Breaking New Ground with Polyurethane Eco‑Friendly Formulations

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Eco-Formulations: Background and Objectives

Polyurethane (PU) has been a cornerstone in various industries for decades, prized for its versatility and durability. However, the growing global emphasis on sustainability has necessitated a paradigm shift in PU formulations. The quest for eco-friendly alternatives stems from increasing environmental concerns, stringent regulations, and a market demand for greener products.

Traditionally, PU production has relied heavily on petroleum-based raw materials and often involves the use of toxic isocyanates. These conventional methods have raised significant environmental and health concerns, prompting the industry to seek more sustainable solutions. The primary objective of developing eco-friendly PU formulations is to reduce the environmental footprint while maintaining or enhancing the material's performance characteristics.

Recent technological advancements have paved the way for innovative approaches in PU synthesis. Bio-based polyols derived from renewable resources such as vegetable oils, lignin, and cellulose have emerged as promising alternatives to their petrochemical counterparts. These bio-based materials not only reduce dependency on fossil fuels but also offer the potential for biodegradability and reduced carbon emissions throughout the product lifecycle.

Another critical aspect of eco-friendly PU formulations is the development of non-isocyanate polyurethanes (NIPUs). This groundbreaking approach aims to eliminate the use of toxic isocyanates, addressing both environmental and occupational health concerns. NIPUs are typically synthesized through the reaction of cyclic carbonates with amines, offering a safer and more sustainable production process.

The evolution of PU eco-formulations also encompasses the integration of recycled content and the design for recyclability. Researchers are exploring methods to incorporate post-consumer PU waste into new formulations, creating a circular economy model for PU products. Additionally, efforts are being made to develop PU materials that can be more easily disassembled or chemically recycled at the end of their life cycle.

Water-based PU systems represent another frontier in eco-friendly formulations. These systems significantly reduce volatile organic compound (VOC) emissions, making them particularly attractive for applications in coatings, adhesives, and sealants. The challenge lies in achieving performance properties comparable to solvent-based systems while maintaining the environmental benefits.

As the industry progresses, the objectives for PU eco-formulations extend beyond environmental considerations. There is a growing focus on enhancing functionality, such as improved thermal insulation, fire resistance, and durability, all while maintaining the eco-friendly profile. This multifaceted approach aims to create PU materials that are not only sustainable but also technologically advanced and economically viable.

Traditionally, PU production has relied heavily on petroleum-based raw materials and often involves the use of toxic isocyanates. These conventional methods have raised significant environmental and health concerns, prompting the industry to seek more sustainable solutions. The primary objective of developing eco-friendly PU formulations is to reduce the environmental footprint while maintaining or enhancing the material's performance characteristics.

Recent technological advancements have paved the way for innovative approaches in PU synthesis. Bio-based polyols derived from renewable resources such as vegetable oils, lignin, and cellulose have emerged as promising alternatives to their petrochemical counterparts. These bio-based materials not only reduce dependency on fossil fuels but also offer the potential for biodegradability and reduced carbon emissions throughout the product lifecycle.

Another critical aspect of eco-friendly PU formulations is the development of non-isocyanate polyurethanes (NIPUs). This groundbreaking approach aims to eliminate the use of toxic isocyanates, addressing both environmental and occupational health concerns. NIPUs are typically synthesized through the reaction of cyclic carbonates with amines, offering a safer and more sustainable production process.

The evolution of PU eco-formulations also encompasses the integration of recycled content and the design for recyclability. Researchers are exploring methods to incorporate post-consumer PU waste into new formulations, creating a circular economy model for PU products. Additionally, efforts are being made to develop PU materials that can be more easily disassembled or chemically recycled at the end of their life cycle.

Water-based PU systems represent another frontier in eco-friendly formulations. These systems significantly reduce volatile organic compound (VOC) emissions, making them particularly attractive for applications in coatings, adhesives, and sealants. The challenge lies in achieving performance properties comparable to solvent-based systems while maintaining the environmental benefits.

