How to Maximize Polyurethane Performance in Coatings?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Coatings Evolution and Objectives

Polyurethane coatings have undergone significant evolution since their introduction in the 1940s. Initially developed as a versatile material for various applications, polyurethanes quickly found their way into the coatings industry due to their exceptional properties. The early stages of polyurethane coatings were characterized by limited durability and performance, primarily used in niche applications.

As technology advanced, the 1960s and 1970s saw a rapid expansion in polyurethane coating formulations. Researchers focused on improving chemical resistance, weatherability, and adhesion properties. This period marked the beginning of polyurethane's widespread adoption in industrial and automotive coatings, setting the stage for further innovations.

The 1980s and 1990s brought about significant breakthroughs in polyurethane chemistry. The development of water-based polyurethane dispersions addressed environmental concerns and regulatory pressures, opening new markets and applications. Simultaneously, advancements in crosslinking technologies led to enhanced durability and performance in harsh environments.

Entering the 21st century, the focus shifted towards maximizing polyurethane performance in coatings. Key objectives emerged, including improving scratch resistance, UV stability, and chemical resistance while maintaining flexibility and adhesion. The industry also aimed to develop more sustainable formulations, reducing VOC emissions and incorporating bio-based raw materials.

Recent years have seen a surge in research aimed at nanotechnology integration, smart coating functionalities, and self-healing properties. These innovations seek to push the boundaries of polyurethane coating performance, addressing challenges in extreme environments and specialized applications.

The current objectives in polyurethane coating technology are multifaceted. Researchers and industry professionals are working towards developing coatings with enhanced abrasion resistance, improved weatherability, and superior chemical resistance. There is also a strong emphasis on creating formulations that offer faster curing times and lower energy consumption during application and curing processes.

Another critical goal is the development of polyurethane coatings with advanced functional properties, such as self-cleaning, anti-microbial, and anti-fouling capabilities. These innovations aim to expand the application range of polyurethane coatings into new markets and industries.

Sustainability remains a key objective, with ongoing efforts to increase the use of renewable raw materials and reduce the environmental impact of polyurethane coatings throughout their lifecycle. This includes research into bio-based polyols and isocyanates, as well as the development of non-isocyanate polyurethanes (NIPUs) as potential alternatives.

As technology advanced, the 1960s and 1970s saw a rapid expansion in polyurethane coating formulations. Researchers focused on improving chemical resistance, weatherability, and adhesion properties. This period marked the beginning of polyurethane's widespread adoption in industrial and automotive coatings, setting the stage for further innovations.

The 1980s and 1990s brought about significant breakthroughs in polyurethane chemistry. The development of water-based polyurethane dispersions addressed environmental concerns and regulatory pressures, opening new markets and applications. Simultaneously, advancements in crosslinking technologies led to enhanced durability and performance in harsh environments.

Entering the 21st century, the focus shifted towards maximizing polyurethane performance in coatings. Key objectives emerged, including improving scratch resistance, UV stability, and chemical resistance while maintaining flexibility and adhesion. The industry also aimed to develop more sustainable formulations, reducing VOC emissions and incorporating bio-based raw materials.

Recent years have seen a surge in research aimed at nanotechnology integration, smart coating functionalities, and self-healing properties. These innovations seek to push the boundaries of polyurethane coating performance, addressing challenges in extreme environments and specialized applications.

The current objectives in polyurethane coating technology are multifaceted. Researchers and industry professionals are working towards developing coatings with enhanced abrasion resistance, improved weatherability, and superior chemical resistance. There is also a strong emphasis on creating formulations that offer faster curing times and lower energy consumption during application and curing processes.

Another critical goal is the development of polyurethane coatings with advanced functional properties, such as self-cleaning, anti-microbial, and anti-fouling capabilities. These innovations aim to expand the application range of polyurethane coatings into new markets and industries.

Sustainability remains a key objective, with ongoing efforts to increase the use of renewable raw materials and reduce the environmental impact of polyurethane coatings throughout their lifecycle. This includes research into bio-based polyols and isocyanates, as well as the development of non-isocyanate polyurethanes (NIPUs) as potential alternatives.

Market Demand Analysis for High-Performance Coatings

The global market for high-performance coatings has been experiencing significant growth, driven by increasing demand across various industries such as automotive, aerospace, construction, and industrial manufacturing. This surge is primarily attributed to the superior properties offered by advanced coating technologies, particularly those incorporating polyurethane.

