Polyurethane Foam Optimization for Insulation Efficiency

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Foam Insulation Background and Objectives

Polyurethane (PU) foam has emerged as a crucial material in the insulation industry, playing a pivotal role in enhancing energy efficiency across various sectors. The evolution of PU foam technology spans several decades, with continuous improvements in its formulation and application techniques. This technological progression has been driven by the growing demand for more effective thermal insulation solutions in construction, refrigeration, and automotive industries.

The primary objective of PU foam insulation optimization is to maximize its thermal resistance while minimizing material usage and environmental impact. This goal aligns with global efforts to reduce energy consumption and greenhouse gas emissions. The development of PU foam insulation has been influenced by stringent energy efficiency regulations and the increasing awareness of sustainable building practices.

Recent advancements in PU foam technology have focused on enhancing its cellular structure to improve insulation properties. Researchers and industry professionals are exploring novel blowing agents, catalysts, and additives to create foam with finer, more uniform cell structures. These innovations aim to reduce thermal conductivity and increase the overall R-value of the insulation material.

Another significant trend in PU foam optimization is the shift towards more environmentally friendly formulations. This includes the development of bio-based polyols and the use of low global warming potential (GWP) blowing agents. These efforts are in response to environmental concerns and regulatory pressures to phase out high-GWP substances previously used in foam production.

The optimization of PU foam for insulation efficiency also encompasses improvements in application techniques. Spray foam technologies have advanced, allowing for more precise and consistent foam application in various construction scenarios. Additionally, the development of pour-in-place and injected foam systems has expanded the versatility of PU foam insulation in different architectural designs and retrofit applications.

As we look towards the future, the objectives for PU foam insulation optimization are becoming increasingly ambitious. These include achieving higher thermal resistance with thinner foam layers, improving fire resistance properties, and enhancing long-term durability. There is also a growing focus on developing closed-loop recycling processes for PU foam, addressing end-of-life considerations and promoting a circular economy approach in the insulation industry.

The primary objective of PU foam insulation optimization is to maximize its thermal resistance while minimizing material usage and environmental impact. This goal aligns with global efforts to reduce energy consumption and greenhouse gas emissions. The development of PU foam insulation has been influenced by stringent energy efficiency regulations and the increasing awareness of sustainable building practices.

Recent advancements in PU foam technology have focused on enhancing its cellular structure to improve insulation properties. Researchers and industry professionals are exploring novel blowing agents, catalysts, and additives to create foam with finer, more uniform cell structures. These innovations aim to reduce thermal conductivity and increase the overall R-value of the insulation material.

Another significant trend in PU foam optimization is the shift towards more environmentally friendly formulations. This includes the development of bio-based polyols and the use of low global warming potential (GWP) blowing agents. These efforts are in response to environmental concerns and regulatory pressures to phase out high-GWP substances previously used in foam production.

The optimization of PU foam for insulation efficiency also encompasses improvements in application techniques. Spray foam technologies have advanced, allowing for more precise and consistent foam application in various construction scenarios. Additionally, the development of pour-in-place and injected foam systems has expanded the versatility of PU foam insulation in different architectural designs and retrofit applications.

As we look towards the future, the objectives for PU foam insulation optimization are becoming increasingly ambitious. These include achieving higher thermal resistance with thinner foam layers, improving fire resistance properties, and enhancing long-term durability. There is also a growing focus on developing closed-loop recycling processes for PU foam, addressing end-of-life considerations and promoting a circular economy approach in the insulation industry.

Market Analysis for High-Efficiency Insulation Materials

The global market for high-efficiency insulation materials has experienced significant growth in recent years, driven by increasing awareness of energy conservation and stringent building regulations. Polyurethane foam, a key player in this market, has gained substantial traction due to its superior insulation properties and versatility in application.

The demand for high-efficiency insulation materials is primarily fueled by the construction industry, particularly in residential and commercial buildings. As energy costs continue to rise and environmental concerns intensify, there is a growing emphasis on improving building energy efficiency. This trend is further reinforced by government initiatives and regulations aimed at reducing carbon emissions and promoting sustainable construction practices.

In the automotive sector, the need for lightweight materials with excellent insulation properties has also contributed to the market growth. Polyurethane foam's ability to provide thermal insulation while reducing vehicle weight aligns well with the industry's push for improved fuel efficiency and reduced emissions.

The market size for high-efficiency insulation materials is projected to expand significantly in the coming years. Factors such as urbanization, renovation of existing buildings, and the development of smart cities are expected to drive this growth. Additionally, the increasing adoption of green building standards and certifications is creating new opportunities for advanced insulation solutions.

