Sustainable Solutions in Polyurethane‑Based Manufacturing

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Sustainability Goals

The polyurethane (PU) industry is increasingly focusing on sustainability goals to address environmental concerns and regulatory pressures. These goals aim to reduce the environmental impact of PU manufacturing processes and products throughout their lifecycle. Key sustainability objectives include minimizing carbon footprint, reducing energy consumption, and promoting circular economy principles.

One primary goal is to decrease greenhouse gas emissions associated with PU production. This involves optimizing manufacturing processes to improve energy efficiency and exploring alternative energy sources such as renewable electricity. Companies are also investing in carbon capture and utilization technologies to mitigate emissions from production facilities.

Another crucial objective is to increase the use of bio-based and recycled raw materials in PU formulations. This includes developing bio-polyols derived from renewable resources like vegetable oils or agricultural waste, as well as incorporating post-consumer recycled content. By reducing reliance on fossil-based feedstocks, the industry aims to lower its overall environmental impact and promote resource conservation.

Water conservation is also a significant focus area. Sustainable PU manufacturing seeks to minimize water usage in production processes and implement closed-loop water recycling systems. Additionally, efforts are being made to reduce or eliminate the use of harmful chemicals and solvents, transitioning towards more environmentally friendly alternatives that comply with stringent regulations like REACH.

Enhancing product durability and recyclability is another key sustainability goal. This involves designing PU products for easier disassembly and recycling at the end of their life cycle. Research is ongoing to develop innovative recycling technologies that can efficiently break down PU materials into their chemical components for reuse in new products.

The industry is also working towards improving the energy efficiency of PU products in their use phase. This is particularly relevant for applications such as insulation materials, where enhanced thermal performance can significantly reduce energy consumption in buildings over the long term.

Lastly, there is a growing emphasis on transparency and lifecycle assessment. PU manufacturers are increasingly adopting standardized methodologies to measure and report the environmental impact of their products, enabling customers to make informed decisions based on sustainability criteria. This includes developing comprehensive Environmental Product Declarations (EPDs) and participating in industry-wide sustainability initiatives.

One primary goal is to decrease greenhouse gas emissions associated with PU production. This involves optimizing manufacturing processes to improve energy efficiency and exploring alternative energy sources such as renewable electricity. Companies are also investing in carbon capture and utilization technologies to mitigate emissions from production facilities.

Another crucial objective is to increase the use of bio-based and recycled raw materials in PU formulations. This includes developing bio-polyols derived from renewable resources like vegetable oils or agricultural waste, as well as incorporating post-consumer recycled content. By reducing reliance on fossil-based feedstocks, the industry aims to lower its overall environmental impact and promote resource conservation.

Water conservation is also a significant focus area. Sustainable PU manufacturing seeks to minimize water usage in production processes and implement closed-loop water recycling systems. Additionally, efforts are being made to reduce or eliminate the use of harmful chemicals and solvents, transitioning towards more environmentally friendly alternatives that comply with stringent regulations like REACH.

Enhancing product durability and recyclability is another key sustainability goal. This involves designing PU products for easier disassembly and recycling at the end of their life cycle. Research is ongoing to develop innovative recycling technologies that can efficiently break down PU materials into their chemical components for reuse in new products.

The industry is also working towards improving the energy efficiency of PU products in their use phase. This is particularly relevant for applications such as insulation materials, where enhanced thermal performance can significantly reduce energy consumption in buildings over the long term.

Lastly, there is a growing emphasis on transparency and lifecycle assessment. PU manufacturers are increasingly adopting standardized methodologies to measure and report the environmental impact of their products, enabling customers to make informed decisions based on sustainability criteria. This includes developing comprehensive Environmental Product Declarations (EPDs) and participating in industry-wide sustainability initiatives.

Green PU Market Demand

The demand for green polyurethane (PU) solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on sustainable manufacturing practices. This shift towards eco-friendly alternatives in the PU industry is primarily fueled by the need to reduce carbon footprint, minimize waste generation, and improve overall product lifecycle sustainability.

Market research indicates that the global green PU market is experiencing significant growth, with a projected compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth is attributed to the rising awareness among consumers and manufacturers about the environmental impact of traditional PU production methods and the increasing adoption of sustainable materials across various industries.

