Exploring Polyurethane Applications in Footwear Design

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Footwear Evolution

The evolution of polyurethane (PU) in footwear design has been a remarkable journey, spanning several decades and revolutionizing the shoe industry. The timeline of PU footwear development can be traced back to the 1970s when PU was first introduced as a material for shoe soles. This innovation marked a significant departure from traditional rubber and leather soles, offering improved durability, flexibility, and comfort.

In the 1980s, PU technology in footwear saw rapid advancements. Manufacturers began experimenting with different formulations, leading to the development of microcellular PU soles. These soles provided enhanced cushioning and shock absorption, making them particularly popular in athletic and casual footwear. The decade also saw the introduction of PU midsoles, which further improved the overall performance of shoes.

The 1990s brought about a new era in PU footwear with the advent of dual-density PU soles. This technology allowed for the creation of soles with varying densities in different areas, optimizing comfort and support. Additionally, the integration of PU into shoe uppers began during this period, offering new possibilities for design and functionality.

As we entered the 2000s, sustainability became a key focus in the footwear industry. This led to the development of bio-based PU materials, derived from renewable resources such as plant oils. These eco-friendly alternatives maintained the performance characteristics of traditional PU while reducing the environmental impact of shoe production.

The 2010s saw a surge in customization and personalization in footwear design. 3D printing technology enabled the creation of complex PU structures tailored to individual foot shapes and gait patterns. This era also witnessed the rise of smart footwear, incorporating PU materials with embedded sensors and responsive properties.

In recent years, the focus has shifted towards circular economy principles in PU footwear. Manufacturers are now developing recyclable and biodegradable PU formulations, addressing end-of-life concerns for shoes. Advanced recycling technologies are being explored to break down PU materials and reuse them in new footwear products, closing the loop in the production cycle.

Looking ahead, the future of PU in footwear design promises even more exciting developments. Research is underway to create self-healing PU materials that can repair minor damage, extending the lifespan of shoes. Additionally, the integration of nanotechnology with PU is expected to yield materials with enhanced properties, such as improved water resistance and thermal regulation.

In the 1980s, PU technology in footwear saw rapid advancements. Manufacturers began experimenting with different formulations, leading to the development of microcellular PU soles. These soles provided enhanced cushioning and shock absorption, making them particularly popular in athletic and casual footwear. The decade also saw the introduction of PU midsoles, which further improved the overall performance of shoes.

The 1990s brought about a new era in PU footwear with the advent of dual-density PU soles. This technology allowed for the creation of soles with varying densities in different areas, optimizing comfort and support. Additionally, the integration of PU into shoe uppers began during this period, offering new possibilities for design and functionality.

As we entered the 2000s, sustainability became a key focus in the footwear industry. This led to the development of bio-based PU materials, derived from renewable resources such as plant oils. These eco-friendly alternatives maintained the performance characteristics of traditional PU while reducing the environmental impact of shoe production.

The 2010s saw a surge in customization and personalization in footwear design. 3D printing technology enabled the creation of complex PU structures tailored to individual foot shapes and gait patterns. This era also witnessed the rise of smart footwear, incorporating PU materials with embedded sensors and responsive properties.

In recent years, the focus has shifted towards circular economy principles in PU footwear. Manufacturers are now developing recyclable and biodegradable PU formulations, addressing end-of-life concerns for shoes. Advanced recycling technologies are being explored to break down PU materials and reuse them in new footwear products, closing the loop in the production cycle.

Looking ahead, the future of PU in footwear design promises even more exciting developments. Research is underway to create self-healing PU materials that can repair minor damage, extending the lifespan of shoes. Additionally, the integration of nanotechnology with PU is expected to yield materials with enhanced properties, such as improved water resistance and thermal regulation.

Market Demand Analysis

The global footwear market has witnessed significant growth in recent years, with a particular emphasis on comfort, performance, and sustainability. Polyurethane (PU) has emerged as a key material in this sector, driving innovation and meeting evolving consumer demands. The market for PU in footwear is expected to expand substantially, fueled by the material's versatility and superior properties.

Consumer preferences are shifting towards lightweight, durable, and comfortable footwear, especially in athletic and casual segments. PU's ability to provide excellent cushioning, shock absorption, and energy return aligns perfectly with these requirements. This has led to increased adoption of PU in midsoles, outsoles, and insoles across various footwear categories.

