Polyurethane in Electronics: Advancing Protective Solutions

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU in Electronics: Evolution and Objectives

Polyurethane (PU) has emerged as a crucial material in the electronics industry, offering advanced protective solutions for various components and devices. The evolution of PU in electronics can be traced back to the mid-20th century when the need for reliable insulation and protection became paramount with the rapid development of electronic technologies.

Initially, PU found its application in simple coatings and encapsulations for electronic components. As the electronics industry progressed, so did the demands placed on protective materials. The miniaturization of devices, increased complexity of circuits, and the need for better thermal management drove the development of more sophisticated PU formulations.

In the 1970s and 1980s, PU began to be widely used in printed circuit boards (PCBs) as a conformal coating, providing protection against moisture, dust, and chemical contaminants. This marked a significant milestone in the material's adoption within the electronics sector. The 1990s saw further advancements in PU chemistry, leading to improved thermal stability and electrical properties, making it suitable for a broader range of applications.

The turn of the millennium brought about a new era for PU in electronics. With the proliferation of portable devices and the Internet of Things (IoT), the demand for flexible, durable, and lightweight protective solutions skyrocketed. PU's versatility allowed it to meet these evolving needs, leading to its incorporation in smartphones, wearables, and other consumer electronics.

Recent years have witnessed a focus on developing eco-friendly and sustainable PU formulations, addressing growing environmental concerns. This has led to the creation of bio-based and recyclable PU materials that maintain the high performance required in electronic applications.

Looking ahead, the objectives for PU in electronics are multifaceted. There is a strong emphasis on enhancing the material's thermal management capabilities to address the increasing heat generation in modern electronic devices. Improving PU's dielectric properties for use in high-frequency applications is another key goal, particularly with the advent of 5G and beyond technologies.

Furthermore, researchers are working on developing PU formulations with advanced self-healing properties, which could significantly extend the lifespan of electronic devices by autonomously repairing minor damages. The integration of smart functionalities, such as piezoelectric or thermochromic properties, into PU materials is also being explored to create more responsive and adaptive protective solutions.

As electronics continue to permeate every aspect of our lives, the role of PU in providing robust, versatile, and innovative protective solutions is set to expand further. The ongoing research and development in this field aim to push the boundaries of what is possible with PU, ensuring its continued relevance and importance in the ever-evolving landscape of electronic technologies.

Initially, PU found its application in simple coatings and encapsulations for electronic components. As the electronics industry progressed, so did the demands placed on protective materials. The miniaturization of devices, increased complexity of circuits, and the need for better thermal management drove the development of more sophisticated PU formulations.

In the 1970s and 1980s, PU began to be widely used in printed circuit boards (PCBs) as a conformal coating, providing protection against moisture, dust, and chemical contaminants. This marked a significant milestone in the material's adoption within the electronics sector. The 1990s saw further advancements in PU chemistry, leading to improved thermal stability and electrical properties, making it suitable for a broader range of applications.

The turn of the millennium brought about a new era for PU in electronics. With the proliferation of portable devices and the Internet of Things (IoT), the demand for flexible, durable, and lightweight protective solutions skyrocketed. PU's versatility allowed it to meet these evolving needs, leading to its incorporation in smartphones, wearables, and other consumer electronics.

Recent years have witnessed a focus on developing eco-friendly and sustainable PU formulations, addressing growing environmental concerns. This has led to the creation of bio-based and recyclable PU materials that maintain the high performance required in electronic applications.

Looking ahead, the objectives for PU in electronics are multifaceted. There is a strong emphasis on enhancing the material's thermal management capabilities to address the increasing heat generation in modern electronic devices. Improving PU's dielectric properties for use in high-frequency applications is another key goal, particularly with the advent of 5G and beyond technologies.

Furthermore, researchers are working on developing PU formulations with advanced self-healing properties, which could significantly extend the lifespan of electronic devices by autonomously repairing minor damages. The integration of smart functionalities, such as piezoelectric or thermochromic properties, into PU materials is also being explored to create more responsive and adaptive protective solutions.

As electronics continue to permeate every aspect of our lives, the role of PU in providing robust, versatile, and innovative protective solutions is set to expand further. The ongoing research and development in this field aim to push the boundaries of what is possible with PU, ensuring its continued relevance and importance in the ever-evolving landscape of electronic technologies.

