Evaluating Polyurethane Safety in Consumer Products

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PU Safety Background

Polyurethane (PU) has been a ubiquitous material in consumer products for decades, owing to its versatility, durability, and cost-effectiveness. The safety of PU in consumer goods has become an increasingly important topic as awareness of potential health and environmental impacts grows. This background exploration aims to provide a comprehensive overview of the historical context, current concerns, and evolving regulatory landscape surrounding PU safety.

The development of PU dates back to the 1930s, with its commercial use expanding rapidly in the post-World War II era. Initially hailed as a revolutionary material, PU found applications in furniture, automotive parts, insulation, and numerous household items. However, as its use became widespread, questions about its long-term safety began to emerge.

One of the primary concerns regarding PU safety is the potential release of volatile organic compounds (VOCs) and other chemicals during manufacturing, use, and disposal. These emissions can include isocyanates, which are known respiratory irritants and potential carcinogens. The off-gassing of these compounds, particularly in enclosed spaces, has raised alarm among consumers and health professionals alike.

Another significant aspect of PU safety is its flammability and the toxic fumes produced when it burns. This concern gained prominence following several high-profile incidents, including furniture fires that resulted in fatalities. As a result, flame retardants are often added to PU products, but these additives have themselves become a subject of safety debates due to their potential health effects.

The environmental impact of PU production and disposal is also a critical component of the safety discussion. The manufacturing process involves petrochemicals and energy-intensive procedures, contributing to carbon emissions and resource depletion. Additionally, the non-biodegradable nature of most PU products poses challenges for waste management and environmental preservation.

Regulatory bodies worldwide have responded to these concerns by implementing various standards and guidelines. In the United States, the Consumer Product Safety Commission (CPSC) has established regulations for PU-containing products, particularly focusing on furniture and children's items. The European Union has introduced REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which impact the use of certain chemicals in PU production.

As research continues to evolve, new findings are shaping the understanding of PU safety. Recent studies have explored the potential for PU to act as an endocrine disruptor and its role in microplastic pollution. These emerging concerns are driving innovation in PU alternatives and safer manufacturing processes.

The industry has responded to safety concerns with efforts to develop bio-based PUs, improve production methods to reduce emissions, and create more easily recyclable PU products. However, balancing performance, cost, and safety remains an ongoing challenge for manufacturers and regulators alike.

The development of PU dates back to the 1930s, with its commercial use expanding rapidly in the post-World War II era. Initially hailed as a revolutionary material, PU found applications in furniture, automotive parts, insulation, and numerous household items. However, as its use became widespread, questions about its long-term safety began to emerge.

One of the primary concerns regarding PU safety is the potential release of volatile organic compounds (VOCs) and other chemicals during manufacturing, use, and disposal. These emissions can include isocyanates, which are known respiratory irritants and potential carcinogens. The off-gassing of these compounds, particularly in enclosed spaces, has raised alarm among consumers and health professionals alike.

Another significant aspect of PU safety is its flammability and the toxic fumes produced when it burns. This concern gained prominence following several high-profile incidents, including furniture fires that resulted in fatalities. As a result, flame retardants are often added to PU products, but these additives have themselves become a subject of safety debates due to their potential health effects.

The environmental impact of PU production and disposal is also a critical component of the safety discussion. The manufacturing process involves petrochemicals and energy-intensive procedures, contributing to carbon emissions and resource depletion. Additionally, the non-biodegradable nature of most PU products poses challenges for waste management and environmental preservation.

Regulatory bodies worldwide have responded to these concerns by implementing various standards and guidelines. In the United States, the Consumer Product Safety Commission (CPSC) has established regulations for PU-containing products, particularly focusing on furniture and children's items. The European Union has introduced REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which impact the use of certain chemicals in PU production.

As research continues to evolve, new findings are shaping the understanding of PU safety. Recent studies have explored the potential for PU to act as an endocrine disruptor and its role in microplastic pollution. These emerging concerns are driving innovation in PU alternatives and safer manufacturing processes.

The industry has responded to safety concerns with efforts to develop bio-based PUs, improve production methods to reduce emissions, and create more easily recyclable PU products. However, balancing performance, cost, and safety remains an ongoing challenge for manufacturers and regulators alike.

