How integration of robotics enhances PHEV assembly

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Robotics Integration Background and Objectives

The integration of robotics in Plug-in Hybrid Electric Vehicle (PHEV) assembly represents a significant technological advancement in the automotive industry. This convergence of robotics and hybrid vehicle production has evolved over the past decade, driven by the increasing demand for more efficient and environmentally friendly transportation solutions. The primary objective of this integration is to enhance the assembly process of PHEVs, improving production efficiency, quality, and consistency while reducing costs and environmental impact.

The development of PHEV technology itself has been a response to the growing need for vehicles that combine the benefits of both electric and conventional combustion engines. As the automotive industry faced pressure to reduce emissions and improve fuel efficiency, PHEVs emerged as a transitional technology between traditional vehicles and fully electric ones. The integration of robotics in PHEV assembly is a natural progression in this technological evolution, aiming to address the complexities associated with producing these hybrid vehicles at scale.

Robotics in automotive manufacturing has a rich history dating back to the 1960s when the first industrial robots were introduced in car factories. However, the specific application of robotics in PHEV assembly presents unique challenges and opportunities. The goal is to leverage advanced robotics capabilities to handle the intricate components of hybrid powertrains, such as battery packs, electric motors, and complex wiring systems, with precision and reliability that surpass human capabilities.

The objectives of integrating robotics in PHEV assembly are multifaceted. Firstly, it aims to increase production speed and throughput, allowing manufacturers to meet the growing demand for hybrid vehicles more efficiently. Secondly, it seeks to improve the consistency and quality of assembly, reducing errors and defects that can be costly and potentially dangerous in complex hybrid systems. Thirdly, the integration aims to enhance workplace safety by automating hazardous tasks and reducing the risk of injury to human workers.

Furthermore, the use of robotics in PHEV assembly aligns with the broader industry trends of Industry 4.0 and smart manufacturing. By incorporating advanced sensors, machine learning, and data analytics, robotic systems can not only perform assembly tasks but also collect and analyze data to optimize the production process continuously. This data-driven approach enables predictive maintenance, real-time quality control, and adaptive manufacturing strategies that can respond to changes in demand or supply chain disruptions.

As we explore the integration of robotics in PHEV assembly, it is essential to consider the technological challenges, market dynamics, and potential future developments that will shape this field. The ongoing evolution of both PHEV technology and robotics capabilities promises to drive further innovations in automotive manufacturing, potentially revolutionizing how we produce the next generation of environmentally friendly vehicles.

The development of PHEV technology itself has been a response to the growing need for vehicles that combine the benefits of both electric and conventional combustion engines. As the automotive industry faced pressure to reduce emissions and improve fuel efficiency, PHEVs emerged as a transitional technology between traditional vehicles and fully electric ones. The integration of robotics in PHEV assembly is a natural progression in this technological evolution, aiming to address the complexities associated with producing these hybrid vehicles at scale.

Robotics in automotive manufacturing has a rich history dating back to the 1960s when the first industrial robots were introduced in car factories. However, the specific application of robotics in PHEV assembly presents unique challenges and opportunities. The goal is to leverage advanced robotics capabilities to handle the intricate components of hybrid powertrains, such as battery packs, electric motors, and complex wiring systems, with precision and reliability that surpass human capabilities.

The objectives of integrating robotics in PHEV assembly are multifaceted. Firstly, it aims to increase production speed and throughput, allowing manufacturers to meet the growing demand for hybrid vehicles more efficiently. Secondly, it seeks to improve the consistency and quality of assembly, reducing errors and defects that can be costly and potentially dangerous in complex hybrid systems. Thirdly, the integration aims to enhance workplace safety by automating hazardous tasks and reducing the risk of injury to human workers.

Furthermore, the use of robotics in PHEV assembly aligns with the broader industry trends of Industry 4.0 and smart manufacturing. By incorporating advanced sensors, machine learning, and data analytics, robotic systems can not only perform assembly tasks but also collect and analyze data to optimize the production process continuously. This data-driven approach enables predictive maintenance, real-time quality control, and adaptive manufacturing strategies that can respond to changes in demand or supply chain disruptions.