In the automotive sector, there is a growing need for coatings that provide enhanced durability, scratch resistance, and aesthetic appeal. Polyurethane-based coatings have gained traction due to their ability to offer superior gloss retention, chemical resistance, and weatherability. The aerospace industry demands coatings that can withstand extreme environmental conditions while maintaining lightweight properties, an area where polyurethane excels.

The construction industry has shown increased interest in high-performance coatings for both interior and exterior applications. Polyurethane coatings are sought after for their ability to provide excellent protection against moisture, UV radiation, and abrasion, while also offering design flexibility and color stability. This trend is particularly evident in the commercial and residential building segments.

Industrial manufacturing represents another key market for high-performance coatings. The need for corrosion-resistant coatings in harsh environments, such as chemical processing plants and offshore structures, has led to a rise in demand for polyurethane-based solutions. These coatings offer superior chemical resistance and durability, extending the lifespan of industrial equipment and infrastructure.

The marine industry has also contributed to the growing demand for high-performance coatings. Polyurethane coatings are increasingly used in marine applications due to their excellent resistance to saltwater, UV radiation, and biofouling. This has led to increased adoption in shipbuilding and maintenance sectors.

Environmental regulations and sustainability concerns have further shaped the market demand for high-performance coatings. There is a growing preference for low-VOC and environmentally friendly coating solutions, driving innovation in water-based and high-solids polyurethane formulations. This trend aligns with the global push towards sustainable manufacturing practices and reduced environmental impact.

The Asia-Pacific region has emerged as a significant market for high-performance coatings, fueled by rapid industrialization, infrastructure development, and automotive production. North America and Europe continue to be strong markets, with a focus on technological advancements and stringent quality standards.

As industries continue to seek coatings with enhanced performance characteristics, the demand for polyurethane-based solutions is expected to grow. The ability of polyurethane to be tailored for specific applications, combined with its overall superior performance, positions it as a key player in the high-performance coatings market for the foreseeable future.

In the automotive sector, there is a growing need for coatings that provide enhanced durability, scratch resistance, and aesthetic appeal. Polyurethane-based coatings have gained traction due to their ability to offer superior gloss retention, chemical resistance, and weatherability. The aerospace industry demands coatings that can withstand extreme environmental conditions while maintaining lightweight properties, an area where polyurethane excels.

The construction industry has shown increased interest in high-performance coatings for both interior and exterior applications. Polyurethane coatings are sought after for their ability to provide excellent protection against moisture, UV radiation, and abrasion, while also offering design flexibility and color stability. This trend is particularly evident in the commercial and residential building segments.

Industrial manufacturing represents another key market for high-performance coatings. The need for corrosion-resistant coatings in harsh environments, such as chemical processing plants and offshore structures, has led to a rise in demand for polyurethane-based solutions. These coatings offer superior chemical resistance and durability, extending the lifespan of industrial equipment and infrastructure.

The marine industry has also contributed to the growing demand for high-performance coatings. Polyurethane coatings are increasingly used in marine applications due to their excellent resistance to saltwater, UV radiation, and biofouling. This has led to increased adoption in shipbuilding and maintenance sectors.

Environmental regulations and sustainability concerns have further shaped the market demand for high-performance coatings. There is a growing preference for low-VOC and environmentally friendly coating solutions, driving innovation in water-based and high-solids polyurethane formulations. This trend aligns with the global push towards sustainable manufacturing practices and reduced environmental impact.

The Asia-Pacific region has emerged as a significant market for high-performance coatings, fueled by rapid industrialization, infrastructure development, and automotive production. North America and Europe continue to be strong markets, with a focus on technological advancements and stringent quality standards.

As industries continue to seek coatings with enhanced performance characteristics, the demand for polyurethane-based solutions is expected to grow. The ability of polyurethane to be tailored for specific applications, combined with its overall superior performance, positions it as a key player in the high-performance coatings market for the foreseeable future.

Current Challenges in Polyurethane Coating Technology

Polyurethane coatings have gained significant popularity in various industries due to their exceptional properties. However, several challenges persist in maximizing their performance. One of the primary issues is achieving optimal balance between hardness and flexibility. While increased hardness enhances scratch resistance, it often compromises flexibility, leading to potential cracking or peeling under stress.