Regionally, North America and Europe currently dominate the market, owing to their stringent building codes and high awareness of energy efficiency. However, the Asia-Pacific region is emerging as a lucrative market, with rapid industrialization and urbanization driving demand for insulation materials. Countries like China and India are expected to be key growth drivers in this region.

The competitive landscape of the high-efficiency insulation materials market is characterized by the presence of both established players and innovative startups. Major companies are investing heavily in research and development to improve the performance and sustainability of their products. There is a growing focus on developing bio-based and recyclable insulation materials to address environmental concerns and meet evolving customer preferences.

Challenges in the market include fluctuating raw material prices and the need for continuous innovation to meet increasingly stringent energy efficiency standards. However, these challenges also present opportunities for companies to differentiate themselves through technological advancements and sustainable practices.

The demand for high-efficiency insulation materials is primarily fueled by the construction industry, particularly in residential and commercial buildings. As energy costs continue to rise and environmental concerns intensify, there is a growing emphasis on improving building energy efficiency. This trend is further reinforced by government initiatives and regulations aimed at reducing carbon emissions and promoting sustainable construction practices.

In the automotive sector, the need for lightweight materials with excellent insulation properties has also contributed to the market growth. Polyurethane foam's ability to provide thermal insulation while reducing vehicle weight aligns well with the industry's push for improved fuel efficiency and reduced emissions.

The market size for high-efficiency insulation materials is projected to expand significantly in the coming years. Factors such as urbanization, renovation of existing buildings, and the development of smart cities are expected to drive this growth. Additionally, the increasing adoption of green building standards and certifications is creating new opportunities for advanced insulation solutions.

Regionally, North America and Europe currently dominate the market, owing to their stringent building codes and high awareness of energy efficiency. However, the Asia-Pacific region is emerging as a lucrative market, with rapid industrialization and urbanization driving demand for insulation materials. Countries like China and India are expected to be key growth drivers in this region.

The competitive landscape of the high-efficiency insulation materials market is characterized by the presence of both established players and innovative startups. Major companies are investing heavily in research and development to improve the performance and sustainability of their products. There is a growing focus on developing bio-based and recyclable insulation materials to address environmental concerns and meet evolving customer preferences.

Challenges in the market include fluctuating raw material prices and the need for continuous innovation to meet increasingly stringent energy efficiency standards. However, these challenges also present opportunities for companies to differentiate themselves through technological advancements and sustainable practices.

Current PU Foam Technology and Challenges

Polyurethane (PU) foam technology has made significant strides in recent years, particularly in the realm of insulation efficiency. The current state of PU foam technology offers a range of solutions for thermal insulation, with closed-cell foams being the most widely used for their superior insulating properties. These foams typically achieve R-values between 6 and 7 per inch, making them highly effective for building insulation.

However, the industry faces several challenges in optimizing PU foam for insulation efficiency. One of the primary concerns is the environmental impact of traditional blowing agents used in foam production. Many countries have phased out hydrochlorofluorocarbons (HCFCs) due to their ozone-depleting properties, leading to a shift towards hydrofluorocarbons (HFCs). Yet, HFCs still contribute to global warming, prompting research into more environmentally friendly alternatives.

Another significant challenge is balancing thermal performance with other desirable properties such as fire resistance, moisture resistance, and structural integrity. Enhancing one property often comes at the expense of others, necessitating careful formulation and processing techniques. For instance, increasing the closed-cell content for better insulation can make the foam more brittle and less resistant to dimensional changes.

The industry is also grappling with the need for improved aging performance of PU foams. Over time, the insulating gases within the foam cells can diffuse out, leading to a gradual decrease in thermal efficiency. This phenomenon, known as thermal drift, poses a long-term challenge for maintaining insulation performance in buildings and appliances.

Cost-effectiveness remains a persistent issue in PU foam technology. While PU foams offer excellent insulation properties, they are generally more expensive than some alternative insulation materials. This cost factor can limit their widespread adoption, particularly in price-sensitive markets or large-scale construction projects.

From a manufacturing perspective, achieving consistent foam quality across large production volumes presents ongoing challenges. Variations in raw material quality, environmental conditions, and processing parameters can lead to inconsistencies in foam density, cell structure, and overall performance. Addressing these variabilities requires sophisticated process control systems and quality assurance measures.