As we explore the integration of robotics in PHEV assembly, it is essential to consider the technological challenges, market dynamics, and potential future developments that will shape this field. The ongoing evolution of both PHEV technology and robotics capabilities promises to drive further innovations in automotive manufacturing, potentially revolutionizing how we produce the next generation of environmentally friendly vehicles.

Market Analysis for Robotics in PHEV Manufacturing

The integration of robotics in Plug-in Hybrid Electric Vehicle (PHEV) manufacturing has significantly transformed the automotive industry, creating a robust market for advanced robotic solutions. This market is characterized by rapid growth and increasing demand, driven by the automotive sector's push towards electrification and the need for more efficient, precise, and flexible production processes.

The global market for robotics in PHEV manufacturing is experiencing substantial expansion, with a compound annual growth rate (CAGR) projected to remain in double digits over the next five years. This growth is fueled by several factors, including the rising demand for PHEVs, stringent quality control requirements, and the need for increased production efficiency to meet consumer expectations.

Key market segments within this sector include assembly line robots, material handling robots, welding robots, and inspection robots. Among these, assembly line robots hold the largest market share due to their critical role in streamlining the complex PHEV production process. Material handling robots are also seeing significant growth, as they enhance logistics efficiency and reduce human intervention in potentially hazardous tasks.

Geographically, Asia-Pacific dominates the market, with China and Japan leading in both production and adoption of robotics for PHEV manufacturing. This is largely due to the region's strong automotive industry and government initiatives supporting electric vehicle production. North America and Europe follow closely, with increasing investments in automation and Industry 4.0 technologies driving market growth.

The market is characterized by intense competition among major players such as ABB, FANUC, KUKA, and Yaskawa Electric. These companies are continuously innovating to provide more advanced, AI-integrated robotic solutions that can adapt to the unique challenges of PHEV assembly. Collaborative robots, or cobots, are emerging as a significant trend, allowing for human-robot collaboration in complex assembly tasks.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for skilled personnel to operate and maintain advanced robotic systems. However, these challenges are offset by the long-term benefits of increased productivity, improved quality, and reduced labor costs.

Looking ahead, the market for robotics in PHEV manufacturing is expected to continue its upward trajectory. Factors such as the increasing adoption of electric vehicles, advancements in AI and machine learning, and the push towards smart factories will likely drive further innovation and market expansion in this sector.

The global market for robotics in PHEV manufacturing is experiencing substantial expansion, with a compound annual growth rate (CAGR) projected to remain in double digits over the next five years. This growth is fueled by several factors, including the rising demand for PHEVs, stringent quality control requirements, and the need for increased production efficiency to meet consumer expectations.

Key market segments within this sector include assembly line robots, material handling robots, welding robots, and inspection robots. Among these, assembly line robots hold the largest market share due to their critical role in streamlining the complex PHEV production process. Material handling robots are also seeing significant growth, as they enhance logistics efficiency and reduce human intervention in potentially hazardous tasks.

Geographically, Asia-Pacific dominates the market, with China and Japan leading in both production and adoption of robotics for PHEV manufacturing. This is largely due to the region's strong automotive industry and government initiatives supporting electric vehicle production. North America and Europe follow closely, with increasing investments in automation and Industry 4.0 technologies driving market growth.

The market is characterized by intense competition among major players such as ABB, FANUC, KUKA, and Yaskawa Electric. These companies are continuously innovating to provide more advanced, AI-integrated robotic solutions that can adapt to the unique challenges of PHEV assembly. Collaborative robots, or cobots, are emerging as a significant trend, allowing for human-robot collaboration in complex assembly tasks.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for skilled personnel to operate and maintain advanced robotic systems. However, these challenges are offset by the long-term benefits of increased productivity, improved quality, and reduced labor costs.

Looking ahead, the market for robotics in PHEV manufacturing is expected to continue its upward trajectory. Factors such as the increasing adoption of electric vehicles, advancements in AI and machine learning, and the push towards smart factories will likely drive further innovation and market expansion in this sector.