Market Demand Analysis for Electronic Protection

The market demand for electronic protection solutions utilizing polyurethane has been steadily increasing, driven by the rapid growth of the electronics industry and the need for more robust protective measures. As electronic devices become increasingly sophisticated and ubiquitous, the requirement for effective protection against environmental factors, physical damage, and electromagnetic interference has become paramount.

The global electronic protection market is experiencing significant expansion, with a particular focus on polyurethane-based solutions. This growth is attributed to the material's versatility, durability, and excellent insulating properties. Polyurethane coatings and encapsulants are being widely adopted across various sectors, including consumer electronics, automotive electronics, industrial equipment, and aerospace applications.

In the consumer electronics segment, the demand for waterproof and shockproof devices has surged, leading to increased use of polyurethane protective coatings. Smartphones, tablets, and wearable devices are prime examples of products benefiting from polyurethane protection, enhancing their resistance to moisture, dust, and impact damage.

The automotive industry is another major driver of market demand for polyurethane-based electronic protection. As vehicles incorporate more advanced electronic systems and sensors, the need for reliable protection against harsh environmental conditions, vibrations, and temperature fluctuations has intensified. Polyurethane coatings and potting compounds are being extensively used to safeguard critical components in engine control units, infotainment systems, and advanced driver assistance systems (ADAS).

Industrial electronics and equipment manufacturers are also contributing to the growing demand for polyurethane protection solutions. In sectors such as manufacturing, energy, and telecommunications, electronic components are often exposed to extreme conditions, including high temperatures, chemicals, and mechanical stress. Polyurethane-based protective measures are increasingly being employed to ensure the longevity and reliability of these critical systems.

The aerospace and defense sectors represent another significant market for polyurethane electronic protection. The stringent requirements for reliability and performance in these industries have led to the adoption of advanced polyurethane formulations that can withstand extreme temperatures, vibrations, and electromagnetic interference.

As the Internet of Things (IoT) continues to expand, the demand for protected electronic devices in various environments is expected to grow further. This trend is likely to drive innovation in polyurethane formulations, leading to the development of more specialized and high-performance protective solutions.

The global electronic protection market is experiencing significant expansion, with a particular focus on polyurethane-based solutions. This growth is attributed to the material's versatility, durability, and excellent insulating properties. Polyurethane coatings and encapsulants are being widely adopted across various sectors, including consumer electronics, automotive electronics, industrial equipment, and aerospace applications.

In the consumer electronics segment, the demand for waterproof and shockproof devices has surged, leading to increased use of polyurethane protective coatings. Smartphones, tablets, and wearable devices are prime examples of products benefiting from polyurethane protection, enhancing their resistance to moisture, dust, and impact damage.

The automotive industry is another major driver of market demand for polyurethane-based electronic protection. As vehicles incorporate more advanced electronic systems and sensors, the need for reliable protection against harsh environmental conditions, vibrations, and temperature fluctuations has intensified. Polyurethane coatings and potting compounds are being extensively used to safeguard critical components in engine control units, infotainment systems, and advanced driver assistance systems (ADAS).

Industrial electronics and equipment manufacturers are also contributing to the growing demand for polyurethane protection solutions. In sectors such as manufacturing, energy, and telecommunications, electronic components are often exposed to extreme conditions, including high temperatures, chemicals, and mechanical stress. Polyurethane-based protective measures are increasingly being employed to ensure the longevity and reliability of these critical systems.

The aerospace and defense sectors represent another significant market for polyurethane electronic protection. The stringent requirements for reliability and performance in these industries have led to the adoption of advanced polyurethane formulations that can withstand extreme temperatures, vibrations, and electromagnetic interference.

As the Internet of Things (IoT) continues to expand, the demand for protected electronic devices in various environments is expected to grow further. This trend is likely to drive innovation in polyurethane formulations, leading to the development of more specialized and high-performance protective solutions.

Current Challenges in PU-based Electronic Protection

The current challenges in polyurethane-based electronic protection are multifaceted and require innovative solutions to meet the evolving demands of the electronics industry. One of the primary issues is the need for enhanced thermal management properties. As electronic devices become more compact and powerful, they generate increasing amounts of heat, which can lead to performance degradation and reduced lifespan. Existing polyurethane formulations struggle to efficiently dissipate heat, necessitating the development of advanced thermal conductive additives or novel polymer structures.

