What Catalyzed the Rise of Green PU Polyol Innovations?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green PU Polyol Evolution and Objectives

The evolution of green polyurethane (PU) polyols represents a significant shift in the chemical industry towards more sustainable and environmentally friendly practices. This transition has been driven by a combination of environmental concerns, regulatory pressures, and market demands for eco-friendly materials. The development of green PU polyols can be traced back to the early 2000s when awareness of the environmental impact of traditional petroleum-based polyols began to grow.

Initially, the focus was on reducing the carbon footprint of polyol production by incorporating renewable resources. This led to the exploration of bio-based raw materials such as vegetable oils, particularly soybean oil, rapeseed oil, and castor oil. These natural oils provided a sustainable alternative to petrochemical-based polyols, offering comparable performance characteristics while significantly reducing environmental impact.

As research progressed, the objectives of green PU polyol innovations expanded beyond simply replacing petroleum-based raw materials. Scientists and engineers began to explore ways to enhance the overall sustainability of the production process, aiming to reduce energy consumption, minimize waste generation, and improve the recyclability of end products. This holistic approach to sustainability became a key driver in the evolution of green PU polyol technologies.

Another important milestone in the development of green PU polyols was the introduction of CO2-based polyols. This innovative approach utilized carbon dioxide as a raw material, effectively turning a greenhouse gas into a valuable chemical feedstock. The technology not only provided a more sustainable alternative to traditional polyols but also contributed to carbon capture and utilization efforts.

The objectives of green PU polyol innovations have continued to evolve, focusing on improving the performance and versatility of these sustainable materials. Researchers have worked to enhance the mechanical properties, thermal stability, and chemical resistance of green polyols to match or exceed those of their petroleum-based counterparts. This has been crucial in expanding the application range of green PU polyols across various industries, including automotive, construction, and consumer goods.

In recent years, the development of green PU polyols has also been driven by the circular economy concept. This has led to increased efforts in designing polyols that facilitate easier recycling and biodegradation of polyurethane products at the end of their life cycle. The goal is to create closed-loop systems where materials can be recovered and reused, further reducing the environmental impact of polyurethane production and consumption.

Initially, the focus was on reducing the carbon footprint of polyol production by incorporating renewable resources. This led to the exploration of bio-based raw materials such as vegetable oils, particularly soybean oil, rapeseed oil, and castor oil. These natural oils provided a sustainable alternative to petrochemical-based polyols, offering comparable performance characteristics while significantly reducing environmental impact.

As research progressed, the objectives of green PU polyol innovations expanded beyond simply replacing petroleum-based raw materials. Scientists and engineers began to explore ways to enhance the overall sustainability of the production process, aiming to reduce energy consumption, minimize waste generation, and improve the recyclability of end products. This holistic approach to sustainability became a key driver in the evolution of green PU polyol technologies.

Another important milestone in the development of green PU polyols was the introduction of CO2-based polyols. This innovative approach utilized carbon dioxide as a raw material, effectively turning a greenhouse gas into a valuable chemical feedstock. The technology not only provided a more sustainable alternative to traditional polyols but also contributed to carbon capture and utilization efforts.

The objectives of green PU polyol innovations have continued to evolve, focusing on improving the performance and versatility of these sustainable materials. Researchers have worked to enhance the mechanical properties, thermal stability, and chemical resistance of green polyols to match or exceed those of their petroleum-based counterparts. This has been crucial in expanding the application range of green PU polyols across various industries, including automotive, construction, and consumer goods.

In recent years, the development of green PU polyols has also been driven by the circular economy concept. This has led to increased efforts in designing polyols that facilitate easier recycling and biodegradation of polyurethane products at the end of their life cycle. The goal is to create closed-loop systems where materials can be recovered and reused, further reducing the environmental impact of polyurethane production and consumption.

Market Demand for Sustainable Polyurethanes

The demand for sustainable polyurethanes has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on chemical production and waste management. This shift in market preferences has catalyzed the rise of green PU polyol innovations, as manufacturers seek to meet the evolving needs of environmentally conscious consumers and comply with emerging sustainability standards.

One of the primary factors fueling this demand is the push for reduced carbon footprints across various industries. Polyurethanes are widely used in automotive, construction, furniture, and packaging sectors, all of which are under pressure to adopt more eco-friendly materials. Green PU polyols, derived from renewable sources such as vegetable oils, offer a promising alternative to traditional petroleum-based polyols, significantly lowering the environmental impact of polyurethane products.