The athletic footwear segment, in particular, has shown robust growth, with PU playing a crucial role in enhancing performance and comfort. Running shoes, cross-trainers, and sports-specific footwear have all benefited from PU's unique characteristics, driving demand for innovative PU formulations tailored to specific athletic needs.

Sustainability has become a major focus in the footwear industry, with consumers increasingly seeking eco-friendly options. PU's potential for recyclability and the development of bio-based PU formulations have positioned it as a material of choice for environmentally conscious brands and consumers. This trend is expected to further boost the demand for PU in footwear applications.

The casual and fashion footwear segments have also embraced PU, leveraging its flexibility in design and color options. PU's ability to mimic the look and feel of leather while offering improved durability and water resistance has made it popular in these categories, particularly in regions with price-sensitive markets.

Geographically, Asia-Pacific dominates the PU footwear market, with China and India being major contributors to growth. The region's large population, rising disposable incomes, and expanding middle class have fueled demand for affordable yet high-quality footwear. North America and Europe follow, with a focus on premium and technologically advanced footwear incorporating PU components.

The COVID-19 pandemic has accelerated certain market trends, such as the demand for comfortable athleisure footwear and the shift towards online retail channels. These changes have further emphasized the importance of PU in footwear design, as brands seek to differentiate their products in a competitive market.

Looking ahead, the market for PU in footwear is poised for continued growth. Factors such as urbanization, increasing health awareness, and the growing popularity of sports and fitness activities are expected to drive demand for PU-based footwear solutions. Additionally, ongoing research and development in PU technology promise to unlock new applications and enhance existing ones, further expanding the material's role in the footwear industry.

Consumer preferences are shifting towards lightweight, durable, and comfortable footwear, especially in athletic and casual segments. PU's ability to provide excellent cushioning, shock absorption, and energy return aligns perfectly with these requirements. This has led to increased adoption of PU in midsoles, outsoles, and insoles across various footwear categories.

The athletic footwear segment, in particular, has shown robust growth, with PU playing a crucial role in enhancing performance and comfort. Running shoes, cross-trainers, and sports-specific footwear have all benefited from PU's unique characteristics, driving demand for innovative PU formulations tailored to specific athletic needs.

Sustainability has become a major focus in the footwear industry, with consumers increasingly seeking eco-friendly options. PU's potential for recyclability and the development of bio-based PU formulations have positioned it as a material of choice for environmentally conscious brands and consumers. This trend is expected to further boost the demand for PU in footwear applications.

The casual and fashion footwear segments have also embraced PU, leveraging its flexibility in design and color options. PU's ability to mimic the look and feel of leather while offering improved durability and water resistance has made it popular in these categories, particularly in regions with price-sensitive markets.

Geographically, Asia-Pacific dominates the PU footwear market, with China and India being major contributors to growth. The region's large population, rising disposable incomes, and expanding middle class have fueled demand for affordable yet high-quality footwear. North America and Europe follow, with a focus on premium and technologically advanced footwear incorporating PU components.

The COVID-19 pandemic has accelerated certain market trends, such as the demand for comfortable athleisure footwear and the shift towards online retail channels. These changes have further emphasized the importance of PU in footwear design, as brands seek to differentiate their products in a competitive market.

Looking ahead, the market for PU in footwear is poised for continued growth. Factors such as urbanization, increasing health awareness, and the growing popularity of sports and fitness activities are expected to drive demand for PU-based footwear solutions. Additionally, ongoing research and development in PU technology promise to unlock new applications and enhance existing ones, further expanding the material's role in the footwear industry.

PU Tech Challenges

Despite the widespread use of polyurethane (PU) in footwear design, several technical challenges persist in optimizing its application. One of the primary issues is achieving the ideal balance between durability and comfort. While PU offers excellent wear resistance, enhancing its flexibility and cushioning properties without compromising longevity remains a significant hurdle.

Another challenge lies in the environmental impact of PU production and disposal. Traditional PU manufacturing processes often involve the use of harmful chemicals and produce significant emissions. Developing eco-friendly alternatives and sustainable production methods that maintain the desirable properties of PU is a pressing concern for the industry.