Current Robotics Technologies in PHEV Assembly

The integration of robotics in PHEV (Plug-in Hybrid Electric Vehicle) assembly has revolutionized the automotive manufacturing process, enhancing efficiency, precision, and quality. Current robotics technologies employed in PHEV assembly encompass a wide range of applications, from material handling to complex assembly tasks.

One of the most prevalent robotic systems in PHEV assembly is the articulated robot arm. These versatile machines are capable of performing multiple tasks, such as welding, painting, and component installation. Advanced sensors and machine vision systems enable these robots to accurately position and manipulate parts, ensuring consistent quality across the production line.

Collaborative robots, or cobots, have gained significant traction in PHEV assembly. These robots are designed to work alongside human operators, combining the strength and precision of machines with the flexibility and problem-solving skills of humans. Cobots are particularly useful in tasks that require both dexterity and force, such as installing delicate electronic components or handling heavy battery packs.

Automated Guided Vehicles (AGVs) play a crucial role in material handling within PHEV assembly plants. These self-navigating vehicles transport components and subassemblies between workstations, optimizing logistics and reducing manual labor. Advanced AGVs utilize LIDAR and other sensors for obstacle detection and efficient path planning, ensuring smooth operations in dynamic factory environments.

Robotic vision systems have become indispensable in PHEV assembly, enabling precise quality control and inspection processes. High-resolution cameras and sophisticated image processing algorithms allow for real-time detection of defects, ensuring that only components meeting stringent quality standards proceed through the assembly line.

In the realm of battery assembly, specialized robotic systems have been developed to handle the unique challenges of PHEV power sources. These robots are designed to manipulate and assemble battery cells with extreme precision, often operating in controlled environments to maintain cleanliness and safety standards critical for battery production.

Additive manufacturing, or 3D printing, has also found its place in PHEV assembly, particularly for producing complex, lightweight components. Robotic systems equipped with 3D printing capabilities can fabricate custom parts on-demand, reducing inventory costs and enabling rapid prototyping of new designs.

The integration of artificial intelligence and machine learning has further enhanced the capabilities of robotic systems in PHEV assembly. These technologies enable robots to adapt to variations in the production process, optimize their movements for improved efficiency, and even predict maintenance needs to minimize downtime.

As PHEV technology continues to evolve, so too do the robotic systems used in their assembly. Current research focuses on developing more flexible and adaptable robotic solutions capable of quickly reconfiguring for different vehicle models or production requirements, ensuring that PHEV manufacturers can respond swiftly to changing market demands and technological advancements.

One of the most prevalent robotic systems in PHEV assembly is the articulated robot arm. These versatile machines are capable of performing multiple tasks, such as welding, painting, and component installation. Advanced sensors and machine vision systems enable these robots to accurately position and manipulate parts, ensuring consistent quality across the production line.

Collaborative robots, or cobots, have gained significant traction in PHEV assembly. These robots are designed to work alongside human operators, combining the strength and precision of machines with the flexibility and problem-solving skills of humans. Cobots are particularly useful in tasks that require both dexterity and force, such as installing delicate electronic components or handling heavy battery packs.

Automated Guided Vehicles (AGVs) play a crucial role in material handling within PHEV assembly plants. These self-navigating vehicles transport components and subassemblies between workstations, optimizing logistics and reducing manual labor. Advanced AGVs utilize LIDAR and other sensors for obstacle detection and efficient path planning, ensuring smooth operations in dynamic factory environments.

Robotic vision systems have become indispensable in PHEV assembly, enabling precise quality control and inspection processes. High-resolution cameras and sophisticated image processing algorithms allow for real-time detection of defects, ensuring that only components meeting stringent quality standards proceed through the assembly line.

In the realm of battery assembly, specialized robotic systems have been developed to handle the unique challenges of PHEV power sources. These robots are designed to manipulate and assemble battery cells with extreme precision, often operating in controlled environments to maintain cleanliness and safety standards critical for battery production.

