How to Develop Fire‑Retardant Polyurethane Products?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fire-Retardant PU Evolution and Objectives

The development of fire-retardant polyurethane products has been a critical focus in the field of materials science and engineering for several decades. This evolution has been driven by the increasing demand for safer and more resilient materials in various industries, including construction, automotive, and furniture manufacturing. The primary objective in this field has been to enhance the fire resistance of polyurethane materials without compromising their desirable properties such as flexibility, durability, and insulation capabilities.

The journey of fire-retardant polyurethane began in the 1970s when concerns about the flammability of synthetic materials gained prominence. Initial approaches focused on incorporating halogenated compounds into polyurethane formulations. However, environmental and health concerns led to a shift towards more sustainable fire-retardant strategies.

In the 1990s, research efforts intensified on developing intumescent systems for polyurethane. These systems, when exposed to heat, form a carbonaceous char layer that insulates the underlying material from fire. This marked a significant advancement in fire-retardant technology for polyurethanes.

The turn of the millennium saw a surge in nanotechnology applications. Researchers began exploring the potential of nanoparticles, such as clay and carbon nanotubes, to enhance the fire-retardant properties of polyurethane. These nanocomposites showed promising results in reducing heat release rates and improving char formation.

Recent years have witnessed a growing emphasis on bio-based and environmentally friendly fire retardants. This trend aligns with the broader movement towards sustainable materials and circular economy principles. Researchers are investigating natural compounds and renewable resources as potential fire-retardant additives for polyurethane.

The current objectives in fire-retardant polyurethane development are multifaceted. Firstly, there is a push to develop more efficient and synergistic fire-retardant systems that can provide comprehensive protection against different fire scenarios. Secondly, researchers aim to minimize the impact of fire retardants on the mechanical and physical properties of polyurethane.

Another key objective is to address the toxicity concerns associated with fire-retardant additives and their combustion products. This includes developing fire-retardant systems that do not release harmful substances during a fire event. Additionally, there is a focus on improving the long-term stability and durability of fire-retardant polyurethane products to ensure sustained performance throughout their lifecycle.

The journey of fire-retardant polyurethane began in the 1970s when concerns about the flammability of synthetic materials gained prominence. Initial approaches focused on incorporating halogenated compounds into polyurethane formulations. However, environmental and health concerns led to a shift towards more sustainable fire-retardant strategies.

In the 1990s, research efforts intensified on developing intumescent systems for polyurethane. These systems, when exposed to heat, form a carbonaceous char layer that insulates the underlying material from fire. This marked a significant advancement in fire-retardant technology for polyurethanes.

The turn of the millennium saw a surge in nanotechnology applications. Researchers began exploring the potential of nanoparticles, such as clay and carbon nanotubes, to enhance the fire-retardant properties of polyurethane. These nanocomposites showed promising results in reducing heat release rates and improving char formation.

Recent years have witnessed a growing emphasis on bio-based and environmentally friendly fire retardants. This trend aligns with the broader movement towards sustainable materials and circular economy principles. Researchers are investigating natural compounds and renewable resources as potential fire-retardant additives for polyurethane.

The current objectives in fire-retardant polyurethane development are multifaceted. Firstly, there is a push to develop more efficient and synergistic fire-retardant systems that can provide comprehensive protection against different fire scenarios. Secondly, researchers aim to minimize the impact of fire retardants on the mechanical and physical properties of polyurethane.

Another key objective is to address the toxicity concerns associated with fire-retardant additives and their combustion products. This includes developing fire-retardant systems that do not release harmful substances during a fire event. Additionally, there is a focus on improving the long-term stability and durability of fire-retardant polyurethane products to ensure sustained performance throughout their lifecycle.

Market Demand Analysis for FR PU Products

The market demand for fire-retardant polyurethane (FR PU) products has been steadily increasing due to stringent safety regulations and growing awareness of fire safety across various industries. The construction sector, in particular, has emerged as a significant driver for FR PU products, with applications in insulation, sealants, and coatings. The rise in high-rise buildings and the need for improved fire safety measures have further boosted the demand for these materials.

