hybrids can potentially offer improved shielding performance while allowing for thinner and lighter device designs.

The healthcare sector is emerging as a promising market for advanced EMI shielding materials. With the increasing use of electronic medical devices and the growing concern over electromagnetic radiation in healthcare settings, there is a rising demand for effective shielding solutions. PU-MXene hybrids could find applications in medical equipment and hospital environments.

Geographically, Asia-Pacific is expected to be the fastest-growing market for EMI shielding materials, driven by the region's robust electronics manufacturing industry and rapid technological advancements. North America and Europe are also significant markets, with strong demand from aerospace, defense, and automotive sectors.

While the market potential for PU-MXene hybrids in EMI shielding applications is substantial, challenges remain in terms of large-scale production, cost-effectiveness, and integration into existing manufacturing processes. Overcoming these hurdles will be crucial for widespread adoption and market penetration of this advanced material technology.

The proliferation of wireless technologies, including 5G networks, IoT devices, and high-speed electronics, has created a pressing need for advanced EMI shielding solutions. PU-MXene hybrids offer a promising alternative to traditional shielding materials due to their unique combination of properties, including high conductivity, flexibility, and lightweight nature.

In the automotive sector, the transition towards electric and autonomous vehicles is driving the demand for EMI shielding materials. These vehicles incorporate numerous electronic components and sensors that require protection from electromagnetic interference to ensure optimal performance and safety. PU-MXene hybrids are well-positioned to address this growing market segment.

The aerospace and defense industries also represent significant opportunities for advanced EMI shielding materials. With the increasing use of composite materials in aircraft construction and the integration of sophisticated electronic systems, there is a growing need for lightweight and effective EMI shielding solutions. PU-MXene hybrids offer potential advantages in terms of weight reduction and enhanced protection.

Consumer electronics remain a key driver of the EMI shielding market. As devices become smaller, more powerful, and increasingly interconnected, the need for effective EMI shielding becomes critical. PU-MXene hybrids can potentially offer improved shielding performance while allowing for thinner and lighter device designs.

The healthcare sector is emerging as a promising market for advanced EMI shielding materials. With the increasing use of electronic medical devices and the growing concern over electromagnetic radiation in healthcare settings, there is a rising demand for effective shielding solutions. PU-MXene hybrids could find applications in medical equipment and hospital environments.

Geographically, Asia-Pacific is expected to be the fastest-growing market for EMI shielding materials, driven by the region's robust electronics manufacturing industry and rapid technological advancements. North America and Europe are also significant markets, with strong demand from aerospace, defense, and automotive sectors.

While the market potential for PU-MXene hybrids in EMI shielding applications is substantial, challenges remain in terms of large-scale production, cost-effectiveness, and integration into existing manufacturing processes. Overcoming these hurdles will be crucial for widespread adoption and market penetration of this advanced material technology.

Current Challenges in PU-MXene Hybrid Development

The development of PU-MXene hybrids for EMI shielding faces several significant challenges that researchers and engineers must overcome to fully realize their potential. One of the primary obstacles is achieving uniform dispersion of MXene nanosheets within the polyurethane matrix. The tendency of MXene flakes to aggregate due to strong van der Waals interactions can lead to inconsistent shielding performance and compromised mechanical properties of the hybrid material.

Another critical challenge lies in maintaining the intrinsic properties of MXene during the hybridization process. The high electrical conductivity and excellent EMI shielding capability of MXene can be adversely affected by oxidation or chemical reactions with the polyurethane components. Preserving the structural integrity and functional characteristics of MXene while ensuring strong interfacial bonding with the PU matrix remains a complex balancing act.

The scalability of production processes for PU-MXene hybrids presents a significant hurdle for industrial applications. Current laboratory-scale synthesis methods often struggle to maintain consistency and quality when scaled up to meet commercial demands. Developing cost-effective and reliable large-scale production techniques is crucial for the widespread adoption of these materials in EMI shielding applications.

Durability and long-term stability of PU-MXene hybrids under various environmental conditions pose another challenge. Exposure to moisture, temperature fluctuations, and mechanical stress can potentially degrade the EMI shielding performance over time. Enhancing the resistance of these hybrids to environmental factors without compromising their shielding efficiency is an ongoing area of research.

