Polyurethane Integration in Renewable Energy Solutions

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU in Renewable Energy: Background and Objectives

Polyurethane (PU) has emerged as a versatile material with significant potential in the renewable energy sector. The integration of PU in renewable energy solutions represents a convergence of material science and sustainable technology, aiming to address the growing global demand for clean energy alternatives. This technological evolution is driven by the urgent need to reduce carbon emissions and mitigate climate change impacts.

The journey of PU in renewable energy applications can be traced back to the early 2000s when researchers began exploring its properties for energy-related uses. Initially, PU was primarily utilized in insulation materials for energy-efficient buildings. However, as renewable energy technologies advanced, so did the applications of PU, expanding into areas such as wind turbine blades, solar panel components, and energy storage systems.

The development of PU in renewable energy has been marked by continuous improvements in material properties, including enhanced durability, weather resistance, and thermal efficiency. These advancements have been crucial in overcoming the challenges posed by harsh environmental conditions often encountered in renewable energy installations.

One of the key drivers behind the integration of PU in renewable energy solutions is its ability to contribute to the overall efficiency and longevity of energy systems. For instance, in wind energy, PU-based composites have shown promise in creating lighter, stronger, and more aerodynamic turbine blades, potentially increasing energy output and reducing maintenance costs.

The objectives of integrating PU in renewable energy solutions are multifaceted. Primarily, there is a focus on enhancing the performance and durability of renewable energy components, thereby improving the overall efficiency and reliability of these systems. Additionally, researchers and industry players aim to develop more sustainable PU formulations, incorporating bio-based materials and improving end-of-life recyclability.

Another critical objective is to reduce the cost of renewable energy technologies through the use of PU. By leveraging the material's unique properties, such as its lightweight nature and excellent insulation capabilities, PU integration aims to contribute to the economic viability of renewable energy projects, making them more competitive with traditional energy sources.

As the renewable energy sector continues to grow, the role of PU is expected to expand further. Future objectives include the development of novel PU-based materials tailored specifically for next-generation renewable energy technologies, such as advanced solar cells, tidal energy systems, and innovative energy storage solutions. These developments are anticipated to play a crucial role in accelerating the global transition towards a more sustainable energy landscape.

The journey of PU in renewable energy applications can be traced back to the early 2000s when researchers began exploring its properties for energy-related uses. Initially, PU was primarily utilized in insulation materials for energy-efficient buildings. However, as renewable energy technologies advanced, so did the applications of PU, expanding into areas such as wind turbine blades, solar panel components, and energy storage systems.

The development of PU in renewable energy has been marked by continuous improvements in material properties, including enhanced durability, weather resistance, and thermal efficiency. These advancements have been crucial in overcoming the challenges posed by harsh environmental conditions often encountered in renewable energy installations.

One of the key drivers behind the integration of PU in renewable energy solutions is its ability to contribute to the overall efficiency and longevity of energy systems. For instance, in wind energy, PU-based composites have shown promise in creating lighter, stronger, and more aerodynamic turbine blades, potentially increasing energy output and reducing maintenance costs.

The objectives of integrating PU in renewable energy solutions are multifaceted. Primarily, there is a focus on enhancing the performance and durability of renewable energy components, thereby improving the overall efficiency and reliability of these systems. Additionally, researchers and industry players aim to develop more sustainable PU formulations, incorporating bio-based materials and improving end-of-life recyclability.

Another critical objective is to reduce the cost of renewable energy technologies through the use of PU. By leveraging the material's unique properties, such as its lightweight nature and excellent insulation capabilities, PU integration aims to contribute to the economic viability of renewable energy projects, making them more competitive with traditional energy sources.

As the renewable energy sector continues to grow, the role of PU is expected to expand further. Future objectives include the development of novel PU-based materials tailored specifically for next-generation renewable energy technologies, such as advanced solar cells, tidal energy systems, and innovative energy storage solutions. These developments are anticipated to play a crucial role in accelerating the global transition towards a more sustainable energy landscape.

Market Analysis for PU-based Renewable Energy Products

The market for polyurethane-based renewable energy products is experiencing significant growth, driven by the increasing global focus on sustainable energy solutions. As governments worldwide implement stricter environmental regulations and set ambitious renewable energy targets, the demand for innovative materials that can enhance the efficiency and durability of renewable energy systems is on the rise.

