Can PU Emulsion Electrospinning Transform Wound Dressings?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Emulsion Electrospinning Background and Objectives

Polyurethane (PU) emulsion electrospinning has emerged as a promising technique in the field of wound dressing development. This innovative approach combines the versatility of PU materials with the advanced manufacturing process of electrospinning, offering potential solutions to longstanding challenges in wound care.

The evolution of wound dressing technology has been driven by the need for more effective healing environments. Traditional dressings often fall short in providing optimal conditions for wound recovery, leading to prolonged healing times and increased risk of complications. PU emulsion electrospinning addresses these issues by enabling the production of highly customizable, nanofiber-based dressings with enhanced properties.

PU has been widely used in medical applications due to its biocompatibility, flexibility, and durability. When formulated as an emulsion, it becomes suitable for electrospinning, a process that creates ultra-fine fibers through the application of an electric field to a polymer solution. This combination allows for the fabrication of wound dressings with unique structural and functional characteristics.

The primary objective of PU emulsion electrospinning in wound dressing applications is to create a new generation of advanced healing materials. These materials aim to provide superior moisture management, enhanced gas permeability, and improved mechanical properties compared to conventional dressings. Additionally, the technique offers the potential for incorporating bioactive agents directly into the nanofiber structure, enabling controlled release of therapeutic substances.

Another key goal is to develop scalable manufacturing processes that can translate laboratory success into commercially viable products. This involves optimizing emulsion formulations, refining electrospinning parameters, and establishing quality control measures to ensure consistent production of high-performance wound dressings.

Researchers are also focusing on tailoring PU emulsion electrospun dressings for specific wound types, such as chronic wounds, burns, or surgical incisions. This customization aims to address the unique healing requirements of different wound environments, potentially revolutionizing personalized wound care approaches.

As the field progresses, there is a growing emphasis on sustainability and cost-effectiveness. Efforts are being made to develop eco-friendly PU emulsions and energy-efficient electrospinning processes, aligning with global trends towards more sustainable healthcare solutions. The ultimate aim is to create wound dressings that not only accelerate healing but also reduce the overall environmental impact of medical waste.

The evolution of wound dressing technology has been driven by the need for more effective healing environments. Traditional dressings often fall short in providing optimal conditions for wound recovery, leading to prolonged healing times and increased risk of complications. PU emulsion electrospinning addresses these issues by enabling the production of highly customizable, nanofiber-based dressings with enhanced properties.

PU has been widely used in medical applications due to its biocompatibility, flexibility, and durability. When formulated as an emulsion, it becomes suitable for electrospinning, a process that creates ultra-fine fibers through the application of an electric field to a polymer solution. This combination allows for the fabrication of wound dressings with unique structural and functional characteristics.

The primary objective of PU emulsion electrospinning in wound dressing applications is to create a new generation of advanced healing materials. These materials aim to provide superior moisture management, enhanced gas permeability, and improved mechanical properties compared to conventional dressings. Additionally, the technique offers the potential for incorporating bioactive agents directly into the nanofiber structure, enabling controlled release of therapeutic substances.

Another key goal is to develop scalable manufacturing processes that can translate laboratory success into commercially viable products. This involves optimizing emulsion formulations, refining electrospinning parameters, and establishing quality control measures to ensure consistent production of high-performance wound dressings.

Researchers are also focusing on tailoring PU emulsion electrospun dressings for specific wound types, such as chronic wounds, burns, or surgical incisions. This customization aims to address the unique healing requirements of different wound environments, potentially revolutionizing personalized wound care approaches.

As the field progresses, there is a growing emphasis on sustainability and cost-effectiveness. Efforts are being made to develop eco-friendly PU emulsions and energy-efficient electrospinning processes, aligning with global trends towards more sustainable healthcare solutions. The ultimate aim is to create wound dressings that not only accelerate healing but also reduce the overall environmental impact of medical waste.

Market Analysis for Advanced Wound Dressings

The advanced wound dressings market has experienced significant growth in recent years, driven by an increasing prevalence of chronic wounds, rising geriatric population, and growing awareness about the importance of advanced wound care. The global market for advanced wound dressings is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years.

Factors contributing to market expansion include the rising incidence of diabetes and obesity, which are associated with an increased risk of chronic wounds. Additionally, the growing aging population worldwide is more susceptible to wounds that require advanced care. Technological advancements in wound dressing materials and designs have also fueled market growth, as healthcare providers seek more effective solutions for wound management.