As the industry progresses, the objectives for PU eco-formulations extend beyond environmental considerations. There is a growing focus on enhancing functionality, such as improved thermal insulation, fire resistance, and durability, all while maintaining the eco-friendly profile. This multifaceted approach aims to create PU materials that are not only sustainable but also technologically advanced and economically viable.

Market Demand for Green Polyurethane Products

The market demand for green polyurethane products has been steadily increasing in recent years, driven by growing environmental awareness and stringent regulations. Consumers and industries alike are seeking sustainable alternatives to traditional polyurethane materials, which are known for their environmental impact and reliance on fossil-based raw materials.

In the construction sector, there is a significant demand for eco-friendly polyurethane insulation materials. These products offer improved energy efficiency in buildings while reducing the carbon footprint associated with their production and use. The automotive industry is another major driver of green polyurethane demand, with manufacturers looking to incorporate sustainable materials in vehicle interiors, seating, and components to meet consumer preferences and regulatory requirements.

The packaging industry is also embracing green polyurethane solutions, particularly for protective foams and cushioning materials. As e-commerce continues to grow, there is an increasing need for sustainable packaging options that can protect goods during shipping while minimizing environmental impact.

In the furniture and bedding sector, consumers are showing a preference for products made with eco-friendly polyurethane foams. This trend is particularly strong in developed markets where health-conscious consumers are willing to pay a premium for products that are free from harmful chemicals and have a lower environmental impact.

The textile industry is another area where green polyurethane products are gaining traction. Sustainable polyurethane coatings and finishes for fabrics are in high demand, especially in the sportswear and outdoor apparel segments.

Market research indicates that the global green polyurethane market is expected to grow significantly in the coming years. This growth is fueled by increasing adoption in various end-use industries and supportive government policies promoting sustainable materials.

However, challenges remain in meeting this growing demand. The higher cost of eco-friendly polyurethane formulations compared to traditional options is a significant barrier to widespread adoption. Additionally, there is a need for further research and development to improve the performance and durability of green polyurethane products to match or exceed that of conventional polyurethanes.

Despite these challenges, the market trajectory for green polyurethane products remains positive. As technology advances and economies of scale are achieved, the cost gap between eco-friendly and traditional polyurethanes is expected to narrow, further driving market growth and adoption across various industries.

In the construction sector, there is a significant demand for eco-friendly polyurethane insulation materials. These products offer improved energy efficiency in buildings while reducing the carbon footprint associated with their production and use. The automotive industry is another major driver of green polyurethane demand, with manufacturers looking to incorporate sustainable materials in vehicle interiors, seating, and components to meet consumer preferences and regulatory requirements.

The packaging industry is also embracing green polyurethane solutions, particularly for protective foams and cushioning materials. As e-commerce continues to grow, there is an increasing need for sustainable packaging options that can protect goods during shipping while minimizing environmental impact.

In the furniture and bedding sector, consumers are showing a preference for products made with eco-friendly polyurethane foams. This trend is particularly strong in developed markets where health-conscious consumers are willing to pay a premium for products that are free from harmful chemicals and have a lower environmental impact.

The textile industry is another area where green polyurethane products are gaining traction. Sustainable polyurethane coatings and finishes for fabrics are in high demand, especially in the sportswear and outdoor apparel segments.

Market research indicates that the global green polyurethane market is expected to grow significantly in the coming years. This growth is fueled by increasing adoption in various end-use industries and supportive government policies promoting sustainable materials.

However, challenges remain in meeting this growing demand. The higher cost of eco-friendly polyurethane formulations compared to traditional options is a significant barrier to widespread adoption. Additionally, there is a need for further research and development to improve the performance and durability of green polyurethane products to match or exceed that of conventional polyurethanes.

Despite these challenges, the market trajectory for green polyurethane products remains positive. As technology advances and economies of scale are achieved, the cost gap between eco-friendly and traditional polyurethanes is expected to narrow, further driving market growth and adoption across various industries.