Market Demand Analysis

The market demand for polyurethane in consumer products has been steadily increasing over the past decade, driven by its versatility, durability, and cost-effectiveness. This synthetic polymer finds applications in a wide range of consumer goods, including furniture, bedding, automotive interiors, footwear, and various household items. The global polyurethane market size was valued at approximately $70 billion in 2020 and is projected to grow at a compound annual growth rate of 5.5% from 2021 to 2028.

Consumer awareness regarding product safety has significantly influenced market dynamics. There is a growing demand for polyurethane products that meet stringent safety standards, particularly in terms of chemical emissions and fire resistance. This trend is especially prominent in developed markets such as North America and Europe, where regulatory bodies have implemented strict guidelines for consumer product safety.

The furniture and bedding sector represents the largest market segment for polyurethane in consumer products. Memory foam mattresses and cushions, which utilize polyurethane foam, have gained substantial popularity due to their comfort and pressure-relieving properties. However, concerns about off-gassing and potential health impacts have led to increased demand for low-emission and bio-based polyurethane alternatives in this sector.

In the automotive industry, polyurethane is extensively used in interior components, including seats, headrests, and dashboard materials. The growing emphasis on lightweight materials for improved fuel efficiency has further boosted the demand for polyurethane in this sector. Simultaneously, there is a rising need for polyurethane formulations that meet stringent volatile organic compound (VOC) emission standards set by automotive manufacturers and regulatory bodies.

The footwear industry has also witnessed a surge in polyurethane usage, particularly in athletic and comfort shoe segments. Consumers are increasingly seeking shoes with enhanced cushioning, durability, and flexibility, properties that polyurethane materials can effectively provide. However, the industry faces challenges in addressing concerns about the environmental impact of polyurethane production and disposal.

Market trends indicate a growing preference for eco-friendly and sustainable polyurethane alternatives. Bio-based polyurethanes derived from renewable resources such as soybean oil, castor oil, and corn are gaining traction. These materials not only address environmental concerns but also offer potential improvements in terms of safety and reduced chemical emissions.

The COVID-19 pandemic has had a mixed impact on the polyurethane market in consumer products. While sectors like furniture and bedding experienced increased demand due to home improvement trends, industries such as automotive and footwear faced temporary setbacks. However, the pandemic has also accelerated the demand for antimicrobial and easy-to-clean polyurethane surfaces, opening new avenues for product development and market growth.

Consumer awareness regarding product safety has significantly influenced market dynamics. There is a growing demand for polyurethane products that meet stringent safety standards, particularly in terms of chemical emissions and fire resistance. This trend is especially prominent in developed markets such as North America and Europe, where regulatory bodies have implemented strict guidelines for consumer product safety.

The furniture and bedding sector represents the largest market segment for polyurethane in consumer products. Memory foam mattresses and cushions, which utilize polyurethane foam, have gained substantial popularity due to their comfort and pressure-relieving properties. However, concerns about off-gassing and potential health impacts have led to increased demand for low-emission and bio-based polyurethane alternatives in this sector.

In the automotive industry, polyurethane is extensively used in interior components, including seats, headrests, and dashboard materials. The growing emphasis on lightweight materials for improved fuel efficiency has further boosted the demand for polyurethane in this sector. Simultaneously, there is a rising need for polyurethane formulations that meet stringent volatile organic compound (VOC) emission standards set by automotive manufacturers and regulatory bodies.

The footwear industry has also witnessed a surge in polyurethane usage, particularly in athletic and comfort shoe segments. Consumers are increasingly seeking shoes with enhanced cushioning, durability, and flexibility, properties that polyurethane materials can effectively provide. However, the industry faces challenges in addressing concerns about the environmental impact of polyurethane production and disposal.

Market trends indicate a growing preference for eco-friendly and sustainable polyurethane alternatives. Bio-based polyurethanes derived from renewable resources such as soybean oil, castor oil, and corn are gaining traction. These materials not only address environmental concerns but also offer potential improvements in terms of safety and reduced chemical emissions.