The market is segmented by product type, including foam dressings, hydrocolloid dressings, film dressings, alginate dressings, hydrogel dressings, and collagen dressings. Among these, foam dressings currently hold a significant market share due to their versatility and effectiveness in managing moderate to heavily exuding wounds.

Geographically, North America dominates the advanced wound dressings market, followed by Europe. This is attributed to the high prevalence of chronic wounds, well-established healthcare infrastructure, and greater adoption of advanced wound care products in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare infrastructure, increasing healthcare expenditure, and rising awareness about advanced wound care techniques.

Key market players in the advanced wound dressings sector include Smith & Nephew, Mölnlycke Health Care, ConvaTec Group, and 3M Company. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to maintain their market positions and expand their product portfolios.

The potential of PU emulsion electrospinning in wound dressings represents an emerging opportunity within this market. This technology offers the possibility of creating highly customizable, nanofiber-based dressings with improved properties such as enhanced breathability, moisture management, and drug delivery capabilities. As the demand for more effective and patient-friendly wound care solutions grows, innovations like PU emulsion electrospinning could significantly impact the market landscape, potentially creating new product categories and driving further market expansion.

Factors contributing to market expansion include the rising incidence of diabetes and obesity, which are associated with an increased risk of chronic wounds. Additionally, the growing aging population worldwide is more susceptible to wounds that require advanced care. Technological advancements in wound dressing materials and designs have also fueled market growth, as healthcare providers seek more effective solutions for wound management.

The market is segmented by product type, including foam dressings, hydrocolloid dressings, film dressings, alginate dressings, hydrogel dressings, and collagen dressings. Among these, foam dressings currently hold a significant market share due to their versatility and effectiveness in managing moderate to heavily exuding wounds.

Geographically, North America dominates the advanced wound dressings market, followed by Europe. This is attributed to the high prevalence of chronic wounds, well-established healthcare infrastructure, and greater adoption of advanced wound care products in these regions. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare infrastructure, increasing healthcare expenditure, and rising awareness about advanced wound care techniques.

Key market players in the advanced wound dressings sector include Smith & Nephew, Mölnlycke Health Care, ConvaTec Group, and 3M Company. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to maintain their market positions and expand their product portfolios.

The potential of PU emulsion electrospinning in wound dressings represents an emerging opportunity within this market. This technology offers the possibility of creating highly customizable, nanofiber-based dressings with improved properties such as enhanced breathability, moisture management, and drug delivery capabilities. As the demand for more effective and patient-friendly wound care solutions grows, innovations like PU emulsion electrospinning could significantly impact the market landscape, potentially creating new product categories and driving further market expansion.

Current Challenges in Wound Dressing Technology

Despite significant advancements in wound care technology, several challenges persist in the development and application of effective wound dressings. One of the primary issues is achieving optimal moisture balance. Wound healing requires a moist environment, but excessive moisture can lead to maceration and delayed healing. Current dressings often struggle to maintain this delicate balance, especially in wounds with varying exudate levels.

Another challenge is the management of wound infections. While many dressings incorporate antimicrobial agents, the rise of antibiotic-resistant bacteria has complicated this approach. There is a growing need for innovative solutions that can effectively combat pathogens without contributing to antimicrobial resistance or causing cytotoxicity to healthy cells.

The ability to promote tissue regeneration remains a significant hurdle. Although some advanced dressings incorporate growth factors or bioactive compounds, their efficacy can be limited by poor stability, controlled release issues, and high production costs. Developing dressings that can actively stimulate wound healing processes while remaining cost-effective is an ongoing challenge.

Adhesion and conformability present another set of difficulties. Dressings must adhere well enough to stay in place but not so strongly that they cause trauma upon removal. Additionally, conforming to complex wound geometries, particularly in areas of high movement, remains problematic for many current dressing technologies.

The biocompatibility of wound dressing materials is also a critical concern. Some patients experience allergic reactions or skin irritation from certain dressing components, necessitating the development of hypoallergenic and biocompatible alternatives that maintain therapeutic efficacy.

Furthermore, there is a growing demand for multifunctional dressings that can address multiple aspects of wound healing simultaneously. However, integrating various functionalities without compromising the overall performance or increasing complexity and cost is a significant challenge.

Lastly, the environmental impact of wound dressings is becoming increasingly important. Many current dressings are not biodegradable or recyclable, contributing to medical waste. Developing eco-friendly alternatives that maintain high performance standards is a pressing need in the field.

