Understanding Polyurethane Chemistry for Better Performance

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Chemistry Evolution

Polyurethane chemistry has undergone significant evolution since its inception in the 1930s. The journey began with Otto Bayer's groundbreaking discovery of the polyaddition reaction between diisocyanates and polyols, which laid the foundation for modern polyurethane technology. This initial breakthrough opened up a vast array of possibilities for creating versatile materials with tailored properties.

In the early stages, the focus was primarily on developing basic polyurethane formulations and understanding the fundamental reaction mechanisms. As the technology progressed, researchers began to explore more complex systems, incorporating various additives and modifiers to enhance specific properties. The 1950s and 1960s saw rapid advancements in polyurethane foam technology, leading to the widespread use of these materials in furniture, automotive, and construction industries.

The 1970s marked a significant shift towards improving the environmental profile of polyurethanes. This period witnessed the development of water-blown foams and the gradual phasing out of chlorofluorocarbon (CFC) blowing agents. Concurrently, efforts were made to enhance the fire resistance of polyurethane materials, addressing safety concerns in various applications.

The 1980s and 1990s brought about a revolution in polyurethane chemistry with the introduction of novel catalysts and the exploration of alternative raw materials. This era saw the emergence of bio-based polyols and the development of more environmentally friendly isocyanates. The focus on sustainability continued to grow, driving research into recyclable and biodegradable polyurethane systems.

In recent years, the evolution of polyurethane chemistry has been characterized by a push towards high-performance and specialty applications. Advanced analytical techniques and computational modeling have enabled a deeper understanding of structure-property relationships, allowing for more precise control over material properties. This has led to the development of polyurethanes with enhanced thermal stability, improved chemical resistance, and superior mechanical properties.

The current frontier in polyurethane chemistry involves the integration of nanotechnology and smart materials concepts. Researchers are exploring the incorporation of nanoparticles and functional additives to create self-healing polyurethanes, shape-memory materials, and stimuli-responsive systems. Additionally, there is a growing interest in developing non-isocyanate polyurethanes (NIPUs) as a sustainable alternative to traditional polyurethane chemistry.

As we look to the future, the evolution of polyurethane chemistry is likely to continue its trajectory towards more sustainable, high-performance materials. The focus will be on developing bio-based and recyclable systems, reducing environmental impact, and expanding the application range of polyurethanes in emerging technologies such as 3D printing, wearable electronics, and advanced coatings.

In the early stages, the focus was primarily on developing basic polyurethane formulations and understanding the fundamental reaction mechanisms. As the technology progressed, researchers began to explore more complex systems, incorporating various additives and modifiers to enhance specific properties. The 1950s and 1960s saw rapid advancements in polyurethane foam technology, leading to the widespread use of these materials in furniture, automotive, and construction industries.

The 1970s marked a significant shift towards improving the environmental profile of polyurethanes. This period witnessed the development of water-blown foams and the gradual phasing out of chlorofluorocarbon (CFC) blowing agents. Concurrently, efforts were made to enhance the fire resistance of polyurethane materials, addressing safety concerns in various applications.

The 1980s and 1990s brought about a revolution in polyurethane chemistry with the introduction of novel catalysts and the exploration of alternative raw materials. This era saw the emergence of bio-based polyols and the development of more environmentally friendly isocyanates. The focus on sustainability continued to grow, driving research into recyclable and biodegradable polyurethane systems.

In recent years, the evolution of polyurethane chemistry has been characterized by a push towards high-performance and specialty applications. Advanced analytical techniques and computational modeling have enabled a deeper understanding of structure-property relationships, allowing for more precise control over material properties. This has led to the development of polyurethanes with enhanced thermal stability, improved chemical resistance, and superior mechanical properties.

The current frontier in polyurethane chemistry involves the integration of nanotechnology and smart materials concepts. Researchers are exploring the incorporation of nanoparticles and functional additives to create self-healing polyurethanes, shape-memory materials, and stimuli-responsive systems. Additionally, there is a growing interest in developing non-isocyanate polyurethanes (NIPUs) as a sustainable alternative to traditional polyurethane chemistry.

As we look to the future, the evolution of polyurethane chemistry is likely to continue its trajectory towards more sustainable, high-performance materials. The focus will be on developing bio-based and recyclable systems, reducing environmental impact, and expanding the application range of polyurethanes in emerging technologies such as 3D printing, wearable electronics, and advanced coatings.