The construction industry, in particular, has shown a strong interest in sustainable polyurethanes for insulation materials. As energy efficiency becomes a critical factor in building design, the demand for high-performance, environmentally friendly insulation solutions has surged. Green PU polyols can provide excellent thermal insulation properties while reducing the overall carbon footprint of buildings, making them increasingly attractive to architects and developers.

In the automotive sector, the shift towards electric vehicles and lightweight materials has further boosted the demand for sustainable polyurethanes. Manufacturers are seeking innovative solutions to reduce vehicle weight and improve fuel efficiency, while also meeting stringent environmental regulations. Green PU polyols offer the potential to create lighter, more sustainable components without compromising on performance or durability.

Consumer awareness and preferences have also played a significant role in driving the market for sustainable polyurethanes. As end-users become more environmentally conscious, there is a growing demand for products made from renewable and biodegradable materials. This trend has extended to furniture, bedding, and packaging industries, where green PU polyols are being incorporated into a wide range of consumer goods.

The circular economy concept has further accelerated the adoption of sustainable polyurethanes. Manufacturers are increasingly focusing on developing polyols that can be easily recycled or biodegraded at the end of their lifecycle. This approach not only addresses environmental concerns but also aligns with regulatory initiatives aimed at reducing waste and promoting resource efficiency.

As the market demand for sustainable polyurethanes continues to grow, it has spurred significant investment in research and development of green PU polyol technologies. Companies are exploring novel bio-based feedstocks, improving production processes, and enhancing the performance characteristics of sustainable polyurethanes to meet diverse application requirements across industries.

One of the primary factors fueling this demand is the push for reduced carbon footprints across various industries. Polyurethanes are widely used in automotive, construction, furniture, and packaging sectors, all of which are under pressure to adopt more eco-friendly materials. Green PU polyols, derived from renewable sources such as vegetable oils, offer a promising alternative to traditional petroleum-based polyols, significantly lowering the environmental impact of polyurethane products.

The construction industry, in particular, has shown a strong interest in sustainable polyurethanes for insulation materials. As energy efficiency becomes a critical factor in building design, the demand for high-performance, environmentally friendly insulation solutions has surged. Green PU polyols can provide excellent thermal insulation properties while reducing the overall carbon footprint of buildings, making them increasingly attractive to architects and developers.

In the automotive sector, the shift towards electric vehicles and lightweight materials has further boosted the demand for sustainable polyurethanes. Manufacturers are seeking innovative solutions to reduce vehicle weight and improve fuel efficiency, while also meeting stringent environmental regulations. Green PU polyols offer the potential to create lighter, more sustainable components without compromising on performance or durability.

Consumer awareness and preferences have also played a significant role in driving the market for sustainable polyurethanes. As end-users become more environmentally conscious, there is a growing demand for products made from renewable and biodegradable materials. This trend has extended to furniture, bedding, and packaging industries, where green PU polyols are being incorporated into a wide range of consumer goods.

The circular economy concept has further accelerated the adoption of sustainable polyurethanes. Manufacturers are increasingly focusing on developing polyols that can be easily recycled or biodegraded at the end of their lifecycle. This approach not only addresses environmental concerns but also aligns with regulatory initiatives aimed at reducing waste and promoting resource efficiency.

As the market demand for sustainable polyurethanes continues to grow, it has spurred significant investment in research and development of green PU polyol technologies. Companies are exploring novel bio-based feedstocks, improving production processes, and enhancing the performance characteristics of sustainable polyurethanes to meet diverse application requirements across industries.

Green PU Polyol Technology Landscape

The green polyurethane (PU) polyol technology landscape has undergone significant transformations in recent years, driven by increasing environmental concerns and regulatory pressures. This shift towards more sustainable and eco-friendly alternatives has catalyzed innovations in the PU polyol industry, leading to the development of various green technologies and processes.

One of the primary drivers of green PU polyol innovations has been the growing demand for bio-based and renewable raw materials. Traditional polyols derived from petroleum-based sources are gradually being replaced by those produced from renewable feedstocks such as vegetable oils, lignin, and recycled materials. This transition has led to the emergence of novel production methods and formulations that reduce the carbon footprint of PU products.

Another key factor in the green PU polyol technology landscape is the focus on improving energy efficiency and reducing emissions during the production process. Manufacturers are investing in advanced reactor designs, catalysts, and process optimizations to minimize energy consumption and waste generation. These efforts have resulted in cleaner production methods that align with sustainability goals and regulatory requirements.