Lastly, the industry faces regulatory challenges related to the use of certain chemicals in PU foam production. Concerns over potential health and environmental impacts of flame retardants and other additives have led to increased scrutiny and evolving regulations. Manufacturers must navigate this complex regulatory landscape while still meeting performance requirements and safety standards.

However, the industry faces several challenges in optimizing PU foam for insulation efficiency. One of the primary concerns is the environmental impact of traditional blowing agents used in foam production. Many countries have phased out hydrochlorofluorocarbons (HCFCs) due to their ozone-depleting properties, leading to a shift towards hydrofluorocarbons (HFCs). Yet, HFCs still contribute to global warming, prompting research into more environmentally friendly alternatives.

Another significant challenge is balancing thermal performance with other desirable properties such as fire resistance, moisture resistance, and structural integrity. Enhancing one property often comes at the expense of others, necessitating careful formulation and processing techniques. For instance, increasing the closed-cell content for better insulation can make the foam more brittle and less resistant to dimensional changes.

The industry is also grappling with the need for improved aging performance of PU foams. Over time, the insulating gases within the foam cells can diffuse out, leading to a gradual decrease in thermal efficiency. This phenomenon, known as thermal drift, poses a long-term challenge for maintaining insulation performance in buildings and appliances.

Cost-effectiveness remains a persistent issue in PU foam technology. While PU foams offer excellent insulation properties, they are generally more expensive than some alternative insulation materials. This cost factor can limit their widespread adoption, particularly in price-sensitive markets or large-scale construction projects.

From a manufacturing perspective, achieving consistent foam quality across large production volumes presents ongoing challenges. Variations in raw material quality, environmental conditions, and processing parameters can lead to inconsistencies in foam density, cell structure, and overall performance. Addressing these variabilities requires sophisticated process control systems and quality assurance measures.

Lastly, the industry faces regulatory challenges related to the use of certain chemicals in PU foam production. Concerns over potential health and environmental impacts of flame retardants and other additives have led to increased scrutiny and evolving regulations. Manufacturers must navigate this complex regulatory landscape while still meeting performance requirements and safety standards.

Existing PU Foam Optimization Strategies

01 Improved thermal insulation properties

Polyurethane foam insulation can be enhanced by modifying its composition and structure to improve thermal conductivity and overall insulation efficiency. This may involve optimizing cell size, incorporating advanced blowing agents, or adding specific fillers to reduce heat transfer through the foam.- Improved foam formulations for enhanced insulation efficiency: Advanced polyurethane foam formulations are developed to enhance insulation efficiency. These formulations may include optimized ratios of isocyanates and polyols, as well as the incorporation of specific additives or fillers to improve thermal resistance properties. The resulting foams exhibit superior insulation performance, contributing to better energy efficiency in buildings and other applications.

- Nanotechnology integration in polyurethane foam insulation: Nanotechnology is applied to polyurethane foam insulation to significantly enhance its efficiency. This involves incorporating nanomaterials such as carbon nanotubes, graphene, or nanoparticles into the foam structure. These nano-enhanced foams demonstrate improved thermal insulation properties, increased strength-to-weight ratio, and better durability, leading to more effective and long-lasting insulation solutions.

- Eco-friendly and sustainable polyurethane foam insulation: Development of environmentally friendly polyurethane foam insulation focuses on using renewable resources and reducing environmental impact. This includes the use of bio-based polyols derived from natural oils, recycled materials, and low Global Warming Potential (GWP) blowing agents. These sustainable foams maintain high insulation efficiency while addressing environmental concerns and meeting stringent regulatory requirements.

- Advanced manufacturing techniques for improved insulation efficiency: Innovative manufacturing processes are employed to enhance the insulation efficiency of polyurethane foams. These techniques may include controlled cell structure formation, optimized curing processes, and precision mixing methods. By fine-tuning the manufacturing parameters, the resulting foams exhibit more uniform cell distribution, reduced thermal bridging, and overall improved insulation performance.

- Smart and adaptive polyurethane foam insulation systems: Development of intelligent polyurethane foam insulation systems that can adapt to changing environmental conditions. These systems may incorporate phase-change materials, temperature-responsive additives, or other smart technologies to dynamically adjust their insulation properties. This results in more efficient insulation performance across various temperature ranges and climatic conditions, optimizing energy conservation in different scenarios.