In the automotive industry, FR PU products are gaining traction for use in interior components, seating, and soundproofing materials. The push for lightweight vehicles and enhanced passenger safety has led to increased adoption of FR PU materials. Similarly, the aerospace sector has shown a growing interest in FR PU products for cabin interiors and insulation, driven by the need for compliance with strict fire safety standards.

The electronics and electrical equipment industry represents another significant market for FR PU products. With the proliferation of electronic devices and the potential fire hazards associated with them, manufacturers are increasingly incorporating FR PU materials in casings, enclosures, and insulation components. This trend is expected to continue as consumer electronics become more prevalent and complex.

The furniture and bedding industry has also witnessed a surge in demand for FR PU products, particularly in public spaces and commercial settings. Hotels, hospitals, and other institutions are prioritizing fire safety in their furnishings, leading to increased adoption of FR PU foams and coatings.

Geographically, North America and Europe lead the market for FR PU products, primarily due to stringent fire safety regulations and well-established construction and automotive industries. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing safety awareness in countries like China and India.

The market for FR PU products is projected to grow at a compound annual growth rate (CAGR) of around 6-8% over the next five years. This growth is attributed to the expanding application areas, technological advancements in FR PU formulations, and the ongoing development of more environmentally friendly fire-retardant solutions.

Despite the positive outlook, challenges remain in the FR PU market. These include the higher cost of FR PU products compared to standard polyurethane materials, concerns about the environmental impact of certain fire-retardant additives, and the need for continuous innovation to meet evolving safety standards and performance requirements across different industries.

In the automotive industry, FR PU products are gaining traction for use in interior components, seating, and soundproofing materials. The push for lightweight vehicles and enhanced passenger safety has led to increased adoption of FR PU materials. Similarly, the aerospace sector has shown a growing interest in FR PU products for cabin interiors and insulation, driven by the need for compliance with strict fire safety standards.

The electronics and electrical equipment industry represents another significant market for FR PU products. With the proliferation of electronic devices and the potential fire hazards associated with them, manufacturers are increasingly incorporating FR PU materials in casings, enclosures, and insulation components. This trend is expected to continue as consumer electronics become more prevalent and complex.

The furniture and bedding industry has also witnessed a surge in demand for FR PU products, particularly in public spaces and commercial settings. Hotels, hospitals, and other institutions are prioritizing fire safety in their furnishings, leading to increased adoption of FR PU foams and coatings.

Geographically, North America and Europe lead the market for FR PU products, primarily due to stringent fire safety regulations and well-established construction and automotive industries. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing safety awareness in countries like China and India.

The market for FR PU products is projected to grow at a compound annual growth rate (CAGR) of around 6-8% over the next five years. This growth is attributed to the expanding application areas, technological advancements in FR PU formulations, and the ongoing development of more environmentally friendly fire-retardant solutions.

Despite the positive outlook, challenges remain in the FR PU market. These include the higher cost of FR PU products compared to standard polyurethane materials, concerns about the environmental impact of certain fire-retardant additives, and the need for continuous innovation to meet evolving safety standards and performance requirements across different industries.

Current FR PU Technology Landscape

The current landscape of fire-retardant polyurethane (FR PU) technology is characterized by a diverse range of approaches and solutions aimed at enhancing the fire resistance of polyurethane products. These technologies can be broadly categorized into three main strategies: additive flame retardants, reactive flame retardants, and inherently flame-retardant polyurethanes.

Additive flame retardants remain the most widely used approach in the industry due to their cost-effectiveness and ease of incorporation. These include halogenated compounds, phosphorus-based additives, and inorganic fillers such as aluminum hydroxide and magnesium hydroxide. While effective, concerns over environmental and health impacts have led to increased scrutiny of halogenated flame retardants, driving research into more sustainable alternatives.