Market Demand Analysis

The global polyurethane market has been experiencing steady growth, driven by increasing demand across various industries. The versatility and unique properties of polyurethanes make them indispensable in sectors such as construction, automotive, furniture, and electronics. As of recent market analyses, the polyurethane market is projected to reach significant valuations in the coming years, with a compound annual growth rate (CAGR) that reflects the industry's robust expansion.

In the construction sector, polyurethanes are gaining traction due to their excellent insulation properties, contributing to energy-efficient building solutions. The growing emphasis on sustainable and green building practices has further boosted the demand for high-performance polyurethane-based materials. Additionally, the automotive industry's shift towards lightweight materials to improve fuel efficiency has led to increased adoption of polyurethane components in vehicle manufacturing.

The furniture industry represents another substantial market for polyurethanes, particularly in the form of flexible foams used in mattresses, cushions, and upholstery. The rising consumer preference for comfortable and durable furniture is driving the demand for polyurethane-based products in this sector. Moreover, the electronics industry utilizes polyurethanes in various applications, including as protective coatings and insulation materials, further expanding the market reach.

Emerging economies, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and urbanization, which is fueling the demand for polyurethane-based products across multiple sectors. These regions are expected to be key growth drivers for the polyurethane market in the coming years.

The increasing focus on sustainability and environmental regulations has led to a growing demand for bio-based and recyclable polyurethanes. This trend is prompting manufacturers to invest in research and development to create more eco-friendly polyurethane formulations, opening up new market opportunities and addressing environmental concerns.

However, the market also faces challenges, such as volatile raw material prices and stringent regulations regarding the use of certain chemicals in polyurethane production. These factors are pushing the industry towards innovation in chemistry and production processes to maintain competitiveness and meet evolving market demands.

In conclusion, the market demand for polyurethanes remains strong, with significant growth potential across various industries. The ongoing research into improving polyurethane chemistry for better performance is crucial to address the evolving market needs, overcome challenges, and capitalize on emerging opportunities in this dynamic sector.

In the construction sector, polyurethanes are gaining traction due to their excellent insulation properties, contributing to energy-efficient building solutions. The growing emphasis on sustainable and green building practices has further boosted the demand for high-performance polyurethane-based materials. Additionally, the automotive industry's shift towards lightweight materials to improve fuel efficiency has led to increased adoption of polyurethane components in vehicle manufacturing.

The furniture industry represents another substantial market for polyurethanes, particularly in the form of flexible foams used in mattresses, cushions, and upholstery. The rising consumer preference for comfortable and durable furniture is driving the demand for polyurethane-based products in this sector. Moreover, the electronics industry utilizes polyurethanes in various applications, including as protective coatings and insulation materials, further expanding the market reach.

Emerging economies, particularly in Asia-Pacific and Latin America, are witnessing rapid industrialization and urbanization, which is fueling the demand for polyurethane-based products across multiple sectors. These regions are expected to be key growth drivers for the polyurethane market in the coming years.

The increasing focus on sustainability and environmental regulations has led to a growing demand for bio-based and recyclable polyurethanes. This trend is prompting manufacturers to invest in research and development to create more eco-friendly polyurethane formulations, opening up new market opportunities and addressing environmental concerns.

However, the market also faces challenges, such as volatile raw material prices and stringent regulations regarding the use of certain chemicals in polyurethane production. These factors are pushing the industry towards innovation in chemistry and production processes to maintain competitiveness and meet evolving market demands.

In conclusion, the market demand for polyurethanes remains strong, with significant growth potential across various industries. The ongoing research into improving polyurethane chemistry for better performance is crucial to address the evolving market needs, overcome challenges, and capitalize on emerging opportunities in this dynamic sector.

Technical Challenges

Polyurethane chemistry presents several technical challenges that researchers and manufacturers must address to enhance performance and expand applications. One of the primary challenges lies in controlling the complex reaction kinetics between isocyanates and polyols. The rate of reaction and the resulting polymer structure are highly sensitive to factors such as temperature, catalyst type, and reactant ratios. Achieving precise control over these parameters is crucial for producing polyurethanes with consistent and desired properties.

Another significant challenge is the moisture sensitivity of isocyanates, a key component in polyurethane synthesis. Isocyanates readily react with water, leading to unwanted side reactions that can compromise the final product's quality. This necessitates stringent moisture control throughout the manufacturing process, from raw material storage to product curing, which can be technically demanding and cost-intensive.