The COVID-19 pandemic has had a mixed impact on the polyurethane market in consumer products. While sectors like furniture and bedding experienced increased demand due to home improvement trends, industries such as automotive and footwear faced temporary setbacks. However, the pandemic has also accelerated the demand for antimicrobial and easy-to-clean polyurethane surfaces, opening new avenues for product development and market growth.

PU Safety Challenges

Polyurethane (PU) has become ubiquitous in consumer products, ranging from furniture and bedding to clothing and footwear. However, its widespread use has raised significant safety concerns, particularly regarding potential health and environmental impacts. One of the primary challenges in evaluating PU safety is the complexity of its chemical composition, which can vary widely depending on the specific formulation and manufacturing process.

A major safety concern is the potential release of volatile organic compounds (VOCs) from PU products. These emissions, which can include formaldehyde and other harmful chemicals, may persist long after manufacturing and contribute to indoor air pollution. This is particularly problematic in enclosed spaces with limited ventilation, potentially leading to respiratory issues and other health problems for consumers.

Another critical challenge is the presence of isocyanates, key components in PU production. While these compounds are typically fully reacted during the manufacturing process, there is a risk of unreacted isocyanates remaining in the final product. Exposure to these chemicals can cause severe respiratory sensitization and allergic reactions, posing significant health risks to both workers and end-users.

The use of flame retardants in PU products presents an additional safety dilemma. While these additives are intended to improve fire safety, many common flame retardants have been linked to endocrine disruption, developmental issues, and potential carcinogenicity. Balancing fire safety requirements with the need to minimize exposure to potentially harmful chemicals remains a significant challenge.

Durability and degradation of PU products also raise safety concerns. As PU materials age or are exposed to environmental factors like heat, light, and moisture, they can break down, potentially releasing harmful substances. This degradation process not only affects product performance but may also increase the risk of chemical exposure over time.

The recycling and disposal of PU products present further challenges. Many PU materials are difficult to recycle, leading to increased landfill waste or incineration, both of which can have negative environmental impacts. The potential release of toxic substances during disposal processes adds another layer of complexity to ensuring the long-term safety of PU use in consumer products.

Addressing these safety challenges requires a multifaceted approach, including improved manufacturing processes, stricter regulatory oversight, and enhanced testing methodologies. Developing safer alternatives to harmful additives and exploring bio-based PU formulations are also crucial steps in mitigating the safety risks associated with polyurethane in consumer products.

A major safety concern is the potential release of volatile organic compounds (VOCs) from PU products. These emissions, which can include formaldehyde and other harmful chemicals, may persist long after manufacturing and contribute to indoor air pollution. This is particularly problematic in enclosed spaces with limited ventilation, potentially leading to respiratory issues and other health problems for consumers.

Another critical challenge is the presence of isocyanates, key components in PU production. While these compounds are typically fully reacted during the manufacturing process, there is a risk of unreacted isocyanates remaining in the final product. Exposure to these chemicals can cause severe respiratory sensitization and allergic reactions, posing significant health risks to both workers and end-users.

The use of flame retardants in PU products presents an additional safety dilemma. While these additives are intended to improve fire safety, many common flame retardants have been linked to endocrine disruption, developmental issues, and potential carcinogenicity. Balancing fire safety requirements with the need to minimize exposure to potentially harmful chemicals remains a significant challenge.

Durability and degradation of PU products also raise safety concerns. As PU materials age or are exposed to environmental factors like heat, light, and moisture, they can break down, potentially releasing harmful substances. This degradation process not only affects product performance but may also increase the risk of chemical exposure over time.

The recycling and disposal of PU products present further challenges. Many PU materials are difficult to recycle, leading to increased landfill waste or incineration, both of which can have negative environmental impacts. The potential release of toxic substances during disposal processes adds another layer of complexity to ensuring the long-term safety of PU use in consumer products.

Addressing these safety challenges requires a multifaceted approach, including improved manufacturing processes, stricter regulatory oversight, and enhanced testing methodologies. Developing safer alternatives to harmful additives and exploring bio-based PU formulations are also crucial steps in mitigating the safety risks associated with polyurethane in consumer products.

