How to Enhance Polyurethane Foam Properties for Comfort?

JUN 25, 20257 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Foam Evolution and Comfort Goals

Polyurethane (PU) foam has undergone significant evolution since its inception in the 1930s. Initially developed as a rigid material, it has transformed into a versatile substance widely used in comfort applications. The journey of PU foam's development has been driven by the continuous pursuit of enhanced comfort properties, aligning with changing consumer expectations and technological advancements.

In the early stages, PU foam was primarily utilized for industrial purposes due to its rigidity and durability. However, as the potential for comfort applications became apparent, researchers began focusing on modifying its chemical composition to achieve softer, more flexible variants. This shift marked the beginning of PU foam's trajectory towards becoming a staple in the comfort industry.

The 1960s and 1970s saw significant breakthroughs in PU foam technology, with the introduction of high-resilience foams that offered improved durability and comfort. These advancements paved the way for PU foam's widespread adoption in furniture, bedding, and automotive seating. The focus on comfort intensified, leading to the development of various foam grades tailored for specific applications.

As consumer awareness of ergonomics and health grew in the late 20th century, the goals for PU foam comfort properties expanded beyond mere softness. Researchers began exploring ways to enhance pressure distribution, temperature regulation, and moisture management within foam structures. This shift reflected a more holistic approach to comfort, considering both immediate feel and long-term physiological effects.

In recent years, the evolution of PU foam has been heavily influenced by sustainability concerns and technological integration. Efforts to develop bio-based polyols and incorporate recycled materials have gained momentum, aiming to reduce the environmental impact of foam production. Simultaneously, the integration of smart materials and sensors into PU foam structures has opened new frontiers in personalized comfort solutions.

The current goals for enhancing PU foam properties for comfort are multifaceted. They include improving durability to maintain comfort over extended periods, optimizing breathability and heat dissipation for better temperature regulation, and developing adaptive foam structures that respond to individual body shapes and movements. Additionally, there is a growing emphasis on reducing off-gassing and enhancing the overall health profile of PU foams.

Looking ahead, the evolution of PU foam is likely to continue focusing on advanced material science and smart technology integration. The ultimate aim is to create foam solutions that not only provide immediate comfort but also contribute to long-term well-being, sustainability, and personalized user experiences.

In the early stages, PU foam was primarily utilized for industrial purposes due to its rigidity and durability. However, as the potential for comfort applications became apparent, researchers began focusing on modifying its chemical composition to achieve softer, more flexible variants. This shift marked the beginning of PU foam's trajectory towards becoming a staple in the comfort industry.

The 1960s and 1970s saw significant breakthroughs in PU foam technology, with the introduction of high-resilience foams that offered improved durability and comfort. These advancements paved the way for PU foam's widespread adoption in furniture, bedding, and automotive seating. The focus on comfort intensified, leading to the development of various foam grades tailored for specific applications.

As consumer awareness of ergonomics and health grew in the late 20th century, the goals for PU foam comfort properties expanded beyond mere softness. Researchers began exploring ways to enhance pressure distribution, temperature regulation, and moisture management within foam structures. This shift reflected a more holistic approach to comfort, considering both immediate feel and long-term physiological effects.

In recent years, the evolution of PU foam has been heavily influenced by sustainability concerns and technological integration. Efforts to develop bio-based polyols and incorporate recycled materials have gained momentum, aiming to reduce the environmental impact of foam production. Simultaneously, the integration of smart materials and sensors into PU foam structures has opened new frontiers in personalized comfort solutions.

The current goals for enhancing PU foam properties for comfort are multifaceted. They include improving durability to maintain comfort over extended periods, optimizing breathability and heat dissipation for better temperature regulation, and developing adaptive foam structures that respond to individual body shapes and movements. Additionally, there is a growing emphasis on reducing off-gassing and enhancing the overall health profile of PU foams.

Looking ahead, the evolution of PU foam is likely to continue focusing on advanced material science and smart technology integration. The ultimate aim is to create foam solutions that not only provide immediate comfort but also contribute to long-term well-being, sustainability, and personalized user experiences.