Current Challenges in Eco-Friendly PU Development

The development of eco-friendly polyurethane (PU) formulations faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the high cost associated with sustainable raw materials. Bio-based polyols and isocyanates, which are essential components in eco-friendly PU production, often come with a premium price tag compared to their petrochemical counterparts. This cost differential makes it difficult for manufacturers to maintain competitive pricing while transitioning to greener alternatives.

Another major challenge lies in achieving comparable performance characteristics to traditional PU products. Eco-friendly formulations may struggle to match the durability, strength, and chemical resistance of conventional PU materials. This performance gap can be particularly pronounced in applications requiring high-performance specifications, such as automotive parts or industrial coatings.

The limited availability of sustainable raw materials poses a significant hurdle for large-scale production. The supply chain for bio-based components is not as well-established as that of petrochemical-derived materials, leading to potential shortages and inconsistencies in quality. This instability can deter manufacturers from fully committing to eco-friendly PU production.

Regulatory compliance and certification processes present additional challenges. While there is a growing push for sustainable materials, the regulatory landscape for eco-friendly PU formulations is still evolving. Manufacturers must navigate complex and sometimes conflicting standards across different regions, which can be time-consuming and costly.

Technical limitations in processing eco-friendly PU formulations also exist. Some bio-based components may require different processing conditions or equipment modifications, necessitating significant investments in new machinery or process adjustments. This can be a substantial barrier for companies looking to transition their existing production lines.

The issue of end-of-life management for eco-friendly PU products remains a challenge. While these formulations aim to reduce environmental impact during production and use, questions persist about their biodegradability and recyclability. Developing effective recycling methods for eco-friendly PU materials is crucial for achieving a truly circular economy.

Lastly, market acceptance and consumer education pose ongoing challenges. Despite growing environmental awareness, there is still a need to educate consumers about the benefits and potential trade-offs of eco-friendly PU products. Overcoming skepticism and building trust in the performance and longevity of these new formulations is essential for market success.

Another major challenge lies in achieving comparable performance characteristics to traditional PU products. Eco-friendly formulations may struggle to match the durability, strength, and chemical resistance of conventional PU materials. This performance gap can be particularly pronounced in applications requiring high-performance specifications, such as automotive parts or industrial coatings.

The limited availability of sustainable raw materials poses a significant hurdle for large-scale production. The supply chain for bio-based components is not as well-established as that of petrochemical-derived materials, leading to potential shortages and inconsistencies in quality. This instability can deter manufacturers from fully committing to eco-friendly PU production.

Regulatory compliance and certification processes present additional challenges. While there is a growing push for sustainable materials, the regulatory landscape for eco-friendly PU formulations is still evolving. Manufacturers must navigate complex and sometimes conflicting standards across different regions, which can be time-consuming and costly.

Technical limitations in processing eco-friendly PU formulations also exist. Some bio-based components may require different processing conditions or equipment modifications, necessitating significant investments in new machinery or process adjustments. This can be a substantial barrier for companies looking to transition their existing production lines.

The issue of end-of-life management for eco-friendly PU products remains a challenge. While these formulations aim to reduce environmental impact during production and use, questions persist about their biodegradability and recyclability. Developing effective recycling methods for eco-friendly PU materials is crucial for achieving a truly circular economy.

Lastly, market acceptance and consumer education pose ongoing challenges. Despite growing environmental awareness, there is still a need to educate consumers about the benefits and potential trade-offs of eco-friendly PU products. Overcoming skepticism and building trust in the performance and longevity of these new formulations is essential for market success.

Existing Eco-Friendly PU Formulation Approaches

01 Bio-based polyurethane formulations

Eco-friendly polyurethane formulations using bio-based materials such as vegetable oils, natural fibers, or recycled content. These formulations reduce reliance on petroleum-based ingredients and lower the environmental impact of polyurethane production.- Bio-based polyurethane formulations: Development of eco-friendly polyurethane using renewable resources and bio-based materials. These formulations aim to reduce the environmental impact by incorporating natural ingredients and reducing reliance on petroleum-based components.

- Recycling and upcycling of polyurethane waste: Methods for recycling and upcycling polyurethane waste to create new products or materials. This approach helps to reduce landfill waste and promotes a circular economy for polyurethane-based products.