The development of water-blown foams and CO2-based polyols represents a significant advancement in green PU technology. These innovations address the environmental concerns associated with traditional blowing agents, offering more sustainable alternatives that reduce the overall environmental impact of PU products. The use of CO2 as a raw material for polyol production not only helps in carbon capture but also provides a pathway for utilizing greenhouse gases in value-added products.

Recycling and circular economy principles have also played a crucial role in shaping the green PU polyol landscape. Technologies for chemical recycling of PU waste to recover polyols and other valuable components have gained traction, offering a sustainable solution to the end-of-life challenges associated with PU products. This approach not only reduces waste but also creates a closed-loop system for PU materials.

The integration of nanotechnology and advanced materials science has further expanded the possibilities for green PU polyols. Nanocomposites and hybrid materials have been developed to enhance the performance and sustainability of PU products, enabling the creation of lighter, stronger, and more durable materials with reduced environmental impact.

Collaborative efforts between industry players, research institutions, and government agencies have accelerated the pace of innovation in green PU polyol technologies. Open innovation platforms, joint research initiatives, and public-private partnerships have fostered knowledge sharing and resource pooling, leading to faster development and commercialization of sustainable PU solutions.

One of the primary drivers of green PU polyol innovations has been the growing demand for bio-based and renewable raw materials. Traditional polyols derived from petroleum-based sources are gradually being replaced by those produced from renewable feedstocks such as vegetable oils, lignin, and recycled materials. This transition has led to the emergence of novel production methods and formulations that reduce the carbon footprint of PU products.

Another key factor in the green PU polyol technology landscape is the focus on improving energy efficiency and reducing emissions during the production process. Manufacturers are investing in advanced reactor designs, catalysts, and process optimizations to minimize energy consumption and waste generation. These efforts have resulted in cleaner production methods that align with sustainability goals and regulatory requirements.

The development of water-blown foams and CO2-based polyols represents a significant advancement in green PU technology. These innovations address the environmental concerns associated with traditional blowing agents, offering more sustainable alternatives that reduce the overall environmental impact of PU products. The use of CO2 as a raw material for polyol production not only helps in carbon capture but also provides a pathway for utilizing greenhouse gases in value-added products.

Recycling and circular economy principles have also played a crucial role in shaping the green PU polyol landscape. Technologies for chemical recycling of PU waste to recover polyols and other valuable components have gained traction, offering a sustainable solution to the end-of-life challenges associated with PU products. This approach not only reduces waste but also creates a closed-loop system for PU materials.

The integration of nanotechnology and advanced materials science has further expanded the possibilities for green PU polyols. Nanocomposites and hybrid materials have been developed to enhance the performance and sustainability of PU products, enabling the creation of lighter, stronger, and more durable materials with reduced environmental impact.

Collaborative efforts between industry players, research institutions, and government agencies have accelerated the pace of innovation in green PU polyol technologies. Open innovation platforms, joint research initiatives, and public-private partnerships have fostered knowledge sharing and resource pooling, leading to faster development and commercialization of sustainable PU solutions.

Current Green PU Polyol Solutions

01 Bio-based polyols for green PU production

Utilizing bio-based materials such as vegetable oils, lignin, or other renewable resources to synthesize polyols for polyurethane production. This approach reduces reliance on petroleum-based raw materials and decreases the carbon footprint of PU products.- Bio-based polyols for green PU production: Utilizing renewable resources to produce bio-based polyols for green polyurethane synthesis. These polyols are derived from natural oils, such as vegetable oils or waste biomass, reducing the environmental impact of PU production. The use of bio-based polyols contributes to the development of more sustainable and eco-friendly polyurethane materials.

- Recycled PET-based polyols: Developing polyols from recycled polyethylene terephthalate (PET) for use in green polyurethane formulations. This approach addresses plastic waste issues while creating value-added products. The recycled PET-based polyols can be used to produce various PU products with improved sustainability profiles.

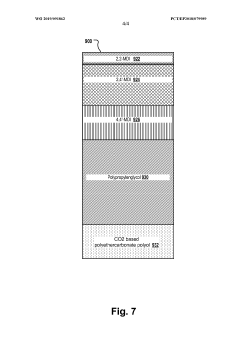

- CO2-based polyols for PU synthesis: Incorporating carbon dioxide as a raw material in polyol production for green polyurethanes. This method helps reduce greenhouse gas emissions by utilizing CO2 as a feedstock. The resulting CO2-based polyols can be used to create more environmentally friendly PU products with a lower carbon footprint.

