Polyurethane Coatings: Advancements in Weather Resistance

JUN 25, 20256 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Coatings Evolution

Polyurethane coatings have undergone significant evolution since their inception in the 1930s. Initially developed as a versatile material for various applications, polyurethane quickly found its place in the coatings industry due to its exceptional properties. The early formulations were primarily focused on basic protection and aesthetics, with limited weather resistance capabilities.

In the 1950s and 1960s, researchers began to explore ways to enhance the durability of polyurethane coatings, particularly in outdoor applications. This period saw the introduction of aliphatic isocyanates, which marked a crucial turning point in improving UV stability and color retention. These advancements allowed polyurethane coatings to maintain their appearance and protective properties for longer periods when exposed to sunlight and other environmental factors.

The 1970s and 1980s witnessed further refinements in polyurethane chemistry, with a focus on developing two-component systems that offered superior performance compared to their single-component counterparts. These systems provided better crosslinking and enhanced resistance to chemicals, abrasion, and weathering. During this time, manufacturers also started incorporating additives and UV stabilizers to further improve the coatings' weather resistance.

The 1990s brought about a shift towards more environmentally friendly formulations. Water-based polyurethane coatings gained popularity as regulations on volatile organic compounds (VOCs) became stricter. These new formulations presented challenges in achieving the same level of performance as solvent-based systems, particularly in terms of weather resistance. However, continuous research and development efforts led to significant improvements in water-based technologies.

Entering the 21st century, nanotechnology began to play a crucial role in the evolution of polyurethane coatings. The incorporation of nanoparticles, such as nano-silica and nano-zinc oxide, into coating formulations resulted in enhanced scratch resistance, UV protection, and overall durability. This nano-enhanced approach opened new possibilities for creating ultra-durable, weather-resistant coatings.

Recent years have seen a focus on smart and self-healing polyurethane coatings. These advanced formulations can respond to environmental stimuli or repair minor damage autonomously, further extending the lifespan and weather resistance of the coatings. Additionally, bio-based polyurethanes have emerged as a sustainable alternative, addressing both environmental concerns and the need for high-performance weather-resistant coatings.

Throughout this evolution, the primary goal has remained consistent: to develop polyurethane coatings that offer superior protection against UV radiation, moisture, temperature fluctuations, and other weathering factors while maintaining their aesthetic properties. The journey from basic formulations to today's high-tech, multi-functional coatings reflects the industry's commitment to innovation and meeting the ever-increasing demands for durable, weather-resistant finishes.

In the 1950s and 1960s, researchers began to explore ways to enhance the durability of polyurethane coatings, particularly in outdoor applications. This period saw the introduction of aliphatic isocyanates, which marked a crucial turning point in improving UV stability and color retention. These advancements allowed polyurethane coatings to maintain their appearance and protective properties for longer periods when exposed to sunlight and other environmental factors.

The 1970s and 1980s witnessed further refinements in polyurethane chemistry, with a focus on developing two-component systems that offered superior performance compared to their single-component counterparts. These systems provided better crosslinking and enhanced resistance to chemicals, abrasion, and weathering. During this time, manufacturers also started incorporating additives and UV stabilizers to further improve the coatings' weather resistance.

The 1990s brought about a shift towards more environmentally friendly formulations. Water-based polyurethane coatings gained popularity as regulations on volatile organic compounds (VOCs) became stricter. These new formulations presented challenges in achieving the same level of performance as solvent-based systems, particularly in terms of weather resistance. However, continuous research and development efforts led to significant improvements in water-based technologies.

Entering the 21st century, nanotechnology began to play a crucial role in the evolution of polyurethane coatings. The incorporation of nanoparticles, such as nano-silica and nano-zinc oxide, into coating formulations resulted in enhanced scratch resistance, UV protection, and overall durability. This nano-enhanced approach opened new possibilities for creating ultra-durable, weather-resistant coatings.

Recent years have seen a focus on smart and self-healing polyurethane coatings. These advanced formulations can respond to environmental stimuli or repair minor damage autonomously, further extending the lifespan and weather resistance of the coatings. Additionally, bio-based polyurethanes have emerged as a sustainable alternative, addressing both environmental concerns and the need for high-performance weather-resistant coatings.