- Low-VOC and non-toxic polyurethane systems: Development of polyurethane formulations with low volatile organic compound (VOC) emissions and reduced toxicity. These systems aim to improve indoor air quality and minimize health risks associated with polyurethane products.

- Energy-efficient polyurethane production processes: Innovative manufacturing techniques and processes that reduce energy consumption and greenhouse gas emissions in polyurethane production. These methods aim to improve the overall environmental footprint of polyurethane manufacturing.

- Biodegradable and compostable polyurethane: Research and development of biodegradable and compostable polyurethane materials. These innovations focus on creating polyurethane products that can naturally decompose in the environment, reducing long-term pollution and waste accumulation.

02 Recycling and upcycling of polyurethane waste

Methods for recycling and upcycling polyurethane waste, including mechanical recycling, chemical recycling, and energy recovery. These processes aim to reduce landfill waste and create a circular economy for polyurethane materials.Expand Specific Solutions03 Low-VOC and non-isocyanate polyurethane systems

Development of polyurethane systems with low volatile organic compound (VOC) emissions and non-isocyanate alternatives. These formulations reduce harmful emissions during production and application, improving indoor air quality and worker safety.Expand Specific Solutions04 Energy-efficient polyurethane production processes

Innovative production processes that reduce energy consumption and greenhouse gas emissions in polyurethane manufacturing. These may include improved catalysts, optimized reaction conditions, or alternative processing methods.Expand Specific Solutions05 Biodegradable and compostable polyurethane materials

Development of biodegradable and compostable polyurethane materials that can break down naturally in the environment. These materials aim to reduce long-term environmental impact and plastic pollution while maintaining desired performance properties.Expand Specific Solutions

Key Players in Green Polyurethane Industry

The eco-friendly polyurethane formulations market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding rapidly, with major players like Covestro, BASF, and Dow actively developing sustainable solutions. The technology is maturing, with companies such as Evonik, DuPont, and Sika AG making significant advancements in bio-based and recyclable polyurethanes. Academic institutions like MIT and the University of California are contributing to research, while specialized firms like Algenesis Corp. are pushing boundaries in biodegradable formulations. The competitive landscape is diverse, with both established chemical giants and innovative startups vying for market share in this evolving sector.

Covestro Deutschland AG

Technical Solution: Covestro has developed a range of eco-friendly polyurethane formulations using bio-based raw materials and CO2 technology. Their cardyon® product line incorporates up to 20% CO2 as a raw material, reducing the carbon footprint of polyurethane production. They have also introduced partially bio-based polyols for rigid foam applications, utilizing plant-based raw materials to replace petroleum-based components. Additionally, Covestro has developed water-based polyurethane dispersions for coatings and adhesives, reducing VOC emissions and improving workplace safety.

Strengths: Innovative use of CO2 as a raw material, reducing carbon footprint. Incorporation of bio-based materials. Development of water-based systems for reduced environmental impact. Weaknesses: Limited percentage of CO2 incorporation. Potential higher costs compared to traditional formulations.

Dow Global Technologies LLC

Technical Solution: Dow has introduced RENUVA™ Mattress Recycling Program, an innovative circular economy initiative for polyurethane foam from end-of-life mattresses. The process involves chemically recycling post-consumer polyurethane foam back to its basic polyol components, which can then be used to create new polyurethane products. This technology significantly reduces waste and the need for virgin raw materials. Dow has also developed VORASURF™ polyurethane additives that enable the production of low-emission flexible foams, addressing indoor air quality concerns.

Strengths: Circular economy approach, reducing waste and virgin material use. Addresses indoor air quality issues. Weaknesses: Limited to specific applications (mattresses). Potential challenges in scaling up the recycling process.

Innovative Bio-Based PU Raw Materials and Processes

Polyurethane compositions

PatentWO2024236175A1

Innovation

- The development of polyurethane formulations incorporating polyacetals with cyclic acetal functional groups, combined with isocyanates and optionally polyols, which provide improved biodegradability and recyclability without sacrificing mechanical properties, allowing for the creation of compostable and chemically recyclable polyurethane polymers and articles.