Another significant challenge lies in improving the weatherability of polyurethane coatings. Exposure to UV radiation and environmental factors can cause degradation, resulting in discoloration, loss of gloss, and reduced protective properties. Developing formulations that maintain long-term durability in outdoor applications remains a key focus area for researchers and manufacturers.

Adhesion to diverse substrates poses another hurdle in polyurethane coating technology. Different materials require specific surface treatments or primer systems to ensure proper bonding. Enhancing adhesion without compromising other coating properties or increasing production costs is an ongoing challenge.

The environmental impact of polyurethane coatings is a growing concern. Traditional solvent-based formulations emit volatile organic compounds (VOCs), contributing to air pollution and potential health hazards. While water-based alternatives have been developed, they often fall short in performance compared to their solvent-based counterparts. Bridging this performance gap while maintaining eco-friendliness is a critical challenge.

Chemical resistance is another area where polyurethane coatings face limitations. Improving resistance to acids, alkalis, and solvents without sacrificing other desirable properties remains a complex task. This is particularly crucial in industrial applications where coatings are exposed to harsh chemicals.

The curing process of polyurethane coatings presents its own set of challenges. Achieving faster curing times without compromising coating quality or increasing energy consumption is a delicate balance. Additionally, ensuring uniform curing across different environmental conditions and substrate geometries adds another layer of complexity.

Lastly, the rising demand for multi-functional coatings poses a significant challenge. Incorporating additional properties such as self-healing, anti-microbial, or conductive capabilities into polyurethane coatings without compromising their core performance attributes requires innovative approaches and advanced material science.

Another significant challenge lies in improving the weatherability of polyurethane coatings. Exposure to UV radiation and environmental factors can cause degradation, resulting in discoloration, loss of gloss, and reduced protective properties. Developing formulations that maintain long-term durability in outdoor applications remains a key focus area for researchers and manufacturers.

Adhesion to diverse substrates poses another hurdle in polyurethane coating technology. Different materials require specific surface treatments or primer systems to ensure proper bonding. Enhancing adhesion without compromising other coating properties or increasing production costs is an ongoing challenge.

The environmental impact of polyurethane coatings is a growing concern. Traditional solvent-based formulations emit volatile organic compounds (VOCs), contributing to air pollution and potential health hazards. While water-based alternatives have been developed, they often fall short in performance compared to their solvent-based counterparts. Bridging this performance gap while maintaining eco-friendliness is a critical challenge.

Chemical resistance is another area where polyurethane coatings face limitations. Improving resistance to acids, alkalis, and solvents without sacrificing other desirable properties remains a complex task. This is particularly crucial in industrial applications where coatings are exposed to harsh chemicals.

The curing process of polyurethane coatings presents its own set of challenges. Achieving faster curing times without compromising coating quality or increasing energy consumption is a delicate balance. Additionally, ensuring uniform curing across different environmental conditions and substrate geometries adds another layer of complexity.

Lastly, the rising demand for multi-functional coatings poses a significant challenge. Incorporating additional properties such as self-healing, anti-microbial, or conductive capabilities into polyurethane coatings without compromising their core performance attributes requires innovative approaches and advanced material science.

Existing Strategies for Enhancing Polyurethane Performance

01 Improved mechanical properties

Polyurethane formulations can be enhanced to improve mechanical properties such as tensile strength, elongation, and tear resistance. This can be achieved through the optimization of the polyol and isocyanate components, as well as the addition of specific additives or reinforcing agents.- Improved mechanical properties: Polyurethane formulations can be modified to enhance mechanical properties such as tensile strength, elongation, and tear resistance. This can be achieved through the use of specific polyols, isocyanates, and chain extenders, as well as by optimizing the hard and soft segment ratios in the polymer structure.

- Enhanced thermal stability: The thermal stability of polyurethanes can be improved by incorporating heat-resistant additives, using thermally stable raw materials, or modifying the polymer structure. This results in materials that maintain their properties at higher temperatures and have improved resistance to thermal degradation.

- Increased chemical resistance: Polyurethanes can be formulated to have improved resistance to various chemicals, solvents, and oils. This is achieved by selecting appropriate raw materials, adjusting the crosslink density, and incorporating specific additives that enhance the chemical resistance of the final product.