Another challenge is the management of wound infections. While many dressings incorporate antimicrobial agents, the rise of antibiotic-resistant bacteria has complicated this approach. There is a growing need for innovative solutions that can effectively combat pathogens without contributing to antimicrobial resistance or causing cytotoxicity to healthy cells.

The ability to promote tissue regeneration remains a significant hurdle. Although some advanced dressings incorporate growth factors or bioactive compounds, their efficacy can be limited by poor stability, controlled release issues, and high production costs. Developing dressings that can actively stimulate wound healing processes while remaining cost-effective is an ongoing challenge.

Adhesion and conformability present another set of difficulties. Dressings must adhere well enough to stay in place but not so strongly that they cause trauma upon removal. Additionally, conforming to complex wound geometries, particularly in areas of high movement, remains problematic for many current dressing technologies.

The biocompatibility of wound dressing materials is also a critical concern. Some patients experience allergic reactions or skin irritation from certain dressing components, necessitating the development of hypoallergenic and biocompatible alternatives that maintain therapeutic efficacy.

Furthermore, there is a growing demand for multifunctional dressings that can address multiple aspects of wound healing simultaneously. However, integrating various functionalities without compromising the overall performance or increasing complexity and cost is a significant challenge.

Lastly, the environmental impact of wound dressings is becoming increasingly important. Many current dressings are not biodegradable or recyclable, contributing to medical waste. Developing eco-friendly alternatives that maintain high performance standards is a pressing need in the field.

Existing PU Emulsion Electrospinning Methods

01 PU emulsion preparation for electrospinning

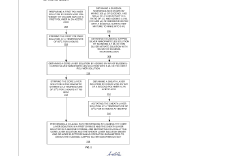

Methods for preparing polyurethane (PU) emulsions suitable for electrospinning. This involves optimizing the composition and properties of the PU emulsion to ensure proper spinnability and fiber formation during the electrospinning process.- PU emulsion preparation for electrospinning: Techniques for preparing polyurethane (PU) emulsions suitable for electrospinning. This involves optimizing the composition and properties of the PU emulsion to ensure it can be effectively electrospun into fibers. The preparation may include adjusting the molecular weight, concentration, and additives in the emulsion to achieve the desired viscosity and conductivity for electrospinning.

- Electrospinning process optimization for PU emulsions: Methods to optimize the electrospinning process specifically for PU emulsions. This includes adjusting parameters such as voltage, flow rate, distance between the nozzle and collector, and environmental conditions to produce uniform and consistent PU nanofibers. The focus is on achieving stable jet formation and controlled fiber deposition.

- Post-treatment of electrospun PU fibers: Techniques for post-processing electrospun PU fibers to enhance their properties or functionality. This may include thermal treatment, chemical crosslinking, or surface modification to improve mechanical strength, hydrophobicity, or other desired characteristics of the fibrous mats.

- Composite PU nanofibers via electrospinning: Development of composite nanofibers by incorporating additional materials into the PU emulsion before electrospinning. This can include the addition of nanoparticles, other polymers, or functional additives to create nanofibers with enhanced properties or multifunctionality.

- Applications of electrospun PU nanofibers: Exploration of various applications for electrospun PU nanofibers produced from emulsions. This includes their use in filtration, tissue engineering, wound dressing, protective clothing, and energy storage devices. The focus is on leveraging the unique properties of PU nanofibers in different fields.

02 Electrospinning process parameters for PU emulsions

Optimization of electrospinning process parameters specific to PU emulsions, including voltage, flow rate, and distance between the nozzle and collector. These parameters are crucial for successful transformation of PU emulsions into nanofibers.Expand Specific Solutions03 Post-treatment of electrospun PU nanofibers

Techniques for post-treatment of electrospun PU nanofibers to enhance their properties or functionality. This may include thermal treatment, chemical modification, or surface functionalization to improve the performance of the resulting nanofiber mats.Expand Specific Solutions04 Incorporation of additives in PU emulsions for electrospinning

Methods for incorporating various additives into PU emulsions to modify the properties of the resulting electrospun nanofibers. These additives can include nanoparticles, functional polymers, or other materials to enhance the performance or functionality of the nanofibers.Expand Specific Solutions05 Applications of electrospun PU nanofibers

Exploration of various applications for electrospun PU nanofibers produced from emulsions. These applications may include filtration, tissue engineering, wound dressing, or other fields where the unique properties of PU nanofibers can be utilized.Expand Specific Solutions

Key Players in Electrospun Wound Dressing Industry

The electrospinning of PU emulsions for wound dressings is an emerging technology in the healthcare sector, currently in its early development stage. The market for advanced wound care products is growing, driven by increasing chronic wounds and surgical procedures. While the technology shows promise, it is still evolving towards maturity. Key players like the University of Akron, Donghua University, and Sichuan University are leading research efforts, with companies such as Covidien Pte Ltd. and Surmodics, Inc. exploring commercial applications. The involvement of diverse institutions, from academic to industrial, indicates growing interest and potential for innovation in this field, though widespread adoption is yet to be achieved.