In the solar energy sector, polyurethane-based products are gaining traction for their application in photovoltaic panel encapsulation and mounting systems. These materials offer excellent weather resistance, thermal insulation, and lightweight properties, contributing to improved panel performance and longevity. The global solar PV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, presenting a substantial opportunity for PU-based products.

Wind energy is another key market for polyurethane applications, particularly in the manufacturing of wind turbine blades. PU-based composites provide superior strength-to-weight ratios, fatigue resistance, and impact resistance compared to traditional materials. With the global wind energy market expected to expand rapidly, the demand for high-performance blade materials is set to increase significantly.

In the energy storage sector, polyurethane-based products are finding applications in advanced battery technologies and thermal energy storage systems. PU foams and coatings are being utilized to enhance the safety, thermal management, and overall performance of lithium-ion batteries and other energy storage devices. As the energy storage market continues to grow, driven by the need for grid stabilization and electric vehicle adoption, the demand for PU-based solutions is expected to surge.

The market for PU-based renewable energy products is also benefiting from advancements in bio-based and recycled polyurethanes. These sustainable alternatives are attracting increased attention from environmentally conscious consumers and businesses, further expanding the market potential.

Geographically, Asia-Pacific is emerging as a key market for PU-based renewable energy products, driven by rapid industrialization, urbanization, and government initiatives to promote clean energy. North America and Europe continue to be significant markets, with a strong focus on technological innovation and sustainability.

However, challenges such as raw material price volatility and competition from alternative materials may impact market growth. Despite these challenges, the overall market outlook for PU-based renewable energy products remains positive, with ample opportunities for innovation and expansion across various renewable energy applications.

In the solar energy sector, polyurethane-based products are gaining traction for their application in photovoltaic panel encapsulation and mounting systems. These materials offer excellent weather resistance, thermal insulation, and lightweight properties, contributing to improved panel performance and longevity. The global solar PV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, presenting a substantial opportunity for PU-based products.

Wind energy is another key market for polyurethane applications, particularly in the manufacturing of wind turbine blades. PU-based composites provide superior strength-to-weight ratios, fatigue resistance, and impact resistance compared to traditional materials. With the global wind energy market expected to expand rapidly, the demand for high-performance blade materials is set to increase significantly.

In the energy storage sector, polyurethane-based products are finding applications in advanced battery technologies and thermal energy storage systems. PU foams and coatings are being utilized to enhance the safety, thermal management, and overall performance of lithium-ion batteries and other energy storage devices. As the energy storage market continues to grow, driven by the need for grid stabilization and electric vehicle adoption, the demand for PU-based solutions is expected to surge.

The market for PU-based renewable energy products is also benefiting from advancements in bio-based and recycled polyurethanes. These sustainable alternatives are attracting increased attention from environmentally conscious consumers and businesses, further expanding the market potential.

Geographically, Asia-Pacific is emerging as a key market for PU-based renewable energy products, driven by rapid industrialization, urbanization, and government initiatives to promote clean energy. North America and Europe continue to be significant markets, with a strong focus on technological innovation and sustainability.

However, challenges such as raw material price volatility and competition from alternative materials may impact market growth. Despite these challenges, the overall market outlook for PU-based renewable energy products remains positive, with ample opportunities for innovation and expansion across various renewable energy applications.

Current Challenges in PU Integration for Renewable Energy

The integration of polyurethane (PU) in renewable energy solutions faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the compatibility of PU materials with various renewable energy components. PU's chemical structure and properties may not always align seamlessly with the requirements of solar panels, wind turbines, or energy storage systems, leading to potential performance issues or reduced efficiency.

Durability and longevity pose another critical challenge. Renewable energy installations are often exposed to harsh environmental conditions, including extreme temperatures, UV radiation, and moisture. While PU offers excellent insulation properties, ensuring its long-term stability and resistance to degradation under these conditions remains a significant hurdle. The development of PU formulations that can withstand prolonged exposure to these elements without compromising performance is crucial for successful integration.

Cost-effectiveness is a persistent challenge in the renewable energy sector, and PU integration is no exception. The production and application of high-performance PU materials suitable for renewable energy solutions can be expensive, potentially increasing the overall cost of renewable energy systems. Balancing the enhanced performance and durability offered by PU with economic viability is essential for widespread adoption.