Reactive flame retardants represent a growing segment of the FR PU technology landscape. These compounds are chemically incorporated into the polyurethane structure during synthesis, offering improved durability and reduced environmental impact compared to additive approaches. Phosphorus-containing polyols and isocyanates are among the most promising reactive flame retardants, providing excellent fire resistance without significantly compromising the physical properties of the polyurethane.

Inherently flame-retardant polyurethanes are an emerging area of research, focusing on the development of novel polymer structures that exhibit intrinsic fire resistance. This approach often involves the incorporation of aromatic or heterocyclic structures into the polyurethane backbone, or the use of high-char-forming components that create a protective barrier during combustion.

Recent advancements in nanotechnology have also made significant contributions to the FR PU landscape. Nanocomposites incorporating materials such as clay, graphene, and carbon nanotubes have shown promising results in enhancing fire resistance while maintaining or even improving other material properties. These nanofillers can act synergistically with traditional flame retardants, allowing for reduced overall additive loadings and improved performance.

The regulatory environment plays a crucial role in shaping the current FR PU technology landscape. Stringent fire safety standards in various industries, coupled with increasing environmental regulations, are driving innovation towards more sustainable and effective flame retardant solutions. This has led to a growing focus on halogen-free technologies and bio-based flame retardants derived from renewable resources.

In conclusion, the current FR PU technology landscape is characterized by a shift towards more sustainable, efficient, and multifunctional flame retardant solutions. While traditional additive approaches remain prevalent, the industry is rapidly evolving towards reactive and inherent flame retardancy strategies, supported by advancements in nanotechnology and a growing emphasis on environmental compatibility.

Additive flame retardants remain the most widely used approach in the industry due to their cost-effectiveness and ease of incorporation. These include halogenated compounds, phosphorus-based additives, and inorganic fillers such as aluminum hydroxide and magnesium hydroxide. While effective, concerns over environmental and health impacts have led to increased scrutiny of halogenated flame retardants, driving research into more sustainable alternatives.

Reactive flame retardants represent a growing segment of the FR PU technology landscape. These compounds are chemically incorporated into the polyurethane structure during synthesis, offering improved durability and reduced environmental impact compared to additive approaches. Phosphorus-containing polyols and isocyanates are among the most promising reactive flame retardants, providing excellent fire resistance without significantly compromising the physical properties of the polyurethane.

Inherently flame-retardant polyurethanes are an emerging area of research, focusing on the development of novel polymer structures that exhibit intrinsic fire resistance. This approach often involves the incorporation of aromatic or heterocyclic structures into the polyurethane backbone, or the use of high-char-forming components that create a protective barrier during combustion.

Recent advancements in nanotechnology have also made significant contributions to the FR PU landscape. Nanocomposites incorporating materials such as clay, graphene, and carbon nanotubes have shown promising results in enhancing fire resistance while maintaining or even improving other material properties. These nanofillers can act synergistically with traditional flame retardants, allowing for reduced overall additive loadings and improved performance.

The regulatory environment plays a crucial role in shaping the current FR PU technology landscape. Stringent fire safety standards in various industries, coupled with increasing environmental regulations, are driving innovation towards more sustainable and effective flame retardant solutions. This has led to a growing focus on halogen-free technologies and bio-based flame retardants derived from renewable resources.

In conclusion, the current FR PU technology landscape is characterized by a shift towards more sustainable, efficient, and multifunctional flame retardant solutions. While traditional additive approaches remain prevalent, the industry is rapidly evolving towards reactive and inherent flame retardancy strategies, supported by advancements in nanotechnology and a growing emphasis on environmental compatibility.

Existing FR PU Solutions

01 Use of halogenated compounds

Halogenated compounds are commonly used as flame retardants in polyurethane products. These compounds work by releasing halogen radicals during combustion, which interfere with the flame propagation process. They can be incorporated into the polyurethane formulation during the manufacturing process to enhance fire retardancy.- Use of halogenated compounds: Halogenated compounds are commonly used as flame retardants in polyurethane products. These compounds, such as brominated or chlorinated additives, interfere with the combustion process by releasing halogen radicals that quench the flame. They can be incorporated into the polyurethane formulation during the manufacturing process to enhance fire retardancy.