Throughout this evolution, the primary goal has remained consistent: to develop polyurethane coatings that offer superior protection against UV radiation, moisture, temperature fluctuations, and other weathering factors while maintaining their aesthetic properties. The journey from basic formulations to today's high-tech, multi-functional coatings reflects the industry's commitment to innovation and meeting the ever-increasing demands for durable, weather-resistant finishes.

Current Solutions

01 UV-resistant additives for polyurethane coatings

Incorporating UV-resistant additives into polyurethane coatings can significantly enhance their weather resistance. These additives, such as UV absorbers and light stabilizers, help protect the coating from degradation caused by sunlight exposure. By preventing UV radiation from penetrating the coating, these additives extend the lifespan of the polyurethane and maintain its appearance and performance over time.- UV-resistant additives for polyurethane coatings: Incorporating UV-resistant additives into polyurethane coatings can significantly enhance their weather resistance. These additives, such as UV absorbers and light stabilizers, protect the coating from degradation caused by sunlight exposure, extending the lifespan and maintaining the appearance of the coated surface.

- Nanoparticle reinforcement for improved durability: The addition of nanoparticles to polyurethane coatings can enhance their weather resistance properties. These nanoparticles, such as silica or titanium dioxide, improve the coating's mechanical strength, scratch resistance, and overall durability when exposed to harsh environmental conditions.

- Fluoropolymer-modified polyurethane coatings: Incorporating fluoropolymers into polyurethane coatings can significantly improve their weather resistance. The fluoropolymer component enhances the coating's resistance to UV radiation, moisture, and chemical degradation, making it ideal for outdoor applications requiring long-term durability.

- Crosslinking agents for enhanced weather resistance: The use of specific crosslinking agents in polyurethane coatings can improve their weather resistance. These agents create stronger bonds within the coating structure, increasing its resistance to environmental factors such as UV radiation, moisture, and temperature fluctuations.

- Bio-based polyurethane coatings with improved weather resistance: Developing bio-based polyurethane coatings with enhanced weather resistance properties is an emerging trend. These coatings utilize renewable resources and offer improved sustainability while maintaining or surpassing the weather resistance of traditional petroleum-based polyurethane coatings.

02 Nanoparticle reinforcement for improved durability

Adding nanoparticles to polyurethane coatings can enhance their weather resistance and overall durability. Nanoparticles such as silica, titanium dioxide, or zinc oxide can be dispersed throughout the coating, improving its mechanical strength, scratch resistance, and barrier properties. This reinforcement helps the coating withstand environmental stresses and maintain its protective qualities for longer periods.Expand Specific Solutions03 Crosslinking agents for enhanced weather resistance

Incorporating specific crosslinking agents into polyurethane formulations can improve their weather resistance. These agents create additional chemical bonds within the coating, increasing its strength and resistance to environmental factors. Properly crosslinked polyurethane coatings exhibit better resistance to moisture, temperature fluctuations, and UV radiation, leading to improved long-term performance in outdoor applications.Expand Specific Solutions04 Fluoropolymer-modified polyurethane coatings

Modifying polyurethane coatings with fluoropolymers can significantly enhance their weather resistance. Fluoropolymers provide excellent resistance to UV radiation, moisture, and chemical attack. By incorporating fluoropolymer components into the polyurethane structure, the resulting coating combines the flexibility and adhesion of polyurethane with the superior weather resistance of fluoropolymers, making it ideal for outdoor applications.Expand Specific Solutions05 Self-healing polyurethane coatings for prolonged weather resistance

Developing self-healing polyurethane coatings can provide long-lasting weather resistance. These innovative coatings incorporate materials that can repair minor damage caused by environmental factors. When exposed to heat or UV light, the self-healing mechanism is activated, allowing the coating to maintain its protective properties over extended periods, even in harsh outdoor conditions.Expand Specific Solutions

Industry Leaders

The polyurethane coatings market for weather resistance is in a mature growth phase, with a global market size expected to reach $29.64 billion by 2027. The technology has evolved significantly, with major players like Covestro Deutschland AG, BASF Corp., and Dow Global Technologies LLC leading innovation. These companies are focusing on developing advanced formulations that offer superior UV resistance, durability, and eco-friendly properties. The competitive landscape is characterized by intense R&D activities, with companies like Kaneka Corp. and Allnex Belgium SA also making significant contributions. The technology's maturity is evident in the diverse applications across industries, from automotive to construction, with ongoing efforts to enhance performance and sustainability.