Market Demand Analysis for Enhanced PU Foam

The global market for enhanced polyurethane (PU) foam is experiencing significant growth, driven by increasing demand for comfort and performance in various applications. The automotive industry represents a major market segment, with a growing emphasis on passenger comfort and noise reduction. Enhanced PU foams are being sought for improved seat cushioning, headrests, and sound insulation, contributing to a superior driving experience.

In the furniture and bedding sector, there is a rising consumer preference for premium comfort products. This trend has led to increased demand for enhanced PU foams that offer better support, pressure distribution, and durability. Memory foam mattresses and pillows, which utilize advanced PU foam technology, have gained substantial market share due to their ability to provide personalized comfort and alleviate sleep-related issues.

The healthcare industry is another key driver of market demand for enhanced PU foams. With an aging global population and growing awareness of ergonomics in medical settings, there is a surge in demand for specialized medical mattresses, cushions, and support surfaces. These products require PU foams with enhanced properties such as pressure redistribution, moisture management, and antimicrobial characteristics.

The sports and leisure sector also contributes to the market demand, with applications in athletic footwear, protective gear, and recreational equipment. Enhanced PU foams are valued for their ability to provide shock absorption, energy return, and lightweight cushioning in these products.

Environmental concerns and sustainability initiatives are influencing market trends, leading to increased demand for bio-based and recyclable PU foams. Manufacturers are investing in research and development to create eco-friendly alternatives that maintain or exceed the comfort properties of traditional PU foams.

The construction industry is another significant market for enhanced PU foams, particularly in insulation applications. Improved thermal and acoustic properties are sought after to meet stringent energy efficiency standards and enhance indoor comfort in buildings.

Geographically, North America and Europe are leading markets for enhanced PU foams, driven by high consumer expectations for comfort and quality. However, the Asia-Pacific region is experiencing the fastest growth, fueled by rapid urbanization, increasing disposable incomes, and a burgeoning middle class demanding higher-quality products.

As the market for enhanced PU foams continues to expand, manufacturers are focusing on innovation to meet evolving consumer needs and regulatory requirements. This includes developing foams with improved resilience, temperature regulation, and customizable comfort levels. The integration of smart materials and nanotechnology in PU foam production is also emerging as a potential game-changer in the industry, promising new levels of comfort and functionality.

In the furniture and bedding sector, there is a rising consumer preference for premium comfort products. This trend has led to increased demand for enhanced PU foams that offer better support, pressure distribution, and durability. Memory foam mattresses and pillows, which utilize advanced PU foam technology, have gained substantial market share due to their ability to provide personalized comfort and alleviate sleep-related issues.

The healthcare industry is another key driver of market demand for enhanced PU foams. With an aging global population and growing awareness of ergonomics in medical settings, there is a surge in demand for specialized medical mattresses, cushions, and support surfaces. These products require PU foams with enhanced properties such as pressure redistribution, moisture management, and antimicrobial characteristics.

The sports and leisure sector also contributes to the market demand, with applications in athletic footwear, protective gear, and recreational equipment. Enhanced PU foams are valued for their ability to provide shock absorption, energy return, and lightweight cushioning in these products.

Environmental concerns and sustainability initiatives are influencing market trends, leading to increased demand for bio-based and recyclable PU foams. Manufacturers are investing in research and development to create eco-friendly alternatives that maintain or exceed the comfort properties of traditional PU foams.

The construction industry is another significant market for enhanced PU foams, particularly in insulation applications. Improved thermal and acoustic properties are sought after to meet stringent energy efficiency standards and enhance indoor comfort in buildings.

Geographically, North America and Europe are leading markets for enhanced PU foams, driven by high consumer expectations for comfort and quality. However, the Asia-Pacific region is experiencing the fastest growth, fueled by rapid urbanization, increasing disposable incomes, and a burgeoning middle class demanding higher-quality products.

As the market for enhanced PU foams continues to expand, manufacturers are focusing on innovation to meet evolving consumer needs and regulatory requirements. This includes developing foams with improved resilience, temperature regulation, and customizable comfort levels. The integration of smart materials and nanotechnology in PU foam production is also emerging as a potential game-changer in the industry, promising new levels of comfort and functionality.