02 Fire-resistant polyurethane foam insulation

Developing fire-resistant polyurethane foam insulation involves incorporating flame retardants or modifying the foam's chemical structure. This enhances the material's ability to withstand high temperatures and slow down fire spread, improving both safety and insulation efficiency.Expand Specific Solutions03 Eco-friendly and sustainable formulations

Creating environmentally friendly polyurethane foam insulation focuses on using renewable resources, reducing harmful emissions, and improving recyclability. This may include bio-based polyols, natural fillers, or alternative blowing agents that have less environmental impact while maintaining insulation efficiency.Expand Specific Solutions04 Spray foam insulation technology

Advancements in spray foam insulation technology aim to improve application methods, curing times, and adhesion properties. This includes developing new spray equipment, optimizing foam expansion, and enhancing the foam's ability to fill gaps and cracks for better overall insulation performance.Expand Specific Solutions05 Nanotechnology in polyurethane foam insulation

Incorporating nanotechnology into polyurethane foam insulation can significantly enhance its performance. This may involve adding nanoparticles or creating nanostructures within the foam to improve thermal resistance, mechanical strength, and durability, resulting in more efficient insulation materials.Expand Specific Solutions

Key Players in PU Foam Insulation Industry

The polyurethane foam insulation market is in a mature growth stage, with a global market size expected to reach $20 billion by 2025. Major players like Dow Global Technologies, BASF, and Covestro dominate the industry, driving innovation in insulation efficiency. The technology's maturity is evident in the diverse applications across sectors, from appliances (Haier, LG Electronics) to automotive (Toyo Tire). Emerging trends focus on eco-friendly formulations and enhanced thermal properties. Companies such as Evonik Operations and Wanhua Chemical are investing in R&D to develop next-generation foam technologies, while appliance manufacturers like Samsung and Panasonic are integrating advanced insulation solutions into their products, indicating a high level of technological sophistication and market competition.

Dow Global Technologies LLC

Technical Solution: Dow has developed a novel polyurethane foam formulation that incorporates nano-sized particles to enhance thermal insulation properties. This technology involves dispersing specially engineered nanoparticles throughout the foam matrix during the manufacturing process. These nanoparticles act as additional barriers to heat transfer, significantly reducing thermal conductivity. The foam also features an optimized cell structure with a higher proportion of closed cells, further improving its insulation efficiency. Additionally, Dow has implemented a proprietary blowing agent system that results in a more uniform foam structure and lower overall density without compromising insulation performance.

Strengths: Superior thermal insulation properties, reduced material usage due to lower density, and potential for thinner insulation layers. Weaknesses: Higher production costs due to nanoparticle incorporation and potential challenges in ensuring uniform dispersion of nanoparticles in large-scale production.

BASF Corp.

Technical Solution: BASF has developed an advanced polyurethane foam system called Elastopor® H, specifically designed for high-performance insulation applications. This system utilizes a unique combination of polyols and isocyanates, along with specialized additives, to create a foam with exceptionally low thermal conductivity. The foam's cell structure is engineered to minimize convection and radiation heat transfer, while the polymer matrix itself has been optimized to reduce conduction. BASF has also incorporated phase change materials (PCMs) into the foam formulation, allowing it to absorb and release heat energy as needed, further enhancing its insulation efficiency across a wide range of temperatures. The production process has been fine-tuned to ensure consistent quality and performance in various environmental conditions.

Strengths: Excellent thermal insulation properties, adaptability to temperature fluctuations due to PCM integration, and proven performance in diverse applications. Weaknesses: Potentially higher cost compared to standard insulation foams and possible complexity in handling and processing PCM-enhanced formulations.

Innovative PU Foam Formulations and Structures

Polyurethane insulating foams and production thereof

PatentWO2021165149A1

Innovation

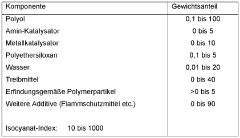

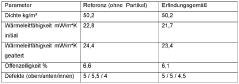

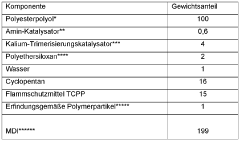

- Incorporating polymer particles with a mean particle size of less than 100 μm, preferably 5 to 50 μm, into the foamable reaction mixtures containing polyisocyanates, reactive hydrogen compounds, blowing agents, and stabilizers, which improves the thermal insulation properties of the resulting polyurethane foams without significantly affecting other relevant foam properties.