University of Akron

Technical Solution: The University of Akron has developed a novel PU emulsion electrospinning technique for wound dressings. Their approach involves creating a stable polyurethane emulsion with optimized viscosity and conductivity for electrospinning. The resulting nanofibers are collected on a rotating mandrel to form a porous, breathable membrane. This membrane is then infused with antimicrobial agents and growth factors to promote wound healing. The electrospun PU dressings demonstrate excellent moisture retention, gas permeability, and mechanical properties suitable for various wound types.

Strengths: Highly customizable, scalable production, and excellent wound conformability. Weaknesses: Potential challenges in long-term stability and cost-effectiveness for large-scale manufacturing.

Donghua University

Technical Solution: Donghua University has pioneered a multi-layer PU emulsion electrospinning technique for advanced wound dressings. Their method involves creating a gradient structure with varying fiber diameters and compositions across the dressing thickness. The outer layer consists of finer fibers for bacterial filtration, while the inner layers have larger fibers for exudate absorption and drug delivery. They have also incorporated temperature-responsive polymers into the PU emulsion to create smart dressings that can release drugs in response to wound temperature changes. This innovative approach allows for controlled release of antimicrobial agents and growth factors over time.

Strengths: Advanced multi-functional design and smart drug delivery capabilities. Weaknesses: Complex manufacturing process may lead to higher production costs and potential scalability issues.

