How to Select the Right Polyurethane Type for Your Needs?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polyurethane Types and Applications Overview

Polyurethane is a versatile polymer with a wide range of applications across various industries. Its unique properties, including durability, flexibility, and resistance to wear and tear, make it an ideal material for numerous products. There are several types of polyurethanes, each with specific characteristics suited for different applications.

Thermoplastic polyurethanes (TPUs) are a popular category known for their elasticity and resistance to oil, grease, and abrasion. They are commonly used in automotive interiors, footwear, and medical devices. TPUs can be easily processed and recycled, making them environmentally friendly options.

Thermoset polyurethanes, on the other hand, are characterized by their ability to maintain their shape even when heated. These are widely used in construction, insulation, and furniture manufacturing. Rigid polyurethane foams, a type of thermoset polyurethane, are excellent insulators and find applications in refrigeration and building insulation.

Polyurethane elastomers combine the elasticity of rubber with the toughness and durability of plastic. They are used in high-performance applications such as industrial rollers, automotive suspension bushings, and seals. These elastomers can be formulated to have varying degrees of hardness and resilience.

Polyurethane coatings offer excellent protection against corrosion, chemicals, and abrasion. They are extensively used in automotive finishes, industrial flooring, and marine applications. These coatings can be formulated to be UV-resistant, making them suitable for outdoor applications.

Waterborne polyurethanes have gained popularity due to their low volatile organic compound (VOC) content, making them environmentally friendly. They are used in adhesives, coatings, and sealants, particularly in applications where low odor and quick drying times are required.

When selecting the right polyurethane type, several factors must be considered. The intended application's specific requirements, such as mechanical properties, chemical resistance, and environmental conditions, play a crucial role. Additionally, processing methods, cost considerations, and regulatory compliance should be taken into account.

Understanding the diverse types of polyurethanes and their applications is essential for making informed decisions in material selection. By carefully evaluating the specific needs of a project and matching them with the appropriate polyurethane type, optimal performance and longevity can be achieved in the final product.

Thermoplastic polyurethanes (TPUs) are a popular category known for their elasticity and resistance to oil, grease, and abrasion. They are commonly used in automotive interiors, footwear, and medical devices. TPUs can be easily processed and recycled, making them environmentally friendly options.

Thermoset polyurethanes, on the other hand, are characterized by their ability to maintain their shape even when heated. These are widely used in construction, insulation, and furniture manufacturing. Rigid polyurethane foams, a type of thermoset polyurethane, are excellent insulators and find applications in refrigeration and building insulation.

Polyurethane elastomers combine the elasticity of rubber with the toughness and durability of plastic. They are used in high-performance applications such as industrial rollers, automotive suspension bushings, and seals. These elastomers can be formulated to have varying degrees of hardness and resilience.

Polyurethane coatings offer excellent protection against corrosion, chemicals, and abrasion. They are extensively used in automotive finishes, industrial flooring, and marine applications. These coatings can be formulated to be UV-resistant, making them suitable for outdoor applications.

Waterborne polyurethanes have gained popularity due to their low volatile organic compound (VOC) content, making them environmentally friendly. They are used in adhesives, coatings, and sealants, particularly in applications where low odor and quick drying times are required.

When selecting the right polyurethane type, several factors must be considered. The intended application's specific requirements, such as mechanical properties, chemical resistance, and environmental conditions, play a crucial role. Additionally, processing methods, cost considerations, and regulatory compliance should be taken into account.

Understanding the diverse types of polyurethanes and their applications is essential for making informed decisions in material selection. By carefully evaluating the specific needs of a project and matching them with the appropriate polyurethane type, optimal performance and longevity can be achieved in the final product.

Market Analysis for Polyurethane Products

The polyurethane market has experienced significant growth in recent years, driven by increasing demand across various industries. The global polyurethane market size was valued at approximately $70 billion in 2020 and is projected to reach $90 billion by 2025, growing at a CAGR of around 5% during the forecast period. This growth is primarily attributed to the versatility and superior properties of polyurethane materials, which find applications in construction, automotive, furniture, electronics, and packaging industries.