Acid-resistant polyurethane and method for producing same

PatentWO2024204388A1

Innovation

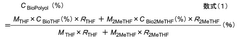

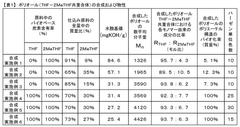

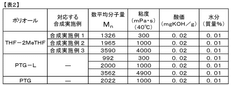

- Development of acid-resistant polyurethane using polytetramethylene ether glycol, which is produced through copolymerization of tetrahydrofuran and 2-methyltetrahydrofuran, utilizing biomass-derived raw materials to achieve high biobased carbon content and improved acid resistance, maintaining breaking strength and elongation after acid treatment.

Environmental Regulations Impacting PU Industry

The polyurethane (PU) industry is facing increasing pressure from environmental regulations worldwide, driving a shift towards more eco-friendly formulations. These regulations aim to reduce the environmental impact of PU production and use, focusing on areas such as volatile organic compound (VOC) emissions, hazardous substances, and end-of-life disposal.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has significantly impacted the PU industry. It requires manufacturers to register chemicals used in PU production and provide safety data, leading to the phase-out of certain hazardous substances. The EU's VOC Solvents Emissions Directive has also pushed for reduced emissions in PU manufacturing processes.

The United States Environmental Protection Agency (EPA) has implemented regulations under the Clean Air Act to limit VOC emissions from PU foam production. Additionally, the EPA's Significant New Alternatives Policy (SNAP) program has restricted the use of certain blowing agents in PU foam manufacturing due to their high global warming potential.

In China, the government has introduced stricter environmental protection laws, including the Air Pollution Prevention and Control Law, which affects PU manufacturers. These regulations have led to increased scrutiny of emissions and waste management practices in the PU industry.

The Montreal Protocol and its amendments have had a global impact on the PU industry by phasing out ozone-depleting substances, including certain blowing agents used in PU foam production. This has driven innovation in alternative blowing agents with lower environmental impact.

Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. This has led to increased focus on recyclability and biodegradability in PU formulations.

Energy efficiency regulations, such as building codes and appliance standards, have indirectly affected the PU industry by driving demand for high-performance insulation materials. This has spurred innovation in PU foam formulations to meet these energy efficiency requirements while maintaining environmental compliance.

As a result of these regulations, the PU industry is investing heavily in research and development of eco-friendly formulations. This includes exploring bio-based polyols, developing water-based systems to reduce VOC emissions, and improving recycling technologies for PU products. The industry is also focusing on life cycle assessments to demonstrate the overall environmental impact of PU products and guide future improvements.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has significantly impacted the PU industry. It requires manufacturers to register chemicals used in PU production and provide safety data, leading to the phase-out of certain hazardous substances. The EU's VOC Solvents Emissions Directive has also pushed for reduced emissions in PU manufacturing processes.

The United States Environmental Protection Agency (EPA) has implemented regulations under the Clean Air Act to limit VOC emissions from PU foam production. Additionally, the EPA's Significant New Alternatives Policy (SNAP) program has restricted the use of certain blowing agents in PU foam manufacturing due to their high global warming potential.

In China, the government has introduced stricter environmental protection laws, including the Air Pollution Prevention and Control Law, which affects PU manufacturers. These regulations have led to increased scrutiny of emissions and waste management practices in the PU industry.

The Montreal Protocol and its amendments have had a global impact on the PU industry by phasing out ozone-depleting substances, including certain blowing agents used in PU foam production. This has driven innovation in alternative blowing agents with lower environmental impact.

Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. This has led to increased focus on recyclability and biodegradability in PU formulations.

Energy efficiency regulations, such as building codes and appliance standards, have indirectly affected the PU industry by driving demand for high-performance insulation materials. This has spurred innovation in PU foam formulations to meet these energy efficiency requirements while maintaining environmental compliance.