Innovations in PU Emulsion Electrospinning

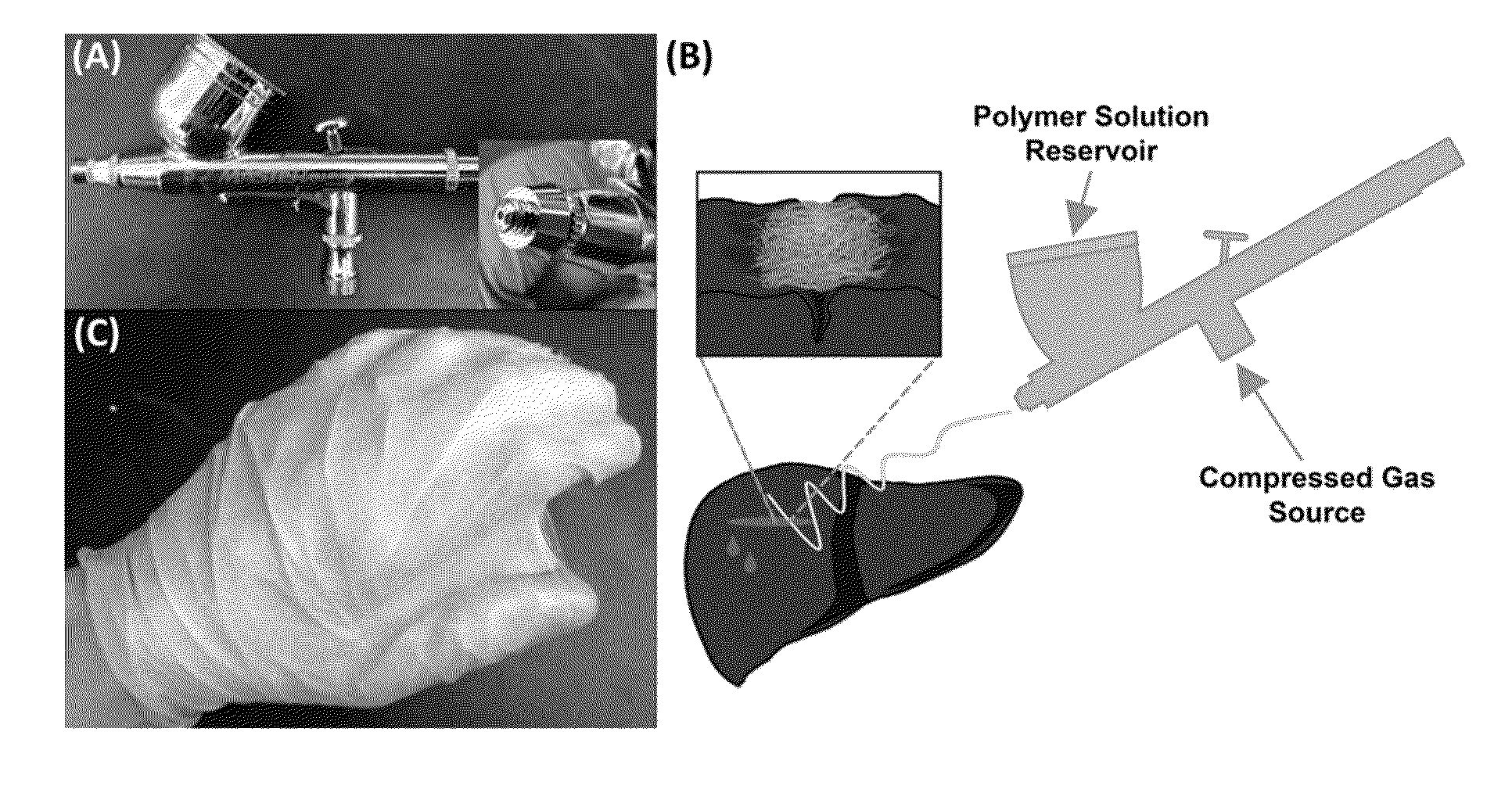

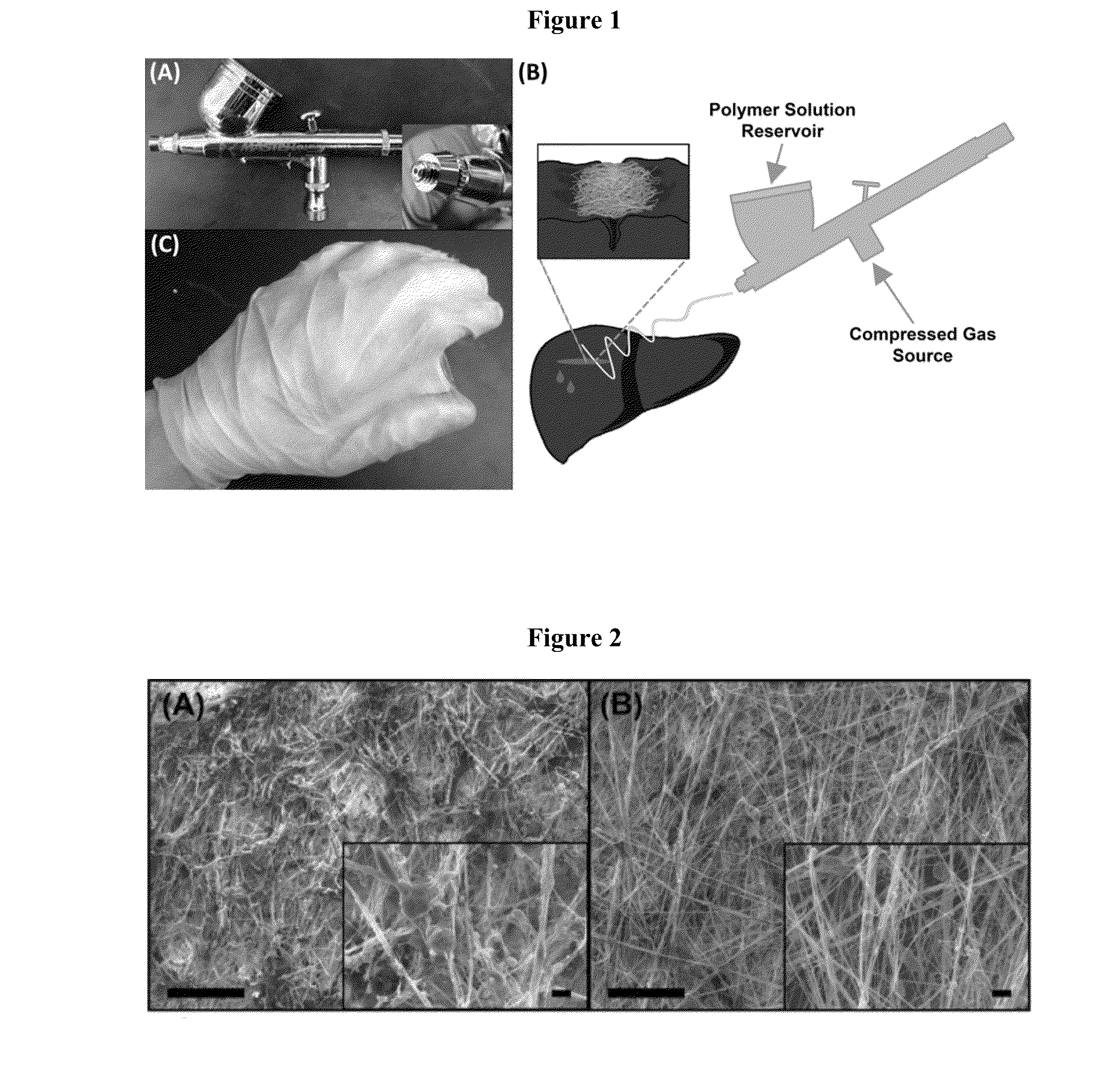

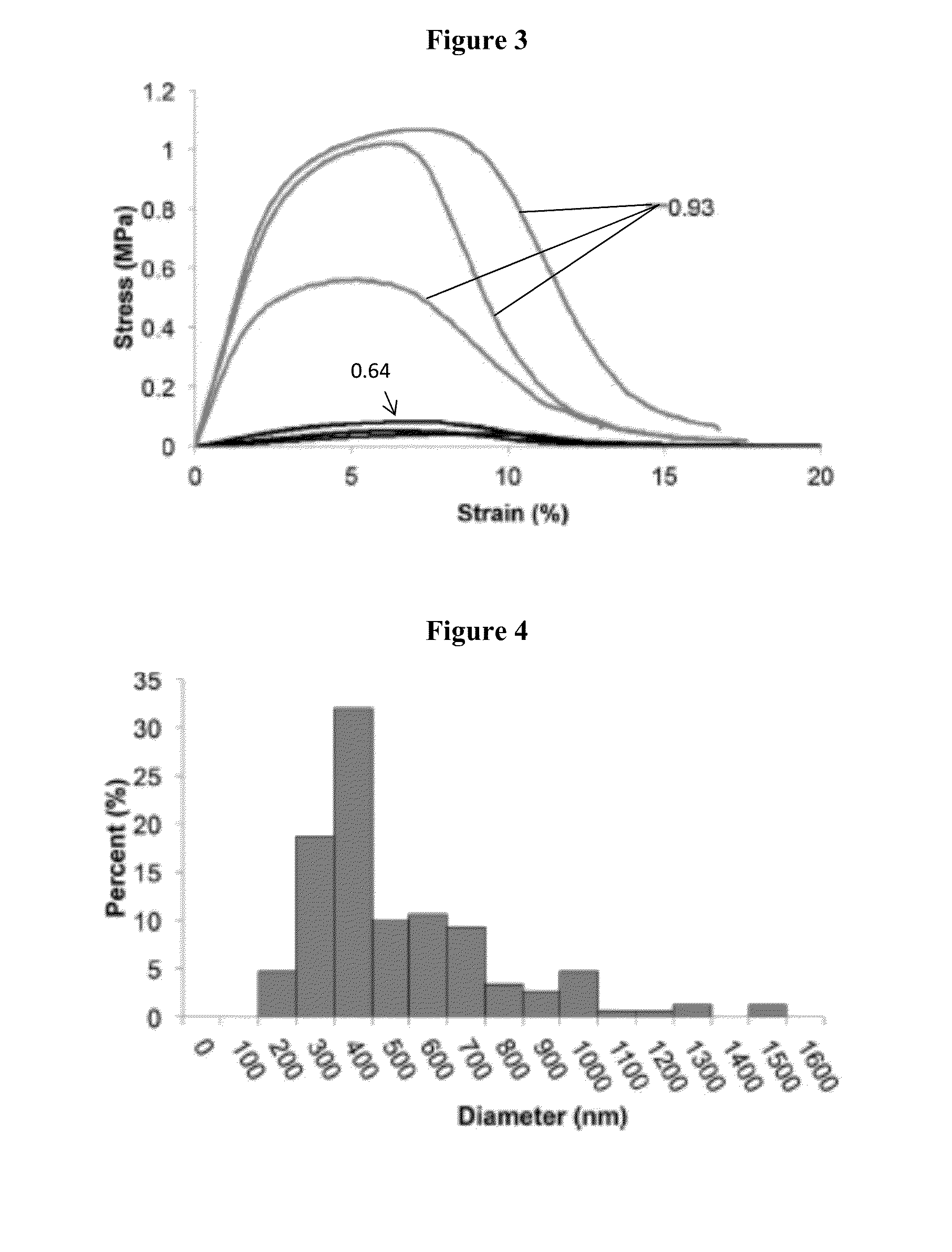

Solution Blow Spun Polymer Fibers, Polymer Blends Therefor and Methods of Use Thereof

PatentActiveUS20150290356A1

Innovation

- Development of biocompatible polymer blends, specifically poly(lactic-co-glycolic acid) (PLGA) and poly(ethylene glycol) (PEG), using solution blow spinning techniques to create adhesive polymer fibers that can be directly deposited on tissues as surgical sealants, hemostatics, or scaffolds, offering modulated adhesive strength and rapid deployment.