Environmental concerns also present challenges in PU integration. Traditional PU materials are often derived from petroleum-based sources, which conflicts with the sustainability goals of renewable energy. The development of bio-based or recyclable PU alternatives that maintain the desired properties while reducing environmental impact is an ongoing challenge for researchers and manufacturers.

Scalability and manufacturing processes pose additional hurdles. Integrating PU into renewable energy components often requires specialized techniques and equipment. Developing efficient, large-scale production methods that can meet the growing demand for renewable energy solutions while maintaining consistent quality and performance of PU materials is a significant challenge.

Regulatory compliance and standardization present another set of challenges. The use of PU in renewable energy applications must adhere to various safety, performance, and environmental regulations. Establishing industry-wide standards for PU integration in renewable energy solutions is crucial for ensuring consistency and reliability across different manufacturers and applications.

Lastly, the challenge of optimizing PU properties for specific renewable energy applications remains. Different renewable energy technologies have unique requirements, and developing tailored PU solutions that address these specific needs while maintaining broad applicability is an ongoing research and development challenge. This includes fine-tuning properties such as thermal insulation, electrical resistance, and mechanical strength to suit various renewable energy components and systems.

Durability and longevity pose another critical challenge. Renewable energy installations are often exposed to harsh environmental conditions, including extreme temperatures, UV radiation, and moisture. While PU offers excellent insulation properties, ensuring its long-term stability and resistance to degradation under these conditions remains a significant hurdle. The development of PU formulations that can withstand prolonged exposure to these elements without compromising performance is crucial for successful integration.

Cost-effectiveness is a persistent challenge in the renewable energy sector, and PU integration is no exception. The production and application of high-performance PU materials suitable for renewable energy solutions can be expensive, potentially increasing the overall cost of renewable energy systems. Balancing the enhanced performance and durability offered by PU with economic viability is essential for widespread adoption.

Environmental concerns also present challenges in PU integration. Traditional PU materials are often derived from petroleum-based sources, which conflicts with the sustainability goals of renewable energy. The development of bio-based or recyclable PU alternatives that maintain the desired properties while reducing environmental impact is an ongoing challenge for researchers and manufacturers.

Scalability and manufacturing processes pose additional hurdles. Integrating PU into renewable energy components often requires specialized techniques and equipment. Developing efficient, large-scale production methods that can meet the growing demand for renewable energy solutions while maintaining consistent quality and performance of PU materials is a significant challenge.

Regulatory compliance and standardization present another set of challenges. The use of PU in renewable energy applications must adhere to various safety, performance, and environmental regulations. Establishing industry-wide standards for PU integration in renewable energy solutions is crucial for ensuring consistency and reliability across different manufacturers and applications.

Lastly, the challenge of optimizing PU properties for specific renewable energy applications remains. Different renewable energy technologies have unique requirements, and developing tailored PU solutions that address these specific needs while maintaining broad applicability is an ongoing research and development challenge. This includes fine-tuning properties such as thermal insulation, electrical resistance, and mechanical strength to suit various renewable energy components and systems.

Existing PU Solutions for Renewable Energy Applications

01 Polyurethane synthesis and composition

This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis often involves the reaction of polyols with isocyanates, and may incorporate additives or modifiers to enhance specific characteristics.- Polyurethane synthesis and composition: This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.

- Polyurethane applications in coatings and films: This point covers the use of polyurethane in coatings and films for various applications. It includes formulations for protective coatings, adhesive films, and surface treatments. The polyurethane-based coatings and films may offer properties such as weather resistance, chemical resistance, and improved adhesion to different substrates.

- Polyurethane foam production and modification: This category relates to the production and modification of polyurethane foams. It includes techniques for creating various types of foams, such as flexible, rigid, or semi-rigid foams, with specific properties like density, cell structure, and thermal insulation. The modifications may involve the use of additives or processing methods to enhance foam characteristics.

- Polyurethane in textile and fiber applications: This point focuses on the use of polyurethane in textile and fiber applications. It includes methods for incorporating polyurethane into fabrics, creating polyurethane fibers, and developing polyurethane-based textile coatings. These applications may result in improved elasticity, moisture management, or durability of textiles and fibers.