- Enhanced durability and weathering resistance: The long-term performance of polyurethanes can be improved by incorporating UV stabilizers, antioxidants, and other additives that protect against environmental factors. This results in materials with better resistance to weathering, oxidation, and degradation over time.

- Improved processing characteristics: The processing performance of polyurethanes can be enhanced by optimizing the reactivity of the components, adjusting the viscosity, and incorporating processing aids. This leads to improved flow properties, reduced cycle times, and better overall manufacturability of polyurethane products.

02 Enhanced thermal stability

Techniques to improve the thermal stability of polyurethane materials, allowing them to maintain their performance at higher temperatures or for longer periods under thermal stress. This may involve the use of specialized additives, modified polymer structures, or novel curing processes.Expand Specific Solutions03 Chemical resistance improvement

Methods to enhance the chemical resistance of polyurethane materials, making them more suitable for applications involving exposure to various solvents, acids, or other aggressive chemicals. This can be achieved through the selection of specific raw materials or the incorporation of protective additives.Expand Specific Solutions04 Durability and weathering resistance

Strategies to improve the long-term durability and weathering resistance of polyurethane products, particularly for outdoor applications. This may include UV stabilizers, antioxidants, or surface treatments to protect against environmental degradation.Expand Specific Solutions05 Adhesion and coating performance

Techniques to enhance the adhesion properties of polyurethane coatings and adhesives, improving their bonding strength to various substrates. This can involve surface treatments, primer systems, or modifications to the polyurethane formulation itself.Expand Specific Solutions

Key Players in Polyurethane Coating Industry

The polyurethane coatings market is in a mature growth stage, with a global market size expected to reach $29.27 billion by 2027. The industry is highly competitive, with key players like BASF, PPG Industries, and Dow Global Technologies leading technological advancements. These companies are focusing on developing high-performance, environmentally friendly formulations to meet stringent regulations and customer demands. The technology maturity varies across different applications, with automotive and construction sectors seeing rapid innovations. Companies such as Covestro, Evonik, and Henkel are investing heavily in R&D to improve durability, chemical resistance, and sustainability of polyurethane coatings, driving the market towards more specialized and value-added products.

BASF Corp.

Technical Solution: BASF has developed a high-performance polyurethane coating system that utilizes their proprietary crosslinking technology. This system incorporates specially designed isocyanates and polyols that form a dense, highly crosslinked network during curing. The resulting coating exhibits exceptional chemical resistance, durability, and weatherability. BASF's formulation also includes advanced additives that enhance UV stability and reduce yellowing over time. The company has optimized the coating's application properties, ensuring excellent flow, leveling, and adhesion to various substrates.

Strengths: Superior chemical and weather resistance, excellent durability, and enhanced UV stability. Weaknesses: Potentially higher cost due to specialized raw materials, may require careful handling during application due to isocyanate content.

PPG Industries Ohio, Inc.

Technical Solution: PPG has innovated a two-component polyurethane coating system that focuses on maximizing flexibility and impact resistance while maintaining excellent chemical resistance. Their technology utilizes a combination of long-chain polyester polyols and aliphatic isocyanates, resulting in a coating with superior elongation properties. PPG's formulation also incorporates nano-sized reinforcing particles that enhance scratch resistance without compromising flexibility. The company has developed a proprietary curing catalyst that allows for faster cure times at lower temperatures, improving energy efficiency in coating applications.

Strengths: Exceptional flexibility and impact resistance, improved scratch resistance, and energy-efficient curing process. Weaknesses: May have lower hardness compared to more rigid systems, potentially higher raw material costs.

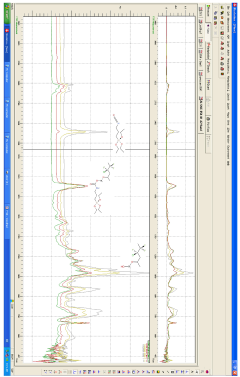

Innovative Approaches in Polyurethane Formulation

A high performance isocyanate free polyurethane resin coating

PatentInactiveAU2021218019A1

Innovation

- A high-performance isocyanate-free polyurethane resin coating formulation using a fluoroethylene vinyl ether (FEVE) moiety and silane-functional isocyanate, catalyzed by bismuth carboxylate at ambient temperature, resulting in a silane-functionalized polyurethane resin with no measurable unreacted isocyanates, offering improved UV resistance and adhesion without the need for primer coats.