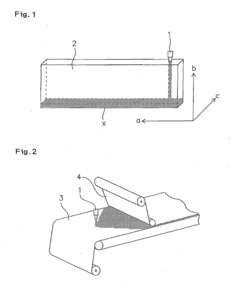

Polyurethane foam panel and production method for polyurethane foam panel

PatentInactiveUS20140148524A1

Innovation

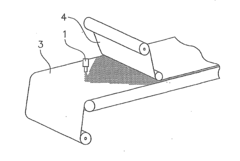

- A polyurethane foam panel is produced by mixing a polyol composition comprising a high-molecular-weight polyether polyol and a short glycol with a polyisocyanate component, where the isocyanate index is controlled, and the panel's thickness direction is oriented perpendicular to the foamed cell direction, optimizing the cell structure for improved heat insulation and flexibility.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of polyurethane foam insulation have become increasingly important in recent years. As the construction industry moves towards more eco-friendly practices, optimizing polyurethane foam for insulation efficiency must also address environmental concerns.

One of the primary environmental issues associated with polyurethane foam is the use of blowing agents. Historically, chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were used, which contributed significantly to ozone depletion. The industry has since transitioned to hydrofluorocarbons (HFCs), which, while less harmful to the ozone layer, still have high global warming potential (GWP). Current research focuses on developing and implementing low-GWP alternatives, such as hydrofluoroolefins (HFOs) and water-blown systems, to minimize the climate impact of polyurethane foam insulation.

The raw materials used in polyurethane foam production also present sustainability challenges. Traditional polyols are derived from petroleum, a non-renewable resource. To address this, researchers are exploring bio-based polyols made from renewable sources like soybean oil, castor oil, and recycled polyethylene terephthalate (PET). These alternatives not only reduce reliance on fossil fuels but also have the potential to sequester carbon, improving the overall environmental footprint of the insulation.

End-of-life considerations are another crucial aspect of sustainability for polyurethane foam insulation. Currently, most foam insulation ends up in landfills, where it can persist for centuries. Developing effective recycling and disposal methods is essential for improving the lifecycle impact of these materials. Emerging technologies, such as chemical recycling processes that break down polyurethane into its constituent components, show promise for creating a more circular economy for foam insulation.

Energy efficiency during the production process is also a key factor in reducing the environmental impact of polyurethane foam insulation. Manufacturers are implementing more efficient production techniques, such as continuous processing and improved curing methods, to reduce energy consumption and associated greenhouse gas emissions. Additionally, optimizing the foam's insulation properties can lead to significant energy savings in buildings over their lifetime, offsetting the initial environmental costs of production.

As regulations and market demands evolve, the industry is also focusing on reducing or eliminating potentially harmful additives, such as flame retardants and catalysts. This shift towards safer chemistry not only improves the environmental profile of the foam but also addresses health concerns for both production workers and end-users. Innovative approaches, like the use of nanoparticles or bio-based additives, are being explored to maintain or enhance performance while reducing environmental impact.

One of the primary environmental issues associated with polyurethane foam is the use of blowing agents. Historically, chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were used, which contributed significantly to ozone depletion. The industry has since transitioned to hydrofluorocarbons (HFCs), which, while less harmful to the ozone layer, still have high global warming potential (GWP). Current research focuses on developing and implementing low-GWP alternatives, such as hydrofluoroolefins (HFOs) and water-blown systems, to minimize the climate impact of polyurethane foam insulation.

The raw materials used in polyurethane foam production also present sustainability challenges. Traditional polyols are derived from petroleum, a non-renewable resource. To address this, researchers are exploring bio-based polyols made from renewable sources like soybean oil, castor oil, and recycled polyethylene terephthalate (PET). These alternatives not only reduce reliance on fossil fuels but also have the potential to sequester carbon, improving the overall environmental footprint of the insulation.

End-of-life considerations are another crucial aspect of sustainability for polyurethane foam insulation. Currently, most foam insulation ends up in landfills, where it can persist for centuries. Developing effective recycling and disposal methods is essential for improving the lifecycle impact of these materials. Emerging technologies, such as chemical recycling processes that break down polyurethane into its constituent components, show promise for creating a more circular economy for foam insulation.

Energy efficiency during the production process is also a key factor in reducing the environmental impact of polyurethane foam insulation. Manufacturers are implementing more efficient production techniques, such as continuous processing and improved curing methods, to reduce energy consumption and associated greenhouse gas emissions. Additionally, optimizing the foam's insulation properties can lead to significant energy savings in buildings over their lifetime, offsetting the initial environmental costs of production.