Co-axial electrospinning-assisted method for fabricating eugenol-capped silver nanofibrous mat for diabetic wound healing

PatentPendingIN202441002288A

Innovation

- A co-axial electrospinning method is employed to fabricate eugenol-capped silver nanofibrous mats, combining a core layer of eugenol-capped silver nanoparticles with a sheath layer of biopolymers like polyvinyl alcohol and deacetylated chitosan, enhancing anti-microbial activity and promoting vascularization and re-epithelialization.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development of wound dressings using PU emulsion electrospinning. The primary concern is ensuring that the materials used in the electrospinning process do not elicit adverse reactions when in contact with human tissue. Polyurethane (PU) has been widely used in medical applications due to its favorable biocompatibility profile, but the specific formulation and processing methods employed in electrospinning must be carefully evaluated.

One of the key aspects to consider is the potential for cytotoxicity. Electrospun PU fibers must undergo rigorous in vitro testing to assess their impact on cell viability and proliferation. This typically involves exposing cultured cells, such as fibroblasts or keratinocytes, to the electrospun materials and monitoring cellular responses. Additionally, the potential for inflammatory reactions must be evaluated, as chronic inflammation can impede the wound healing process.

The degradation behavior of electrospun PU wound dressings is another critical factor. While some degree of biodegradation may be desirable for certain applications, it is essential to ensure that any breakdown products are non-toxic and do not interfere with the healing process. Long-term studies are necessary to assess the stability of the dressings under physiological conditions and to identify any potential issues related to material degradation over time.

Sterilization compatibility is a crucial consideration for wound dressings. The electrospun PU materials must be able to withstand common sterilization methods, such as ethylene oxide treatment or gamma irradiation, without compromising their structural integrity or biocompatibility. The effects of sterilization on the physical and chemical properties of the electrospun fibers must be thoroughly investigated to ensure that the dressings remain safe and effective after processing.

The potential for allergic reactions is another important safety consideration. While PU is generally well-tolerated, some individuals may be sensitive to certain components of the material. Comprehensive allergenicity testing and careful selection of additives and processing aids are necessary to minimize the risk of adverse reactions in patients.

Furthermore, the interaction between electrospun PU dressings and the wound environment must be carefully evaluated. This includes assessing factors such as moisture management, gas permeability, and the potential for bacterial colonization. The dressings should promote an optimal wound healing environment while minimizing the risk of infection or other complications.

Regulatory compliance is a critical aspect of biocompatibility and safety considerations. Developers of PU emulsion electrospun wound dressings must adhere to stringent guidelines set forth by regulatory bodies such as the FDA and EMA. This involves conducting a comprehensive battery of tests in accordance with standards such as ISO 10993, which outlines the biological evaluation of medical devices.

One of the key aspects to consider is the potential for cytotoxicity. Electrospun PU fibers must undergo rigorous in vitro testing to assess their impact on cell viability and proliferation. This typically involves exposing cultured cells, such as fibroblasts or keratinocytes, to the electrospun materials and monitoring cellular responses. Additionally, the potential for inflammatory reactions must be evaluated, as chronic inflammation can impede the wound healing process.

The degradation behavior of electrospun PU wound dressings is another critical factor. While some degree of biodegradation may be desirable for certain applications, it is essential to ensure that any breakdown products are non-toxic and do not interfere with the healing process. Long-term studies are necessary to assess the stability of the dressings under physiological conditions and to identify any potential issues related to material degradation over time.

Sterilization compatibility is a crucial consideration for wound dressings. The electrospun PU materials must be able to withstand common sterilization methods, such as ethylene oxide treatment or gamma irradiation, without compromising their structural integrity or biocompatibility. The effects of sterilization on the physical and chemical properties of the electrospun fibers must be thoroughly investigated to ensure that the dressings remain safe and effective after processing.

The potential for allergic reactions is another important safety consideration. While PU is generally well-tolerated, some individuals may be sensitive to certain components of the material. Comprehensive allergenicity testing and careful selection of additives and processing aids are necessary to minimize the risk of adverse reactions in patients.