Additive manufacturing, or 3D printing, has also found its place in PHEV assembly, particularly for producing complex, lightweight components. Robotic systems equipped with 3D printing capabilities can fabricate custom parts on-demand, reducing inventory costs and enabling rapid prototyping of new designs.

The integration of artificial intelligence and machine learning has further enhanced the capabilities of robotic systems in PHEV assembly. These technologies enable robots to adapt to variations in the production process, optimize their movements for improved efficiency, and even predict maintenance needs to minimize downtime.

As PHEV technology continues to evolve, so too do the robotic systems used in their assembly. Current research focuses on developing more flexible and adaptable robotic solutions capable of quickly reconfiguring for different vehicle models or production requirements, ensuring that PHEV manufacturers can respond swiftly to changing market demands and technological advancements.

Existing Robotic Solutions for PHEV Assembly

01 Advanced robotic control systems

Implementing sophisticated control systems in robotic assembly to enhance precision, speed, and adaptability. These systems may include advanced algorithms, machine learning, and real-time feedback mechanisms to optimize assembly processes and improve overall efficiency.- Advanced robotic control systems: Implementing sophisticated control systems in robotic assembly processes to enhance precision, speed, and adaptability. These systems may include advanced algorithms, machine learning, and real-time feedback mechanisms to optimize assembly operations and improve overall efficiency.

- Modular and flexible assembly systems: Developing modular and reconfigurable robotic assembly systems that can be easily adapted to different product lines or manufacturing requirements. This approach allows for greater flexibility in production, reduced downtime during changeovers, and improved scalability of assembly operations.

- Human-robot collaboration in assembly: Integrating collaborative robots (cobots) into assembly processes to work alongside human operators. This approach combines the strengths of both humans and robots, enhancing overall productivity, safety, and ergonomics in assembly tasks.

- Vision-guided assembly systems: Incorporating advanced vision systems and image processing techniques to guide robotic assembly operations. These systems enable robots to accurately identify, locate, and manipulate components, improving assembly precision and reducing errors.

- End-effector innovations for assembly: Developing specialized end-effectors and gripping mechanisms tailored for specific assembly tasks. These innovations may include multi-functional tools, adaptive grippers, or smart end-effectors with integrated sensors to enhance the robot's ability to handle diverse components and perform complex assembly operations.

02 Collaborative robotics in assembly

Integrating collaborative robots (cobots) into assembly lines to work alongside human operators. This approach combines the strengths of both robots and humans, improving flexibility, safety, and productivity in complex assembly tasks.Expand Specific Solutions03 Vision-guided assembly systems

Incorporating advanced vision systems and image processing technologies to guide robotic assembly operations. These systems enable robots to accurately identify, locate, and manipulate components, enhancing assembly precision and reducing errors.Expand Specific Solutions04 Modular and reconfigurable assembly systems

Developing flexible, modular robotic assembly systems that can be easily reconfigured for different products or production volumes. This approach improves adaptability to changing market demands and reduces downtime during product changeovers.Expand Specific Solutions05 AI-powered assembly optimization

Leveraging artificial intelligence and machine learning algorithms to continuously optimize robotic assembly processes. These systems can analyze data from multiple sources to identify inefficiencies, predict maintenance needs, and suggest improvements in real-time.Expand Specific Solutions

Key Players in PHEV Robotics Integration

The integration of robotics in PHEV assembly is in a growth phase, with the market expanding rapidly due to increasing demand for efficient and sustainable automotive production. The technology is maturing, but still evolving, with varying levels of implementation across manufacturers. Companies like Ford, Hyundai, and Volkswagen are at the forefront, leveraging advanced robotics to enhance assembly line efficiency and precision. Emerging players such as Fruitcore Robotics and ROBOTIS are introducing innovative solutions, while established industrial robotics firms like ABB and KUKA are adapting their technologies for PHEV-specific applications. The competitive landscape is dynamic, with automakers and robotics specialists collaborating to optimize PHEV production processes.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced robotic system for PHEV assembly that integrates collaborative robots (cobots) with human workers. This system utilizes vision-guided robots for precise component placement and assembly tasks. Ford's approach includes a flexible manufacturing line with modular stations that can be easily reconfigured for different PHEV models. The company has implemented AI-powered quality control systems that use machine learning algorithms to detect defects in real-time during the assembly process[1]. Additionally, Ford has introduced exoskeleton technology to assist workers in ergonomically challenging tasks, reducing fatigue and improving efficiency[2].

