What PU Structural Gels Will Power Soft Actuator Design?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Structural Gel Evolution and Objectives

Polyurethane (PU) structural gels have emerged as a promising material for soft actuator design, offering a unique combination of flexibility, strength, and responsiveness. The evolution of PU structural gels can be traced back to the early 2000s when researchers began exploring the potential of combining polyurethane chemistry with hydrogel technology. This fusion aimed to create materials that could maintain structural integrity while exhibiting the adaptive properties characteristic of hydrogels.

The initial development focused on improving the mechanical properties of PU gels, addressing challenges such as low tensile strength and poor durability. Researchers experimented with various crosslinking methods and polymer compositions to enhance the gel's structural stability without compromising its flexibility. By the mid-2010s, significant progress had been made in creating PU structural gels that could withstand repeated deformation cycles, a crucial requirement for soft actuator applications.

A key milestone in the evolution of PU structural gels was the introduction of stimuli-responsive properties. Scientists incorporated functional groups and nanoparticles into the PU matrix, enabling the gels to respond to external stimuli such as temperature, pH, and electric fields. This breakthrough opened up new possibilities for creating smart, adaptive soft actuators capable of complex movements and interactions with their environment.

The current objectives in PU structural gel research for soft actuator design are multifaceted. One primary goal is to further enhance the actuation speed and force output of gel-based actuators. This involves optimizing the gel's composition and structure to achieve faster response times and stronger mechanical outputs. Another objective is to improve the energy efficiency of PU gel actuators, reducing the amount of energy required to trigger and sustain actuation.

Researchers are also focusing on developing PU structural gels with improved biocompatibility and biodegradability. This is particularly important for applications in biomedical engineering and environmental sensing, where the materials may come into contact with living tissues or need to degrade safely after use. Additionally, there is a growing interest in creating multi-functional PU gels that can simultaneously act as sensors and actuators, paving the way for more integrated and sophisticated soft robotic systems.

Looking ahead, the field aims to scale up the production of PU structural gels while maintaining consistent properties and performance. This is crucial for transitioning from laboratory prototypes to commercially viable soft actuator products. Researchers are exploring advanced manufacturing techniques, such as 3D printing and microfluidics, to achieve precise control over gel structure and composition at larger scales.

The initial development focused on improving the mechanical properties of PU gels, addressing challenges such as low tensile strength and poor durability. Researchers experimented with various crosslinking methods and polymer compositions to enhance the gel's structural stability without compromising its flexibility. By the mid-2010s, significant progress had been made in creating PU structural gels that could withstand repeated deformation cycles, a crucial requirement for soft actuator applications.

A key milestone in the evolution of PU structural gels was the introduction of stimuli-responsive properties. Scientists incorporated functional groups and nanoparticles into the PU matrix, enabling the gels to respond to external stimuli such as temperature, pH, and electric fields. This breakthrough opened up new possibilities for creating smart, adaptive soft actuators capable of complex movements and interactions with their environment.

The current objectives in PU structural gel research for soft actuator design are multifaceted. One primary goal is to further enhance the actuation speed and force output of gel-based actuators. This involves optimizing the gel's composition and structure to achieve faster response times and stronger mechanical outputs. Another objective is to improve the energy efficiency of PU gel actuators, reducing the amount of energy required to trigger and sustain actuation.

Researchers are also focusing on developing PU structural gels with improved biocompatibility and biodegradability. This is particularly important for applications in biomedical engineering and environmental sensing, where the materials may come into contact with living tissues or need to degrade safely after use. Additionally, there is a growing interest in creating multi-functional PU gels that can simultaneously act as sensors and actuators, paving the way for more integrated and sophisticated soft robotic systems.

Looking ahead, the field aims to scale up the production of PU structural gels while maintaining consistent properties and performance. This is crucial for transitioning from laboratory prototypes to commercially viable soft actuator products. Researchers are exploring advanced manufacturing techniques, such as 3D printing and microfluidics, to achieve precise control over gel structure and composition at larger scales.