The adhesion of PU to other materials used in shoe construction presents another technical obstacle. Ensuring strong, long-lasting bonds between PU components and materials like leather, textiles, and other synthetics is crucial for overall shoe integrity. This challenge is particularly pronounced in athletic footwear, where shoes are subjected to intense stress and varying environmental conditions.

Customization and rapid prototyping pose additional challenges in PU footwear applications. As the demand for personalized footwear grows, manufacturers face difficulties in efficiently producing small batches or custom designs while maintaining cost-effectiveness. Developing adaptable PU formulations and manufacturing processes that can accommodate diverse design requirements without sacrificing quality or increasing production time is a significant technical hurdle.

The thermal management properties of PU in footwear also present ongoing challenges. Improving the breathability and moisture-wicking capabilities of PU components while preserving their structural integrity and performance characteristics is an area of active research and development. This is particularly crucial for athletic and outdoor footwear, where temperature regulation and moisture control significantly impact user comfort and performance.

Lastly, the integration of smart technologies into PU footwear components introduces a new set of technical challenges. Incorporating sensors, responsive materials, or other electronic elements into PU structures without compromising the material's core properties or the overall shoe design requires innovative approaches to material science and manufacturing processes.

Another challenge lies in the environmental impact of PU production and disposal. Traditional PU manufacturing processes often involve the use of harmful chemicals and produce significant emissions. Developing eco-friendly alternatives and sustainable production methods that maintain the desirable properties of PU is a pressing concern for the industry.

The adhesion of PU to other materials used in shoe construction presents another technical obstacle. Ensuring strong, long-lasting bonds between PU components and materials like leather, textiles, and other synthetics is crucial for overall shoe integrity. This challenge is particularly pronounced in athletic footwear, where shoes are subjected to intense stress and varying environmental conditions.

Customization and rapid prototyping pose additional challenges in PU footwear applications. As the demand for personalized footwear grows, manufacturers face difficulties in efficiently producing small batches or custom designs while maintaining cost-effectiveness. Developing adaptable PU formulations and manufacturing processes that can accommodate diverse design requirements without sacrificing quality or increasing production time is a significant technical hurdle.

The thermal management properties of PU in footwear also present ongoing challenges. Improving the breathability and moisture-wicking capabilities of PU components while preserving their structural integrity and performance characteristics is an area of active research and development. This is particularly crucial for athletic and outdoor footwear, where temperature regulation and moisture control significantly impact user comfort and performance.

Lastly, the integration of smart technologies into PU footwear components introduces a new set of technical challenges. Incorporating sensors, responsive materials, or other electronic elements into PU structures without compromising the material's core properties or the overall shoe design requires innovative approaches to material science and manufacturing processes.

Current PU Solutions

01 Polyurethane synthesis and composition

This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.- Polyurethane synthesis and composition: This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis often involves the reaction of polyols with isocyanates, with the addition of catalysts and other additives to control the reaction and final properties.

- Polyurethane applications in coatings and films: This point covers the use of polyurethane in various coating and film applications. Polyurethane coatings and films are known for their excellent durability, chemical resistance, and versatility. They are used in industries such as automotive, construction, and electronics for protective and decorative purposes. The formulations are often tailored to meet specific performance requirements.

- Polyurethane foam technology: This category encompasses the development and production of polyurethane foams. It includes various types of foams such as flexible, rigid, and spray foams. The technology involves controlling the foam structure, density, and properties through the use of specific formulations, blowing agents, and processing techniques. Applications range from insulation materials to cushioning in furniture and automotive interiors.

- Polyurethane in adhesives and sealants: This point focuses on the use of polyurethane in adhesive and sealant applications. Polyurethane-based adhesives and sealants offer excellent bonding strength, flexibility, and resistance to environmental factors. They are used in various industries, including construction, automotive, and packaging. The formulations are often designed to provide specific curing mechanisms, adhesion properties, and durability.

- Sustainable and bio-based polyurethane: This category covers the development of sustainable and bio-based polyurethane materials. It includes the use of renewable resources, such as plant-based polyols, to replace petroleum-based components in polyurethane production. The focus is on reducing environmental impact while maintaining or improving the performance of polyurethane products. This area also encompasses research into biodegradable polyurethane formulations.