The optimization of MXene loading in the PU matrix to achieve maximum EMI shielding effectiveness while maintaining desirable mechanical properties is a complex task. Excessive MXene content can lead to brittleness and reduced flexibility, while insufficient loading may not provide adequate shielding. Striking the right balance to meet both EMI shielding and mechanical requirements is crucial for practical applications.

Furthermore, the development of PU-MXene hybrids with multifunctional properties beyond EMI shielding, such as thermal management or self-healing capabilities, presents additional challenges. Integrating these functionalities without compromising the primary EMI shielding performance requires innovative material design and synthesis approaches.

Lastly, the environmental impact and recyclability of PU-MXene hybrids are growing concerns. Developing eco-friendly synthesis methods and exploring end-of-life recycling options for these materials are essential for ensuring their sustainability and compliance with increasingly stringent environmental regulations.

Another critical challenge lies in maintaining the intrinsic properties of MXene during the hybridization process. The high electrical conductivity and excellent EMI shielding capability of MXene can be adversely affected by oxidation or chemical reactions with the polyurethane components. Preserving the structural integrity and functional characteristics of MXene while ensuring strong interfacial bonding with the PU matrix remains a complex balancing act.

The scalability of production processes for PU-MXene hybrids presents a significant hurdle for industrial applications. Current laboratory-scale synthesis methods often struggle to maintain consistency and quality when scaled up to meet commercial demands. Developing cost-effective and reliable large-scale production techniques is crucial for the widespread adoption of these materials in EMI shielding applications.

Durability and long-term stability of PU-MXene hybrids under various environmental conditions pose another challenge. Exposure to moisture, temperature fluctuations, and mechanical stress can potentially degrade the EMI shielding performance over time. Enhancing the resistance of these hybrids to environmental factors without compromising their shielding efficiency is an ongoing area of research.

The optimization of MXene loading in the PU matrix to achieve maximum EMI shielding effectiveness while maintaining desirable mechanical properties is a complex task. Excessive MXene content can lead to brittleness and reduced flexibility, while insufficient loading may not provide adequate shielding. Striking the right balance to meet both EMI shielding and mechanical requirements is crucial for practical applications.

Furthermore, the development of PU-MXene hybrids with multifunctional properties beyond EMI shielding, such as thermal management or self-healing capabilities, presents additional challenges. Integrating these functionalities without compromising the primary EMI shielding performance requires innovative material design and synthesis approaches.

Lastly, the environmental impact and recyclability of PU-MXene hybrids are growing concerns. Developing eco-friendly synthesis methods and exploring end-of-life recycling options for these materials are essential for ensuring their sustainability and compliance with increasingly stringent environmental regulations.

Existing PU-MXene Hybrid Solutions for EMI Shielding

01 PU-MXene composite materials for EMI shielding

Polyurethane (PU) and MXene hybrid materials are developed for electromagnetic interference (EMI) shielding applications. These composites combine the flexibility and processability of PU with the excellent electrical conductivity and EMI shielding properties of MXene, resulting in lightweight and effective shielding materials.- PU-MXene composite materials for EMI shielding: Polyurethane (PU) and MXene hybrid materials are combined to create composite materials with enhanced electromagnetic interference (EMI) shielding properties. These composites leverage the flexibility and durability of PU with the excellent electrical conductivity and EMI shielding capabilities of MXene, resulting in lightweight and effective shielding materials for various applications.

- Fabrication methods for PU-MXene hybrid materials: Various fabrication techniques are employed to create PU-MXene hybrid materials for EMI shielding. These methods may include solution mixing, in-situ polymerization, and layer-by-layer assembly. The fabrication process is optimized to ensure uniform dispersion of MXene within the PU matrix, maximizing the shielding effectiveness of the resulting composite.

- Tuning EMI shielding performance through composition control: The EMI shielding performance of PU-MXene hybrids can be tuned by controlling the composition and ratio of the components. Adjusting the MXene content, PU molecular weight, and incorporating additional conductive fillers allows for optimization of the shielding effectiveness across a wide frequency range while maintaining desirable mechanical properties.