Another significant challenge lies in achieving optimal balance between flexibility and durability. Electronic components often require protection that can withstand mechanical stress while maintaining flexibility for various form factors. Current polyurethane solutions may either be too rigid, risking crack formation under stress, or too soft, compromising long-term protection. This dilemma calls for innovative approaches in polymer chemistry to create materials with adaptive mechanical properties.

Electromagnetic interference (EMI) shielding presents a growing concern in the era of 5G and IoT devices. Traditional polyurethane coatings offer limited EMI protection, leaving sensitive electronic components vulnerable to external electromagnetic disturbances. Developing polyurethane formulations with inherent EMI shielding capabilities or incorporating conductive fillers without compromising other protective properties remains a significant technical hurdle.

The increasing focus on environmental sustainability poses another challenge for polyurethane-based electronic protection. Many current formulations rely on petroleum-based raw materials and contain potentially harmful additives. There is a pressing need to develop bio-based polyurethanes and environmentally friendly additives that maintain or exceed the performance of conventional solutions while reducing the ecological footprint.

Adhesion to diverse substrate materials is an ongoing challenge in electronic protection. As electronics incorporate a wider range of materials, including advanced composites and flexible substrates, polyurethane coatings must adapt to ensure strong, long-lasting adhesion across various surface types. This requires the development of new surface treatment techniques or polyurethane formulations with enhanced adhesion properties.

Lastly, the miniaturization trend in electronics demands ever-thinner protective layers without compromising performance. Achieving uniform, defect-free coatings at microscale thicknesses while maintaining barrier properties against moisture, chemicals, and environmental contaminants remains a significant technical challenge. This necessitates advancements in application techniques and polymer chemistry to create high-performance, ultra-thin polyurethane protective solutions.

Another significant challenge lies in achieving optimal balance between flexibility and durability. Electronic components often require protection that can withstand mechanical stress while maintaining flexibility for various form factors. Current polyurethane solutions may either be too rigid, risking crack formation under stress, or too soft, compromising long-term protection. This dilemma calls for innovative approaches in polymer chemistry to create materials with adaptive mechanical properties.

Electromagnetic interference (EMI) shielding presents a growing concern in the era of 5G and IoT devices. Traditional polyurethane coatings offer limited EMI protection, leaving sensitive electronic components vulnerable to external electromagnetic disturbances. Developing polyurethane formulations with inherent EMI shielding capabilities or incorporating conductive fillers without compromising other protective properties remains a significant technical hurdle.

The increasing focus on environmental sustainability poses another challenge for polyurethane-based electronic protection. Many current formulations rely on petroleum-based raw materials and contain potentially harmful additives. There is a pressing need to develop bio-based polyurethanes and environmentally friendly additives that maintain or exceed the performance of conventional solutions while reducing the ecological footprint.

Adhesion to diverse substrate materials is an ongoing challenge in electronic protection. As electronics incorporate a wider range of materials, including advanced composites and flexible substrates, polyurethane coatings must adapt to ensure strong, long-lasting adhesion across various surface types. This requires the development of new surface treatment techniques or polyurethane formulations with enhanced adhesion properties.

Lastly, the miniaturization trend in electronics demands ever-thinner protective layers without compromising performance. Achieving uniform, defect-free coatings at microscale thicknesses while maintaining barrier properties against moisture, chemicals, and environmental contaminants remains a significant technical challenge. This necessitates advancements in application techniques and polymer chemistry to create high-performance, ultra-thin polyurethane protective solutions.

Existing PU Solutions for Electronic Protection

01 Polyurethane coatings for surface protection

Polyurethane coatings are used to protect various surfaces from wear, corrosion, and environmental damage. These coatings can be applied to materials such as metal, concrete, and wood to enhance their durability and longevity. The polyurethane forms a protective barrier that resists chemicals, abrasion, and moisture.- Polyurethane coatings for surface protection: Polyurethane coatings are applied to various surfaces to provide protection against wear, corrosion, and environmental factors. These coatings offer durability, flexibility, and resistance to chemicals, making them suitable for a wide range of applications including automotive, industrial, and construction sectors.

- Polyurethane foam for impact protection: Polyurethane foam is used in various protective applications due to its shock-absorbing properties. It is commonly employed in packaging, automotive safety components, and personal protective equipment to minimize impact forces and provide cushioning.

- Polyurethane-based protective coatings for marine applications: Specialized polyurethane coatings are developed for marine environments to protect boats, ships, and offshore structures from corrosion, fouling, and water damage. These coatings offer excellent adhesion to various substrates and resistance to saltwater and UV radiation.