As regulations and market demands evolve, the industry is also focusing on reducing or eliminating potentially harmful additives, such as flame retardants and catalysts. This shift towards safer chemistry not only improves the environmental profile of the foam but also addresses health concerns for both production workers and end-users. Innovative approaches, like the use of nanoparticles or bio-based additives, are being explored to maintain or enhance performance while reducing environmental impact.

Regulatory Framework for Insulation Materials

The regulatory framework for insulation materials plays a crucial role in ensuring the safety, performance, and environmental sustainability of polyurethane foam insulation. In the United States, the primary regulatory bodies overseeing insulation materials include the Environmental Protection Agency (EPA), the Consumer Product Safety Commission (CPSC), and the Department of Energy (DOE).

The EPA regulates the production and use of chemicals in insulation materials, particularly focusing on the reduction of volatile organic compounds (VOCs) and ozone-depleting substances. Under the Toxic Substances Control Act (TSCA), manufacturers must report new chemical substances and demonstrate their safety before market introduction. The EPA also enforces the Significant New Use Rule (SNUR) for certain chemicals used in polyurethane foam production, ensuring that potentially harmful substances are properly evaluated and controlled.

Building codes and standards set by organizations such as the International Code Council (ICC) and ASTM International provide guidelines for the use of insulation materials in construction. These codes often reference specific requirements for fire resistance, thermal performance, and moisture control. The International Energy Conservation Code (IECC) establishes minimum insulation requirements for buildings, which vary by climate zone and construction type.

The CPSC focuses on consumer safety aspects of insulation materials, including flammability and off-gassing. They enforce regulations such as the Federal Flammable Fabrics Act, which sets standards for the flammability of foam plastic insulation used in building materials. Additionally, the CPSC monitors and regulates the use of flame retardants in polyurethane foam to balance fire safety with potential health risks.

Energy efficiency standards, overseen by the DOE, impact the development and application of insulation materials. The Energy Policy and Conservation Act (EPCA) mandates the establishment of energy conservation standards for various products and equipment, including building insulation. These standards drive innovation in polyurethane foam formulations to achieve higher R-values and improved thermal performance.

Globally, regulations such as the European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation influence the composition and production of polyurethane foam insulation. REACH requires manufacturers to register chemical substances and assess their potential risks, promoting the development of safer alternatives and more sustainable production processes.

As environmental concerns grow, regulations are increasingly focusing on the lifecycle impact of insulation materials. This includes considerations for recycling, disposal, and the use of renewable or bio-based raw materials in polyurethane foam production. The EU's Circular Economy Action Plan, for instance, emphasizes the need for sustainable product design and improved waste management practices, which will likely influence future regulations on insulation materials.

The EPA regulates the production and use of chemicals in insulation materials, particularly focusing on the reduction of volatile organic compounds (VOCs) and ozone-depleting substances. Under the Toxic Substances Control Act (TSCA), manufacturers must report new chemical substances and demonstrate their safety before market introduction. The EPA also enforces the Significant New Use Rule (SNUR) for certain chemicals used in polyurethane foam production, ensuring that potentially harmful substances are properly evaluated and controlled.

Building codes and standards set by organizations such as the International Code Council (ICC) and ASTM International provide guidelines for the use of insulation materials in construction. These codes often reference specific requirements for fire resistance, thermal performance, and moisture control. The International Energy Conservation Code (IECC) establishes minimum insulation requirements for buildings, which vary by climate zone and construction type.

The CPSC focuses on consumer safety aspects of insulation materials, including flammability and off-gassing. They enforce regulations such as the Federal Flammable Fabrics Act, which sets standards for the flammability of foam plastic insulation used in building materials. Additionally, the CPSC monitors and regulates the use of flame retardants in polyurethane foam to balance fire safety with potential health risks.

Energy efficiency standards, overseen by the DOE, impact the development and application of insulation materials. The Energy Policy and Conservation Act (EPCA) mandates the establishment of energy conservation standards for various products and equipment, including building insulation. These standards drive innovation in polyurethane foam formulations to achieve higher R-values and improved thermal performance.

Globally, regulations such as the European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation influence the composition and production of polyurethane foam insulation. REACH requires manufacturers to register chemical substances and assess their potential risks, promoting the development of safer alternatives and more sustainable production processes.

As environmental concerns grow, regulations are increasingly focusing on the lifecycle impact of insulation materials. This includes considerations for recycling, disposal, and the use of renewable or bio-based raw materials in polyurethane foam production. The EU's Circular Economy Action Plan, for instance, emphasizes the need for sustainable product design and improved waste management practices, which will likely influence future regulations on insulation materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!