- Optimized catalysts for green polyol production: Developing and utilizing advanced catalysts to improve the efficiency and selectivity of green polyol synthesis. These catalysts enhance the conversion of renewable feedstocks or recycled materials into high-quality polyols suitable for PU applications. The optimized catalytic processes contribute to more sustainable and economically viable green polyol production.

- Functionalized green polyols for enhanced PU properties: Modifying bio-based or recycled polyols to improve their reactivity and compatibility with isocyanates in PU formulations. This approach involves introducing specific functional groups or adjusting the molecular structure of green polyols to enhance the mechanical, thermal, or chemical properties of the resulting polyurethanes. The functionalized green polyols enable the production of high-performance, sustainable PU materials.

02 Recycled PET-based polyols

Developing methods to convert recycled polyethylene terephthalate (PET) into polyols suitable for PU production. This process helps address plastic waste issues while creating a more sustainable source of polyols for the PU industry.Expand Specific Solutions03 CO2-based polyols

Incorporating carbon dioxide as a raw material in polyol synthesis, effectively reducing greenhouse gas emissions and creating a more environmentally friendly polyol production process. This method often involves the use of catalysts to facilitate CO2 incorporation into the polyol structure.Expand Specific Solutions04 Natural oil-based polyols with improved properties

Enhancing the properties of natural oil-based polyols through chemical modifications or blending techniques to improve their reactivity, compatibility, and performance in PU applications. This approach aims to make bio-based polyols more competitive with traditional petroleum-based alternatives.Expand Specific Solutions05 Green polyol production processes

Developing environmentally friendly production processes for polyols, including the use of non-toxic catalysts, solvent-free reactions, and energy-efficient methods. These processes aim to reduce the environmental impact of polyol manufacturing while maintaining or improving product quality.Expand Specific Solutions

Key Players in Green PU Polyol Industry

The rise of green PU polyol innovations has been catalyzed by increasing environmental concerns and regulatory pressures, driving the industry towards more sustainable solutions. This market is in a growth phase, with expanding applications across various sectors. The global green polyols market size is projected to reach significant figures, indicating substantial potential. Technological maturity varies, with companies like BASF Corp., Covestro Deutschland AG, and Dow Global Technologies LLC leading in advanced bio-based polyol development. Emerging players such as Hongbaoli Group Corp. Ltd. and Wanhua Chemical Group Co., Ltd. are also making strides in eco-friendly polyol technologies. Universities and research institutions, including Sichuan University and Nanjing Tech University, are contributing to fundamental research, pushing the boundaries of green polyol innovation.

BASF Corp.

Technical Solution: BASF has developed a range of bio-based polyols under their Ecovio® brand. These polyols are derived from renewable resources such as vegetable oils and are used in the production of green polyurethanes. BASF's technology focuses on optimizing the molecular structure of these bio-based polyols to achieve properties comparable to petroleum-based alternatives. They employ a proprietary catalytic process to convert plant-based oils into polyols with controlled functionality and molecular weight, ensuring consistent performance in various PU applications.

Strengths: Extensive R&D capabilities, global market presence, and established supply chains. Weaknesses: Higher production costs compared to traditional polyols, potential limitations in certain high-performance applications.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered the development of CO2-based polyols, marketed under the cardyon® brand. This innovative technology captures and utilizes CO2 as a raw material in polyol production, reducing the reliance on fossil-based resources. The process involves a proprietary catalyst system that enables the efficient incorporation of CO2 into the polyol structure. These CO2-based polyols can replace up to 20% of the petroleum-based raw materials traditionally used in polyurethane production, significantly reducing the carbon footprint of the final products.

Strengths: Unique CO2 utilization technology, reduced carbon footprint, and potential for circular economy integration. Weaknesses: Limited CO2 incorporation percentage, potential scalability challenges.