- Polyurethane protective films and membranes: Thin polyurethane films and membranes are used for protection in various applications, including electronic devices, textiles, and construction materials. These films provide water resistance, breathability, and protection against abrasion and chemicals while maintaining flexibility.

- Polyurethane-based protective gear and equipment: Polyurethane is utilized in the manufacturing of protective gear and equipment for sports, industrial, and military applications. Its properties allow for the creation of lightweight, durable, and impact-resistant items such as helmets, body armor, and protective pads.

02 Polyurethane foam for impact protection

Polyurethane foam is utilized in various applications for impact protection and shock absorption. This material can be molded into different shapes and densities to provide cushioning and energy dissipation in products such as automotive parts, sports equipment, and packaging materials.Expand Specific Solutions03 Polyurethane-based protective films and coatings

Thin polyurethane films and coatings are developed for protecting surfaces against scratches, UV radiation, and chemical exposure. These films can be applied to electronic devices, automotive exteriors, and other products to maintain their appearance and functionality over time.Expand Specific Solutions04 Polyurethane in protective gear and equipment

Polyurethane materials are incorporated into various protective gear and equipment designs. This includes items such as helmets, body armor, and safety footwear, where the material's properties contribute to impact resistance, flexibility, and overall protection for the user.Expand Specific Solutions05 Polyurethane sealants for waterproofing and insulation

Polyurethane-based sealants and adhesives are used for waterproofing and insulation in construction and industrial applications. These products provide effective protection against moisture intrusion, air leakage, and thermal transfer, enhancing the durability and energy efficiency of structures.Expand Specific Solutions

Key Players in PU Electronic Protection Industry

The market for polyurethane in electronics is experiencing rapid growth, driven by increasing demand for protective solutions in electronic devices. The industry is in a mature stage, with established players like BASF, Covestro, and Dow Silicones leading the market. However, emerging companies such as Resonac Holdings and Avient Corp are introducing innovative solutions, intensifying competition. The market size is expanding, fueled by the growing electronics industry and the need for advanced protective materials. Technological maturity varies, with companies like Samsung Electronics and 3M Innovative Properties pushing boundaries in application-specific formulations. Overall, the competitive landscape is characterized by a mix of large chemical conglomerates and specialized materials companies, all vying for market share through continuous innovation and product development.

BASF Corp.

Technical Solution: BASF has developed a range of polyurethane solutions for electronics protection, including their Elastocoat® and Elastoskin® product lines. These materials offer excellent electrical insulation properties and can be customized for specific applications. BASF's polyurethane systems provide protection against moisture, dust, and mechanical stress, ensuring the longevity and reliability of electronic components. They have also developed UV-resistant formulations to prevent yellowing and degradation when exposed to sunlight, making them suitable for outdoor electronic applications.

Strengths: Wide range of customizable solutions, excellent insulation properties, and UV-resistant formulations. Weaknesses: May require specialized application equipment and processes.

Avient Corp.

Technical Solution: Avient Corporation has developed a series of thermoplastic polyurethane (TPU) materials specifically designed for electronics protection. Their Versaflex™ TPU product line offers excellent flexibility, durability, and chemical resistance. These materials can be used in overmolding applications for connectors, cables, and other electronic components, providing a robust barrier against environmental factors. Avient's TPU solutions also feature customizable hardness levels, allowing manufacturers to balance protection and flexibility based on specific application requirements.

Strengths: Excellent flexibility and durability, customizable hardness levels. Weaknesses: May have limitations in extreme temperature applications compared to some thermoset polyurethanes.

Innovative PU Formulations for Electronics

transparent polyurethanes containing electronic components

PatentInactiveDE102013200907A1

Innovation

- A method involving compact polyurethane elastomers and casting resins is used to embed electronic components, avoiding macroscopic phase separation and using aliphatic isocyanates to create a transparent polyurethane body with high mechanical stability and scratch resistance.