In the construction sector, polyurethane-based insulation materials are gaining traction due to their excellent thermal insulation properties and energy efficiency benefits. The automotive industry is another major consumer of polyurethane products, utilizing them in seat cushions, interior trims, and bumpers. The furniture industry also contributes significantly to the market demand, with polyurethane foams being widely used in mattresses, sofas, and chairs.

Regionally, Asia-Pacific dominates the polyurethane market, accounting for the largest share of global consumption. This is primarily due to rapid industrialization, urbanization, and increasing disposable income in countries like China and India. North America and Europe follow, with mature markets and a focus on sustainable and bio-based polyurethane products.

The market is characterized by intense competition among key players such as BASF, Covestro, Huntsman Corporation, and Dow Chemical Company. These companies are investing heavily in research and development to introduce innovative products and gain a competitive edge. The trend towards eco-friendly and sustainable polyurethane products is gaining momentum, with manufacturers focusing on developing bio-based and recyclable alternatives.

Consumer preferences are shifting towards high-performance and durable materials, driving the demand for specialized polyurethane products. The packaging industry, in particular, is witnessing increased adoption of polyurethane-based materials for protective packaging solutions. Additionally, the growing emphasis on energy-efficient buildings and stringent regulations regarding insulation are boosting the demand for polyurethane insulation materials in the construction sector.

However, the market faces challenges such as volatile raw material prices and environmental concerns associated with traditional polyurethane production. To address these issues, manufacturers are exploring alternative raw materials and production processes to reduce environmental impact and improve sustainability. The development of water-based polyurethane systems and the use of recycled content in polyurethane products are some of the initiatives being undertaken to meet evolving market demands and regulatory requirements.

In the construction sector, polyurethane-based insulation materials are gaining traction due to their excellent thermal insulation properties and energy efficiency benefits. The automotive industry is another major consumer of polyurethane products, utilizing them in seat cushions, interior trims, and bumpers. The furniture industry also contributes significantly to the market demand, with polyurethane foams being widely used in mattresses, sofas, and chairs.

Regionally, Asia-Pacific dominates the polyurethane market, accounting for the largest share of global consumption. This is primarily due to rapid industrialization, urbanization, and increasing disposable income in countries like China and India. North America and Europe follow, with mature markets and a focus on sustainable and bio-based polyurethane products.

The market is characterized by intense competition among key players such as BASF, Covestro, Huntsman Corporation, and Dow Chemical Company. These companies are investing heavily in research and development to introduce innovative products and gain a competitive edge. The trend towards eco-friendly and sustainable polyurethane products is gaining momentum, with manufacturers focusing on developing bio-based and recyclable alternatives.

Consumer preferences are shifting towards high-performance and durable materials, driving the demand for specialized polyurethane products. The packaging industry, in particular, is witnessing increased adoption of polyurethane-based materials for protective packaging solutions. Additionally, the growing emphasis on energy-efficient buildings and stringent regulations regarding insulation are boosting the demand for polyurethane insulation materials in the construction sector.

However, the market faces challenges such as volatile raw material prices and environmental concerns associated with traditional polyurethane production. To address these issues, manufacturers are exploring alternative raw materials and production processes to reduce environmental impact and improve sustainability. The development of water-based polyurethane systems and the use of recycled content in polyurethane products are some of the initiatives being undertaken to meet evolving market demands and regulatory requirements.

Current Challenges in Polyurethane Selection

The selection of the right polyurethane type presents several challenges in today's market due to the vast array of options available and the complexity of application requirements. One of the primary difficulties lies in understanding the diverse properties of different polyurethane formulations and how they align with specific needs. Engineers and product designers often struggle to navigate through the myriad of options, including thermoplastic polyurethanes (TPUs), thermoset polyurethanes, and various hybrid systems.

A significant challenge is balancing performance requirements with cost considerations. High-performance polyurethanes often come at a premium, forcing decision-makers to weigh the benefits against budget constraints. This becomes particularly complex when dealing with applications that demand a combination of properties, such as high abrasion resistance, flexibility, and chemical resistance.

Environmental concerns and regulatory compliance add another layer of complexity to the selection process. With increasing focus on sustainability, there is a growing demand for bio-based and recyclable polyurethanes. However, these eco-friendly options may not always match the performance of traditional polyurethanes, creating a dilemma for those prioritizing both environmental responsibility and product efficacy.