The development of more environmentally friendly and sustainable polyurethane systems poses a considerable technical hurdle. Traditional polyurethanes often rely on petroleum-based raw materials and may contain harmful substances like volatile organic compounds (VOCs). Formulating bio-based alternatives or reducing VOC emissions while maintaining performance characteristics requires extensive research and innovation in raw material sourcing and chemical formulation.

Improving the fire resistance of polyurethanes without compromising other desirable properties remains a persistent challenge. Conventional flame retardants can negatively impact mechanical properties or introduce toxicity concerns. Developing novel flame-retardant systems that are both effective and environmentally benign is an ongoing area of research.

The long-term durability of polyurethanes, particularly in harsh environments or under extreme conditions, presents another technical challenge. Issues such as hydrolytic stability, UV resistance, and thermal degradation can limit the lifespan and application range of polyurethane products. Enhancing these properties often requires careful molecular design and the incorporation of specialized additives or modifiers.

Achieving better compatibility between different polyurethane components, especially in multi-phase systems or composites, is crucial for expanding applications. Incompatibility can lead to phase separation, reduced mechanical properties, or poor adhesion. Developing novel compatibilizers or surface modification techniques to improve interfacial interactions is an active area of research.

Lastly, the scalability of new polyurethane technologies from laboratory to industrial production presents significant challenges. Processes that work well at small scales may encounter unforeseen difficulties when scaled up, such as heat management issues, mixing inefficiencies, or changes in reaction kinetics. Overcoming these scale-up challenges requires a deep understanding of process engineering and often necessitates the development of specialized equipment or manufacturing techniques.

Another significant challenge is the moisture sensitivity of isocyanates, a key component in polyurethane synthesis. Isocyanates readily react with water, leading to unwanted side reactions that can compromise the final product's quality. This necessitates stringent moisture control throughout the manufacturing process, from raw material storage to product curing, which can be technically demanding and cost-intensive.

The development of more environmentally friendly and sustainable polyurethane systems poses a considerable technical hurdle. Traditional polyurethanes often rely on petroleum-based raw materials and may contain harmful substances like volatile organic compounds (VOCs). Formulating bio-based alternatives or reducing VOC emissions while maintaining performance characteristics requires extensive research and innovation in raw material sourcing and chemical formulation.

Improving the fire resistance of polyurethanes without compromising other desirable properties remains a persistent challenge. Conventional flame retardants can negatively impact mechanical properties or introduce toxicity concerns. Developing novel flame-retardant systems that are both effective and environmentally benign is an ongoing area of research.

The long-term durability of polyurethanes, particularly in harsh environments or under extreme conditions, presents another technical challenge. Issues such as hydrolytic stability, UV resistance, and thermal degradation can limit the lifespan and application range of polyurethane products. Enhancing these properties often requires careful molecular design and the incorporation of specialized additives or modifiers.

Achieving better compatibility between different polyurethane components, especially in multi-phase systems or composites, is crucial for expanding applications. Incompatibility can lead to phase separation, reduced mechanical properties, or poor adhesion. Developing novel compatibilizers or surface modification techniques to improve interfacial interactions is an active area of research.

Lastly, the scalability of new polyurethane technologies from laboratory to industrial production presents significant challenges. Processes that work well at small scales may encounter unforeseen difficulties when scaled up, such as heat management issues, mixing inefficiencies, or changes in reaction kinetics. Overcoming these scale-up challenges requires a deep understanding of process engineering and often necessitates the development of specialized equipment or manufacturing techniques.

Current PU Solutions

01 Improved mechanical properties

Polyurethane formulations can be optimized to enhance mechanical properties such as tensile strength, elongation, and tear resistance. This can be achieved through careful selection of raw materials, adjusting the ratio of hard and soft segments, and incorporating specific additives or fillers.- Improved mechanical properties: Polyurethane formulations can be optimized to enhance mechanical properties such as tensile strength, elongation, and tear resistance. This can be achieved through careful selection of raw materials, adjusting the ratio of hard and soft segments, and incorporating specific additives or fillers.

- Enhanced thermal stability: Techniques to improve the thermal stability of polyurethanes include the use of heat-resistant monomers, incorporation of flame retardants, and modification of the polymer structure. These methods can result in polyurethanes with better performance at elevated temperatures and improved fire resistance.