Breakthrough Green PU Polyol Technologies

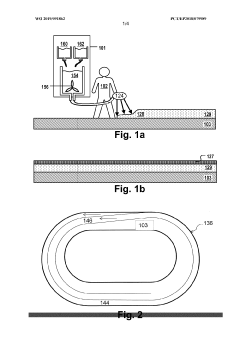

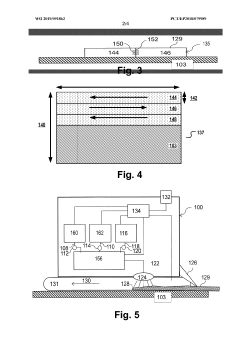

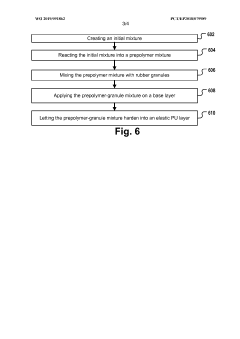

PU-prepolymer mixture derived from a co 2-based polyol

PatentWO2019091862A1

Innovation

- A method using a mixture of methylene diphenyl diisocyanate (MDI) monomers with a high concentration of 2,2' MDI and a CO2-based polyethercarbonate polyol, combined with plant-based oils and other additives, to create a prepolymer mixture with optimal viscosity and reaction speed for in-situ generation of elastic PU-based floorings, reducing carbon footprint and enhancing sustainability.

Production of PU foams using recycled polyols

PatentWO2023275029A1

Innovation

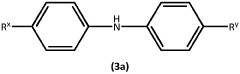

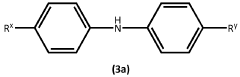

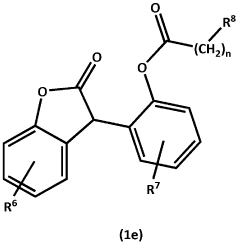

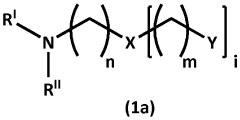

- A process involving the use of recycled polyols stabilized with specific antioxidants, such as those of formulas 1d and 3a, in combination with isocyanate components, catalysts, and foam stabilizers, ensuring adequate thermal-oxidative stabilization to prevent discoloration and ensure safety during foam production.

Environmental Regulations Driving Green PU Polyols

Environmental regulations have played a pivotal role in catalyzing the rise of green PU polyol innovations. The increasing global focus on sustainability and environmental protection has led to stringent regulations aimed at reducing the environmental impact of various industries, including the polyurethane sector.

One of the primary drivers has been the implementation of volatile organic compound (VOC) emission regulations. These regulations have forced manufacturers to seek alternatives to traditional petroleum-based polyols, which often release harmful VOCs during production and use. Green PU polyols, derived from renewable resources such as vegetable oils or recycled materials, offer a solution to this challenge by significantly reducing VOC emissions.

Carbon footprint reduction targets set by governments worldwide have also spurred innovation in green PU polyols. As countries strive to meet their commitments under international agreements like the Paris Accord, industries are under pressure to adopt more sustainable practices. Green PU polyols, with their lower carbon footprint compared to conventional polyols, have become an attractive option for manufacturers looking to reduce their environmental impact.

Waste management regulations have further accelerated the development of green PU polyols. Stricter rules on waste disposal and landfill use have encouraged the exploration of recycling technologies. This has led to innovations in the production of polyols from recycled PET bottles and other plastic waste, creating a circular economy approach within the polyurethane industry.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential. By requiring manufacturers to assess and manage the risks posed by chemicals they produce or import, REACH has incentivized the development of safer, more environmentally friendly alternatives, including green PU polyols.

Energy efficiency standards in construction and automotive industries have indirectly boosted green PU polyol innovations. As these sectors seek materials that can help meet energy performance requirements, green PU polyols have emerged as a viable solution due to their excellent insulation properties and potential for lightweight applications.

The introduction of eco-labeling and green certification programs has also contributed to the rise of green PU polyols. These initiatives have created market incentives for manufacturers to adopt more sustainable materials, as consumers and businesses increasingly prioritize environmentally friendly products.

One of the primary drivers has been the implementation of volatile organic compound (VOC) emission regulations. These regulations have forced manufacturers to seek alternatives to traditional petroleum-based polyols, which often release harmful VOCs during production and use. Green PU polyols, derived from renewable resources such as vegetable oils or recycled materials, offer a solution to this challenge by significantly reducing VOC emissions.

Carbon footprint reduction targets set by governments worldwide have also spurred innovation in green PU polyols. As countries strive to meet their commitments under international agreements like the Paris Accord, industries are under pressure to adopt more sustainable practices. Green PU polyols, with their lower carbon footprint compared to conventional polyols, have become an attractive option for manufacturers looking to reduce their environmental impact.

Waste management regulations have further accelerated the development of green PU polyols. Stricter rules on waste disposal and landfill use have encouraged the exploration of recycling technologies. This has led to innovations in the production of polyols from recycled PET bottles and other plastic waste, creating a circular economy approach within the polyurethane industry.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has been particularly influential. By requiring manufacturers to assess and manage the risks posed by chemicals they produce or import, REACH has incentivized the development of safer, more environmentally friendly alternatives, including green PU polyols.