The rapidly evolving nature of polyurethane technology also poses a challenge. New formulations and manufacturing processes are continually being developed, making it difficult for professionals to stay updated on the latest advancements. This knowledge gap can lead to suboptimal choices or missed opportunities for innovation in product design.

Application-specific requirements further complicate the selection process. For instance, polyurethanes used in medical devices must meet stringent biocompatibility standards, while those used in automotive applications might need to withstand extreme temperatures and UV exposure. The challenge lies in finding a polyurethane type that not only meets these specific criteria but also performs well across various parameters.

Another hurdle is the lack of standardized testing methods across different polyurethane types. This inconsistency makes it challenging to compare properties accurately, especially when dealing with novel formulations or specialized applications. Manufacturers often rely on proprietary testing methods, which can lead to discrepancies in reported performance data.

Lastly, the global supply chain for polyurethane raw materials introduces volatility in availability and pricing. Fluctuations in the supply of key components can impact the consistency of polyurethane formulations, making long-term planning and quality control more challenging. This unpredictability adds another layer of complexity to the selection process, particularly for industries with stringent quality requirements or long product development cycles.

A significant challenge is balancing performance requirements with cost considerations. High-performance polyurethanes often come at a premium, forcing decision-makers to weigh the benefits against budget constraints. This becomes particularly complex when dealing with applications that demand a combination of properties, such as high abrasion resistance, flexibility, and chemical resistance.

Environmental concerns and regulatory compliance add another layer of complexity to the selection process. With increasing focus on sustainability, there is a growing demand for bio-based and recyclable polyurethanes. However, these eco-friendly options may not always match the performance of traditional polyurethanes, creating a dilemma for those prioritizing both environmental responsibility and product efficacy.

The rapidly evolving nature of polyurethane technology also poses a challenge. New formulations and manufacturing processes are continually being developed, making it difficult for professionals to stay updated on the latest advancements. This knowledge gap can lead to suboptimal choices or missed opportunities for innovation in product design.

Application-specific requirements further complicate the selection process. For instance, polyurethanes used in medical devices must meet stringent biocompatibility standards, while those used in automotive applications might need to withstand extreme temperatures and UV exposure. The challenge lies in finding a polyurethane type that not only meets these specific criteria but also performs well across various parameters.

Another hurdle is the lack of standardized testing methods across different polyurethane types. This inconsistency makes it challenging to compare properties accurately, especially when dealing with novel formulations or specialized applications. Manufacturers often rely on proprietary testing methods, which can lead to discrepancies in reported performance data.

Lastly, the global supply chain for polyurethane raw materials introduces volatility in availability and pricing. Fluctuations in the supply of key components can impact the consistency of polyurethane formulations, making long-term planning and quality control more challenging. This unpredictability adds another layer of complexity to the selection process, particularly for industries with stringent quality requirements or long product development cycles.

Existing Polyurethane Selection Methodologies

01 Polyurethane synthesis and composition

This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.- Polyurethane synthesis and composition: This category focuses on the synthesis and composition of polyurethane materials. It includes various methods for producing polyurethane with specific properties, such as improved durability, flexibility, or chemical resistance. The synthesis may involve different types of isocyanates, polyols, and additives to achieve desired characteristics.

- Polyurethane applications in coatings and films: This category covers the use of polyurethane in coatings and films for various applications. It includes formulations for protective coatings, decorative finishes, and functional films. The polyurethane-based coatings and films may offer properties such as weather resistance, abrasion resistance, and enhanced adhesion to different substrates.

- Polyurethane foam technology: This category encompasses innovations in polyurethane foam production and properties. It includes advancements in foam formulations, processing techniques, and the development of specialized foam products. The foams may be designed for applications such as insulation, cushioning, or structural components with specific density, rigidity, or thermal properties.

- Polyurethane in adhesives and sealants: This category focuses on the use of polyurethane in adhesive and sealant applications. It covers formulations and technologies for creating strong, flexible bonds between various materials. The polyurethane-based adhesives and sealants may offer advantages such as moisture resistance, durability, and the ability to bond dissimilar substrates.