Key sectors driving the demand for green PU include construction, automotive, furniture, and packaging. In the construction industry, there is a growing preference for green PU-based insulation materials due to their energy-efficient properties and lower environmental impact. The automotive sector is increasingly incorporating green PU in interior components, seating, and lightweight parts to meet stringent emission standards and improve fuel efficiency.

The furniture industry is another major consumer of green PU, with manufacturers responding to consumer demand for eco-friendly and non-toxic materials in home and office furnishings. Similarly, the packaging sector is exploring green PU alternatives to reduce plastic waste and improve recyclability of packaging materials.

Geographically, Europe and North America are leading the adoption of green PU solutions, driven by stringent environmental regulations and consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, propelled by rapid industrialization, urbanization, and increasing environmental consciousness in countries like China and India.

Despite the growing demand, challenges remain in the widespread adoption of green PU. These include higher production costs compared to traditional PU, limited availability of bio-based raw materials, and the need for further technological advancements to improve performance characteristics. However, ongoing research and development efforts are focused on addressing these challenges, with innovations in bio-based polyols, recycling technologies, and water-based PU systems showing promising results.

As sustainability becomes a core focus for businesses across industries, the demand for green PU is expected to continue its upward trajectory. This trend is further supported by government initiatives promoting circular economy principles and the implementation of stricter environmental regulations globally. Manufacturers and suppliers in the PU industry are increasingly investing in sustainable solutions to meet this growing market demand and secure a competitive edge in the evolving landscape of environmentally conscious manufacturing.

Market research indicates that the global green PU market is experiencing significant growth, with a projected compound annual growth rate (CAGR) of over 7% from 2021 to 2026. This growth is attributed to the rising awareness among consumers and manufacturers about the environmental impact of traditional PU production methods and the increasing adoption of sustainable materials across various industries.

Key sectors driving the demand for green PU include construction, automotive, furniture, and packaging. In the construction industry, there is a growing preference for green PU-based insulation materials due to their energy-efficient properties and lower environmental impact. The automotive sector is increasingly incorporating green PU in interior components, seating, and lightweight parts to meet stringent emission standards and improve fuel efficiency.

The furniture industry is another major consumer of green PU, with manufacturers responding to consumer demand for eco-friendly and non-toxic materials in home and office furnishings. Similarly, the packaging sector is exploring green PU alternatives to reduce plastic waste and improve recyclability of packaging materials.

Geographically, Europe and North America are leading the adoption of green PU solutions, driven by stringent environmental regulations and consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, propelled by rapid industrialization, urbanization, and increasing environmental consciousness in countries like China and India.

Despite the growing demand, challenges remain in the widespread adoption of green PU. These include higher production costs compared to traditional PU, limited availability of bio-based raw materials, and the need for further technological advancements to improve performance characteristics. However, ongoing research and development efforts are focused on addressing these challenges, with innovations in bio-based polyols, recycling technologies, and water-based PU systems showing promising results.

As sustainability becomes a core focus for businesses across industries, the demand for green PU is expected to continue its upward trajectory. This trend is further supported by government initiatives promoting circular economy principles and the implementation of stricter environmental regulations globally. Manufacturers and suppliers in the PU industry are increasingly investing in sustainable solutions to meet this growing market demand and secure a competitive edge in the evolving landscape of environmentally conscious manufacturing.

PU Eco-Challenges

Polyurethane (PU) manufacturing faces significant environmental challenges due to its reliance on fossil-based raw materials and energy-intensive processes. The industry's ecological footprint is substantial, with concerns ranging from resource depletion to greenhouse gas emissions and waste generation.

One of the primary eco-challenges in PU production is the use of petroleum-derived polyols and isocyanates as key raw materials. These non-renewable resources contribute to the depletion of fossil fuels and increase the carbon footprint of PU products. Additionally, the production of isocyanates involves hazardous chemicals and generates toxic by-products, posing risks to both human health and the environment.

Energy consumption during PU manufacturing is another critical issue. The production process requires high temperatures and pressures, leading to significant energy use and associated carbon emissions. This energy-intensive nature of PU manufacturing contributes to climate change and conflicts with global efforts to reduce greenhouse gas emissions.