02 Polyurethane applications in coatings and adhesives

This category covers the use of polyurethane in coatings and adhesives. It includes formulations for various applications such as automotive coatings, industrial adhesives, and protective finishes. The focus is on developing polyurethane-based products with enhanced adhesion, durability, and resistance to environmental factors.Expand Specific Solutions03 Polyurethane foam technology

This category encompasses innovations in polyurethane foam production and properties. It includes methods for creating various types of foam, such as flexible, rigid, or viscoelastic foams, with specific characteristics like improved insulation, fire resistance, or biodegradability. The focus is on optimizing foam structure and performance for different applications.Expand Specific Solutions04 Sustainable and bio-based polyurethanes

This category focuses on developing environmentally friendly polyurethane materials. It includes the use of renewable resources, such as plant-based polyols, to replace petroleum-based components. The emphasis is on creating sustainable polyurethanes with reduced environmental impact while maintaining or improving performance characteristics.Expand Specific Solutions05 Polyurethane in medical and healthcare applications

This category covers the use of polyurethane in medical devices, implants, and healthcare products. It includes developments in biocompatible polyurethanes, drug-eluting materials, and antimicrobial surfaces. The focus is on creating polyurethane-based materials that meet the specific requirements of medical applications, such as long-term stability in the body and controlled drug release.Expand Specific Solutions

Footwear Industry Players

The polyurethane applications in footwear design market is in a growth phase, driven by increasing demand for comfortable and durable footwear. The global market size is expanding, with a projected CAGR of 5.8% from 2021 to 2028. Technologically, the field is moderately mature, with ongoing innovations focused on sustainability and performance enhancement. Key players like BASF Corp., Covestro Deutschland AG, and Dow Global Technologies LLC are leading in R&D, while companies such as Croda International Plc and Kao Corp. are contributing to material advancements. Emerging players like ShanDong Inov Polyurethane Co., Ltd. and ZheJiang AoKang Shoes Co., Ltd. are also making significant strides, particularly in regional markets, indicating a competitive and dynamic industry landscape.

BASF Corp.

Technical Solution: BASF has developed a range of polyurethane solutions for footwear, including their Elastopan® and Elastollan® product lines. These materials offer customizable properties such as density, hardness, and resilience. BASF's technology focuses on creating lightweight, durable, and comfortable midsoles and outsoles. They have also introduced bio-based polyurethanes, incorporating renewable raw materials to enhance sustainability in footwear production.

Strengths: Wide range of customizable properties, strong focus on sustainability with bio-based options. Weaknesses: May be more expensive than traditional materials, requires specialized processing equipment.

Covestro Deutschland AG

Technical Solution: Covestro has developed INSQIN® technology, a water-based polyurethane (PU) technology for textile coating in footwear. This innovative approach eliminates the need for solvents, reducing environmental impact and improving worker safety. Their technology allows for the creation of breathable, durable, and high-performance synthetic materials for shoe uppers. Additionally, Covestro offers Desmopan® thermoplastic polyurethanes (TPU) for outsoles, providing excellent abrasion resistance and flexibility.

Strengths: Environmentally friendly water-based technology, versatile applications in both uppers and outsoles. Weaknesses: May require adaptation of existing manufacturing processes, potentially higher initial investment costs.

Key PU Patents

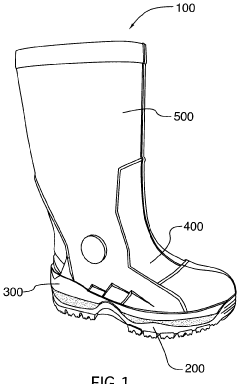

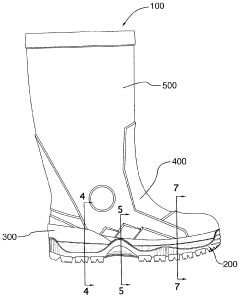

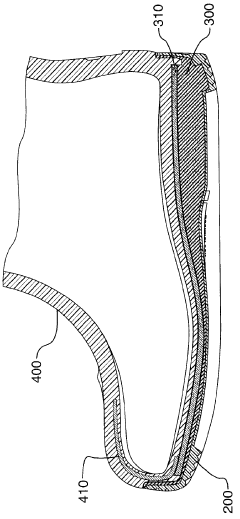

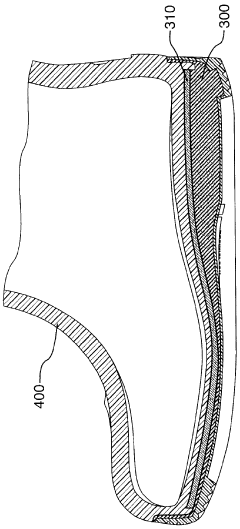

Footwear construction and method

PatentActiveCA2641977A1

Innovation

- The integration of a rubber outsole with a polyurethane midsole and upper using a polyurethane adhesive, combined with injection molding to bond the components, ensuring a strong and durable footwear product with improved cold-weather performance.