Strengths: Improved precision and consistency in assembly, increased production flexibility, enhanced worker safety and ergonomics. Weaknesses: High initial investment costs, potential complexity in system integration and maintenance.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely has implemented an innovative robotic system for PHEV assembly that focuses on adaptability and efficiency. Their approach includes the use of modular robotic cells that can be quickly reconfigured to accommodate different PHEV models. Geely's system incorporates advanced machine learning algorithms for optimizing robot movements and reducing cycle times. The company has also developed a unique human-robot collaboration system that uses gesture recognition and augmented reality to enhance communication between workers and robots[9]. Additionally, Geely has implemented an AI-powered quality control system that uses computer vision to detect defects in real-time during the assembly process, significantly reducing error rates and improving overall product quality[10].

Strengths: Highly adaptable and reconfigurable system, innovative human-robot collaboration techniques, advanced AI-powered quality control. Weaknesses: Potentially higher initial costs, may require significant training for workers to adapt to new technologies.

Innovative Robotics Technologies for PHEVs

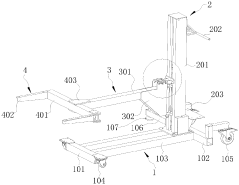

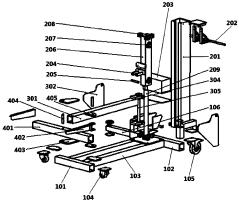

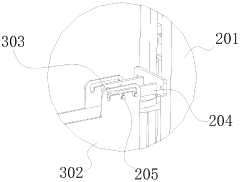

PHEV power battery disassembling and assembling machine

PatentActiveCN109774672A

Innovation

- A PHEV power battery disassembly and assembly machine is designed, including a base component, a vertical slide rail component, a swing arm component and a power battery clamp. The stable lifting and movement of the power battery is achieved through a hydraulic cylinder and a remote control pneumatic hydraulic pump. It is equipped with a positioning flipper. The plate and universal ball ensure precise positioning, and the clamp can adjust the clamping angle and opening size to accommodate different types of batteries.

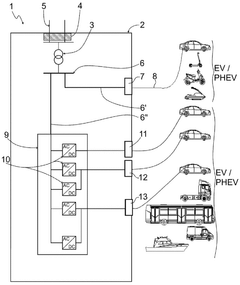

Integrated prefabricated power charging system for electric vehicles and plug-in hybrid vehicles connected directly to medium voltage electrical network and a method for changing an electric or hybrid vehicle

PatentWO2025017353A1

Innovation

- An integrated prefabricated power charging system connected directly to a medium voltage electrical network, which includes a transformer to convert medium voltage AC to low voltage AC, and AC/DC converters to provide charging options for various vehicles, allowing for simultaneous charging of multiple vehicles at high speeds.

Environmental Impact of Robotics in PHEV Production

The integration of robotics in PHEV (Plug-in Hybrid Electric Vehicle) assembly has significant environmental implications, both positive and negative. On the positive side, robotic systems can greatly enhance the precision and efficiency of manufacturing processes, leading to reduced material waste and improved energy efficiency. This increased efficiency translates to lower resource consumption and reduced environmental impact per vehicle produced.

Robotics also enables more consistent quality control, which can lead to longer-lasting vehicles with fewer defects. This, in turn, reduces the need for replacements and repairs, thereby decreasing the overall environmental footprint of PHEVs throughout their lifecycle. Additionally, robots can handle hazardous materials more safely than human workers, reducing the risk of environmental contamination from spills or accidents.

However, the environmental impact of robotics in PHEV production is not entirely positive. The manufacturing of robots themselves requires significant resources and energy, potentially offsetting some of the environmental gains in the short term. The increased automation may also lead to higher energy consumption in factories, particularly if not managed efficiently.