- Chemical resistance and durability: Polyurethane performance can be enhanced by improving its resistance to chemicals, solvents, and environmental factors. This can involve modifying the polymer backbone, using specialized coatings, or incorporating specific additives to protect against degradation and extend the material's lifespan.

- Adhesion and coating properties: Formulations can be developed to enhance the adhesion of polyurethanes to various substrates and improve their coating properties. This may involve the use of specific adhesion promoters, surface treatments, or modifications to the polyurethane chemistry to increase compatibility with different materials.

- Environmental and sustainability improvements: Research focuses on developing more sustainable polyurethane formulations, including bio-based raw materials, recyclable or biodegradable polyurethanes, and reducing or eliminating harmful substances. These improvements aim to enhance the environmental performance of polyurethanes while maintaining or improving their functional properties.

02 Enhanced thermal stability

Techniques to improve the thermal stability of polyurethane materials involve the use of heat-resistant monomers, cross-linking agents, or the incorporation of nanoparticles. These modifications can result in polyurethanes with better performance at elevated temperatures and improved resistance to thermal degradation.Expand Specific Solutions03 Chemical resistance and durability

Polyurethane performance can be enhanced by improving its resistance to chemicals, solvents, and environmental factors. This can be achieved through the use of specialized isocyanates, polyols, or surface treatments, resulting in more durable and long-lasting polyurethane products.Expand Specific Solutions04 Adhesion and coating properties

Formulations can be developed to enhance the adhesion of polyurethane to various substrates and improve its coating properties. This may involve the use of specific adhesion promoters, surface treatments, or the incorporation of functional groups that increase compatibility with different materials.Expand Specific Solutions05 Environmental and sustainability aspects

Research focuses on developing more environmentally friendly polyurethane formulations, including bio-based polyols, water-based systems, and recyclable or biodegradable polyurethanes. These innovations aim to improve the overall sustainability and reduce the environmental impact of polyurethane products.Expand Specific Solutions

Key Industry Players

The polyurethane chemistry market is in a mature growth stage, with a global market size expected to reach $79.2 billion by 2025. The technology is well-established, yet continuous innovation drives performance improvements. Key players like BASF, Dow, and Covestro lead in research and development, focusing on enhancing material properties and sustainability. Emerging companies from China, such as Shandong Inov Polyurethane and Qingdao University of Science & Technology, are increasingly contributing to technological advancements. The industry sees a trend towards bio-based polyurethanes and improved recycling methods, with companies like Cargill and DSM investing in sustainable solutions. Collaboration between industry leaders and academic institutions, such as Sichuan University and Beijing University of Chemical Technology, is accelerating the pace of innovation in this field.

BASF Corp.

Technical Solution: BASF has developed a novel polyurethane chemistry approach focusing on improving the performance of their products. They have introduced a new line of isocyanates and polyols that offer enhanced reactivity and crosslinking capabilities. This technology allows for the creation of polyurethanes with improved mechanical properties, thermal stability, and chemical resistance. BASF's innovation also includes the development of bio-based polyols derived from renewable resources, addressing the growing demand for sustainable materials in the polyurethane industry.

Strengths: Advanced chemical expertise, wide range of applications, sustainability focus. Weaknesses: Higher production costs, potential regulatory challenges with new formulations.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a breakthrough in polyurethane chemistry by developing a new catalyst system that significantly enhances the control over the polymerization process. This technology allows for precise tuning of reaction kinetics, resulting in polyurethanes with tailored properties such as improved durability, flexibility, and weatherability. Dow's innovation also includes the integration of nanotechnology into polyurethane formulations, creating materials with enhanced strength-to-weight ratios and self-healing capabilities.

Strengths: Precise control over material properties, innovative nanotechnology integration. Weaknesses: Complex manufacturing process, potential scalability issues.

Core PU Innovations

Polyurethane dispersion and ink composition

PatentPendingEP4495155A1

Innovation

- A polyurethane dispersion with a specific composition, including a polyurethane resin derived from an isocyanate group-terminated prepolymer and a chain extender, with controlled acid value, urethane and urea group concentrations, and aromatic ring concentration, is developed to enhance color developability, adhesion, and followability.