Current Safety Solutions

01 Flame retardant polyurethane formulations

Developing polyurethane formulations with improved flame retardant properties to enhance safety in various applications. This involves incorporating specific additives or modifying the polymer structure to reduce flammability and improve fire resistance.- Flame retardant polyurethane formulations: Developing polyurethane formulations with improved flame retardant properties to enhance safety in various applications. This involves incorporating specific additives or modifying the polymer structure to reduce flammability and improve fire resistance.

- Low-emission polyurethane systems: Creating polyurethane systems with reduced volatile organic compound (VOC) emissions and lower toxicity. These formulations aim to improve indoor air quality and minimize potential health risks associated with polyurethane products.

- Protective equipment for polyurethane handling: Designing and implementing personal protective equipment (PPE) specifically for handling polyurethane materials. This includes specialized gloves, respirators, and protective clothing to minimize exposure risks during manufacturing and application processes.

- Safe curing and post-processing techniques: Developing improved curing and post-processing methods for polyurethane products to ensure complete reaction of components and minimize the presence of unreacted isocyanates. This includes optimizing curing conditions and implementing proper ventilation systems.

- Environmental impact assessment and recycling: Conducting comprehensive environmental impact assessments of polyurethane products throughout their lifecycle and developing safe recycling methods. This involves analyzing potential ecological effects and creating processes for the safe disposal or reuse of polyurethane materials.

02 Low-emission polyurethane systems

Creating polyurethane systems with reduced volatile organic compound (VOC) emissions and lower toxicity. These formulations aim to improve indoor air quality and minimize potential health risks associated with polyurethane products.Expand Specific Solutions03 Protective equipment for polyurethane handling

Designing and implementing personal protective equipment (PPE) specifically for handling polyurethane materials. This includes specialized gloves, respirators, and protective clothing to minimize exposure risks during manufacturing and application processes.Expand Specific Solutions04 Safe polyurethane application techniques

Developing and implementing safe application techniques for polyurethane products, particularly in spray foam insulation and coating applications. This involves proper equipment usage, ventilation systems, and application procedures to minimize exposure risks.Expand Specific Solutions05 Environmental impact assessment of polyurethanes

Conducting comprehensive environmental impact assessments of polyurethane materials throughout their lifecycle. This includes evaluating production processes, use phase, and end-of-life disposal to identify and mitigate potential environmental and health risks associated with polyurethanes.Expand Specific Solutions

Key Industry Players

The evaluation of polyurethane safety in consumer products is at a mature stage, with a global market size expected to reach $79.2 billion by 2025. The industry is characterized by intense competition among key players like BASF, Covestro, and Dow Global Technologies. These companies are investing heavily in R&D to develop safer, more sustainable polyurethane formulations. The technology maturity varies across applications, with established safety protocols in furniture and automotive sectors, while emerging concerns in food packaging and medical devices drive ongoing research. Universities such as Sichuan University and South China University of Technology are contributing to advancements in polyurethane safety assessment methodologies, collaborating with industry leaders to address evolving regulatory requirements and consumer demands for safer materials.

BASF Corp.

Technical Solution: BASF Corp. has developed a comprehensive approach to evaluating polyurethane safety in consumer products. Their method involves advanced toxicological testing, including in vitro and in vivo studies, to assess potential health risks. They utilize state-of-the-art analytical techniques to identify and quantify any harmful substances that may leach from polyurethane materials. BASF also employs life cycle assessment tools to evaluate the environmental impact of their polyurethane products throughout their entire lifecycle, from production to disposal.

Strengths: Comprehensive testing methodology, advanced analytical capabilities, and a holistic approach to product safety. Weaknesses: Potentially time-consuming and costly evaluation process, which may slow down product development and market entry.

Covestro Deutschland AG

Technical Solution: Covestro Deutschland AG has implemented a multi-tiered safety evaluation system for polyurethane in consumer products. Their approach includes rigorous raw material screening, process safety assessments, and finished product testing. They utilize advanced polymer chemistry to develop safer alternatives to traditional polyurethane formulations, focusing on reducing or eliminating potentially harmful additives. Covestro also employs predictive toxicology models and high-throughput screening methods to rapidly assess the safety profile of new polyurethane formulations before they reach the consumer market.

Strengths: Innovative approach to safer polyurethane formulations, rapid screening capabilities. Weaknesses: May face challenges in balancing improved safety with maintaining desired material properties.