- Polyurethane in medical and biocompatible applications: This category covers the use of polyurethane in medical and biocompatible applications. It includes the development of polyurethane-based materials for medical devices, implants, and drug delivery systems. The focus is on creating biocompatible polyurethanes with specific properties such as controlled degradation, antimicrobial activity, or enhanced cell adhesion.

02 Polyurethane applications in coatings and films

This point covers the use of polyurethane in various coating and film applications. Polyurethane coatings and films are utilized for their durability, chemical resistance, and versatility. Applications include protective coatings for industrial equipment, automotive finishes, and packaging materials. The formulations may be tailored for specific performance requirements such as weather resistance or adhesion properties.Expand Specific Solutions03 Polyurethane foam technology

This category encompasses advancements in polyurethane foam technology. It includes innovations in foam formulation, processing techniques, and the development of specialized foam products. Areas of focus may include improving insulation properties, enhancing fire resistance, or creating biodegradable foam alternatives. The technology also covers the production of flexible and rigid foams for various applications.Expand Specific Solutions04 Polyurethane in textile and fiber applications

This point addresses the use of polyurethane in textile and fiber-related applications. It includes the development of polyurethane fibers, coatings for fabrics, and elastomeric materials for use in clothing and other textile products. The technology may focus on improving stretch properties, moisture management, or durability of textile materials incorporating polyurethane components.Expand Specific Solutions05 Environmentally friendly polyurethane innovations

This category focuses on developing more environmentally friendly polyurethane materials and processes. It includes research into bio-based polyols, recyclable polyurethane formulations, and methods to reduce or eliminate harmful chemicals in polyurethane production. The innovations aim to improve the sustainability of polyurethane products while maintaining or enhancing their performance characteristics.Expand Specific Solutions

Key Players in PU and Renewable Energy Industries

The integration of polyurethane in renewable energy solutions is gaining momentum, with the market currently in a growth phase. The global market size for this application is expanding rapidly, driven by increasing demand for sustainable materials in the energy sector. Technologically, the field is advancing, with companies like Covestro Deutschland AG, Dow Global Technologies LLC, and DuPont de Nemours, Inc. leading innovation. These firms are developing high-performance polyurethane materials tailored for renewable energy applications. While the technology is maturing, there's still significant room for improvement and new applications, particularly in areas such as wind turbine blades, solar panel encapsulation, and energy storage solutions. Research institutions like the Institute of Chemical Industry of Forest Products CAF and Nanjing Forestry University are also contributing to technological advancements, indicating a collaborative industry-academia approach to innovation in this field.

Covestro Deutschland AG

Technical Solution: Covestro has developed a novel polyurethane-based solution for renewable energy applications, focusing on wind turbine blades. Their technology involves using polyurethane resins to create lighter, stronger, and more durable wind turbine blades. The process includes a two-component system: a polyol component derived from renewable resources and an isocyanate component. This formulation allows for faster curing times, reduced energy consumption during manufacturing, and improved overall performance of the wind turbine blades.

Strengths: Lighter weight, improved durability, faster production times, and use of renewable resources. Weaknesses: Potential higher initial costs and limited long-term performance data compared to traditional materials.

Dow Global Technologies LLC

Technical Solution: Dow has developed a polyurethane-based solution for solar panel encapsulation. Their technology utilizes a two-component polyurethane system that provides excellent protection for solar cells while enhancing energy efficiency. The polyurethane encapsulant offers superior weatherability, UV resistance, and thermal management properties. This innovation allows for increased solar panel lifespan and improved energy conversion efficiency. Additionally, Dow's solution incorporates recycled and bio-based materials, contributing to a more sustainable manufacturing process.

Strengths: Enhanced solar panel durability, improved energy efficiency, and use of sustainable materials. Weaknesses: Potentially higher production costs and the need for specialized application equipment.

Innovative PU Formulations for Energy Efficiency

Natural oil based copolymer polyols and polyurethane products made therefrom

PatentActiveEP2240527A1

Innovation

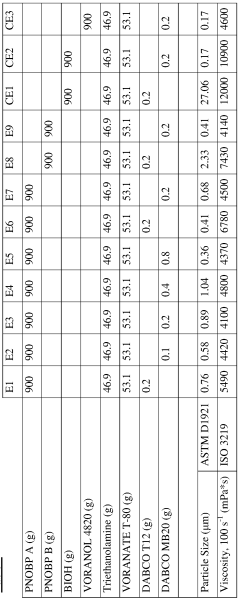

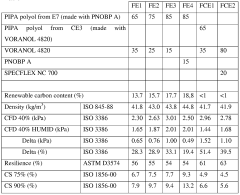

- A method involving a polyol composition that combines conventional petroleum-based polyols with natural oil-derived polyols, including dispersed polymer particles like acrylonitrile, polystyrene, and polyurea or polyurethane-urea particles, to form polyurethane foams that increase the use of renewable resources while maintaining load-bearing properties.