Covestro Deutschland AG

Technical Solution: Covestro has developed a novel polyurethane coating technology that enhances weather resistance through the incorporation of aliphatic isocyanates and specialized polyols. This formulation creates a highly cross-linked structure that provides excellent UV stability and moisture resistance. The coating also includes advanced light stabilizers and antioxidants to further improve its durability in harsh environmental conditions. Covestro's technology allows for the application of thinner coatings while maintaining superior protection, resulting in reduced material consumption and improved cost-effectiveness.

Strengths: Superior UV and moisture resistance, improved durability, reduced material consumption. Weaknesses: Potentially higher initial cost, may require specialized application equipment.

Dow Global Technologies LLC

Technical Solution: Dow has introduced a breakthrough in polyurethane coatings with their VORASURF™ technology. This innovation focuses on creating a self-stratifying coating system that forms a protective barrier against environmental factors. The coating separates into distinct layers during curing, with the top layer providing enhanced weather resistance while the bottom layer ensures strong adhesion to the substrate. Dow's formulation includes proprietary additives that improve the coating's hydrophobicity and resistance to chemical degradation, making it particularly suitable for outdoor applications in diverse climates.

Strengths: Self-stratifying technology for optimized performance, excellent adhesion, and enhanced chemical resistance. Weaknesses: May have limitations in certain extreme environments, potentially complex formulation process.

Key Innovations

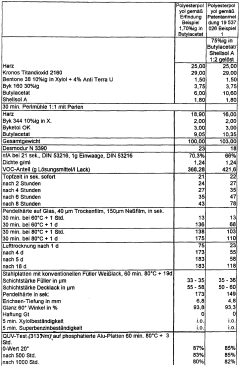

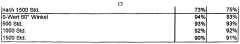

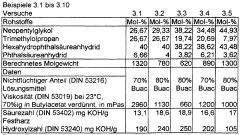

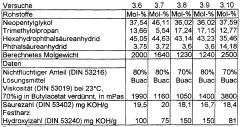

Novel polyester polyols and their use as the polyol component in two-component polyurethane paints

PatentWO1997031964A1

Innovation

- Development of new polyester polyols with specific molecular structures and compositions that can be crosslinked with polyisocyanates, offering reduced solvent needs, rapid drying at low temperatures, and enhanced mechanical and chemical resistance, along with improved weather resistance and gloss retention.

Polyurethane polymer

PatentWO2002098944A1

Innovation

- A polyurethane polymer is developed using mercapto groups at the ends of the molecular chain, obtained through reversible addition-elimination chain transfer polymerization, combined with an organic polyisocyanate, to enhance the polymer's resistance properties.

Environmental Impact

The environmental impact of polyurethane coatings, particularly in the context of advancements in weather resistance, is a critical consideration in the development and application of these materials. As the demand for more durable and weather-resistant coatings increases, it is essential to evaluate their ecological footprint throughout their lifecycle.

One of the primary environmental concerns associated with polyurethane coatings is the emission of volatile organic compounds (VOCs) during application and curing processes. Traditional solvent-based polyurethane coatings have been known to release significant amounts of VOCs, contributing to air pollution and potential health hazards. However, recent advancements in weather-resistant polyurethane coatings have led to the development of low-VOC and zero-VOC formulations, significantly reducing their environmental impact.

Water-based polyurethane coatings have emerged as a more environmentally friendly alternative to solvent-based systems. These coatings not only reduce VOC emissions but also minimize the use of harmful solvents during the manufacturing process. Additionally, water-based formulations often require less energy for application and drying, further reducing their carbon footprint.