Soft Actuator Market Analysis

The soft actuator market is experiencing significant growth, driven by the increasing demand for flexible and adaptable robotic systems across various industries. This market segment is particularly promising due to the unique capabilities of soft actuators, which offer advantages over traditional rigid actuators in terms of safety, compliance, and versatility.

In the healthcare sector, soft actuators are finding applications in wearable devices, prosthetics, and minimally invasive surgical tools. The aging population and the rise in chronic diseases are fueling the demand for advanced medical devices, creating a substantial market opportunity for soft actuator technologies. The global medical robotics market, which includes soft actuator applications, is projected to grow at a robust rate in the coming years.

The industrial automation sector is another key driver for the soft actuator market. As manufacturing processes become more complex and require greater flexibility, soft actuators are being integrated into collaborative robots and adaptive gripping systems. This trend is particularly evident in industries such as automotive, electronics, and food processing, where delicate handling and human-robot collaboration are essential.

The consumer electronics industry is also embracing soft actuator technology, particularly in the development of haptic feedback systems for virtual and augmented reality devices. As the VR/AR market expands, the demand for more realistic and immersive tactile experiences is expected to drive innovation in soft actuator design.

Environmental concerns and the push for energy-efficient solutions are creating new opportunities for soft actuators in the automotive and aerospace industries. Lightweight, flexible actuators can contribute to improved fuel efficiency and reduced emissions in vehicles and aircraft.

Geographically, North America and Europe are currently leading the soft actuator market, with significant research and development activities taking place in these regions. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing adoption of automation technologies, and substantial investments in healthcare infrastructure.

Despite the promising outlook, the soft actuator market faces challenges such as the need for standardization, scalability issues, and the relatively high cost of materials and manufacturing processes. Overcoming these hurdles will be crucial for widespread adoption across industries.

As the technology matures and becomes more cost-effective, the soft actuator market is poised for substantial growth. The development of advanced materials, such as PU structural gels, will play a pivotal role in enhancing the performance and expanding the applications of soft actuators, further driving market expansion in the coming years.

In the healthcare sector, soft actuators are finding applications in wearable devices, prosthetics, and minimally invasive surgical tools. The aging population and the rise in chronic diseases are fueling the demand for advanced medical devices, creating a substantial market opportunity for soft actuator technologies. The global medical robotics market, which includes soft actuator applications, is projected to grow at a robust rate in the coming years.

The industrial automation sector is another key driver for the soft actuator market. As manufacturing processes become more complex and require greater flexibility, soft actuators are being integrated into collaborative robots and adaptive gripping systems. This trend is particularly evident in industries such as automotive, electronics, and food processing, where delicate handling and human-robot collaboration are essential.

The consumer electronics industry is also embracing soft actuator technology, particularly in the development of haptic feedback systems for virtual and augmented reality devices. As the VR/AR market expands, the demand for more realistic and immersive tactile experiences is expected to drive innovation in soft actuator design.

Environmental concerns and the push for energy-efficient solutions are creating new opportunities for soft actuators in the automotive and aerospace industries. Lightweight, flexible actuators can contribute to improved fuel efficiency and reduced emissions in vehicles and aircraft.

Geographically, North America and Europe are currently leading the soft actuator market, with significant research and development activities taking place in these regions. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing adoption of automation technologies, and substantial investments in healthcare infrastructure.

Despite the promising outlook, the soft actuator market faces challenges such as the need for standardization, scalability issues, and the relatively high cost of materials and manufacturing processes. Overcoming these hurdles will be crucial for widespread adoption across industries.

As the technology matures and becomes more cost-effective, the soft actuator market is poised for substantial growth. The development of advanced materials, such as PU structural gels, will play a pivotal role in enhancing the performance and expanding the applications of soft actuators, further driving market expansion in the coming years.

PU Gel Technology Status and Challenges

Polyurethane (PU) structural gels have emerged as a promising material for soft actuator design, offering unique properties that combine flexibility, strength, and responsiveness. However, the current state of PU gel technology presents both significant advancements and notable challenges.