- Polyurethane modifications and additives: This category deals with modifications to polyurethane materials and the use of additives to enhance their properties. It includes techniques for improving specific characteristics such as fire resistance, UV stability, or biodegradability. The modifications may involve chemical alterations to the polyurethane structure or the incorporation of specialized additives.

02 Polyurethane applications in coatings and films

This point covers the use of polyurethane in various coating and film applications. It includes formulations for protective coatings, adhesive films, and specialty surface treatments. The polyurethane-based coatings and films may offer properties such as weather resistance, chemical resistance, and improved adhesion to different substrates.Expand Specific Solutions03 Polyurethane foam technology

This category encompasses innovations in polyurethane foam production and properties. It includes advancements in foam formulations, processing techniques, and the development of specialized foam products. The foams may have applications in insulation, cushioning, packaging, and other industries requiring lightweight, durable materials.Expand Specific Solutions04 Polyurethane in textile and fiber applications

This point focuses on the use of polyurethane in textile and fiber-related applications. It includes the development of polyurethane-based fibers, coatings for textiles, and composite materials incorporating polyurethane. These innovations may enhance fabric properties such as elasticity, water resistance, and durability.Expand Specific Solutions05 Environmentally friendly polyurethane innovations

This category covers advancements in making polyurethane more environmentally friendly. It includes the development of bio-based polyurethanes, recyclable formulations, and production methods with reduced environmental impact. These innovations aim to address sustainability concerns while maintaining the desirable properties of polyurethane materials.Expand Specific Solutions

Key Manufacturers and Suppliers in the Industry

The polyurethane market is in a mature growth stage, with a global market size expected to reach $79.2 billion by 2027. The technology for selecting the right polyurethane type is well-established but continually evolving. Key players like BASF, Covestro, and DuPont are driving innovation in this field, focusing on developing sustainable and high-performance polyurethane solutions. Companies such as Sika Technology AG and Evonik Operations GmbH are also contributing to advancements in specialized applications. The competitive landscape is characterized by ongoing research and development efforts to improve product properties, expand application areas, and address environmental concerns, with a growing emphasis on bio-based and recyclable polyurethanes.

BASF Corp.

Technical Solution: BASF has developed a comprehensive range of polyurethane solutions tailored for various applications. Their technology focuses on creating customized polyurethane systems that can be fine-tuned for specific performance requirements. BASF's approach involves a modular chemistry platform that allows for the adjustment of key properties such as hardness, flexibility, and chemical resistance. They have also invested in bio-based polyols to create more sustainable polyurethane options, addressing the growing demand for eco-friendly materials.

Strengths: Wide range of customizable solutions, strong R&D capabilities, and focus on sustainability. Weaknesses: Potentially higher costs due to customization, and complexity in selection process for customers.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced polyurethane technologies that focus on enhancing material performance and durability. Their approach includes the development of specialized additives and modifiers that can be incorporated into polyurethane formulations to achieve specific properties. DuPont's technology also emphasizes the creation of high-performance polyurethane elastomers and foams that offer improved resistance to chemicals, abrasion, and extreme temperatures. They have also made strides in developing polyurethane systems with reduced environmental impact, including water-based formulations and products with lower VOC emissions.

Strengths: Expertise in high-performance materials, strong focus on durability and chemical resistance. Weaknesses: May be less suitable for low-cost applications, and potentially limited options for highly flexible materials.