The durability and weather resistance of advanced polyurethane coatings also contribute to their environmental profile. By extending the lifespan of coated surfaces, these coatings reduce the need for frequent reapplication, thereby minimizing waste generation and resource consumption. This longevity factor is particularly significant in outdoor applications, where coatings are exposed to harsh environmental conditions.

Another aspect of environmental impact is the potential for polyurethane coatings to improve the energy efficiency of buildings. Weather-resistant polyurethane coatings can enhance the thermal insulation properties of structures, reducing energy consumption for heating and cooling. This indirect environmental benefit can be substantial over the lifetime of a building.

The end-of-life management of polyurethane coatings is an area of growing concern and research. While these coatings offer excellent durability, their disposal and recycling present challenges. Efforts are being made to develop more easily recyclable formulations and to establish effective recycling processes for polyurethane coating waste.

Biodegradability is another frontier in the environmental improvement of polyurethane coatings. Research is ongoing to develop bio-based polyurethanes that can degrade naturally at the end of their useful life, reducing their long-term environmental impact. However, balancing biodegradability with the required weather resistance and durability remains a significant challenge.

In conclusion, while advancements in weather-resistant polyurethane coatings have led to improvements in their environmental profile, particularly in terms of VOC emissions and durability, there is still room for further progress in areas such as recyclability and biodegradability. The ongoing research and development in this field continue to strive for a balance between performance and environmental sustainability.

One of the primary environmental concerns associated with polyurethane coatings is the emission of volatile organic compounds (VOCs) during application and curing processes. Traditional solvent-based polyurethane coatings have been known to release significant amounts of VOCs, contributing to air pollution and potential health hazards. However, recent advancements in weather-resistant polyurethane coatings have led to the development of low-VOC and zero-VOC formulations, significantly reducing their environmental impact.

Water-based polyurethane coatings have emerged as a more environmentally friendly alternative to solvent-based systems. These coatings not only reduce VOC emissions but also minimize the use of harmful solvents during the manufacturing process. Additionally, water-based formulations often require less energy for application and drying, further reducing their carbon footprint.

The durability and weather resistance of advanced polyurethane coatings also contribute to their environmental profile. By extending the lifespan of coated surfaces, these coatings reduce the need for frequent reapplication, thereby minimizing waste generation and resource consumption. This longevity factor is particularly significant in outdoor applications, where coatings are exposed to harsh environmental conditions.

Another aspect of environmental impact is the potential for polyurethane coatings to improve the energy efficiency of buildings. Weather-resistant polyurethane coatings can enhance the thermal insulation properties of structures, reducing energy consumption for heating and cooling. This indirect environmental benefit can be substantial over the lifetime of a building.

The end-of-life management of polyurethane coatings is an area of growing concern and research. While these coatings offer excellent durability, their disposal and recycling present challenges. Efforts are being made to develop more easily recyclable formulations and to establish effective recycling processes for polyurethane coating waste.

Biodegradability is another frontier in the environmental improvement of polyurethane coatings. Research is ongoing to develop bio-based polyurethanes that can degrade naturally at the end of their useful life, reducing their long-term environmental impact. However, balancing biodegradability with the required weather resistance and durability remains a significant challenge.

In conclusion, while advancements in weather-resistant polyurethane coatings have led to improvements in their environmental profile, particularly in terms of VOC emissions and durability, there is still room for further progress in areas such as recyclability and biodegradability. The ongoing research and development in this field continue to strive for a balance between performance and environmental sustainability.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of polyurethane coatings with advanced weather resistance. As environmental concerns and safety standards continue to evolve, manufacturers must navigate an increasingly complex landscape of regulations and guidelines.

In the United States, the Environmental Protection Agency (EPA) sets stringent standards for volatile organic compound (VOC) emissions from coatings. The Clean Air Act amendments have led to the implementation of more stringent VOC limits, pushing manufacturers to develop low-VOC and zero-VOC polyurethane coating formulations. These regulations vary by state and region, with California's South Coast Air Quality Management District (SCAQMD) often setting the benchmark for the most stringent VOC limits nationwide.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has significantly impacted the polyurethane coatings industry. REACH requires manufacturers to register chemical substances and demonstrate their safe use throughout the supply chain. This has led to increased transparency and the phasing out of certain hazardous substances in coating formulations.