The development of PU gels has seen remarkable progress in recent years, with researchers successfully creating materials that exhibit excellent mechanical properties and stimuli-responsiveness. These gels can undergo reversible deformation in response to various external stimuli, such as temperature, pH, or electric fields, making them ideal candidates for soft actuators.

One of the primary challenges in PU gel technology is achieving a balance between mechanical strength and flexibility. While PU gels offer superior elasticity compared to traditional rigid materials, they often lack the durability required for long-term use in demanding applications. Researchers are actively working on enhancing the mechanical properties of PU gels without compromising their flexibility, exploring various crosslinking strategies and incorporating reinforcing agents.

Another significant hurdle is the control of actuation behavior. Current PU gels often exhibit non-linear responses to stimuli, making precise control of actuator movement challenging. This unpredictability limits their application in scenarios requiring high precision, such as medical devices or robotic manipulators. Efforts are underway to develop more predictable and controllable actuation mechanisms within PU gel structures.

The scalability of PU gel production remains a concern for widespread industrial adoption. While laboratory-scale synthesis has shown promising results, scaling up the production process while maintaining consistent material properties poses significant challenges. Researchers are investigating new manufacturing techniques, including 3D printing and advanced molding processes, to address this issue.

Biocompatibility is another critical aspect of PU gel technology, particularly for applications in biomedical fields. While PU materials are generally considered biocompatible, the long-term effects of PU gels in biological environments are not fully understood. Ongoing research focuses on developing PU gel formulations that are not only safe for biological use but also capable of interacting beneficially with living tissues.

The environmental impact of PU gels is an emerging concern. As the demand for sustainable materials grows, researchers are exploring bio-based precursors and environmentally friendly synthesis methods to reduce the carbon footprint of PU gel production. However, balancing eco-friendliness with the desired material properties remains a significant challenge.

In terms of geographical distribution, PU gel technology research is concentrated in several key regions. North America and Europe lead in fundamental research and patent filings, while Asia, particularly China and Japan, shows rapid growth in applied research and industrial applications. This global distribution of expertise presents opportunities for international collaboration but also challenges in terms of intellectual property rights and technology transfer.

The development of PU gels has seen remarkable progress in recent years, with researchers successfully creating materials that exhibit excellent mechanical properties and stimuli-responsiveness. These gels can undergo reversible deformation in response to various external stimuli, such as temperature, pH, or electric fields, making them ideal candidates for soft actuators.

One of the primary challenges in PU gel technology is achieving a balance between mechanical strength and flexibility. While PU gels offer superior elasticity compared to traditional rigid materials, they often lack the durability required for long-term use in demanding applications. Researchers are actively working on enhancing the mechanical properties of PU gels without compromising their flexibility, exploring various crosslinking strategies and incorporating reinforcing agents.

Another significant hurdle is the control of actuation behavior. Current PU gels often exhibit non-linear responses to stimuli, making precise control of actuator movement challenging. This unpredictability limits their application in scenarios requiring high precision, such as medical devices or robotic manipulators. Efforts are underway to develop more predictable and controllable actuation mechanisms within PU gel structures.

The scalability of PU gel production remains a concern for widespread industrial adoption. While laboratory-scale synthesis has shown promising results, scaling up the production process while maintaining consistent material properties poses significant challenges. Researchers are investigating new manufacturing techniques, including 3D printing and advanced molding processes, to address this issue.

Biocompatibility is another critical aspect of PU gel technology, particularly for applications in biomedical fields. While PU materials are generally considered biocompatible, the long-term effects of PU gels in biological environments are not fully understood. Ongoing research focuses on developing PU gel formulations that are not only safe for biological use but also capable of interacting beneficially with living tissues.

The environmental impact of PU gels is an emerging concern. As the demand for sustainable materials grows, researchers are exploring bio-based precursors and environmentally friendly synthesis methods to reduce the carbon footprint of PU gel production. However, balancing eco-friendliness with the desired material properties remains a significant challenge.