Waste management in PU production and end-of-life disposal presents further environmental challenges. PU foams, in particular, are difficult to recycle due to their complex chemical structure and the presence of additives. As a result, a large portion of PU waste ends up in landfills or is incinerated, contributing to soil and air pollution.

The use of chemical blowing agents in PU foam production, especially for insulation applications, has raised concerns about their global warming potential and ozone depletion effects. While many ozone-depleting substances have been phased out, some current alternatives still have significant environmental impacts.

Water pollution is another eco-challenge associated with PU manufacturing. The production process can generate wastewater containing various chemicals, including unreacted monomers, catalysts, and solvents. If not properly treated, this wastewater can contaminate water bodies and harm aquatic ecosystems.

The durability of PU products, while often seen as an advantage, also presents environmental challenges. Many PU-based materials have long degradation times, persisting in the environment for extended periods. This persistence contributes to the accumulation of plastic waste in ecosystems, particularly in marine environments.

Addressing these eco-challenges requires a multifaceted approach, including the development of bio-based and recycled raw materials, improvement of energy efficiency in manufacturing processes, and innovation in recycling and waste management technologies for PU products. The industry must also focus on developing safer alternatives to hazardous chemicals used in PU production and improving overall life cycle sustainability of PU-based products.

One of the primary eco-challenges in PU production is the use of petroleum-derived polyols and isocyanates as key raw materials. These non-renewable resources contribute to the depletion of fossil fuels and increase the carbon footprint of PU products. Additionally, the production of isocyanates involves hazardous chemicals and generates toxic by-products, posing risks to both human health and the environment.

Energy consumption during PU manufacturing is another critical issue. The production process requires high temperatures and pressures, leading to significant energy use and associated carbon emissions. This energy-intensive nature of PU manufacturing contributes to climate change and conflicts with global efforts to reduce greenhouse gas emissions.

Waste management in PU production and end-of-life disposal presents further environmental challenges. PU foams, in particular, are difficult to recycle due to their complex chemical structure and the presence of additives. As a result, a large portion of PU waste ends up in landfills or is incinerated, contributing to soil and air pollution.

The use of chemical blowing agents in PU foam production, especially for insulation applications, has raised concerns about their global warming potential and ozone depletion effects. While many ozone-depleting substances have been phased out, some current alternatives still have significant environmental impacts.

Water pollution is another eco-challenge associated with PU manufacturing. The production process can generate wastewater containing various chemicals, including unreacted monomers, catalysts, and solvents. If not properly treated, this wastewater can contaminate water bodies and harm aquatic ecosystems.

The durability of PU products, while often seen as an advantage, also presents environmental challenges. Many PU-based materials have long degradation times, persisting in the environment for extended periods. This persistence contributes to the accumulation of plastic waste in ecosystems, particularly in marine environments.

Addressing these eco-challenges requires a multifaceted approach, including the development of bio-based and recycled raw materials, improvement of energy efficiency in manufacturing processes, and innovation in recycling and waste management technologies for PU products. The industry must also focus on developing safer alternatives to hazardous chemicals used in PU production and improving overall life cycle sustainability of PU-based products.

Green PU Solutions

01 Bio-based polyurethane materials

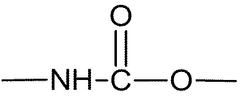

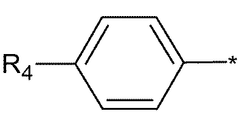

Sustainable polyurethane manufacturing involves the use of bio-based raw materials derived from renewable sources. These materials can replace traditional petroleum-based polyols and isocyanates, reducing the environmental impact of polyurethane production. Bio-based polyurethanes often exhibit comparable or superior properties to conventional polyurethanes while offering improved sustainability.- Bio-based polyurethane materials: Sustainable polyurethane manufacturing involves the use of bio-based raw materials derived from renewable resources. These materials can replace traditional petroleum-based polyols and isocyanates, reducing the environmental impact of polyurethane production. Bio-based polyurethanes often exhibit comparable or superior properties to conventional polyurethanes while offering improved sustainability.

- Recycling and upcycling of polyurethane waste: Sustainable polyurethane manufacturing incorporates recycling and upcycling processes for post-consumer and post-industrial polyurethane waste. These methods involve chemical or mechanical recycling techniques to break down polyurethane materials into their constituent components or to repurpose them for new applications, reducing waste and conserving resources.