Polyurethane compound and shoe soles made therefrom

PatentActiveUS20080269371A1

Innovation

- A polyurethane compound combining a reaction product of isocyanate and polytetramethylene ether glycol with an organic wax, which enhances abrasion resistance without requiring additional additives like PTFE, and uses polyether polyols instead of polyester polyols.

Sustainability in PU

Sustainability has become a critical focus in the polyurethane (PU) industry, particularly in footwear design. As environmental concerns grow, manufacturers are increasingly seeking eco-friendly alternatives and sustainable practices in PU production and application. One significant advancement is the development of bio-based polyurethanes, which utilize renewable resources such as plant-derived oils or recycled materials as feedstock. These bio-based PUs offer comparable performance to traditional petroleum-based counterparts while reducing the carbon footprint of footwear production.

Recycling and circular economy principles are also gaining traction in the PU footwear sector. Innovative technologies are emerging to enable the efficient recycling of PU materials, allowing for the recovery and reuse of valuable components. This not only reduces waste but also conserves resources and energy. Some companies are implementing take-back programs, where used footwear is collected and processed to recover PU materials for new products.

Water-based PU systems represent another sustainable innovation in footwear design. These systems significantly reduce or eliminate the use of volatile organic compounds (VOCs) and other harmful solvents, improving worker safety and minimizing environmental impact. Water-based PUs also offer excellent adhesion properties and can be formulated to meet specific performance requirements for different footwear applications.

Energy efficiency in PU production processes is another area of focus for sustainability. Advanced manufacturing techniques, such as reaction injection molding (RIM) and microcellular foam technologies, are being optimized to reduce energy consumption and material waste. These processes allow for more precise control over PU formulations and properties, resulting in higher-quality footwear components with improved durability and performance.

Biodegradable PU formulations are also being explored as a potential solution to end-of-life waste management. While challenges remain in balancing biodegradability with the required durability and performance of footwear, research in this area is progressing. Some biodegradable PUs have shown promise in laboratory settings, breaking down under specific environmental conditions without compromising their functional properties during use.

The integration of sustainable PU technologies in footwear design extends beyond material composition to encompass the entire product lifecycle. This holistic approach considers factors such as production efficiency, transportation logistics, and end-of-life disposal. By optimizing these aspects, manufacturers can further reduce the environmental impact of PU footwear while maintaining or even enhancing product quality and performance.

Recycling and circular economy principles are also gaining traction in the PU footwear sector. Innovative technologies are emerging to enable the efficient recycling of PU materials, allowing for the recovery and reuse of valuable components. This not only reduces waste but also conserves resources and energy. Some companies are implementing take-back programs, where used footwear is collected and processed to recover PU materials for new products.

Water-based PU systems represent another sustainable innovation in footwear design. These systems significantly reduce or eliminate the use of volatile organic compounds (VOCs) and other harmful solvents, improving worker safety and minimizing environmental impact. Water-based PUs also offer excellent adhesion properties and can be formulated to meet specific performance requirements for different footwear applications.

Energy efficiency in PU production processes is another area of focus for sustainability. Advanced manufacturing techniques, such as reaction injection molding (RIM) and microcellular foam technologies, are being optimized to reduce energy consumption and material waste. These processes allow for more precise control over PU formulations and properties, resulting in higher-quality footwear components with improved durability and performance.

Biodegradable PU formulations are also being explored as a potential solution to end-of-life waste management. While challenges remain in balancing biodegradability with the required durability and performance of footwear, research in this area is progressing. Some biodegradable PUs have shown promise in laboratory settings, breaking down under specific environmental conditions without compromising their functional properties during use.

The integration of sustainable PU technologies in footwear design extends beyond material composition to encompass the entire product lifecycle. This holistic approach considers factors such as production efficiency, transportation logistics, and end-of-life disposal. By optimizing these aspects, manufacturers can further reduce the environmental impact of PU footwear while maintaining or even enhancing product quality and performance.