Innovative Approaches in Polyurethane Formulation

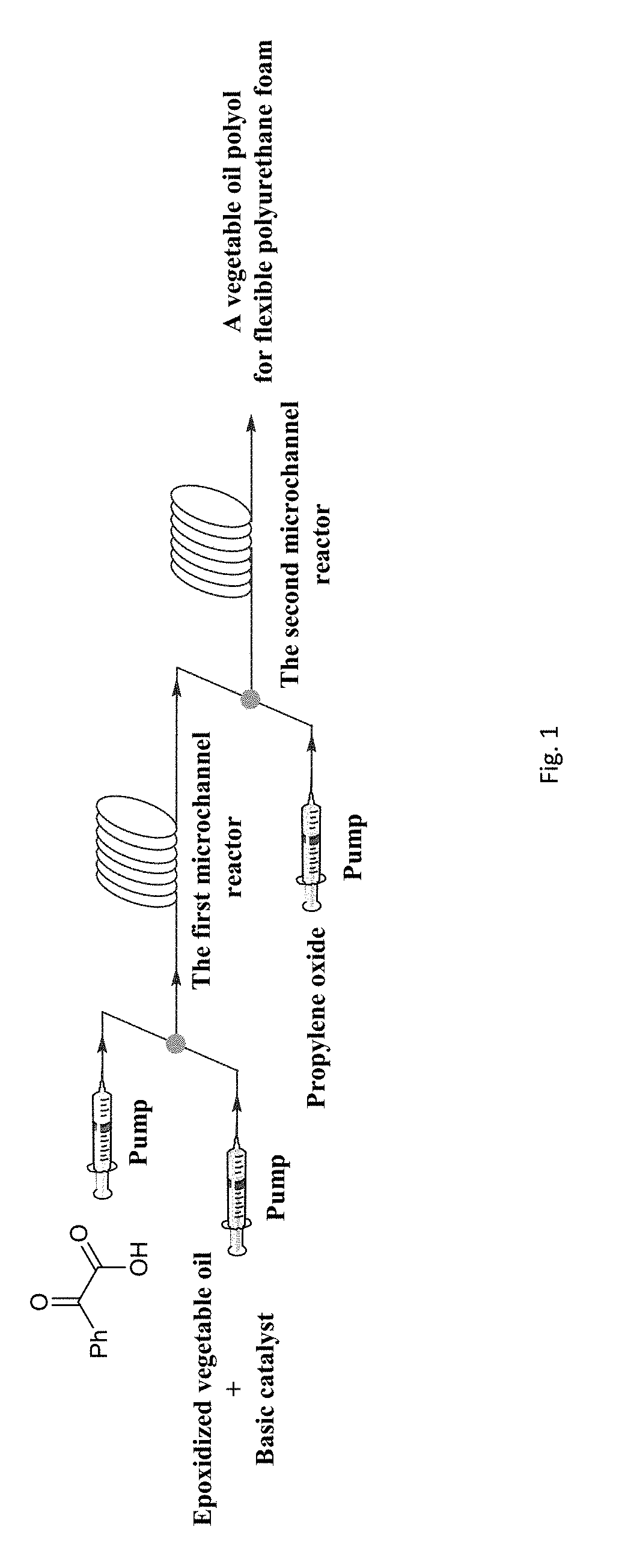

Vegetable Oil Polyol for Flexible Polyurethane Foam and Preparation Method and Application Thereof

PatentInactiveUS20190119493A1

Innovation

- A method involving a microchannel reaction device for ring-opening and addition polymerization reactions using epoxidized vegetable oil, benzoylformic acid, and propylene oxide, which allows for the efficient production of a vegetable oil polyol suitable for flexible polyurethane foam, reducing energy consumption and enabling continuous operation.

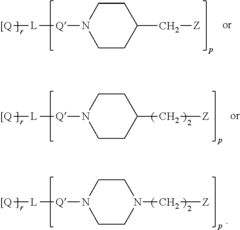

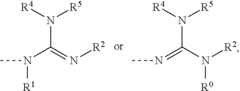

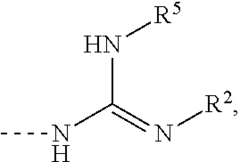

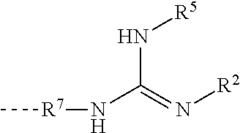

Catalyst containing guanidine groups

PatentActiveUS20180148545A1

Innovation

- A catalyst with the formula (Qr-L-Q′-Y-A-Z) is used, featuring an aliphatic guanidine group with high catalytic activity and low volatility, which ensures rapid curing and stability without odor or migration, prepared from commercially available inexpensive materials.

Environmental Impact and Sustainability Considerations

The selection of polyurethane types for various applications must consider their environmental impact and sustainability aspects. Polyurethanes are widely used in numerous industries due to their versatility, but their production and disposal can have significant environmental implications.