Existing PU Foam Comfort Solutions

01 Composition modifications for improved comfort

Polyurethane foam comfort can be enhanced by modifying the foam composition. This includes adjusting the ratio of polyols, isocyanates, and additives to achieve desired softness and support. Incorporating specific additives like cell openers or using specialized polyols can result in a more open-cell structure, leading to improved air circulation and comfort.- Composition modifications for improved comfort: Polyurethane foam comfort can be enhanced by modifying the foam composition. This includes adjusting the ratio of polyols, isocyanates, and additives to create a softer, more resilient foam. Incorporating specific additives like cell openers or using specialized polyols can result in a more open-cell structure, improving air circulation and overall comfort.

- Surface treatments for enhanced comfort: Various surface treatments can be applied to polyurethane foam to improve comfort. These may include applying comfort layers, such as memory foam or gel-infused foam, on top of the base polyurethane foam. Additionally, treatments like embossing or convoluting the foam surface can create ergonomic patterns that enhance pressure distribution and overall comfort.

- Density and firmness optimization: The comfort of polyurethane foam can be optimized by carefully controlling its density and firmness. This involves adjusting the foam formulation and manufacturing process to achieve the desired balance between support and softness. Techniques such as variable pressure foaming or using multiple layers of foam with different densities can create a more comfortable and supportive product.

- Integration of cooling technologies: To enhance comfort, especially in bedding and seating applications, cooling technologies can be integrated into polyurethane foam. This may involve incorporating phase change materials, using open-cell structures to improve air circulation, or adding gel-infused layers. These technologies help regulate temperature and moisture, contributing to a more comfortable user experience.

- Eco-friendly and sustainable comfort solutions: Developing eco-friendly and sustainable polyurethane foam solutions that maintain or improve comfort is a growing focus. This includes using bio-based polyols, incorporating recycled materials, or developing foam formulations with reduced environmental impact. These approaches aim to provide comfortable polyurethane foam products while addressing environmental concerns.

02 Density and firmness optimization

The comfort of polyurethane foam can be optimized by carefully controlling its density and firmness. Lower density foams tend to be softer and more comfortable for cushioning applications, while higher density foams provide better support. Balancing these factors can create foam with ideal comfort characteristics for specific applications such as mattresses or seating.Expand Specific Solutions03 Surface treatments for enhanced comfort

Various surface treatments can be applied to polyurethane foam to enhance comfort. These may include adding a comfort layer of softer foam, applying a fabric or gel coating, or using convoluted or textured surfaces. Such treatments can improve the feel of the foam against the skin and provide additional cushioning or cooling effects.Expand Specific Solutions04 Viscoelastic and gel-infused foams

Incorporating viscoelastic properties or infusing gels into polyurethane foams can significantly enhance comfort. These modifications allow the foam to conform to body contours and distribute pressure more evenly. They also provide temperature regulation benefits, contributing to overall comfort in applications like bedding and seating.Expand Specific Solutions05 Sustainable and eco-friendly comfort solutions

Developing sustainable and eco-friendly polyurethane foams that maintain or improve comfort is a growing focus. This includes using bio-based polyols, incorporating recycled materials, or developing foam formulations that reduce environmental impact without compromising on comfort. These innovations aim to meet increasing consumer demand for sustainable products while ensuring optimal comfort.Expand Specific Solutions

Core Innovations in PU Foam Technology

Flexible polyurethane foams having improved long-term performance characteristics

PatentWO2020126586A1

Innovation

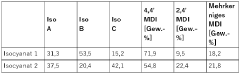

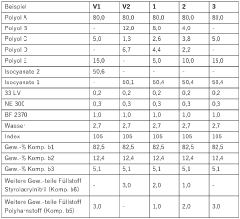

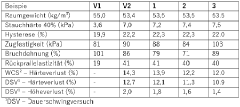

- A polyurethane foam formulation using specific polyether polyol mixtures with varying hydroxyl numbers, ethylene oxide content, and primary OH groups, combined with polyurea, to achieve enhanced mechanical properties and comfort features, including high compression hardness, tensile strength, and rebound elasticity, while maintaining low density.

Upholstered furniture

PatentInactiveEP1335656A2

Innovation

- Combining a spring base, either conventional or with flexible tubular fabric, with a multi-layer upholstery using viscoelastic polyurethane foam that has a unique crystallization point and compressive strength properties, allowing for increased flexibility and comfort by reducing viscosity with body heat, and using a specific mixture of polyols, isocyanates, and auxiliaries to achieve desired viscoelasticity.