PU Performance Testing

Performance testing is a critical aspect of polyurethane (PU) application in footwear design, ensuring that the material meets the rigorous demands of modern footwear. The testing process encompasses a wide range of parameters, each designed to evaluate specific properties crucial for optimal shoe performance and durability.

One of the primary tests conducted on PU materials for footwear is the abrasion resistance test. This assessment measures the material's ability to withstand wear and tear from repeated friction, simulating real-world usage conditions. The test typically involves subjecting PU samples to controlled abrasive forces and measuring the material loss over time. High abrasion resistance is particularly important for outsoles, which are in constant contact with various surfaces.

Flexibility testing is another key component of PU performance evaluation. This test assesses the material's ability to bend and flex without cracking or breaking, a crucial property for comfortable and responsive footwear. Flexibility tests often involve repeated bending cycles at different temperatures to simulate various environmental conditions.

Compression set testing is essential for evaluating the PU's ability to maintain its shape and cushioning properties over time. This test measures the material's recovery after being subjected to prolonged compression, which is particularly relevant for midsoles and insoles that need to provide consistent comfort and support throughout the shoe's lifespan.

Tensile strength and elongation tests are conducted to assess the PU's overall durability and elasticity. These tests measure the material's ability to withstand stretching forces without tearing or deforming permanently. High tensile strength and appropriate elongation are crucial for maintaining the structural integrity of the shoe during use.

Chemical resistance testing is also performed to ensure that the PU can withstand exposure to various substances it may encounter during use, such as sweat, water, and cleaning agents. This involves exposing PU samples to different chemicals and evaluating any changes in properties or appearance.

Thermal stability tests are conducted to assess how PU performs under different temperature conditions. This is particularly important for footwear that may be used in extreme environments or subjected to high temperatures during manufacturing processes.

Density and hardness measurements are routinely performed to ensure consistency in PU formulations. These properties directly impact the shoe's weight, comfort, and performance characteristics. Shore hardness tests are commonly used to quantify the material's resistance to indentation.

Finally, environmental impact assessments are increasingly becoming part of PU performance testing. These evaluations consider factors such as biodegradability, recyclability, and the presence of harmful substances, aligning with growing consumer demand for sustainable footwear options.

One of the primary tests conducted on PU materials for footwear is the abrasion resistance test. This assessment measures the material's ability to withstand wear and tear from repeated friction, simulating real-world usage conditions. The test typically involves subjecting PU samples to controlled abrasive forces and measuring the material loss over time. High abrasion resistance is particularly important for outsoles, which are in constant contact with various surfaces.

Flexibility testing is another key component of PU performance evaluation. This test assesses the material's ability to bend and flex without cracking or breaking, a crucial property for comfortable and responsive footwear. Flexibility tests often involve repeated bending cycles at different temperatures to simulate various environmental conditions.

Compression set testing is essential for evaluating the PU's ability to maintain its shape and cushioning properties over time. This test measures the material's recovery after being subjected to prolonged compression, which is particularly relevant for midsoles and insoles that need to provide consistent comfort and support throughout the shoe's lifespan.

Tensile strength and elongation tests are conducted to assess the PU's overall durability and elasticity. These tests measure the material's ability to withstand stretching forces without tearing or deforming permanently. High tensile strength and appropriate elongation are crucial for maintaining the structural integrity of the shoe during use.

Chemical resistance testing is also performed to ensure that the PU can withstand exposure to various substances it may encounter during use, such as sweat, water, and cleaning agents. This involves exposing PU samples to different chemicals and evaluating any changes in properties or appearance.

Thermal stability tests are conducted to assess how PU performs under different temperature conditions. This is particularly important for footwear that may be used in extreme environments or subjected to high temperatures during manufacturing processes.

Density and hardness measurements are routinely performed to ensure consistency in PU formulations. These properties directly impact the shoe's weight, comfort, and performance characteristics. Shore hardness tests are commonly used to quantify the material's resistance to indentation.

Finally, environmental impact assessments are increasingly becoming part of PU performance testing. These evaluations consider factors such as biodegradability, recyclability, and the presence of harmful substances, aligning with growing consumer demand for sustainable footwear options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!