Natural oil based polymer polyols and polyurethane products made therefrom

PatentWO2010151431A1

Innovation

- Development of natural oil-based polymer polyols with specific molecular structures and ether groups, allowing for in situ polymerization to create polyurethane foams with high renewable content while maintaining load-bearing and humid aging properties.

Environmental Impact of PU in Renewable Energy Systems

The integration of polyurethane (PU) in renewable energy solutions has significant environmental implications that warrant careful consideration. While PU materials contribute to the efficiency and durability of renewable energy systems, their production and disposal processes can have both positive and negative environmental impacts.

On the positive side, PU's excellent insulation properties contribute to improved energy efficiency in solar panels and wind turbines. This enhanced efficiency translates to increased renewable energy generation, potentially offsetting the use of fossil fuels and reducing overall carbon emissions. Additionally, PU's lightweight nature reduces transportation-related emissions and enables the construction of larger, more efficient wind turbine blades.

However, the production of PU involves petrochemicals and energy-intensive processes, which can result in greenhouse gas emissions and resource depletion. The use of isocyanates in PU manufacturing also raises concerns about potential environmental contamination and health risks if not properly managed. These factors partially offset the environmental benefits gained from improved renewable energy system performance.

End-of-life considerations for PU components in renewable energy systems present another environmental challenge. While some PU materials can be recycled, the process is often complex and energy-intensive. Improper disposal of PU waste can lead to long-term environmental pollution, as these materials may not biodegrade readily.

Recent advancements in bio-based and recyclable PU formulations offer promising solutions to mitigate these environmental concerns. Bio-based PUs derived from renewable resources such as vegetable oils or agricultural waste can reduce reliance on petrochemicals and lower the carbon footprint of production. Additionally, the development of chemically recyclable PUs allows for more efficient material recovery and reuse, potentially creating a closed-loop system for PU components in renewable energy applications.

The environmental impact of PU in renewable energy systems extends beyond its lifecycle. By enhancing the performance and longevity of renewable energy technologies, PU indirectly contributes to the reduction of fossil fuel dependence and associated environmental degradation. This positive impact must be weighed against the direct environmental costs of PU production and disposal.

To fully assess the environmental impact, lifecycle assessments (LCAs) are crucial. These analyses consider the entire environmental footprint of PU in renewable energy applications, from raw material extraction to end-of-life disposal or recycling. LCAs help identify areas for improvement and guide the development of more sustainable PU solutions for the renewable energy sector.

On the positive side, PU's excellent insulation properties contribute to improved energy efficiency in solar panels and wind turbines. This enhanced efficiency translates to increased renewable energy generation, potentially offsetting the use of fossil fuels and reducing overall carbon emissions. Additionally, PU's lightweight nature reduces transportation-related emissions and enables the construction of larger, more efficient wind turbine blades.

However, the production of PU involves petrochemicals and energy-intensive processes, which can result in greenhouse gas emissions and resource depletion. The use of isocyanates in PU manufacturing also raises concerns about potential environmental contamination and health risks if not properly managed. These factors partially offset the environmental benefits gained from improved renewable energy system performance.

End-of-life considerations for PU components in renewable energy systems present another environmental challenge. While some PU materials can be recycled, the process is often complex and energy-intensive. Improper disposal of PU waste can lead to long-term environmental pollution, as these materials may not biodegrade readily.

Recent advancements in bio-based and recyclable PU formulations offer promising solutions to mitigate these environmental concerns. Bio-based PUs derived from renewable resources such as vegetable oils or agricultural waste can reduce reliance on petrochemicals and lower the carbon footprint of production. Additionally, the development of chemically recyclable PUs allows for more efficient material recovery and reuse, potentially creating a closed-loop system for PU components in renewable energy applications.