- Energy-efficient production processes: Implementing energy-efficient production processes is crucial for sustainable polyurethane manufacturing. This includes optimizing reaction conditions, using advanced catalysts, and employing innovative equipment designs to reduce energy consumption during polyurethane synthesis and processing. These improvements lead to lower greenhouse gas emissions and reduced production costs.

- Water-based and solvent-free polyurethane systems: Sustainable polyurethane manufacturing focuses on developing water-based and solvent-free polyurethane systems. These formulations reduce or eliminate the use of volatile organic compounds (VOCs) and hazardous air pollutants, improving worker safety and minimizing environmental impact. Water-based polyurethanes also offer advantages in terms of ease of application and cleanup.

- Life cycle assessment and circular economy principles: Incorporating life cycle assessment (LCA) and circular economy principles into polyurethane manufacturing enhances sustainability. This approach considers the environmental impact of polyurethane products from raw material extraction to end-of-life disposal, promoting the use of renewable resources, minimizing waste generation, and designing products for easy disassembly and recycling.

02 Recycling and circular economy in polyurethane production

Implementing recycling processes and adopting circular economy principles in polyurethane manufacturing enhances sustainability. This includes developing methods for breaking down and reusing polyurethane waste, as well as designing products for easier disassembly and recycling at the end of their lifecycle. Such approaches reduce waste and minimize the need for virgin raw materials.Expand Specific Solutions03 Energy-efficient polyurethane manufacturing processes

Improving energy efficiency in polyurethane production processes is crucial for sustainability. This involves optimizing reaction conditions, developing low-temperature curing methods, and implementing advanced process control systems. Energy-efficient manufacturing reduces greenhouse gas emissions and overall environmental impact associated with polyurethane production.Expand Specific Solutions04 Water-based and solvent-free polyurethane systems

Developing water-based and solvent-free polyurethane systems contributes to sustainability by reducing volatile organic compound (VOC) emissions and minimizing the use of harmful solvents. These environmentally friendly formulations maintain the desired performance characteristics while improving worker safety and reducing environmental impact.Expand Specific Solutions05 Sustainable additives and fillers for polyurethane

Incorporating sustainable additives and fillers into polyurethane formulations enhances overall sustainability. This includes using natural fibers, recycled materials, or bio-based additives to improve specific properties or reduce the amount of synthetic materials required. These sustainable additives can contribute to improved biodegradability or reduced carbon footprint of the final polyurethane products.Expand Specific Solutions

Key PU Manufacturers

The research on sustainable solutions in polyurethane-based manufacturing is in a growth phase, with increasing market size driven by environmental concerns and regulatory pressures. The global polyurethane market is projected to reach significant value in the coming years. Technologically, the field is advancing rapidly, with major players like Covestro Deutschland AG, Dow Global Technologies LLC, and BASF Corp. leading innovation. These companies, along with others such as DuPont de Nemours, Inc. and Bayer AG, are investing heavily in developing bio-based polyols, recycling technologies, and more sustainable production processes. The competition is intense, with both established chemical giants and specialized firms like Resinate Materials Group, Inc. contributing to technological advancements in this sector.

Covestro Deutschland AG

Technical Solution: Covestro has developed a range of sustainable polyurethane solutions, including their cardyon® technology, which uses CO2 as a raw material to produce polyols. This innovative approach reduces the reliance on fossil-based resources and helps to close the carbon loop. The company has also introduced bio-based aniline for polyurethane production, derived from biomass instead of crude oil. Covestro's INSQIN® technology enables waterborne polyurethane coatings for textiles, reducing solvent use and improving worker safety. Additionally, their Bayflex® RIM Pultrusion technology allows for the production of lightweight, high-strength polyurethane composites for various industries.

Strengths: Pioneering CO2 utilization technology, diverse sustainable product range, strong focus on innovation. Weaknesses: High initial costs for implementing new technologies, potential scalability challenges for some solutions.

Dow Global Technologies LLC

Technical Solution: Dow has developed RENUVA™ Mattress Recycling Program, a circular economy initiative for polyurethane foam from end-of-life mattresses. This technology chemically recycles polyurethane foam into polyols, which can be used to create new polyurethane products. Dow also offers VORASURF™ polyurethane additives that enhance foam performance while reducing environmental impact. Their SPECFLEX™ Microcellular Polyurethane Systems provide lightweight, durable solutions for automotive applications, improving fuel efficiency and reducing emissions. Furthermore, Dow's VORAMER™ prepolymers enable the production of solvent-free, low-VOC polyurethane coatings and adhesives.