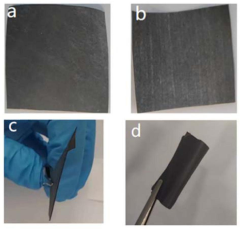

- Flexible and stretchable EMI shielding materials: PU-MXene hybrids are developed as flexible and stretchable EMI shielding materials for wearable electronics and conformal shielding applications. These materials maintain their shielding effectiveness under mechanical deformation, making them suitable for dynamic environments and integration into soft electronic devices.

- Multi-functional PU-MXene composites: PU-MXene hybrid materials are engineered to provide multiple functionalities beyond EMI shielding. These composites can offer additional properties such as thermal management, energy storage capabilities, and self-healing characteristics, making them versatile materials for advanced electronic and aerospace applications.

02 Fabrication methods for PU-MXene hybrid materials

Various fabrication techniques are employed to create PU-MXene hybrid materials, including solution mixing, in-situ polymerization, and layer-by-layer assembly. These methods aim to achieve uniform dispersion of MXene within the PU matrix and optimize the interfacial interactions between the components for enhanced EMI shielding performance.Expand Specific Solutions03 Structural design of PU-MXene composites for EMI shielding

The structural design of PU-MXene composites plays a crucial role in their EMI shielding effectiveness. Strategies such as creating multilayer structures, incorporating conductive networks, and optimizing the aspect ratio and orientation of MXene sheets within the PU matrix are explored to enhance the overall shielding performance.Expand Specific Solutions04 Surface modification and functionalization of MXene for improved compatibility with PU

Surface modification and functionalization techniques are applied to MXene to improve its compatibility with the PU matrix. These methods enhance the dispersion of MXene in PU and strengthen the interfacial interactions, leading to improved mechanical properties and EMI shielding performance of the resulting hybrid materials.Expand Specific Solutions05 Applications and performance evaluation of PU-MXene EMI shielding materials

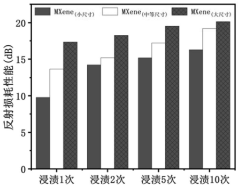

PU-MXene hybrid materials find applications in various fields requiring EMI shielding, such as electronics, aerospace, and healthcare. The performance of these materials is evaluated through measurements of shielding effectiveness, reflection loss, and absorption capabilities across different frequency ranges. Factors such as thickness, MXene content, and operating conditions are considered in assessing their practical applicability.Expand Specific Solutions

Key Players in PU-MXene Hybrid Research

The development of PU-MXene hybrids for EMI shielding is in its early stages, with significant potential for growth. The market size is expanding rapidly due to increasing demand for electromagnetic interference protection in various industries. Technologically, the field is evolving quickly, with several key players making advancements. Drexel University, a pioneer in MXene research, leads in fundamental developments. Companies like Murata Manufacturing Co. Ltd. are exploring commercial applications, while academic institutions such as Zhejiang University of Technology and Fudan University are contributing to material innovations. The collaboration between industry and academia, exemplified by partnerships like Chung Ang University Industry Academic Cooperation Foundation, is accelerating progress in this emerging field.

Shaanxi University of Science & Technology

Technical Solution: The university has developed a novel PU-MXene hybrid material for EMI shielding. Their approach involves incorporating MXene nanosheets into polyurethane matrices through a solution mixing method, followed by in-situ polymerization. This process creates a well-dispersed and interconnected MXene network within the PU matrix, significantly enhancing the EMI shielding effectiveness. The researchers have optimized the MXene content and fabrication parameters to achieve a balance between flexibility and shielding performance.

Strengths: High EMI shielding effectiveness, good flexibility, and lightweight nature. Weaknesses: Potential challenges in large-scale production and long-term stability of MXene in the polymer matrix.

Drexel University

Technical Solution: Drexel University, pioneers in MXene research, have developed advanced PU-MXene hybrids for EMI shielding. Their approach involves creating highly aligned MXene films within PU matrices using a vacuum-assisted filtration method. This technique results in a layered structure that maximizes the EMI shielding capabilities of MXenes while maintaining the flexibility of PU. The researchers have also explored surface functionalization of MXenes to improve their compatibility with PU, leading to enhanced interfacial interactions and overall performance.

Strengths: Excellent EMI shielding performance, highly oriented structure, and good mechanical properties. Weaknesses: Complex fabrication process and potential high cost for large-scale production.