Environmental Impact of PU Foam Production

The production of polyurethane (PU) foam has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of various chemicals, including isocyanates and polyols, which can contribute to air and water pollution if not properly managed. Volatile organic compounds (VOCs) emitted during production can lead to smog formation and pose health risks to workers and nearby communities.

Energy consumption is another critical factor in the environmental impact of PU foam production. The process requires substantial energy inputs for mixing, heating, and curing, often relying on fossil fuels. This contributes to greenhouse gas emissions and exacerbates climate change concerns. Additionally, the transportation of raw materials and finished products adds to the carbon footprint of PU foam manufacturing.

Water usage and wastewater management are also important environmental considerations. The production process may require significant amounts of water for cooling and cleaning, potentially straining local water resources. Proper treatment of wastewater is essential to prevent contamination of water bodies and ecosystems.

The disposal of PU foam products at the end of their lifecycle presents further environmental challenges. Many PU foams are not biodegradable and can persist in landfills for extended periods. Incineration of PU foam waste can release toxic substances, including hydrogen cyanide and isocyanates, necessitating advanced emission control systems.

However, the industry has been making strides in addressing these environmental concerns. Innovations in raw material sourcing, such as the use of bio-based polyols, are reducing reliance on petroleum-derived ingredients. Closed-loop manufacturing systems are being implemented to minimize waste and recycle materials. Some manufacturers are adopting water-blown foam technologies, which reduce the need for chemical blowing agents and decrease VOC emissions.

Efforts to improve energy efficiency in production processes are also underway. This includes the use of more efficient equipment, heat recovery systems, and renewable energy sources. These measures not only reduce the environmental impact but also often lead to cost savings for manufacturers.

The development of recyclable and biodegradable PU foams is an area of active research, aiming to address end-of-life environmental issues. Some companies are exploring chemical recycling methods to break down PU foam into its constituent components, allowing for the creation of new products from recycled materials.

As environmental regulations become more stringent globally, PU foam manufacturers are increasingly adopting life cycle assessment (LCA) approaches to comprehensively evaluate and mitigate the environmental impacts of their products from cradle to grave. This holistic view is driving innovations in product design, manufacturing processes, and waste management strategies, ultimately leading to more sustainable PU foam production practices.

Energy consumption is another critical factor in the environmental impact of PU foam production. The process requires substantial energy inputs for mixing, heating, and curing, often relying on fossil fuels. This contributes to greenhouse gas emissions and exacerbates climate change concerns. Additionally, the transportation of raw materials and finished products adds to the carbon footprint of PU foam manufacturing.

Water usage and wastewater management are also important environmental considerations. The production process may require significant amounts of water for cooling and cleaning, potentially straining local water resources. Proper treatment of wastewater is essential to prevent contamination of water bodies and ecosystems.

The disposal of PU foam products at the end of their lifecycle presents further environmental challenges. Many PU foams are not biodegradable and can persist in landfills for extended periods. Incineration of PU foam waste can release toxic substances, including hydrogen cyanide and isocyanates, necessitating advanced emission control systems.

However, the industry has been making strides in addressing these environmental concerns. Innovations in raw material sourcing, such as the use of bio-based polyols, are reducing reliance on petroleum-derived ingredients. Closed-loop manufacturing systems are being implemented to minimize waste and recycle materials. Some manufacturers are adopting water-blown foam technologies, which reduce the need for chemical blowing agents and decrease VOC emissions.

Efforts to improve energy efficiency in production processes are also underway. This includes the use of more efficient equipment, heat recovery systems, and renewable energy sources. These measures not only reduce the environmental impact but also often lead to cost savings for manufacturers.

The development of recyclable and biodegradable PU foams is an area of active research, aiming to address end-of-life environmental issues. Some companies are exploring chemical recycling methods to break down PU foam into its constituent components, allowing for the creation of new products from recycled materials.

As environmental regulations become more stringent globally, PU foam manufacturers are increasingly adopting life cycle assessment (LCA) approaches to comprehensively evaluate and mitigate the environmental impacts of their products from cradle to grave. This holistic view is driving innovations in product design, manufacturing processes, and waste management strategies, ultimately leading to more sustainable PU foam production practices.