- Phosphorus-based flame retardants: Phosphorus-containing compounds are effective flame retardants for polyurethane products. These additives work by promoting char formation and creating a protective barrier that limits oxygen access to the burning material. They can be reactive or additive and are often used in combination with other flame retardant systems for improved performance.

- Intumescent systems: Intumescent flame retardant systems are used in polyurethane products to create an expanded, carbonaceous char layer when exposed to heat. This char acts as an insulating barrier, protecting the underlying material from further combustion. These systems typically consist of a carbon source, an acid source, and a blowing agent that work synergistically to provide fire protection.

- Nanocomposite flame retardants: Incorporating nanoparticles, such as clay, graphene, or metal oxides, into polyurethane formulations can significantly improve fire retardancy. These nanocomposites enhance the formation of a protective char layer, reduce heat release rates, and improve the overall flame resistance of the material. They can be used in combination with traditional flame retardants for enhanced performance.

- Reactive flame retardants: Reactive flame retardants are chemically incorporated into the polyurethane polymer structure during synthesis. These compounds, such as phosphorus-containing polyols or isocyanates, become an integral part of the polymer backbone, providing inherent flame retardancy without negatively impacting other material properties. This approach can lead to more durable and environmentally friendly flame-retardant polyurethane products.

02 Phosphorus-based flame retardants

Phosphorus-containing compounds are effective flame retardants for polyurethane products. They act by promoting char formation and creating a protective barrier on the material surface. These additives can be either reactive or non-reactive and are often used in combination with other flame retardant systems for improved performance.Expand Specific Solutions03 Intumescent systems

Intumescent flame retardant systems are used in polyurethane products to create an expanded, carbonaceous char layer when exposed to heat. This char layer acts as an insulating barrier, protecting the underlying material from heat and oxygen. Intumescent systems typically consist of a carbon source, an acid source, and a blowing agent.Expand Specific Solutions04 Nanocomposite flame retardants

Nanocomposite flame retardants, such as nanoclays or carbon nanotubes, are incorporated into polyurethane matrices to improve fire retardancy. These nanoparticles can enhance char formation, reduce heat release rates, and improve the overall flame retardant properties of the polyurethane products.Expand Specific Solutions05 Synergistic flame retardant combinations

Combining different types of flame retardants can lead to synergistic effects, improving the overall fire retardancy of polyurethane products. These combinations may include halogenated compounds with phosphorus-based additives, or inorganic flame retardants with intumescent systems. The synergistic approach allows for lower overall flame retardant loadings while maintaining or improving performance.Expand Specific Solutions

Key Players in FR PU Industry

The development of fire-retardant polyurethane products is in a mature stage, with a growing market driven by stringent safety regulations and increasing awareness of fire safety. The global market size for fire-retardant materials is expanding, with polyurethane-based products playing a significant role. Technologically, the field is advancing rapidly, with major players like BASF Corp., Covestro Deutschland AG, and Albemarle Corp. leading innovation. These companies are focusing on developing more environmentally friendly and efficient fire-retardant solutions. Emerging players such as Shandong University of Technology and Nanjing Tech University are contributing to technological advancements through research collaborations. The competitive landscape is characterized by a mix of established chemical corporations and specialized material technology firms, with ongoing efforts to improve performance and sustainability of fire-retardant polyurethane products.

Albemarle Corp.

Technical Solution: Albemarle specializes in developing flame retardant additives for various polymers, including polyurethanes. Their SAYTEX line of flame retardants includes both halogenated and non-halogenated options for polyurethane applications. For example, their SAYTEX RZ-12 is a reactive flame retardant specifically designed for rigid polyurethane foams. It chemically incorporates into the polymer structure during the foaming process, providing excellent flame retardancy without significantly affecting the foam's physical properties. Albemarle also offers synergistic flame retardant systems that combine multiple additives to achieve optimal fire performance while minimizing overall additive loading.