Core Innovations in PU-MXene Hybrid Synthesis

Electrically tunable electromagnetic interference shielding devices with two-dimensional transition metal carbides and nitrides (mxenes)

PatentWO2023250136A3

Innovation

- Utilization of MXenes, a novel family of 2D transition metal carbides and nitrides, for tunable EMI shielding.

- Incorporation of an electrolyte-filled separator between two MXene portions to enable electrical tunability of EMI shielding effectiveness.

- Development of a thin, adaptive EMI protection device that can be controlled by applying an electrical potential.

Electromagnetic shielding composite material of impregnated fabric containing MXene nanosheets and rubber film and preparation method of electromagnetic shielding composite material

PatentPendingCN117656615A

Innovation

- MXene nanosheets of different sizes are combined with natural rubber membranes, and a double-layer structure is constructed by impregnating the fabric and hot pressing. The adhesion of natural rubber is used to combine with the fabric without external adhesive to form high conductivity and high flexibility. Electromagnetic shielding composite materials.

Environmental Impact of PU-MXene Hybrid Materials

The environmental impact of PU-MXene hybrid materials is a crucial consideration in their development and application for EMI shielding. These innovative composites, while offering superior electromagnetic interference (EMI) shielding capabilities, also present unique environmental challenges and opportunities throughout their lifecycle.

During the production phase, the synthesis of MXenes typically involves the use of strong acids and etching processes, which can generate hazardous waste. However, the integration of MXenes into polyurethane (PU) matrices may potentially reduce the overall environmental footprint compared to traditional metal-based EMI shielding materials. The polymer component, being organic, can be derived from renewable sources, potentially offsetting some of the environmental concerns associated with MXene production.

The durability and longevity of PU-MXene hybrids play a significant role in their environmental impact. These materials are expected to have extended lifespans due to their robust mechanical properties and resistance to environmental degradation. This longevity could lead to reduced waste generation and resource consumption over time, as fewer replacements would be needed compared to less durable shielding materials.

End-of-life considerations for PU-MXene hybrids are complex. While the polyurethane component can potentially be biodegradable or recyclable, depending on its specific formulation, the MXene component presents challenges for disposal or recycling. Research into effective separation and recovery methods for MXenes from the polymer matrix is ongoing, with the aim of enabling circular economy approaches for these advanced materials.

The lightweight nature of PU-MXene hybrids offers indirect environmental benefits, particularly in mobile and transportation applications. By reducing the overall weight of electronic devices or vehicles, these materials can contribute to improved fuel efficiency and reduced emissions in the use phase of products incorporating them.

Furthermore, the enhanced EMI shielding efficiency of PU-MXene hybrids may lead to a reduction in the quantity of shielding material required for effective protection. This could result in material savings and, consequently, a lower environmental impact in terms of resource extraction and processing.

However, the potential release of nanomaterials into the environment during the use or disposal of PU-MXene hybrids remains a concern. The long-term effects of MXene nanoparticles on ecosystems and human health are not yet fully understood, necessitating ongoing research and careful risk assessment.

During the production phase, the synthesis of MXenes typically involves the use of strong acids and etching processes, which can generate hazardous waste. However, the integration of MXenes into polyurethane (PU) matrices may potentially reduce the overall environmental footprint compared to traditional metal-based EMI shielding materials. The polymer component, being organic, can be derived from renewable sources, potentially offsetting some of the environmental concerns associated with MXene production.

The durability and longevity of PU-MXene hybrids play a significant role in their environmental impact. These materials are expected to have extended lifespans due to their robust mechanical properties and resistance to environmental degradation. This longevity could lead to reduced waste generation and resource consumption over time, as fewer replacements would be needed compared to less durable shielding materials.

End-of-life considerations for PU-MXene hybrids are complex. While the polyurethane component can potentially be biodegradable or recyclable, depending on its specific formulation, the MXene component presents challenges for disposal or recycling. Research into effective separation and recovery methods for MXenes from the polymer matrix is ongoing, with the aim of enabling circular economy approaches for these advanced materials.

The lightweight nature of PU-MXene hybrids offers indirect environmental benefits, particularly in mobile and transportation applications. By reducing the overall weight of electronic devices or vehicles, these materials can contribute to improved fuel efficiency and reduced emissions in the use phase of products incorporating them.