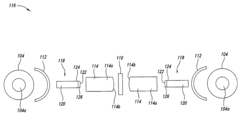

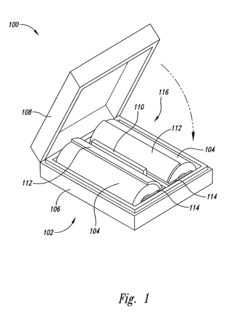

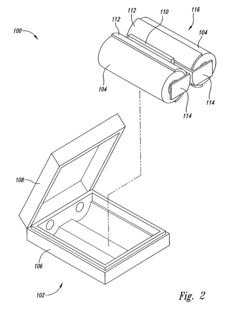

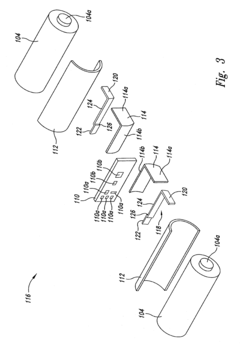

Electrical insulation system and method for electrical power storage component separation

PatentActiveUS20100058575A1

Innovation

- The use of polyurethane elastomer-based materials, such as tapes, which offer enhanced durability and resistance to puncture and penetration, ensuring reliable electrical separation between components in battery packs.

Environmental Impact of PU in Electronics

The environmental impact of polyurethane (PU) in electronics is a complex issue that requires careful consideration. As the use of PU in electronic devices continues to grow, it is essential to assess its ecological footprint throughout the product lifecycle.

PU production involves the use of petrochemicals, which can contribute to greenhouse gas emissions and resource depletion. However, the longevity and protective properties of PU in electronics can lead to extended product lifespans, potentially offsetting some of these initial environmental costs.

During the use phase, PU's excellent insulation properties can contribute to improved energy efficiency in electronic devices. This can result in reduced power consumption and, consequently, lower carbon emissions over the product's lifetime. Additionally, PU's resistance to moisture and chemicals helps prevent premature device failure, further extending the useful life of electronics.

End-of-life management of PU in electronics presents significant challenges. While some PU formulations are recyclable, the complex nature of electronic components often makes separation and recycling difficult. Incineration of PU-containing electronics can release toxic substances, necessitating advanced pollution control measures.

Recent advancements in bio-based and biodegradable PU formulations offer promising alternatives with potentially reduced environmental impacts. These materials can be derived from renewable resources and may be more easily recycled or biodegraded at the end of their life cycle.

The electronics industry is increasingly adopting eco-design principles, incorporating environmental considerations into product development. This includes exploring PU alternatives and improving the recyclability of PU-containing components. Some manufacturers are implementing take-back programs and investing in recycling technologies to address the end-of-life challenges associated with PU in electronics.

Regulatory frameworks, such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive, are driving improvements in the environmental performance of electronics, including the use of PU. These regulations encourage the development of more sustainable materials and better end-of-life management practices.

As the industry continues to evolve, ongoing research and development efforts are focused on minimizing the environmental impact of PU in electronics. This includes exploring new synthesis methods, improving recycling technologies, and developing more environmentally friendly alternatives that maintain the protective properties crucial for electronic applications.

PU production involves the use of petrochemicals, which can contribute to greenhouse gas emissions and resource depletion. However, the longevity and protective properties of PU in electronics can lead to extended product lifespans, potentially offsetting some of these initial environmental costs.

During the use phase, PU's excellent insulation properties can contribute to improved energy efficiency in electronic devices. This can result in reduced power consumption and, consequently, lower carbon emissions over the product's lifetime. Additionally, PU's resistance to moisture and chemicals helps prevent premature device failure, further extending the useful life of electronics.

End-of-life management of PU in electronics presents significant challenges. While some PU formulations are recyclable, the complex nature of electronic components often makes separation and recycling difficult. Incineration of PU-containing electronics can release toxic substances, necessitating advanced pollution control measures.

Recent advancements in bio-based and biodegradable PU formulations offer promising alternatives with potentially reduced environmental impacts. These materials can be derived from renewable resources and may be more easily recycled or biodegraded at the end of their life cycle.

The electronics industry is increasingly adopting eco-design principles, incorporating environmental considerations into product development. This includes exploring PU alternatives and improving the recyclability of PU-containing components. Some manufacturers are implementing take-back programs and investing in recycling technologies to address the end-of-life challenges associated with PU in electronics.

Regulatory frameworks, such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive, are driving improvements in the environmental performance of electronics, including the use of PU. These regulations encourage the development of more sustainable materials and better end-of-life management practices.

As the industry continues to evolve, ongoing research and development efforts are focused on minimizing the environmental impact of PU in electronics. This includes exploring new synthesis methods, improving recycling technologies, and developing more environmentally friendly alternatives that maintain the protective properties crucial for electronic applications.

Durability and Longevity Considerations

Durability and longevity are critical factors in the application of polyurethane in electronics, particularly for protective solutions. The ability of polyurethane coatings and encapsulants to withstand various environmental stressors over extended periods is essential for ensuring the reliability and performance of electronic devices.