In terms of geographical distribution, PU gel technology research is concentrated in several key regions. North America and Europe lead in fundamental research and patent filings, while Asia, particularly China and Japan, shows rapid growth in applied research and industrial applications. This global distribution of expertise presents opportunities for international collaboration but also challenges in terms of intellectual property rights and technology transfer.

Current PU Gel Solutions for Soft Actuators

01 Polyurethane gel compositions for structural applications

Polyurethane gel compositions are developed for structural applications, offering improved mechanical properties and durability. These gels can be formulated with specific additives to enhance their structural integrity and load-bearing capabilities, making them suitable for various industrial and construction uses.- Polyurethane gel compositions for structural applications: Polyurethane gel compositions are developed for structural applications, offering improved mechanical properties and durability. These gels can be formulated to provide specific characteristics such as flexibility, strength, and impact resistance, making them suitable for various industrial and construction uses.

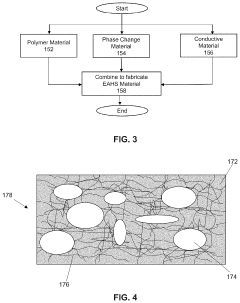

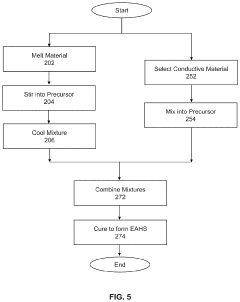

- Energy storage and power management in PU structural gels: PU structural gels are engineered to incorporate energy storage capabilities and power management features. These advanced materials can store and release energy, potentially serving as power sources or energy-efficient components in various applications.

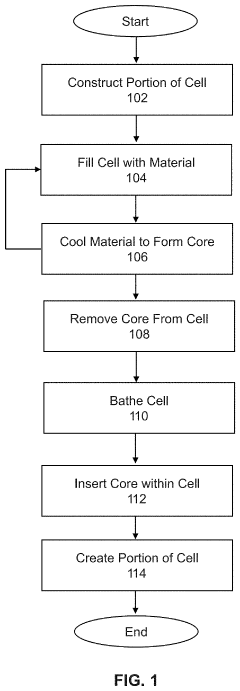

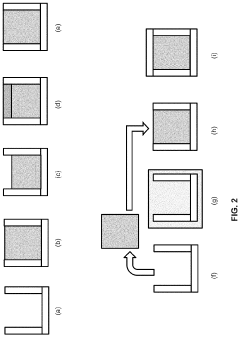

- Manufacturing processes for PU structural gel power systems: Innovative manufacturing processes are developed to produce PU structural gel power systems efficiently. These methods focus on optimizing gel formation, incorporating power-related components, and ensuring consistent quality in the final product.

- Applications of PU structural gels in electronic devices: PU structural gels find applications in electronic devices, providing both structural support and power-related functionalities. These gels can be used in flexible electronics, wearable devices, and other innovative technologies that require both mechanical stability and energy management.

- Environmental and safety considerations in PU structural gel power systems: Research focuses on developing environmentally friendly and safe PU structural gel power systems. This includes the use of sustainable materials, reducing environmental impact, and ensuring safety in various applications, particularly in consumer products and industrial settings.

02 Energy storage and power generation using PU structural gels

PU structural gels are utilized in energy storage and power generation systems. These gels can be engineered to store and release energy efficiently, potentially serving as components in batteries, capacitors, or other power storage devices. Their structural properties allow for integration into various energy-related applications.Expand Specific Solutions03 PU structural gels in electronic and sensor applications

PU structural gels find applications in electronic devices and sensors. Their unique properties allow for the development of flexible, durable, and responsive components in various electronic systems. These gels can be used in touch-sensitive interfaces, pressure sensors, or as protective coatings for electronic components.Expand Specific Solutions04 Manufacturing processes for PU structural gels

Advanced manufacturing processes are developed for producing PU structural gels with specific properties. These processes may involve precise control of chemical reactions, innovative mixing techniques, or the incorporation of nanomaterials to achieve desired structural and functional characteristics in the final gel product.Expand Specific Solutions05 Environmental applications of PU structural gels