Furthermore, the enhanced EMI shielding efficiency of PU-MXene hybrids may lead to a reduction in the quantity of shielding material required for effective protection. This could result in material savings and, consequently, a lower environmental impact in terms of resource extraction and processing.

However, the potential release of nanomaterials into the environment during the use or disposal of PU-MXene hybrids remains a concern. The long-term effects of MXene nanoparticles on ecosystems and human health are not yet fully understood, necessitating ongoing research and careful risk assessment.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for PU-MXene hybrids in EMI shielding applications are crucial for their widespread adoption and commercial viability. One of the primary challenges lies in the large-scale production of MXene, which currently relies on manual etching and delamination processes. To address this, researchers are exploring automated synthesis methods and continuous flow production techniques to increase MXene yield and consistency.

For PU-MXene composite manufacturing, several scalable approaches are being investigated. Solution mixing and in-situ polymerization have shown promise for achieving uniform dispersion of MXene in the polymer matrix. However, these methods may face challenges in maintaining MXene's unique properties during processing. Melt compounding, a widely used industrial technique for polymer composites, is being adapted for PU-MXene systems, with a focus on optimizing processing parameters to prevent MXene degradation.

The development of spray coating and roll-to-roll manufacturing processes for PU-MXene films is gaining traction, offering potential for high-throughput production of EMI shielding materials. These techniques allow for precise control over film thickness and composition, which are critical for achieving optimal shielding performance. Additionally, 3D printing of PU-MXene composites is being explored for creating complex geometries and customized shielding solutions.

Quality control and characterization of PU-MXene hybrids at industrial scales present another set of challenges. Advanced inline monitoring techniques, such as real-time spectroscopy and electrical property measurements, are being developed to ensure consistent product quality. The stability and shelf life of PU-MXene composites under various environmental conditions are also being investigated to address long-term performance concerns.

Environmental and safety considerations in the manufacturing process are paramount. Efforts are underway to develop green synthesis routes for MXene production, reducing the use of hazardous etchants. For PU-MXene composite manufacturing, the focus is on minimizing solvent use and implementing efficient recycling systems to reduce environmental impact.

Cost-effectiveness remains a significant factor in scaling up production. Current research aims to optimize material utilization and streamline manufacturing processes to reduce overall production costs. This includes exploring alternative precursors for MXene synthesis and developing more efficient purification methods. As production scales up, economies of scale are expected to drive down costs, making PU-MXene hybrids more competitive in the EMI shielding market.

For PU-MXene composite manufacturing, several scalable approaches are being investigated. Solution mixing and in-situ polymerization have shown promise for achieving uniform dispersion of MXene in the polymer matrix. However, these methods may face challenges in maintaining MXene's unique properties during processing. Melt compounding, a widely used industrial technique for polymer composites, is being adapted for PU-MXene systems, with a focus on optimizing processing parameters to prevent MXene degradation.

The development of spray coating and roll-to-roll manufacturing processes for PU-MXene films is gaining traction, offering potential for high-throughput production of EMI shielding materials. These techniques allow for precise control over film thickness and composition, which are critical for achieving optimal shielding performance. Additionally, 3D printing of PU-MXene composites is being explored for creating complex geometries and customized shielding solutions.

Quality control and characterization of PU-MXene hybrids at industrial scales present another set of challenges. Advanced inline monitoring techniques, such as real-time spectroscopy and electrical property measurements, are being developed to ensure consistent product quality. The stability and shelf life of PU-MXene composites under various environmental conditions are also being investigated to address long-term performance concerns.

Environmental and safety considerations in the manufacturing process are paramount. Efforts are underway to develop green synthesis routes for MXene production, reducing the use of hazardous etchants. For PU-MXene composite manufacturing, the focus is on minimizing solvent use and implementing efficient recycling systems to reduce environmental impact.

Cost-effectiveness remains a significant factor in scaling up production. Current research aims to optimize material utilization and streamline manufacturing processes to reduce overall production costs. This includes exploring alternative precursors for MXene synthesis and developing more efficient purification methods. As production scales up, economies of scale are expected to drive down costs, making PU-MXene hybrids more competitive in the EMI shielding market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!