As a result of these regulations, the PU industry is investing heavily in research and development of eco-friendly formulations. This includes exploring bio-based polyols, developing water-based systems to reduce VOC emissions, and improving recycling technologies for PU products. The industry is also focusing on life cycle assessments to demonstrate the overall environmental impact of PU products and guide future improvements.

Life Cycle Assessment of Eco-Friendly PU Products

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of eco-friendly polyurethane (PU) products throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, providing valuable insights into the sustainability of these innovative formulations.

The assessment typically begins with the sourcing and production of raw materials. For eco-friendly PU products, this often involves the use of bio-based polyols derived from renewable resources such as vegetable oils or recycled materials. The environmental impact of cultivating and processing these alternative feedstocks is compared to traditional petroleum-based inputs, considering factors like land use, water consumption, and greenhouse gas emissions.

Manufacturing processes are then scrutinized, focusing on energy consumption, waste generation, and emissions. Eco-friendly PU formulations often employ more efficient production methods, such as room temperature curing or reduced isocyanate content, which can significantly lower energy requirements and minimize harmful emissions.

The use phase of eco-friendly PU products is evaluated for durability, performance, and potential environmental benefits. This may include improved insulation properties in construction applications, leading to reduced energy consumption in buildings, or enhanced longevity in automotive parts, resulting in fewer replacements and less waste generation over time.

End-of-life considerations are particularly important for eco-friendly PU products. The assessment examines various disposal options, including recycling, biodegradation, and energy recovery. Many eco-friendly formulations are designed for easier recycling or biodegradability, potentially reducing the environmental burden associated with traditional PU waste.

LCA also considers the transportation and distribution of raw materials and finished products, evaluating the carbon footprint associated with logistics. This aspect can be particularly relevant when comparing locally sourced bio-based materials to imported petroleum-based alternatives.

The results of a comprehensive LCA provide valuable data for comparing eco-friendly PU products with conventional alternatives. Key metrics often include global warming potential, resource depletion, water footprint, and toxicity indicators. These assessments help manufacturers identify hotspots in the product lifecycle where environmental improvements can be made and guide future research and development efforts.

Moreover, LCA findings support marketing claims and can be used to obtain environmental certifications, enhancing the market position of eco-friendly PU products. They also provide consumers and policymakers with transparent information to make informed decisions about product selection and regulatory frameworks.

The assessment typically begins with the sourcing and production of raw materials. For eco-friendly PU products, this often involves the use of bio-based polyols derived from renewable resources such as vegetable oils or recycled materials. The environmental impact of cultivating and processing these alternative feedstocks is compared to traditional petroleum-based inputs, considering factors like land use, water consumption, and greenhouse gas emissions.

Manufacturing processes are then scrutinized, focusing on energy consumption, waste generation, and emissions. Eco-friendly PU formulations often employ more efficient production methods, such as room temperature curing or reduced isocyanate content, which can significantly lower energy requirements and minimize harmful emissions.

The use phase of eco-friendly PU products is evaluated for durability, performance, and potential environmental benefits. This may include improved insulation properties in construction applications, leading to reduced energy consumption in buildings, or enhanced longevity in automotive parts, resulting in fewer replacements and less waste generation over time.

End-of-life considerations are particularly important for eco-friendly PU products. The assessment examines various disposal options, including recycling, biodegradation, and energy recovery. Many eco-friendly formulations are designed for easier recycling or biodegradability, potentially reducing the environmental burden associated with traditional PU waste.

LCA also considers the transportation and distribution of raw materials and finished products, evaluating the carbon footprint associated with logistics. This aspect can be particularly relevant when comparing locally sourced bio-based materials to imported petroleum-based alternatives.

The results of a comprehensive LCA provide valuable data for comparing eco-friendly PU products with conventional alternatives. Key metrics often include global warming potential, resource depletion, water footprint, and toxicity indicators. These assessments help manufacturers identify hotspots in the product lifecycle where environmental improvements can be made and guide future research and development efforts.

Moreover, LCA findings support marketing claims and can be used to obtain environmental certifications, enhancing the market position of eco-friendly PU products. They also provide consumers and policymakers with transparent information to make informed decisions about product selection and regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!