Strengths: Innovative recycling technologies, comprehensive product portfolio, strong market position. Weaknesses: Dependence on petrochemical feedstocks, potential regulatory challenges in different markets.

Bio-based PU Innovations

Polyol-based compounds

PatentWO2025058264A1

Innovation

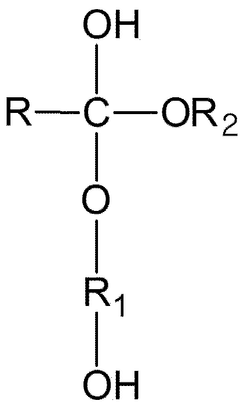

- Development of a new polyol compound derived from natural fatty acids or waste oils, synthesized through an eco-friendly method, which can be used as a soft segment component in polyurethane production.

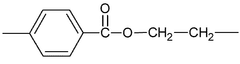

Sustainable polyester polyol compositions

PatentActiveUS20180030197A1

Innovation

- A polyester polyol composition made from digested thermoplastic polyester, glycol, castor oil, and ricinoleic acid, with specific weight percentages and hydroxyl functionality ranges, providing a sustainable and high-performance option for flexible polyurethane foams.

PU Recycling Strategies

Polyurethane (PU) recycling strategies have become increasingly important in the pursuit of sustainable manufacturing practices. The growing environmental concerns and regulatory pressures have driven the development of various recycling methods for PU-based products. These strategies can be broadly categorized into mechanical, chemical, and thermal recycling approaches.

Mechanical recycling involves grinding or shredding PU waste into smaller particles, which can then be reprocessed into new products. This method is particularly effective for thermoplastic polyurethanes (TPUs) and can be applied to both pre-consumer and post-consumer waste. The recycled material can be used as filler in new PU formulations or blended with virgin materials to create new products. However, mechanical recycling may result in some degradation of material properties, limiting its applications in high-performance products.

Chemical recycling, also known as feedstock recycling, breaks down PU waste into its chemical components through various processes such as glycolysis, hydrolysis, or aminolysis. This approach allows for the recovery of valuable raw materials, including polyols and isocyanates, which can be used to produce new PU products. Chemical recycling offers the advantage of maintaining material quality and enables the production of high-value recycled materials. However, it often requires more complex infrastructure and may involve higher processing costs compared to mechanical recycling.

Thermal recycling, or energy recovery, involves the incineration of PU waste to generate heat and electricity. While this method does not recover materials for reuse, it can be an effective way to manage PU waste that is not suitable for mechanical or chemical recycling. Advanced thermal recycling technologies, such as gasification and pyrolysis, can potentially recover valuable chemicals and reduce emissions compared to traditional incineration methods.

Emerging technologies in PU recycling include the development of bio-based and biodegradable polyurethanes, which can be more easily recycled or composted at the end of their life cycle. Additionally, advanced sorting and separation technologies are being developed to improve the efficiency of recycling processes and enable the recovery of higher-quality materials from mixed waste streams.

The implementation of effective PU recycling strategies requires collaboration across the value chain, from manufacturers to recyclers and end-users. Designing products for recyclability, establishing efficient collection and sorting systems, and developing markets for recycled materials are all crucial aspects of creating a circular economy for polyurethane-based products.

Mechanical recycling involves grinding or shredding PU waste into smaller particles, which can then be reprocessed into new products. This method is particularly effective for thermoplastic polyurethanes (TPUs) and can be applied to both pre-consumer and post-consumer waste. The recycled material can be used as filler in new PU formulations or blended with virgin materials to create new products. However, mechanical recycling may result in some degradation of material properties, limiting its applications in high-performance products.

Chemical recycling, also known as feedstock recycling, breaks down PU waste into its chemical components through various processes such as glycolysis, hydrolysis, or aminolysis. This approach allows for the recovery of valuable raw materials, including polyols and isocyanates, which can be used to produce new PU products. Chemical recycling offers the advantage of maintaining material quality and enables the production of high-value recycled materials. However, it often requires more complex infrastructure and may involve higher processing costs compared to mechanical recycling.