Furthermore, the interaction between electrospun PU dressings and the wound environment must be carefully evaluated. This includes assessing factors such as moisture management, gas permeability, and the potential for bacterial colonization. The dressings should promote an optimal wound healing environment while minimizing the risk of infection or other complications.

Regulatory compliance is a critical aspect of biocompatibility and safety considerations. Developers of PU emulsion electrospun wound dressings must adhere to stringent guidelines set forth by regulatory bodies such as the FDA and EMA. This involves conducting a comprehensive battery of tests in accordance with standards such as ISO 10993, which outlines the biological evaluation of medical devices.

Cost-Effectiveness and Scalability Analysis

The cost-effectiveness and scalability of PU emulsion electrospinning for wound dressings are critical factors in determining its potential to transform the field. From a cost perspective, PU emulsion electrospinning offers several advantages over traditional methods. The process utilizes water-based polyurethane emulsions, which are generally less expensive and more environmentally friendly than solvent-based systems. This reduces material costs and eliminates the need for costly solvent recovery systems, potentially lowering overall production expenses.

Furthermore, the electrospinning process itself is relatively energy-efficient, requiring minimal heat input compared to other fiber production methods. This can lead to reduced energy costs in large-scale manufacturing. The equipment used for electrospinning is also relatively simple and can be scaled up through multiplexing, allowing for increased production capacity without proportional increases in capital investment.

However, there are challenges to consider in terms of scalability. While lab-scale electrospinning setups are straightforward, scaling up to industrial production levels presents technical hurdles. These include maintaining consistent fiber quality across larger production areas, managing the increased complexity of multiple spinnerets, and ensuring uniform deposition of fibers over larger surface areas. Addressing these challenges may require significant research and development investment, potentially offsetting some of the initial cost advantages.

In terms of production efficiency, PU emulsion electrospinning has the potential for high throughput. The process can produce nanofibers at a rapid rate, and the use of multiple spinnerets can further increase output. This high productivity, combined with the ability to produce fibers with tailored properties, could lead to more cost-effective production of advanced wound dressings.

The scalability of the technology also depends on the availability of raw materials and the stability of the supply chain. As PU emulsions are widely used in various industries, there is generally a robust supply network, which bodes well for large-scale production. However, the specific formulations required for electrospinning may need to be sourced from specialized suppliers, potentially affecting costs and availability.

When considering market adoption, the cost-effectiveness of PU emulsion electrospun wound dressings must be evaluated against existing products. While production costs may be competitive, the overall economic viability will depend on factors such as regulatory approval processes, marketing expenses, and healthcare reimbursement policies. The potential for improved healing outcomes and reduced treatment durations could offset higher initial product costs, making these advanced dressings attractive to healthcare providers and payers.

Furthermore, the electrospinning process itself is relatively energy-efficient, requiring minimal heat input compared to other fiber production methods. This can lead to reduced energy costs in large-scale manufacturing. The equipment used for electrospinning is also relatively simple and can be scaled up through multiplexing, allowing for increased production capacity without proportional increases in capital investment.

However, there are challenges to consider in terms of scalability. While lab-scale electrospinning setups are straightforward, scaling up to industrial production levels presents technical hurdles. These include maintaining consistent fiber quality across larger production areas, managing the increased complexity of multiple spinnerets, and ensuring uniform deposition of fibers over larger surface areas. Addressing these challenges may require significant research and development investment, potentially offsetting some of the initial cost advantages.

In terms of production efficiency, PU emulsion electrospinning has the potential for high throughput. The process can produce nanofibers at a rapid rate, and the use of multiple spinnerets can further increase output. This high productivity, combined with the ability to produce fibers with tailored properties, could lead to more cost-effective production of advanced wound dressings.

The scalability of the technology also depends on the availability of raw materials and the stability of the supply chain. As PU emulsions are widely used in various industries, there is generally a robust supply network, which bodes well for large-scale production. However, the specific formulations required for electrospinning may need to be sourced from specialized suppliers, potentially affecting costs and availability.

When considering market adoption, the cost-effectiveness of PU emulsion electrospun wound dressings must be evaluated against existing products. While production costs may be competitive, the overall economic viability will depend on factors such as regulatory approval processes, marketing expenses, and healthcare reimbursement policies. The potential for improved healing outcomes and reduced treatment durations could offset higher initial product costs, making these advanced dressings attractive to healthcare providers and payers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!