Energy efficiency standards in construction and automotive industries have indirectly boosted green PU polyol innovations. As these sectors seek materials that can help meet energy performance requirements, green PU polyols have emerged as a viable solution due to their excellent insulation properties and potential for lightweight applications.

The introduction of eco-labeling and green certification programs has also contributed to the rise of green PU polyols. These initiatives have created market incentives for manufacturers to adopt more sustainable materials, as consumers and businesses increasingly prioritize environmentally friendly products.

Life Cycle Assessment of Green PU Polyols

Life Cycle Assessment (LCA) of green PU polyols has become a crucial tool in evaluating the environmental impact and sustainability of these innovative materials. The assessment typically covers the entire lifecycle of green PU polyols, from raw material extraction to end-of-life disposal or recycling. This comprehensive approach allows for a holistic understanding of the environmental footprint associated with their production and use.

The LCA process for green PU polyols begins with the analysis of raw material sourcing. This stage examines the environmental impacts of extracting and processing bio-based feedstocks, such as vegetable oils or recycled materials, compared to traditional petroleum-based sources. Factors considered include land use changes, water consumption, and greenhouse gas emissions associated with cultivation and harvesting of bio-based materials.

The production phase of green PU polyols is then scrutinized, focusing on energy consumption, chemical processes, and waste generation. This stage often reveals significant environmental benefits compared to conventional polyols, as green alternatives typically require less energy-intensive processes and produce fewer harmful byproducts. The assessment also considers the potential for using renewable energy sources in manufacturing, further reducing the carbon footprint.

Transportation and distribution aspects are evaluated to account for the environmental impact of moving raw materials, intermediates, and final products. This includes analyzing different modes of transport and their associated emissions, as well as considering the geographical proximity of raw material sources to production facilities.

The use phase of green PU polyols in various applications, such as foams, coatings, and adhesives, is assessed for its environmental performance. This includes evaluating factors like durability, energy efficiency in end-use products, and potential for off-gassing or leaching of harmful substances. The extended lifespan and improved performance of products made with green PU polyols often contribute positively to their overall environmental profile.

End-of-life scenarios are a critical component of the LCA, examining options for disposal, recycling, or biodegradation of products containing green PU polyols. This stage assesses the potential for circular economy practices, such as chemical recycling or composting, which can significantly reduce the overall environmental impact of these materials.

The results of LCA studies on green PU polyols typically demonstrate reduced global warming potential, lower fossil fuel depletion, and decreased ecotoxicity compared to conventional polyols. However, these assessments also highlight areas for improvement, such as optimizing bio-based feedstock production to minimize land use changes and water consumption.

The LCA process for green PU polyols begins with the analysis of raw material sourcing. This stage examines the environmental impacts of extracting and processing bio-based feedstocks, such as vegetable oils or recycled materials, compared to traditional petroleum-based sources. Factors considered include land use changes, water consumption, and greenhouse gas emissions associated with cultivation and harvesting of bio-based materials.

The production phase of green PU polyols is then scrutinized, focusing on energy consumption, chemical processes, and waste generation. This stage often reveals significant environmental benefits compared to conventional polyols, as green alternatives typically require less energy-intensive processes and produce fewer harmful byproducts. The assessment also considers the potential for using renewable energy sources in manufacturing, further reducing the carbon footprint.

Transportation and distribution aspects are evaluated to account for the environmental impact of moving raw materials, intermediates, and final products. This includes analyzing different modes of transport and their associated emissions, as well as considering the geographical proximity of raw material sources to production facilities.

The use phase of green PU polyols in various applications, such as foams, coatings, and adhesives, is assessed for its environmental performance. This includes evaluating factors like durability, energy efficiency in end-use products, and potential for off-gassing or leaching of harmful substances. The extended lifespan and improved performance of products made with green PU polyols often contribute positively to their overall environmental profile.

End-of-life scenarios are a critical component of the LCA, examining options for disposal, recycling, or biodegradation of products containing green PU polyols. This stage assesses the potential for circular economy practices, such as chemical recycling or composting, which can significantly reduce the overall environmental impact of these materials.

The results of LCA studies on green PU polyols typically demonstrate reduced global warming potential, lower fossil fuel depletion, and decreased ecotoxicity compared to conventional polyols. However, these assessments also highlight areas for improvement, such as optimizing bio-based feedstock production to minimize land use changes and water consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!