The environmental impact of PU in renewable energy systems extends beyond its lifecycle. By enhancing the performance and longevity of renewable energy technologies, PU indirectly contributes to the reduction of fossil fuel dependence and associated environmental degradation. This positive impact must be weighed against the direct environmental costs of PU production and disposal.

To fully assess the environmental impact, lifecycle assessments (LCAs) are crucial. These analyses consider the entire environmental footprint of PU in renewable energy applications, from raw material extraction to end-of-life disposal or recycling. LCAs help identify areas for improvement and guide the development of more sustainable PU solutions for the renewable energy sector.

Regulatory Framework for PU Use in Energy Sector

The regulatory framework for polyurethane (PU) use in the energy sector is a complex and evolving landscape that significantly impacts the integration of PU in renewable energy solutions. As governments worldwide strive to meet climate change targets and promote sustainable energy practices, the regulations surrounding PU applications in this field have become increasingly stringent and comprehensive.

At the international level, organizations such as the United Nations Framework Convention on Climate Change (UNFCCC) and the International Renewable Energy Agency (IRENA) have established guidelines that indirectly influence PU use in renewable energy systems. These guidelines often emphasize the importance of life cycle assessments, environmental impact studies, and the promotion of circular economy principles, all of which affect how PU materials are developed, utilized, and disposed of in energy applications.

In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of PU in the energy sector. REACH requires manufacturers and importers to register chemicals, including those used in PU production, and assess their potential risks to human health and the environment. This regulation has led to the development of more environmentally friendly PU formulations specifically tailored for renewable energy applications.

The United States Environmental Protection Agency (EPA) has implemented regulations under the Toxic Substances Control Act (TSCA) that impact PU use in energy solutions. These regulations focus on the assessment and management of chemical risks associated with PU materials, including their potential environmental and health impacts when used in renewable energy systems.

Many countries have also introduced specific regulations targeting the energy efficiency and environmental performance of renewable energy technologies. For instance, the EU's Ecodesign Directive sets mandatory ecological requirements for energy-related products, including those incorporating PU materials. This directive has driven innovation in PU formulations to meet stringent energy efficiency and recyclability standards.

In the context of waste management and end-of-life considerations, regulations such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive have implications for PU use in renewable energy systems. These regulations mandate proper disposal and recycling practices for materials used in energy-related products, encouraging the development of more easily recyclable PU formulations.

As the renewable energy sector continues to grow, regulatory bodies are increasingly focusing on the sustainability and circularity of materials used in energy solutions. This trend is likely to lead to more specific regulations governing PU use in renewable energy applications, potentially including requirements for bio-based content, recyclability, and reduced environmental footprint throughout the product lifecycle.

At the international level, organizations such as the United Nations Framework Convention on Climate Change (UNFCCC) and the International Renewable Energy Agency (IRENA) have established guidelines that indirectly influence PU use in renewable energy systems. These guidelines often emphasize the importance of life cycle assessments, environmental impact studies, and the promotion of circular economy principles, all of which affect how PU materials are developed, utilized, and disposed of in energy applications.

In the European Union, the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of PU in the energy sector. REACH requires manufacturers and importers to register chemicals, including those used in PU production, and assess their potential risks to human health and the environment. This regulation has led to the development of more environmentally friendly PU formulations specifically tailored for renewable energy applications.

The United States Environmental Protection Agency (EPA) has implemented regulations under the Toxic Substances Control Act (TSCA) that impact PU use in energy solutions. These regulations focus on the assessment and management of chemical risks associated with PU materials, including their potential environmental and health impacts when used in renewable energy systems.

Many countries have also introduced specific regulations targeting the energy efficiency and environmental performance of renewable energy technologies. For instance, the EU's Ecodesign Directive sets mandatory ecological requirements for energy-related products, including those incorporating PU materials. This directive has driven innovation in PU formulations to meet stringent energy efficiency and recyclability standards.

In the context of waste management and end-of-life considerations, regulations such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive have implications for PU use in renewable energy systems. These regulations mandate proper disposal and recycling practices for materials used in energy-related products, encouraging the development of more easily recyclable PU formulations.

As the renewable energy sector continues to grow, regulatory bodies are increasingly focusing on the sustainability and circularity of materials used in energy solutions. This trend is likely to lead to more specific regulations governing PU use in renewable energy applications, potentially including requirements for bio-based content, recyclability, and reduced environmental footprint throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!