Global efforts to reduce the use of isocyanates, a key component in traditional polyurethane coatings, have gained momentum due to their potential health risks. Regulatory bodies worldwide are implementing stricter exposure limits and safety protocols for isocyanate-containing products. This has spurred innovation in non-isocyanate polyurethane (NIPU) technologies, which offer improved safety profiles while maintaining weather resistance properties.

The construction industry, a major user of weather-resistant polyurethane coatings, faces additional regulatory challenges. Building codes and standards, such as those set by the International Code Council (ICC), increasingly emphasize the use of materials that enhance energy efficiency and durability. Polyurethane coatings must meet these standards while also complying with fire safety regulations and green building certifications like LEED (Leadership in Energy and Environmental Design).

In the automotive sector, regulations focusing on fuel efficiency and emissions reduction have indirect implications for polyurethane coatings. Manufacturers are developing lighter, more durable coatings that contribute to overall vehicle weight reduction without compromising weather resistance or longevity.

As sustainability becomes a key focus for regulators, extended producer responsibility (EPR) programs are emerging. These programs hold manufacturers accountable for the entire lifecycle of their products, including disposal. This shift is driving research into more easily recyclable or biodegradable polyurethane coating formulations that maintain high weather resistance.

Compliance with these diverse and evolving regulations requires ongoing investment in research and development, as well as robust quality control and documentation processes. Manufacturers must stay ahead of regulatory trends, anticipating future requirements and adapting their formulations accordingly. This proactive approach not only ensures compliance but also positions companies as industry leaders in sustainable and safe coating technologies.

In the United States, the Environmental Protection Agency (EPA) sets stringent standards for volatile organic compound (VOC) emissions from coatings. The Clean Air Act amendments have led to the implementation of more stringent VOC limits, pushing manufacturers to develop low-VOC and zero-VOC polyurethane coating formulations. These regulations vary by state and region, with California's South Coast Air Quality Management District (SCAQMD) often setting the benchmark for the most stringent VOC limits nationwide.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has significantly impacted the polyurethane coatings industry. REACH requires manufacturers to register chemical substances and demonstrate their safe use throughout the supply chain. This has led to increased transparency and the phasing out of certain hazardous substances in coating formulations.

Global efforts to reduce the use of isocyanates, a key component in traditional polyurethane coatings, have gained momentum due to their potential health risks. Regulatory bodies worldwide are implementing stricter exposure limits and safety protocols for isocyanate-containing products. This has spurred innovation in non-isocyanate polyurethane (NIPU) technologies, which offer improved safety profiles while maintaining weather resistance properties.

The construction industry, a major user of weather-resistant polyurethane coatings, faces additional regulatory challenges. Building codes and standards, such as those set by the International Code Council (ICC), increasingly emphasize the use of materials that enhance energy efficiency and durability. Polyurethane coatings must meet these standards while also complying with fire safety regulations and green building certifications like LEED (Leadership in Energy and Environmental Design).

In the automotive sector, regulations focusing on fuel efficiency and emissions reduction have indirect implications for polyurethane coatings. Manufacturers are developing lighter, more durable coatings that contribute to overall vehicle weight reduction without compromising weather resistance or longevity.

As sustainability becomes a key focus for regulators, extended producer responsibility (EPR) programs are emerging. These programs hold manufacturers accountable for the entire lifecycle of their products, including disposal. This shift is driving research into more easily recyclable or biodegradable polyurethane coating formulations that maintain high weather resistance.

Compliance with these diverse and evolving regulations requires ongoing investment in research and development, as well as robust quality control and documentation processes. Manufacturers must stay ahead of regulatory trends, anticipating future requirements and adapting their formulations accordingly. This proactive approach not only ensures compliance but also positions companies as industry leaders in sustainable and safe coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!