Traditional polyurethanes are often derived from petroleum-based raw materials, which contribute to carbon emissions and resource depletion. However, recent advancements have led to the development of bio-based polyurethanes, utilizing renewable resources such as vegetable oils, lignin, and other plant-based materials. These alternatives offer reduced carbon footprints and decreased reliance on fossil fuels.

The manufacturing process of polyurethanes also plays a crucial role in their environmental impact. Energy-efficient production methods and the use of low-emission technologies can significantly reduce the overall environmental burden. Additionally, some manufacturers have implemented closed-loop systems to recycle and reuse solvents and other materials, minimizing waste generation.

End-of-life considerations are equally important when selecting polyurethane types. Some polyurethanes are designed for easier recycling or biodegradability, aligning with circular economy principles. Thermoplastic polyurethanes, for instance, can be melted and reshaped, facilitating recycling processes. Conversely, thermoset polyurethanes are more challenging to recycle but may offer superior durability, potentially extending product lifespans.

Water-based polyurethane systems have gained traction as environmentally friendly alternatives to solvent-based options. These formulations reduce volatile organic compound (VOC) emissions, improving air quality and worker safety. However, their performance characteristics may differ from traditional solvent-based systems, necessitating careful evaluation for specific applications.

The durability and longevity of polyurethane products also factor into their sustainability profile. Selecting high-quality, long-lasting polyurethanes can reduce the frequency of replacements, thereby conserving resources and minimizing waste generation over time. This aspect is particularly relevant in applications such as construction materials, automotive components, and durable consumer goods.

When considering polyurethane types, it is essential to evaluate their potential for off-gassing and the release of harmful substances during use. Some formulations may emit volatile organic compounds or contain potentially hazardous additives. Opting for low-emission or certified eco-friendly polyurethanes can mitigate these risks and contribute to healthier indoor environments.

Ultimately, the selection of the right polyurethane type should balance performance requirements with environmental considerations. This may involve trade-offs between immediate cost, long-term sustainability, and functional properties. As regulations and consumer preferences increasingly prioritize environmental sustainability, choosing polyurethanes with reduced environmental impacts can offer competitive advantages and future-proof product designs.

Traditional polyurethanes are often derived from petroleum-based raw materials, which contribute to carbon emissions and resource depletion. However, recent advancements have led to the development of bio-based polyurethanes, utilizing renewable resources such as vegetable oils, lignin, and other plant-based materials. These alternatives offer reduced carbon footprints and decreased reliance on fossil fuels.

The manufacturing process of polyurethanes also plays a crucial role in their environmental impact. Energy-efficient production methods and the use of low-emission technologies can significantly reduce the overall environmental burden. Additionally, some manufacturers have implemented closed-loop systems to recycle and reuse solvents and other materials, minimizing waste generation.

End-of-life considerations are equally important when selecting polyurethane types. Some polyurethanes are designed for easier recycling or biodegradability, aligning with circular economy principles. Thermoplastic polyurethanes, for instance, can be melted and reshaped, facilitating recycling processes. Conversely, thermoset polyurethanes are more challenging to recycle but may offer superior durability, potentially extending product lifespans.

Water-based polyurethane systems have gained traction as environmentally friendly alternatives to solvent-based options. These formulations reduce volatile organic compound (VOC) emissions, improving air quality and worker safety. However, their performance characteristics may differ from traditional solvent-based systems, necessitating careful evaluation for specific applications.

The durability and longevity of polyurethane products also factor into their sustainability profile. Selecting high-quality, long-lasting polyurethanes can reduce the frequency of replacements, thereby conserving resources and minimizing waste generation over time. This aspect is particularly relevant in applications such as construction materials, automotive components, and durable consumer goods.

When considering polyurethane types, it is essential to evaluate their potential for off-gassing and the release of harmful substances during use. Some formulations may emit volatile organic compounds or contain potentially hazardous additives. Opting for low-emission or certified eco-friendly polyurethanes can mitigate these risks and contribute to healthier indoor environments.

Ultimately, the selection of the right polyurethane type should balance performance requirements with environmental considerations. This may involve trade-offs between immediate cost, long-term sustainability, and functional properties. As regulations and consumer preferences increasingly prioritize environmental sustainability, choosing polyurethanes with reduced environmental impacts can offer competitive advantages and future-proof product designs.