Quick-drying, energy-elastic, scratch-resistant and stable coating compounds

PatentActiveEP3116926A1

Innovation

- The development of two-component polyurethane coating compositions comprising polyisocyanate, hydroxyl-containing poly(meth)acrylate polyol, and branched polyester polyol, where the acid number of the polyester polyol is greater than 30 mg KOH/g, and the acid and hydroxyl groups are in a specific molar mixing ratio, with less than 20% free diacid and/or tri-acid, and no tetra-alcohol, optimized for solvent-based systems.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of polyurethane coatings have become increasingly important in recent years. As regulations tighten and consumer awareness grows, the coatings industry is under pressure to develop more eco-friendly solutions without compromising performance. One of the primary concerns is the use of volatile organic compounds (VOCs) in traditional solvent-based polyurethane coatings. These VOCs contribute to air pollution and can pose health risks to both workers and end-users.

To address this issue, manufacturers are focusing on developing low-VOC and zero-VOC formulations. Water-based polyurethane coatings have gained significant traction as a more environmentally friendly alternative. These coatings reduce harmful emissions during application and curing, while still providing excellent durability and chemical resistance. Additionally, high-solids polyurethane formulations are being developed to minimize solvent content while maintaining desired performance characteristics.

Another critical aspect of sustainability in polyurethane coatings is the sourcing of raw materials. Bio-based polyols derived from renewable resources such as vegetable oils, lignin, and sugar are being incorporated into coating formulations to reduce reliance on petroleum-based ingredients. These bio-based alternatives not only lower the carbon footprint of the coatings but also contribute to the circular economy by utilizing waste products from other industries.

The end-of-life considerations for polyurethane coatings are also receiving increased attention. Researchers are exploring ways to improve the recyclability and biodegradability of these coatings. Some innovative approaches include the development of reversible chemistries that allow for easier separation and recycling of coating components. Additionally, the incorporation of biodegradable additives and the use of enzymatic degradation techniques are being investigated to address the long-term environmental impact of polyurethane coatings.

Energy efficiency in the production and application of polyurethane coatings is another area of focus for sustainability improvements. Manufacturers are optimizing their production processes to reduce energy consumption and waste generation. This includes the implementation of more efficient mixing and application technologies, as well as the use of renewable energy sources in manufacturing facilities.

As the industry moves towards more sustainable practices, life cycle assessment (LCA) tools are being employed to evaluate the overall environmental impact of polyurethane coatings. These assessments consider factors such as raw material extraction, production, use phase, and end-of-life disposal to provide a comprehensive view of a coating's environmental footprint. This information is crucial for guiding future developments and ensuring that sustainability improvements are meaningful and quantifiable.

To address this issue, manufacturers are focusing on developing low-VOC and zero-VOC formulations. Water-based polyurethane coatings have gained significant traction as a more environmentally friendly alternative. These coatings reduce harmful emissions during application and curing, while still providing excellent durability and chemical resistance. Additionally, high-solids polyurethane formulations are being developed to minimize solvent content while maintaining desired performance characteristics.

Another critical aspect of sustainability in polyurethane coatings is the sourcing of raw materials. Bio-based polyols derived from renewable resources such as vegetable oils, lignin, and sugar are being incorporated into coating formulations to reduce reliance on petroleum-based ingredients. These bio-based alternatives not only lower the carbon footprint of the coatings but also contribute to the circular economy by utilizing waste products from other industries.

The end-of-life considerations for polyurethane coatings are also receiving increased attention. Researchers are exploring ways to improve the recyclability and biodegradability of these coatings. Some innovative approaches include the development of reversible chemistries that allow for easier separation and recycling of coating components. Additionally, the incorporation of biodegradable additives and the use of enzymatic degradation techniques are being investigated to address the long-term environmental impact of polyurethane coatings.

Energy efficiency in the production and application of polyurethane coatings is another area of focus for sustainability improvements. Manufacturers are optimizing their production processes to reduce energy consumption and waste generation. This includes the implementation of more efficient mixing and application technologies, as well as the use of renewable energy sources in manufacturing facilities.

As the industry moves towards more sustainable practices, life cycle assessment (LCA) tools are being employed to evaluate the overall environmental impact of polyurethane coatings. These assessments consider factors such as raw material extraction, production, use phase, and end-of-life disposal to provide a comprehensive view of a coating's environmental footprint. This information is crucial for guiding future developments and ensuring that sustainability improvements are meaningful and quantifiable.