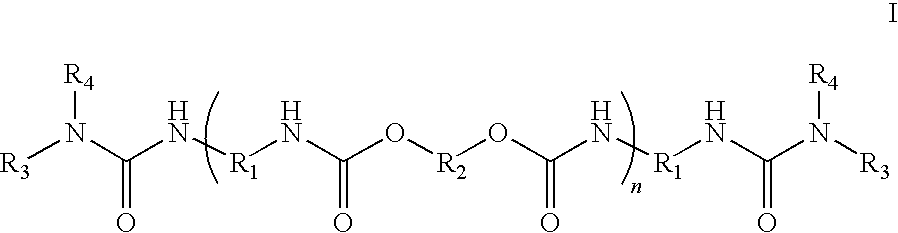

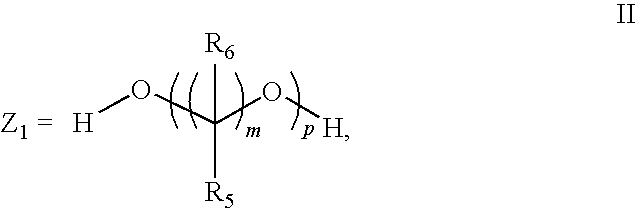

Urea-terminated ether polyurethanes and aqueous dispersions thereof

PatentInactiveUS20090259012A1

Innovation

- Development of water-dispersible urea-terminated polyurethanes based on certain polyether diols, which include a polyurethane composition with a urea content of at least 2 wt% and a polyether diol component that provides improved dispersibility, hydrophilicity, flexibility, and toughness, allowing for better interactions with pigments and other components.

Environmental Impact

Polyurethane chemistry has significant environmental implications that must be carefully considered in the pursuit of better performance. The production, use, and disposal of polyurethanes can impact ecosystems and human health in various ways. One of the primary concerns is the use of isocyanates, which are essential components in polyurethane synthesis. These compounds are known to be toxic and can pose risks to workers and the environment if not properly handled.

The manufacturing process of polyurethanes often involves the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. Emissions from these processes can contribute to air pollution and the formation of ground-level ozone, which has adverse effects on both human health and the environment. Additionally, the energy-intensive nature of polyurethane production contributes to greenhouse gas emissions and climate change.

Waste management is another critical environmental aspect of polyurethane chemistry. Many polyurethane products are not biodegradable and can persist in the environment for extended periods. This has led to concerns about the accumulation of plastic waste in landfills and oceans. However, recent advancements in recycling technologies have shown promise in addressing this issue. Chemical recycling methods, such as glycolysis and hydrolysis, can break down polyurethane waste into its constituent components, allowing for the creation of new products.

The development of bio-based polyurethanes represents a significant step towards reducing the environmental impact of these materials. By utilizing renewable resources such as plant-based polyols, manufacturers can decrease their reliance on petroleum-derived raw materials. This shift not only reduces the carbon footprint of polyurethane production but also helps to conserve finite fossil fuel resources.

Water-based polyurethane systems have emerged as an environmentally friendly alternative to solvent-based formulations. These systems significantly reduce VOC emissions and minimize the use of hazardous chemicals, making them safer for both workers and the environment. Furthermore, advances in catalysis and reaction engineering have led to more efficient production processes, reducing energy consumption and waste generation.

As the industry moves towards more sustainable practices, life cycle assessments (LCAs) have become crucial tools in evaluating the environmental impact of polyurethane products. These assessments consider all stages of a product's life, from raw material extraction to disposal, providing valuable insights into areas where improvements can be made. By utilizing LCAs, manufacturers can make informed decisions to optimize their processes and formulations for better environmental performance.

The manufacturing process of polyurethanes often involves the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. Emissions from these processes can contribute to air pollution and the formation of ground-level ozone, which has adverse effects on both human health and the environment. Additionally, the energy-intensive nature of polyurethane production contributes to greenhouse gas emissions and climate change.

Waste management is another critical environmental aspect of polyurethane chemistry. Many polyurethane products are not biodegradable and can persist in the environment for extended periods. This has led to concerns about the accumulation of plastic waste in landfills and oceans. However, recent advancements in recycling technologies have shown promise in addressing this issue. Chemical recycling methods, such as glycolysis and hydrolysis, can break down polyurethane waste into its constituent components, allowing for the creation of new products.

The development of bio-based polyurethanes represents a significant step towards reducing the environmental impact of these materials. By utilizing renewable resources such as plant-based polyols, manufacturers can decrease their reliance on petroleum-derived raw materials. This shift not only reduces the carbon footprint of polyurethane production but also helps to conserve finite fossil fuel resources.