One of the primary considerations in durability is the resistance to moisture and humidity. Polyurethane formulations designed for electronics must maintain their protective properties even in high-humidity environments. Advanced moisture-resistant polyurethanes incorporate hydrophobic additives or are chemically modified to repel water molecules, preventing ingress and potential corrosion of sensitive electronic components.

Thermal stability is another crucial aspect of longevity. Electronic devices often operate at elevated temperatures, and protective polyurethane solutions must maintain their structural integrity and insulating properties across a wide temperature range. High-performance polyurethanes are engineered to resist thermal degradation, preventing cracking, discoloration, or loss of adhesion that could compromise device protection.

UV resistance is particularly important for outdoor electronic applications or devices exposed to sunlight. Polyurethane formulations with UV stabilizers or inherent UV-resistant properties help prevent yellowing, embrittlement, and degradation of the protective layer over time. This ensures that the aesthetic and functional qualities of the coating or encapsulant are preserved throughout the device's lifespan.

Chemical resistance is also a key factor in durability considerations. Polyurethanes used in electronics must withstand exposure to various chemicals, including cleaning agents, solvents, and potentially corrosive substances. Advanced formulations incorporate chemical-resistant additives or utilize specialized polymer structures to enhance resistance to a broad spectrum of chemical agents.

Mechanical durability, including resistance to abrasion, impact, and flexing, is essential for protecting electronics in demanding environments. High-performance polyurethanes are designed with enhanced cross-linking and optimized molecular structures to provide superior mechanical properties, ensuring that the protective layer remains intact even under physical stress.

Long-term adhesion is a critical aspect of polyurethane longevity in electronic applications. The material must maintain strong adhesion to various substrates, including metals, plastics, and ceramics, throughout the device's operational life. Advanced surface treatment techniques and specialized adhesion promoters are employed to enhance the long-term bonding capabilities of polyurethane coatings and encapsulants.

To address these durability and longevity considerations, manufacturers are continuously developing new polyurethane formulations and processing techniques. These advancements include the use of nanocomposites to enhance overall material properties, the development of self-healing polyurethanes that can repair minor damage, and the integration of smart materials that can adapt to changing environmental conditions.

One of the primary considerations in durability is the resistance to moisture and humidity. Polyurethane formulations designed for electronics must maintain their protective properties even in high-humidity environments. Advanced moisture-resistant polyurethanes incorporate hydrophobic additives or are chemically modified to repel water molecules, preventing ingress and potential corrosion of sensitive electronic components.

Thermal stability is another crucial aspect of longevity. Electronic devices often operate at elevated temperatures, and protective polyurethane solutions must maintain their structural integrity and insulating properties across a wide temperature range. High-performance polyurethanes are engineered to resist thermal degradation, preventing cracking, discoloration, or loss of adhesion that could compromise device protection.

UV resistance is particularly important for outdoor electronic applications or devices exposed to sunlight. Polyurethane formulations with UV stabilizers or inherent UV-resistant properties help prevent yellowing, embrittlement, and degradation of the protective layer over time. This ensures that the aesthetic and functional qualities of the coating or encapsulant are preserved throughout the device's lifespan.

Chemical resistance is also a key factor in durability considerations. Polyurethanes used in electronics must withstand exposure to various chemicals, including cleaning agents, solvents, and potentially corrosive substances. Advanced formulations incorporate chemical-resistant additives or utilize specialized polymer structures to enhance resistance to a broad spectrum of chemical agents.

Mechanical durability, including resistance to abrasion, impact, and flexing, is essential for protecting electronics in demanding environments. High-performance polyurethanes are designed with enhanced cross-linking and optimized molecular structures to provide superior mechanical properties, ensuring that the protective layer remains intact even under physical stress.

Long-term adhesion is a critical aspect of polyurethane longevity in electronic applications. The material must maintain strong adhesion to various substrates, including metals, plastics, and ceramics, throughout the device's operational life. Advanced surface treatment techniques and specialized adhesion promoters are employed to enhance the long-term bonding capabilities of polyurethane coatings and encapsulants.

To address these durability and longevity considerations, manufacturers are continuously developing new polyurethane formulations and processing techniques. These advancements include the use of nanocomposites to enhance overall material properties, the development of self-healing polyurethanes that can repair minor damage, and the integration of smart materials that can adapt to changing environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!