PU structural gels are employed in environmental applications, such as water treatment, pollution control, or as components in eco-friendly materials. These gels can be designed to absorb contaminants, facilitate chemical reactions for environmental remediation, or serve as structural elements in sustainable construction materials.Expand Specific Solutions

Key Players in PU Gel and Soft Actuator Industry

The development of PU structural gels for soft actuator design is in an emerging phase, with significant potential for growth. The market size is expanding as soft robotics and biomimetic applications gain traction. Technologically, the field is rapidly evolving, with varying levels of maturity among key players. Academic institutions like Harvard College, Cornell University, and Zhejiang University are at the forefront of research, while companies such as BASF Corp. and Wanhua Chemical Group are advancing commercial applications. Collaborations between academia and industry, exemplified by partnerships involving National University of Singapore and Nanyang Technological University, are accelerating innovation. The competitive landscape is diverse, with both established chemical companies and specialized startups like Artimus Robotics contributing to technological advancements.

BASF Corp.

Technical Solution: BASF has developed a series of advanced PU structural gels for soft actuator applications. Their approach combines traditional polyurethane chemistry with novel additives and processing techniques to create materials with enhanced responsiveness and durability. BASF's PU gels feature a unique network structure that allows for rapid and reversible deformation under various stimuli, such as electric fields or temperature changes. These materials are designed to maintain their performance over many actuation cycles, making them suitable for long-term use in soft robotics and other dynamic applications.

Strengths: High durability, consistent performance over time. Weaknesses: May have higher production costs due to complex formulations.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed a range of polyurethane-based structural gels for soft actuator applications. Their approach focuses on creating tailored PU formulations with specific mechanical and chemical properties. By adjusting the ratio of hard and soft segments in the polymer structure, they can fine-tune the material's elasticity, strength, and response to external stimuli. These PU gels are designed to be highly responsive to electrical or thermal inputs, enabling precise control in soft actuator systems.

Strengths: Customizable material properties, scalable production. Weaknesses: May require specific activation methods depending on the formulation.

Innovative PU Gel Formulations for Actuation

System and methods for fabricating actuators and electrically actuated hydraulic solid materials

PatentActiveUS20210339511A1

Innovation

- The development of Electrically Actuated Hydraulic Solid (EAHS) materials, comprising a polymer matrix with a phase change material and conductive components, which allows for the creation of 3D printed actuators that can generate high forces and stresses at low voltages and currents, replicating the functionality of traditional wax actuators through a distributed cellular structure.

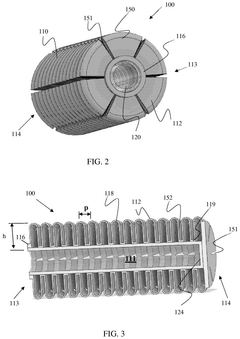

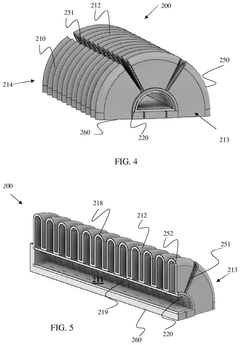

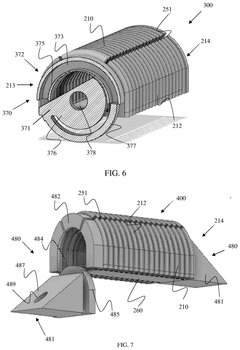

Soft Robotic Modular and Reconfigurable Actuator

PatentPendingUS20250025999A1

Innovation

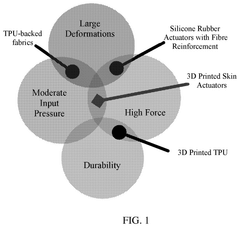

- The development of a soft robotic actuator comprising a corrugated sleeve made of TPU and a bladder made of silicone rubber, where the bladder is detachably secured inside the corrugated sleeve, allowing for controlled extension and bending by inflating/deflating the bladder.