Core Safety Innovations

Polyurethane urea solutions

PatentInactiveUS7425516B2

Innovation

- The use of γ-butyrolactone as a solvent, either alone or in mixtures with other toxicologically acceptable solvents, in combination with macrodiols, diisocyanates, and chain extenders, to create stable polyurethaneurea solutions that do not require harmful solvents like toluene or dimethylformamide, ensuring high storage stability and maintaining coating properties.

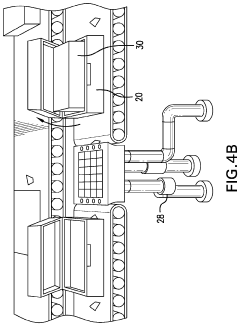

Self rising board molding

PatentActiveUS20220339888A1

Innovation

- A manufacturing process using compressed nonwoven materials as expandable substrates in a mold, allowing for the creation of three-dimensional objects with tailored properties by expanding the substrates to fill the mold shape, which can include laminating with other materials and using steam heating with vacuum pressure for uniform expansion and easier removal.

Regulatory Framework

The regulatory framework surrounding polyurethane safety in consumer products is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Consumer Product Safety Commission (CPSC) plays a pivotal role in overseeing the safety of polyurethane-containing products. The CPSC enforces regulations such as the Consumer Product Safety Act and the Federal Hazardous Substances Act, which set standards for chemical safety in consumer goods.

The Environmental Protection Agency (EPA) also contributes significantly to the regulatory landscape through the Toxic Substances Control Act (TSCA). This act empowers the EPA to require reporting, record-keeping, and testing of chemicals like those used in polyurethane production. The agency has the authority to restrict the manufacture and use of substances that pose unreasonable risks to human health or the environment.

On a global scale, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly influential. REACH requires manufacturers and importers to register chemicals and provide safety data, impacting polyurethane-containing products entering the EU market. This regulation has set a high standard for chemical safety that many other countries aspire to emulate.

In addition to these overarching regulations, specific standards exist for different product categories. For instance, polyurethane foam used in furniture and bedding must comply with flammability standards set by organizations like the National Fire Protection Association (NFPA) in the US. These standards aim to reduce fire hazards associated with polyurethane-containing products.

The food contact materials sector is subject to stringent regulations when polyurethane is used. The US Food and Drug Administration (FDA) regulates food contact substances through the Food Contact Notification Program, ensuring that materials like polyurethane used in food packaging or processing equipment do not pose health risks.

Occupational safety is another crucial aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) in the US sets exposure limits for isocyanates, key components in polyurethane production, to protect workers in manufacturing environments.

As awareness of environmental and health impacts grows, regulations are evolving to address emerging concerns. For example, some jurisdictions are implementing restrictions on certain flame retardants commonly used in polyurethane foam, due to potential health risks. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from manufacturers and importers of polyurethane-containing consumer products.

The Environmental Protection Agency (EPA) also contributes significantly to the regulatory landscape through the Toxic Substances Control Act (TSCA). This act empowers the EPA to require reporting, record-keeping, and testing of chemicals like those used in polyurethane production. The agency has the authority to restrict the manufacture and use of substances that pose unreasonable risks to human health or the environment.

On a global scale, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is particularly influential. REACH requires manufacturers and importers to register chemicals and provide safety data, impacting polyurethane-containing products entering the EU market. This regulation has set a high standard for chemical safety that many other countries aspire to emulate.

In addition to these overarching regulations, specific standards exist for different product categories. For instance, polyurethane foam used in furniture and bedding must comply with flammability standards set by organizations like the National Fire Protection Association (NFPA) in the US. These standards aim to reduce fire hazards associated with polyurethane-containing products.

The food contact materials sector is subject to stringent regulations when polyurethane is used. The US Food and Drug Administration (FDA) regulates food contact substances through the Food Contact Notification Program, ensuring that materials like polyurethane used in food packaging or processing equipment do not pose health risks.

Occupational safety is another crucial aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) in the US sets exposure limits for isocyanates, key components in polyurethane production, to protect workers in manufacturing environments.