Water-based polyurethane systems have emerged as an environmentally friendly alternative to solvent-based formulations. These systems significantly reduce VOC emissions and minimize the use of hazardous chemicals, making them safer for both workers and the environment. Furthermore, advances in catalysis and reaction engineering have led to more efficient production processes, reducing energy consumption and waste generation.

As the industry moves towards more sustainable practices, life cycle assessments (LCAs) have become crucial tools in evaluating the environmental impact of polyurethane products. These assessments consider all stages of a product's life, from raw material extraction to disposal, providing valuable insights into areas where improvements can be made. By utilizing LCAs, manufacturers can make informed decisions to optimize their processes and formulations for better environmental performance.

PU Safety Regulations

Polyurethane (PU) safety regulations have become increasingly stringent in recent years due to growing concerns about potential health and environmental impacts. These regulations primarily focus on the raw materials used in PU production, particularly isocyanates and certain additives, as well as the finished products and their applications.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for various isocyanates used in PU manufacturing. These limits are designed to protect workers from respiratory sensitization and other health hazards associated with isocyanate exposure. Similarly, the European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require manufacturers to assess and manage the risks posed by chemicals used in PU production.

The automotive industry, a major consumer of PU products, has also implemented its own set of safety standards. These include regulations on volatile organic compound (VOC) emissions from PU-based materials used in vehicle interiors, as well as requirements for flame retardancy and toxicity of PU foams used in seating and insulation.

In the construction sector, building codes have been updated to address the fire safety of PU-based insulation materials. Many jurisdictions now require specific fire-resistant ratings for PU foam insulation used in residential and commercial buildings. Additionally, some regions have implemented restrictions on the use of certain flame retardants in PU products due to environmental and health concerns.

The furniture and bedding industry has seen the introduction of flammability standards for PU foam, such as California's Technical Bulletin 117-2013. These regulations aim to reduce the risk of fire spread while also addressing concerns about the use of potentially harmful flame retardant chemicals.

Environmental regulations have also impacted PU manufacturing, with a focus on reducing emissions and waste. Many countries have implemented restrictions on the use of ozone-depleting substances as blowing agents in PU foam production, leading to the development of more environmentally friendly alternatives.

As the understanding of PU chemistry continues to evolve, safety regulations are likely to become more comprehensive and nuanced. Future regulatory trends may include increased focus on the recyclability and end-of-life management of PU products, as well as the development of bio-based and more sustainable PU formulations. Manufacturers and researchers in the PU industry must stay abreast of these evolving regulations to ensure compliance and drive innovation towards safer and more sustainable PU technologies.

In the United States, the Occupational Safety and Health Administration (OSHA) has established permissible exposure limits (PELs) for various isocyanates used in PU manufacturing. These limits are designed to protect workers from respiratory sensitization and other health hazards associated with isocyanate exposure. Similarly, the European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which require manufacturers to assess and manage the risks posed by chemicals used in PU production.

The automotive industry, a major consumer of PU products, has also implemented its own set of safety standards. These include regulations on volatile organic compound (VOC) emissions from PU-based materials used in vehicle interiors, as well as requirements for flame retardancy and toxicity of PU foams used in seating and insulation.

In the construction sector, building codes have been updated to address the fire safety of PU-based insulation materials. Many jurisdictions now require specific fire-resistant ratings for PU foam insulation used in residential and commercial buildings. Additionally, some regions have implemented restrictions on the use of certain flame retardants in PU products due to environmental and health concerns.

The furniture and bedding industry has seen the introduction of flammability standards for PU foam, such as California's Technical Bulletin 117-2013. These regulations aim to reduce the risk of fire spread while also addressing concerns about the use of potentially harmful flame retardant chemicals.

Environmental regulations have also impacted PU manufacturing, with a focus on reducing emissions and waste. Many countries have implemented restrictions on the use of ozone-depleting substances as blowing agents in PU foam production, leading to the development of more environmentally friendly alternatives.

As the understanding of PU chemistry continues to evolve, safety regulations are likely to become more comprehensive and nuanced. Future regulatory trends may include increased focus on the recyclability and end-of-life management of PU products, as well as the development of bio-based and more sustainable PU formulations. Manufacturers and researchers in the PU industry must stay abreast of these evolving regulations to ensure compliance and drive innovation towards safer and more sustainable PU technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!