Regulatory Standards for PU Foam in Consumer Products

Regulatory standards for polyurethane (PU) foam in consumer products play a crucial role in ensuring safety, quality, and performance. These standards are established by various regulatory bodies and industry organizations to address potential health and environmental concerns associated with PU foam production and use.

In the United States, the Consumer Product Safety Commission (CPSC) sets guidelines for PU foam in consumer products, particularly focusing on flammability requirements. The CPSC enforces standards such as 16 CFR Part 1633 for mattresses and 16 CFR Part 1634 for upholstered furniture, which mandate specific fire resistance levels for PU foam-containing products.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects PU foam manufacturers and importers. This regulation requires companies to register chemicals used in foam production and provide safety information. Additionally, the EU's General Product Safety Directive (GPSD) ensures that consumer products, including those containing PU foam, meet general safety requirements.

Environmental concerns have led to the development of standards addressing volatile organic compound (VOC) emissions from PU foam. The GREENGUARD Certification program, administered by UL Environment, sets strict limits on chemical emissions from foam products. Similarly, the CertiPUR-US program in the United States certifies flexible polyurethane foams for content, emissions, and durability.

Specific industry sectors have their own regulatory standards for PU foam. In the automotive industry, for instance, the Federal Motor Vehicle Safety Standards (FMVSS) in the US include requirements for foam used in vehicle interiors, focusing on flammability and occupant protection.

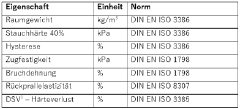

International standards organizations also contribute to PU foam regulations. The International Organization for Standardization (ISO) has developed standards such as ISO 3386 for determining stress-strain characteristics of flexible cellular materials, which applies to PU foam used in various consumer products.

As sustainability becomes increasingly important, new standards are emerging to address the environmental impact of PU foam. The Cradle to Cradle Certified Product Standard, for example, evaluates products based on material health, material reutilization, renewable energy use, water stewardship, and social fairness, influencing the production and disposal of PU foam products.

Compliance with these regulatory standards is essential for manufacturers seeking to enhance PU foam properties for comfort while ensuring product safety and environmental responsibility. As research continues to improve foam performance, regulatory bodies are likely to update and refine these standards to reflect new findings and address emerging concerns in the industry.

In the United States, the Consumer Product Safety Commission (CPSC) sets guidelines for PU foam in consumer products, particularly focusing on flammability requirements. The CPSC enforces standards such as 16 CFR Part 1633 for mattresses and 16 CFR Part 1634 for upholstered furniture, which mandate specific fire resistance levels for PU foam-containing products.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects PU foam manufacturers and importers. This regulation requires companies to register chemicals used in foam production and provide safety information. Additionally, the EU's General Product Safety Directive (GPSD) ensures that consumer products, including those containing PU foam, meet general safety requirements.

Environmental concerns have led to the development of standards addressing volatile organic compound (VOC) emissions from PU foam. The GREENGUARD Certification program, administered by UL Environment, sets strict limits on chemical emissions from foam products. Similarly, the CertiPUR-US program in the United States certifies flexible polyurethane foams for content, emissions, and durability.

Specific industry sectors have their own regulatory standards for PU foam. In the automotive industry, for instance, the Federal Motor Vehicle Safety Standards (FMVSS) in the US include requirements for foam used in vehicle interiors, focusing on flammability and occupant protection.

International standards organizations also contribute to PU foam regulations. The International Organization for Standardization (ISO) has developed standards such as ISO 3386 for determining stress-strain characteristics of flexible cellular materials, which applies to PU foam used in various consumer products.

As sustainability becomes increasingly important, new standards are emerging to address the environmental impact of PU foam. The Cradle to Cradle Certified Product Standard, for example, evaluates products based on material health, material reutilization, renewable energy use, water stewardship, and social fairness, influencing the production and disposal of PU foam products.

Compliance with these regulatory standards is essential for manufacturers seeking to enhance PU foam properties for comfort while ensuring product safety and environmental responsibility. As research continues to improve foam performance, regulatory bodies are likely to update and refine these standards to reflect new findings and address emerging concerns in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!