Thermal recycling, or energy recovery, involves the incineration of PU waste to generate heat and electricity. While this method does not recover materials for reuse, it can be an effective way to manage PU waste that is not suitable for mechanical or chemical recycling. Advanced thermal recycling technologies, such as gasification and pyrolysis, can potentially recover valuable chemicals and reduce emissions compared to traditional incineration methods.

Emerging technologies in PU recycling include the development of bio-based and biodegradable polyurethanes, which can be more easily recycled or composted at the end of their life cycle. Additionally, advanced sorting and separation technologies are being developed to improve the efficiency of recycling processes and enable the recovery of higher-quality materials from mixed waste streams.

The implementation of effective PU recycling strategies requires collaboration across the value chain, from manufacturers to recyclers and end-users. Designing products for recyclability, establishing efficient collection and sorting systems, and developing markets for recycled materials are all crucial aspects of creating a circular economy for polyurethane-based products.

PU Environmental Impact

Polyurethane (PU) manufacturing has significant environmental impacts that require urgent attention and sustainable solutions. The production process of PU involves the use of petrochemical-based raw materials, which contribute to resource depletion and greenhouse gas emissions. Additionally, the use of isocyanates in PU production poses health risks to workers and potential environmental hazards if not properly managed.

One of the primary environmental concerns associated with PU manufacturing is the release of volatile organic compounds (VOCs) during production and application processes. These emissions can lead to air pollution and contribute to the formation of ground-level ozone, a key component of smog. Furthermore, the disposal of PU products at the end of their lifecycle presents challenges, as many PU materials are not biodegradable and can persist in landfills for extended periods.

The energy-intensive nature of PU production also contributes to its environmental footprint. The synthesis of polyols and isocyanates, the two main components of PU, requires substantial energy inputs, often derived from fossil fuels. This reliance on non-renewable energy sources further exacerbates the carbon footprint of PU manufacturing.

Water pollution is another significant concern in PU production. The use of solvents and other chemicals in the manufacturing process can lead to the contamination of water sources if not properly treated and disposed of. This pollution can have detrimental effects on aquatic ecosystems and potentially impact human health through contaminated water supplies.

The durability of PU products, while often seen as an advantage, can also contribute to long-term environmental issues. Many PU-based materials, such as foams used in furniture and automotive applications, are difficult to recycle and often end up in landfills or incineration facilities. This disposal method not only wastes valuable resources but also releases harmful substances into the environment.

To address these environmental challenges, the PU industry is increasingly focusing on developing sustainable alternatives and improving production processes. This includes exploring bio-based raw materials to reduce reliance on petrochemicals, implementing more efficient manufacturing techniques to minimize energy consumption and emissions, and developing innovative recycling and upcycling methods for PU products at the end of their lifecycle.

One of the primary environmental concerns associated with PU manufacturing is the release of volatile organic compounds (VOCs) during production and application processes. These emissions can lead to air pollution and contribute to the formation of ground-level ozone, a key component of smog. Furthermore, the disposal of PU products at the end of their lifecycle presents challenges, as many PU materials are not biodegradable and can persist in landfills for extended periods.

The energy-intensive nature of PU production also contributes to its environmental footprint. The synthesis of polyols and isocyanates, the two main components of PU, requires substantial energy inputs, often derived from fossil fuels. This reliance on non-renewable energy sources further exacerbates the carbon footprint of PU manufacturing.

Water pollution is another significant concern in PU production. The use of solvents and other chemicals in the manufacturing process can lead to the contamination of water sources if not properly treated and disposed of. This pollution can have detrimental effects on aquatic ecosystems and potentially impact human health through contaminated water supplies.

The durability of PU products, while often seen as an advantage, can also contribute to long-term environmental issues. Many PU-based materials, such as foams used in furniture and automotive applications, are difficult to recycle and often end up in landfills or incineration facilities. This disposal method not only wastes valuable resources but also releases harmful substances into the environment.

To address these environmental challenges, the PU industry is increasingly focusing on developing sustainable alternatives and improving production processes. This includes exploring bio-based raw materials to reduce reliance on petrochemicals, implementing more efficient manufacturing techniques to minimize energy consumption and emissions, and developing innovative recycling and upcycling methods for PU products at the end of their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!