Material Safety and Environmental Impact

The safety and environmental impact of polyurethane (PU) structural gels used in soft actuator design are critical considerations for their widespread adoption and long-term sustainability. These materials offer unique properties that make them attractive for soft robotics applications, but their potential risks and environmental consequences must be carefully evaluated.

From a safety perspective, the primary concerns revolve around the chemical composition and potential toxicity of PU gels. Many PU formulations contain isocyanates, which can pose health risks if not properly handled during manufacturing or if released during use. Inhalation of isocyanate vapors can cause respiratory irritation and sensitization, potentially leading to occupational asthma in workers exposed to these compounds. Additionally, some PU gels may contain additives or plasticizers that could leach out over time, raising concerns about long-term exposure for users of soft actuator devices.

To address these safety issues, researchers and manufacturers are exploring alternative formulations and production methods. Bio-based polyurethanes derived from renewable resources are being developed to reduce reliance on potentially harmful petrochemical-based components. These bio-PUs often exhibit lower toxicity profiles and may offer improved biocompatibility for applications involving human interaction. Furthermore, advanced encapsulation techniques and surface treatments are being investigated to minimize the release of potentially harmful substances from PU gels during use.

Environmental considerations for PU structural gels encompass their entire lifecycle, from production to disposal. The manufacturing process of traditional PU gels often involves energy-intensive steps and the use of volatile organic compounds (VOCs), contributing to air pollution and greenhouse gas emissions. However, recent advancements in green chemistry and sustainable manufacturing practices are helping to mitigate these impacts. Water-based PU systems and solvent-free production methods are being developed to reduce VOC emissions and improve the overall environmental footprint of PU gel production.

End-of-life management for PU gels presents another significant environmental challenge. Many PU materials are not easily biodegradable and can persist in the environment for extended periods. To address this issue, researchers are exploring the development of biodegradable PU gels that can break down under specific environmental conditions without releasing harmful byproducts. Additionally, recycling technologies for PU materials are being advanced, including chemical recycling methods that can break down PU gels into their constituent monomers for reuse in new products.

The potential for microplastic pollution from wear and degradation of PU gels in soft actuators is also a growing concern. As these materials flex and deform during use, they may shed microscopic particles that could enter ecosystems. Research is ongoing to develop more durable PU formulations that resist fragmentation and to create containment strategies that prevent the release of particles from soft actuator devices.

From a safety perspective, the primary concerns revolve around the chemical composition and potential toxicity of PU gels. Many PU formulations contain isocyanates, which can pose health risks if not properly handled during manufacturing or if released during use. Inhalation of isocyanate vapors can cause respiratory irritation and sensitization, potentially leading to occupational asthma in workers exposed to these compounds. Additionally, some PU gels may contain additives or plasticizers that could leach out over time, raising concerns about long-term exposure for users of soft actuator devices.

To address these safety issues, researchers and manufacturers are exploring alternative formulations and production methods. Bio-based polyurethanes derived from renewable resources are being developed to reduce reliance on potentially harmful petrochemical-based components. These bio-PUs often exhibit lower toxicity profiles and may offer improved biocompatibility for applications involving human interaction. Furthermore, advanced encapsulation techniques and surface treatments are being investigated to minimize the release of potentially harmful substances from PU gels during use.

Environmental considerations for PU structural gels encompass their entire lifecycle, from production to disposal. The manufacturing process of traditional PU gels often involves energy-intensive steps and the use of volatile organic compounds (VOCs), contributing to air pollution and greenhouse gas emissions. However, recent advancements in green chemistry and sustainable manufacturing practices are helping to mitigate these impacts. Water-based PU systems and solvent-free production methods are being developed to reduce VOC emissions and improve the overall environmental footprint of PU gel production.

End-of-life management for PU gels presents another significant environmental challenge. Many PU materials are not easily biodegradable and can persist in the environment for extended periods. To address this issue, researchers are exploring the development of biodegradable PU gels that can break down under specific environmental conditions without releasing harmful byproducts. Additionally, recycling technologies for PU materials are being advanced, including chemical recycling methods that can break down PU gels into their constituent monomers for reuse in new products.