Strengths: Wide range of flame retardant options, including both reactive and additive solutions, strong expertise in flame retardant chemistry. Weaknesses: Some products may contain halogenated compounds, which face increasing regulatory scrutiny, potential for additive migration in non-reactive systems.

BASF Corp.

Technical Solution: BASF has developed a range of fire-retardant polyurethane solutions, including their Elastocoat C spray coating system. This system incorporates halogen-free flame retardants and intumescent additives into the polyurethane matrix. When exposed to fire, the coating expands to form a protective char layer, insulating the underlying material and slowing fire spread. BASF also offers Elastopor H, a rigid polyurethane foam system with enhanced fire resistance properties, suitable for building insulation applications.

Strengths: Wide range of fire-retardant solutions for various applications, strong R&D capabilities, global presence. Weaknesses: Higher cost compared to non-fire-retardant alternatives, potential environmental concerns with some flame retardant additives.

Core FR PU Innovations

Flame-retardant polyurethane materials

PatentInactiveUS20170226273A1

Innovation

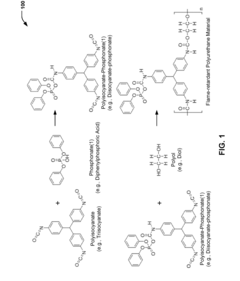

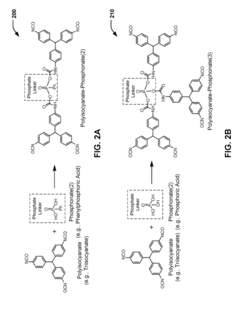

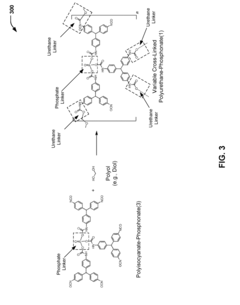

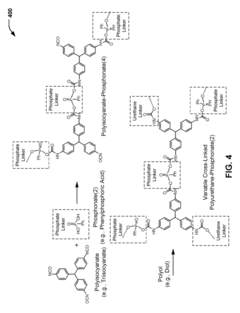

- A process involving the chemical reaction of a polyisocyanate with at least three isocyanate groups and a phosphonate with one or more hydroxyl groups to form a polyisocyanate-phosphonate compound, which is then mixed with a polyol and polymerized to create flame-retardant polyurethane materials, including cross-linked versions, without the use of halogen-containing additives.

Inherent flame retardant rigid polyurethane foam

PatentActiveUS20170073488A1

Innovation

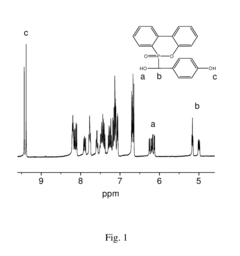

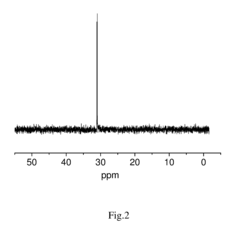

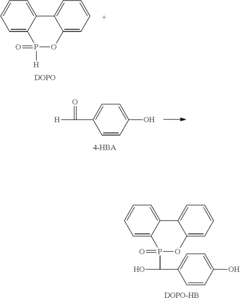

- Incorporating a reactive phosphorus-containing flame retardant, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-4-hydroxybenzyl alcohol (DOPO-HB), into the molecular chain of polyurethane foam, creating covalent bonds that integrate flame retardance without the need for excessive additive amounts, ensuring compatibility and maintaining material performance.

Environmental Impact of FR PU

The development of fire-retardant polyurethane (FR PU) products has significant environmental implications that must be carefully considered. These products, while essential for fire safety, can have both positive and negative impacts on the environment throughout their lifecycle.

One of the primary environmental benefits of FR PU products is their potential to reduce the severity and spread of fires. By limiting fire propagation, these materials can minimize the release of toxic fumes and particulate matter into the atmosphere during fire incidents. This reduction in air pollution can have positive effects on both human health and the environment, particularly in urban areas where fire risks are higher.