As awareness of environmental and health impacts grows, regulations are evolving to address emerging concerns. For example, some jurisdictions are implementing restrictions on certain flame retardants commonly used in polyurethane foam, due to potential health risks. This dynamic regulatory environment necessitates ongoing vigilance and adaptation from manufacturers and importers of polyurethane-containing consumer products.

Environmental Impact

Polyurethane, a versatile synthetic polymer, has become ubiquitous in consumer products due to its durability and flexibility. However, its environmental impact throughout its lifecycle raises significant concerns. The production of polyurethane involves the use of isocyanates and polyols, both derived from petrochemicals. This reliance on fossil fuels contributes to carbon emissions and resource depletion, exacerbating climate change and environmental degradation.

During the manufacturing process, volatile organic compounds (VOCs) are released, potentially harming air quality and posing health risks to workers and nearby communities. Additionally, the production of polyurethane foam often involves the use of blowing agents, some of which have been linked to ozone depletion. While regulations have phased out the most harmful substances, alternatives may still have environmental consequences that require further study.

The disposal of polyurethane products presents another environmental challenge. Polyurethane is not biodegradable and can persist in landfills for centuries. Incineration, an alternative disposal method, releases toxic fumes and greenhouse gases. Recycling polyurethane is technically possible but economically challenging, leading to low recycling rates and increased waste accumulation.

Microplastic pollution is an emerging concern associated with polyurethane products. As these items degrade over time, they can shed microscopic particles that enter waterways and ecosystems. These microplastics can be ingested by marine life, potentially entering the food chain and impacting biodiversity.

The environmental footprint of polyurethane extends to its use phase as well. Some polyurethane products, particularly those used in furniture and bedding, may off-gas chemicals over time, contributing to indoor air pollution. This can have implications for human health and the broader environment, as these chemicals eventually make their way into the atmosphere.

Efforts to mitigate the environmental impact of polyurethane are ongoing. Research into bio-based polyurethanes, derived from renewable resources such as plant oils, shows promise in reducing the reliance on petrochemicals. Improved manufacturing processes aim to minimize emissions and energy consumption. Additionally, advancements in recycling technologies offer hope for more efficient end-of-life management of polyurethane products.

As consumer awareness grows, there is increasing pressure on manufacturers to adopt more sustainable practices and develop environmentally friendly alternatives. Balancing the beneficial properties of polyurethane with its environmental impact remains a critical challenge for the industry, requiring ongoing innovation and regulatory oversight to ensure the safety of both consumers and the planet.

During the manufacturing process, volatile organic compounds (VOCs) are released, potentially harming air quality and posing health risks to workers and nearby communities. Additionally, the production of polyurethane foam often involves the use of blowing agents, some of which have been linked to ozone depletion. While regulations have phased out the most harmful substances, alternatives may still have environmental consequences that require further study.

The disposal of polyurethane products presents another environmental challenge. Polyurethane is not biodegradable and can persist in landfills for centuries. Incineration, an alternative disposal method, releases toxic fumes and greenhouse gases. Recycling polyurethane is technically possible but economically challenging, leading to low recycling rates and increased waste accumulation.

Microplastic pollution is an emerging concern associated with polyurethane products. As these items degrade over time, they can shed microscopic particles that enter waterways and ecosystems. These microplastics can be ingested by marine life, potentially entering the food chain and impacting biodiversity.

The environmental footprint of polyurethane extends to its use phase as well. Some polyurethane products, particularly those used in furniture and bedding, may off-gas chemicals over time, contributing to indoor air pollution. This can have implications for human health and the broader environment, as these chemicals eventually make their way into the atmosphere.

Efforts to mitigate the environmental impact of polyurethane are ongoing. Research into bio-based polyurethanes, derived from renewable resources such as plant oils, shows promise in reducing the reliance on petrochemicals. Improved manufacturing processes aim to minimize emissions and energy consumption. Additionally, advancements in recycling technologies offer hope for more efficient end-of-life management of polyurethane products.

As consumer awareness grows, there is increasing pressure on manufacturers to adopt more sustainable practices and develop environmentally friendly alternatives. Balancing the beneficial properties of polyurethane with its environmental impact remains a critical challenge for the industry, requiring ongoing innovation and regulatory oversight to ensure the safety of both consumers and the planet.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!