The potential for microplastic pollution from wear and degradation of PU gels in soft actuators is also a growing concern. As these materials flex and deform during use, they may shed microscopic particles that could enter ecosystems. Research is ongoing to develop more durable PU formulations that resist fragmentation and to create containment strategies that prevent the release of particles from soft actuator devices.

Scalability and Manufacturing Processes

The scalability and manufacturing processes of PU structural gels for soft actuator design are critical factors in determining their widespread adoption and commercial viability. Current manufacturing methods for PU gels typically involve solution casting or melt processing techniques. However, these methods often face challenges in terms of scalability, consistency, and cost-effectiveness when considering large-scale production.

One promising approach to improve scalability is the development of continuous manufacturing processes. Extrusion-based methods, for instance, offer the potential for high-throughput production of PU gel structures with consistent properties. By optimizing extrusion parameters such as temperature, pressure, and flow rate, manufacturers can achieve better control over the gel's microstructure and mechanical properties.

Another avenue for enhancing scalability is the implementation of modular manufacturing systems. These systems allow for flexible production scales, enabling manufacturers to adjust output based on demand without significant retooling. Modular approaches also facilitate easier maintenance and upgrades, potentially reducing downtime and improving overall production efficiency.

Additive manufacturing techniques, particularly 3D printing, are emerging as powerful tools for fabricating complex PU gel structures. While currently limited in scale, ongoing advancements in 3D printing technologies promise to increase build volumes and printing speeds, making them increasingly viable for larger-scale production of soft actuators.

To address consistency challenges in PU gel manufacturing, in-line quality control measures are being developed. These include real-time monitoring of gel properties during production using spectroscopic techniques or mechanical testing. Such measures can help ensure that the produced gels meet the required specifications for soft actuator applications.

The environmental impact of PU gel manufacturing processes is also a growing concern. Efforts are being made to develop more sustainable production methods, such as using bio-based precursors or implementing solvent recycling systems. These approaches not only reduce the environmental footprint but can also lead to cost savings in large-scale production.

As the demand for soft actuators grows, the integration of PU gel manufacturing processes with existing industrial infrastructure becomes crucial. This integration may involve adapting current polymer processing equipment or developing specialized production lines tailored to PU gel fabrication. Such integration efforts are essential for leveraging existing manufacturing expertise and reducing the barriers to large-scale adoption.

One promising approach to improve scalability is the development of continuous manufacturing processes. Extrusion-based methods, for instance, offer the potential for high-throughput production of PU gel structures with consistent properties. By optimizing extrusion parameters such as temperature, pressure, and flow rate, manufacturers can achieve better control over the gel's microstructure and mechanical properties.

Another avenue for enhancing scalability is the implementation of modular manufacturing systems. These systems allow for flexible production scales, enabling manufacturers to adjust output based on demand without significant retooling. Modular approaches also facilitate easier maintenance and upgrades, potentially reducing downtime and improving overall production efficiency.

Additive manufacturing techniques, particularly 3D printing, are emerging as powerful tools for fabricating complex PU gel structures. While currently limited in scale, ongoing advancements in 3D printing technologies promise to increase build volumes and printing speeds, making them increasingly viable for larger-scale production of soft actuators.

To address consistency challenges in PU gel manufacturing, in-line quality control measures are being developed. These include real-time monitoring of gel properties during production using spectroscopic techniques or mechanical testing. Such measures can help ensure that the produced gels meet the required specifications for soft actuator applications.

The environmental impact of PU gel manufacturing processes is also a growing concern. Efforts are being made to develop more sustainable production methods, such as using bio-based precursors or implementing solvent recycling systems. These approaches not only reduce the environmental footprint but can also lead to cost savings in large-scale production.

As the demand for soft actuators grows, the integration of PU gel manufacturing processes with existing industrial infrastructure becomes crucial. This integration may involve adapting current polymer processing equipment or developing specialized production lines tailored to PU gel fabrication. Such integration efforts are essential for leveraging existing manufacturing expertise and reducing the barriers to large-scale adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!