However, the production of FR PU materials often involves the use of chemical additives that may pose environmental concerns. Many traditional flame retardants, such as halogenated compounds, have been associated with persistent organic pollutants (POPs) that can accumulate in the environment and food chains. These substances may have long-term ecological impacts, affecting wildlife and ecosystems.

The disposal of FR PU products at the end of their lifecycle presents another environmental challenge. Some flame retardants can leach into soil and water systems when products are landfilled, potentially contaminating groundwater and aquatic ecosystems. Incineration of FR PU waste may release toxic gases if not properly managed, contributing to air pollution and greenhouse gas emissions.

Recent advancements in FR PU technology have focused on developing more environmentally friendly alternatives. Phosphorus-based and nitrogen-based flame retardants are being explored as less persistent options. Additionally, the integration of naturally derived fire-retardant substances, such as those from plant sources, is an emerging area of research aimed at reducing the environmental footprint of these materials.

The lifecycle assessment of FR PU products is crucial for understanding their overall environmental impact. This includes evaluating the energy consumption and emissions associated with raw material extraction, manufacturing processes, product use, and end-of-life disposal or recycling. Efforts to improve the recyclability and biodegradability of FR PU materials are ongoing, with the goal of creating more sustainable fire-retardant solutions.

Regulatory frameworks play a significant role in shaping the environmental impact of FR PU products. Stricter regulations on chemical use and disposal have led to innovations in flame retardant technologies and manufacturing processes. These regulations aim to balance fire safety requirements with environmental protection, driving the industry towards more sustainable practices.

One of the primary environmental benefits of FR PU products is their potential to reduce the severity and spread of fires. By limiting fire propagation, these materials can minimize the release of toxic fumes and particulate matter into the atmosphere during fire incidents. This reduction in air pollution can have positive effects on both human health and the environment, particularly in urban areas where fire risks are higher.

However, the production of FR PU materials often involves the use of chemical additives that may pose environmental concerns. Many traditional flame retardants, such as halogenated compounds, have been associated with persistent organic pollutants (POPs) that can accumulate in the environment and food chains. These substances may have long-term ecological impacts, affecting wildlife and ecosystems.

The disposal of FR PU products at the end of their lifecycle presents another environmental challenge. Some flame retardants can leach into soil and water systems when products are landfilled, potentially contaminating groundwater and aquatic ecosystems. Incineration of FR PU waste may release toxic gases if not properly managed, contributing to air pollution and greenhouse gas emissions.

Recent advancements in FR PU technology have focused on developing more environmentally friendly alternatives. Phosphorus-based and nitrogen-based flame retardants are being explored as less persistent options. Additionally, the integration of naturally derived fire-retardant substances, such as those from plant sources, is an emerging area of research aimed at reducing the environmental footprint of these materials.

The lifecycle assessment of FR PU products is crucial for understanding their overall environmental impact. This includes evaluating the energy consumption and emissions associated with raw material extraction, manufacturing processes, product use, and end-of-life disposal or recycling. Efforts to improve the recyclability and biodegradability of FR PU materials are ongoing, with the goal of creating more sustainable fire-retardant solutions.

Regulatory frameworks play a significant role in shaping the environmental impact of FR PU products. Stricter regulations on chemical use and disposal have led to innovations in flame retardant technologies and manufacturing processes. These regulations aim to balance fire safety requirements with environmental protection, driving the industry towards more sustainable practices.

FR PU Testing and Certification

The development of fire-retardant polyurethane products requires rigorous testing and certification to ensure compliance with safety standards and regulations. These processes are crucial for validating the effectiveness of fire-retardant properties and ensuring the products meet industry requirements.

Testing procedures for fire-retardant polyurethane products typically involve a series of standardized tests designed to evaluate their fire resistance, smoke production, and toxicity. One of the most common tests is the UL 94 flammability test, which assesses the material's ability to self-extinguish and resist ignition. This test categorizes materials into different flammability ratings, such as V-0, V-1, and V-2, with V-0 being the highest level of fire resistance.