Regulatory Landscape for Polyurethane Coatings

The regulatory landscape for polyurethane coatings is complex and ever-evolving, with significant implications for manufacturers, formulators, and end-users. At the forefront of these regulations are environmental and health concerns, driving the industry towards more sustainable and safer practices.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polyurethane coatings. The agency's Toxic Substances Control Act (TSCA) mandates the evaluation and regulation of chemicals, including those used in polyurethane formulations. Additionally, the Clean Air Act sets limits on volatile organic compound (VOC) emissions, pushing manufacturers to develop low-VOC and zero-VOC polyurethane coating solutions.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has far-reaching effects on the polyurethane coatings industry. It requires manufacturers to register chemicals, assess their hazards, and communicate safety information. The EU has also implemented restrictions on certain isocyanates, key components in polyurethane production, due to their potential health risks.

In Asia, countries like China and Japan have been strengthening their chemical regulations. China's new chemical substance notification system, similar to REACH, impacts polyurethane coating manufacturers operating in or exporting to the country. Japan's Chemical Substances Control Law (CSCL) also requires notification and evaluation of new chemical substances.

Global efforts to reduce greenhouse gas emissions and combat climate change are influencing the regulatory landscape. Many countries are implementing policies that favor low-carbon and bio-based materials, encouraging innovation in polyurethane coating formulations.

Occupational safety regulations, such as those enforced by OSHA in the US, set standards for worker protection during the application of polyurethane coatings. These regulations often require proper ventilation, personal protective equipment, and training for workers handling isocyanates and other potentially hazardous chemicals.

The food contact materials (FCM) sector faces particularly stringent regulations. In the EU, the Framework Regulation (EC) No 1935/2004 sets overall requirements for materials in contact with food, while specific measures exist for certain substances used in polyurethane coatings intended for food packaging.

As sustainability becomes increasingly important, extended producer responsibility (EPR) regulations are emerging. These policies hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling, pushing for more environmentally friendly polyurethane coating formulations and application methods.

To maximize polyurethane performance in coatings while navigating this complex regulatory landscape, manufacturers must stay informed of current and upcoming regulations, invest in research and development of compliant formulations, and proactively engage with regulatory bodies to shape future policies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating polyurethane coatings. The agency's Toxic Substances Control Act (TSCA) mandates the evaluation and regulation of chemicals, including those used in polyurethane formulations. Additionally, the Clean Air Act sets limits on volatile organic compound (VOC) emissions, pushing manufacturers to develop low-VOC and zero-VOC polyurethane coating solutions.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has far-reaching effects on the polyurethane coatings industry. It requires manufacturers to register chemicals, assess their hazards, and communicate safety information. The EU has also implemented restrictions on certain isocyanates, key components in polyurethane production, due to their potential health risks.

In Asia, countries like China and Japan have been strengthening their chemical regulations. China's new chemical substance notification system, similar to REACH, impacts polyurethane coating manufacturers operating in or exporting to the country. Japan's Chemical Substances Control Law (CSCL) also requires notification and evaluation of new chemical substances.

Global efforts to reduce greenhouse gas emissions and combat climate change are influencing the regulatory landscape. Many countries are implementing policies that favor low-carbon and bio-based materials, encouraging innovation in polyurethane coating formulations.

Occupational safety regulations, such as those enforced by OSHA in the US, set standards for worker protection during the application of polyurethane coatings. These regulations often require proper ventilation, personal protective equipment, and training for workers handling isocyanates and other potentially hazardous chemicals.

The food contact materials (FCM) sector faces particularly stringent regulations. In the EU, the Framework Regulation (EC) No 1935/2004 sets overall requirements for materials in contact with food, while specific measures exist for certain substances used in polyurethane coatings intended for food packaging.

As sustainability becomes increasingly important, extended producer responsibility (EPR) regulations are emerging. These policies hold manufacturers responsible for the entire lifecycle of their products, including disposal and recycling, pushing for more environmentally friendly polyurethane coating formulations and application methods.

To maximize polyurethane performance in coatings while navigating this complex regulatory landscape, manufacturers must stay informed of current and upcoming regulations, invest in research and development of compliant formulations, and proactively engage with regulatory bodies to shape future policies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!