Performance Testing and Quality Assurance Methods

Performance testing and quality assurance methods play a crucial role in selecting the right polyurethane type for specific needs. These processes ensure that the chosen polyurethane meets the required standards and performs optimally in its intended application. A comprehensive testing regime typically includes physical, chemical, and mechanical property evaluations.

Physical property tests assess characteristics such as density, hardness, and color stability. Density measurements help determine the material's weight and potential for buoyancy applications. Hardness testing, often using Shore A or Shore D scales, provides insight into the polyurethane's resistance to indentation and its suitability for various load-bearing applications. Color stability tests evaluate the material's resistance to UV radiation and environmental factors, which is particularly important for outdoor or exposed applications.

Chemical resistance testing is essential to ensure the polyurethane can withstand exposure to various substances it may encounter during use. This includes immersion tests in oils, solvents, and other chemicals relevant to the intended application. Additionally, hydrolysis resistance testing assesses the material's ability to maintain its properties when exposed to moisture and heat over time.

Mechanical property evaluations form a critical component of performance testing. Tensile strength and elongation tests measure the material's ability to withstand stretching forces and its flexibility. Tear strength testing assesses resistance to tearing or propagation of cuts. Compression set tests determine the material's ability to return to its original shape after prolonged compression, which is crucial for sealing and cushioning applications.

Abrasion resistance testing is particularly important for polyurethanes used in high-wear applications. Methods such as the Taber Abrasion Test or DIN Abrasion Test can quantify the material's resistance to surface wear and help predict its longevity in demanding environments.

Dynamic mechanical analysis (DMA) provides valuable insights into the viscoelastic properties of polyurethanes across a range of temperatures and frequencies. This test helps in understanding how the material will behave under various operating conditions and can be particularly useful in selecting polyurethanes for applications involving vibration damping or temperature fluctuations.

Quality assurance methods extend beyond initial testing to include batch-to-batch consistency checks and long-term stability assessments. Statistical process control (SPC) techniques are often employed to monitor key properties and ensure consistent quality across production runs. Accelerated aging tests, such as heat aging or weathering simulations, help predict the long-term performance and durability of the polyurethane in its intended environment.

Physical property tests assess characteristics such as density, hardness, and color stability. Density measurements help determine the material's weight and potential for buoyancy applications. Hardness testing, often using Shore A or Shore D scales, provides insight into the polyurethane's resistance to indentation and its suitability for various load-bearing applications. Color stability tests evaluate the material's resistance to UV radiation and environmental factors, which is particularly important for outdoor or exposed applications.

Chemical resistance testing is essential to ensure the polyurethane can withstand exposure to various substances it may encounter during use. This includes immersion tests in oils, solvents, and other chemicals relevant to the intended application. Additionally, hydrolysis resistance testing assesses the material's ability to maintain its properties when exposed to moisture and heat over time.

Mechanical property evaluations form a critical component of performance testing. Tensile strength and elongation tests measure the material's ability to withstand stretching forces and its flexibility. Tear strength testing assesses resistance to tearing or propagation of cuts. Compression set tests determine the material's ability to return to its original shape after prolonged compression, which is crucial for sealing and cushioning applications.

Abrasion resistance testing is particularly important for polyurethanes used in high-wear applications. Methods such as the Taber Abrasion Test or DIN Abrasion Test can quantify the material's resistance to surface wear and help predict its longevity in demanding environments.

Dynamic mechanical analysis (DMA) provides valuable insights into the viscoelastic properties of polyurethanes across a range of temperatures and frequencies. This test helps in understanding how the material will behave under various operating conditions and can be particularly useful in selecting polyurethanes for applications involving vibration damping or temperature fluctuations.

Quality assurance methods extend beyond initial testing to include batch-to-batch consistency checks and long-term stability assessments. Statistical process control (SPC) techniques are often employed to monitor key properties and ensure consistent quality across production runs. Accelerated aging tests, such as heat aging or weathering simulations, help predict the long-term performance and durability of the polyurethane in its intended environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!