Another critical test is the cone calorimeter test, which measures heat release rate, smoke production, and other fire-related properties. This test provides valuable data on how the material behaves when exposed to heat and flames, offering insights into its overall fire performance. Additionally, the limiting oxygen index (LOI) test determines the minimum concentration of oxygen required to support combustion, providing a quantitative measure of the material's flame retardancy.

For specific applications, such as building materials or automotive components, additional tests may be required. These can include the ASTM E84 surface burning characteristics test for building materials or the Federal Motor Vehicle Safety Standard (FMVSS) 302 for automotive interiors. These tests evaluate factors such as flame spread, smoke development, and burn rate under conditions relevant to their intended use.

Certification processes for fire-retardant polyurethane products involve third-party testing and verification to ensure compliance with relevant standards and regulations. Organizations such as Underwriters Laboratories (UL), FM Approvals, and Intertek provide certification services for fire-retardant materials. The certification process typically includes a comprehensive review of test results, manufacturing processes, and quality control measures.

To obtain certification, manufacturers must submit their products for testing at accredited laboratories. The test results are then evaluated against the specific requirements of the relevant standards or regulations. If the product meets or exceeds these requirements, it may be awarded certification. This certification often includes periodic follow-up inspections and testing to ensure ongoing compliance.

It's important to note that certification requirements can vary depending on the intended application and geographic region. For example, products intended for use in the European Union may need to comply with the Construction Products Regulation (CPR) and obtain CE marking, while those for the US market might require compliance with standards set by the National Fire Protection Association (NFPA) or the International Building Code (IBC).

Manufacturers of fire-retardant polyurethane products must stay informed about evolving standards and regulations to ensure their products remain compliant. This may involve ongoing research and development efforts to improve fire-retardant properties and meet increasingly stringent safety requirements.

Testing procedures for fire-retardant polyurethane products typically involve a series of standardized tests designed to evaluate their fire resistance, smoke production, and toxicity. One of the most common tests is the UL 94 flammability test, which assesses the material's ability to self-extinguish and resist ignition. This test categorizes materials into different flammability ratings, such as V-0, V-1, and V-2, with V-0 being the highest level of fire resistance.

Another critical test is the cone calorimeter test, which measures heat release rate, smoke production, and other fire-related properties. This test provides valuable data on how the material behaves when exposed to heat and flames, offering insights into its overall fire performance. Additionally, the limiting oxygen index (LOI) test determines the minimum concentration of oxygen required to support combustion, providing a quantitative measure of the material's flame retardancy.

For specific applications, such as building materials or automotive components, additional tests may be required. These can include the ASTM E84 surface burning characteristics test for building materials or the Federal Motor Vehicle Safety Standard (FMVSS) 302 for automotive interiors. These tests evaluate factors such as flame spread, smoke development, and burn rate under conditions relevant to their intended use.

Certification processes for fire-retardant polyurethane products involve third-party testing and verification to ensure compliance with relevant standards and regulations. Organizations such as Underwriters Laboratories (UL), FM Approvals, and Intertek provide certification services for fire-retardant materials. The certification process typically includes a comprehensive review of test results, manufacturing processes, and quality control measures.

To obtain certification, manufacturers must submit their products for testing at accredited laboratories. The test results are then evaluated against the specific requirements of the relevant standards or regulations. If the product meets or exceeds these requirements, it may be awarded certification. This certification often includes periodic follow-up inspections and testing to ensure ongoing compliance.

It's important to note that certification requirements can vary depending on the intended application and geographic region. For example, products intended for use in the European Union may need to comply with the Construction Products Regulation (CPR) and obtain CE marking, while those for the US market might require compliance with standards set by the National Fire Protection Association (NFPA) or the International Building Code (IBC).

Manufacturers of fire-retardant polyurethane products must stay informed about evolving standards and regulations to ensure their products remain compliant. This may involve ongoing research and development efforts to improve fire-retardant properties and meet increasingly stringent safety requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!