Another consideration is the potential for increased production capacity enabled by robotics. While this can lead to economies of scale and potentially lower costs for PHEVs, it may also result in increased overall production and consumption of vehicles, which could have negative environmental consequences if not balanced with proper end-of-life vehicle management and recycling programs.

The use of robotics in PHEV assembly also presents opportunities for more advanced recycling and remanufacturing processes. Robots can be programmed to disassemble vehicles more efficiently and accurately, facilitating better sorting and recovery of materials. This can significantly improve the circularity of the automotive industry, reducing the need for virgin materials and minimizing waste.

Furthermore, the precision of robotic assembly can contribute to the production of more energy-efficient PHEVs. Tighter tolerances and more accurate assembly of components like batteries, electric motors, and power electronics can lead to improved vehicle performance and energy efficiency, reducing the environmental impact during the use phase of the vehicle's life cycle.

In conclusion, while the integration of robotics in PHEV assembly offers substantial environmental benefits through increased efficiency and precision, it also presents challenges that need to be carefully managed to ensure a net positive environmental impact. The key lies in balancing the benefits of automation with responsible resource management and sustainable manufacturing practices.

Robotics also enables more consistent quality control, which can lead to longer-lasting vehicles with fewer defects. This, in turn, reduces the need for replacements and repairs, thereby decreasing the overall environmental footprint of PHEVs throughout their lifecycle. Additionally, robots can handle hazardous materials more safely than human workers, reducing the risk of environmental contamination from spills or accidents.

However, the environmental impact of robotics in PHEV production is not entirely positive. The manufacturing of robots themselves requires significant resources and energy, potentially offsetting some of the environmental gains in the short term. The increased automation may also lead to higher energy consumption in factories, particularly if not managed efficiently.

Another consideration is the potential for increased production capacity enabled by robotics. While this can lead to economies of scale and potentially lower costs for PHEVs, it may also result in increased overall production and consumption of vehicles, which could have negative environmental consequences if not balanced with proper end-of-life vehicle management and recycling programs.

The use of robotics in PHEV assembly also presents opportunities for more advanced recycling and remanufacturing processes. Robots can be programmed to disassemble vehicles more efficiently and accurately, facilitating better sorting and recovery of materials. This can significantly improve the circularity of the automotive industry, reducing the need for virgin materials and minimizing waste.

Furthermore, the precision of robotic assembly can contribute to the production of more energy-efficient PHEVs. Tighter tolerances and more accurate assembly of components like batteries, electric motors, and power electronics can lead to improved vehicle performance and energy efficiency, reducing the environmental impact during the use phase of the vehicle's life cycle.

In conclusion, while the integration of robotics in PHEV assembly offers substantial environmental benefits through increased efficiency and precision, it also presents challenges that need to be carefully managed to ensure a net positive environmental impact. The key lies in balancing the benefits of automation with responsible resource management and sustainable manufacturing practices.

Cost-Benefit Analysis of Robotic PHEV Assembly

The integration of robotics in PHEV assembly processes presents a compelling case for cost-benefit analysis. Initial investment in robotic systems for PHEV production lines can be substantial, often ranging from $500,000 to $2 million per robot, depending on complexity and functionality. However, these upfront costs are typically offset by long-term savings and efficiency gains.

Labor cost reduction is a primary benefit of robotic integration. Automated assembly lines can operate 24/7 with minimal human intervention, potentially reducing labor costs by 40-60% over traditional assembly methods. This is particularly significant in high-wage regions where labor expenses constitute a major portion of production costs.

Quality improvements and consistency in production are additional advantages. Robots can perform repetitive tasks with high precision, reducing error rates by up to 80% compared to manual assembly. This leads to fewer defects, less waste, and lower warranty claim costs, which can result in savings of 2-5% of total production costs annually.

Increased production speed and throughput are notable benefits of robotic PHEV assembly. Automated lines can achieve cycle time reductions of 30-50%, significantly boosting overall production capacity. This allows manufacturers to meet growing demand for PHEVs without proportional increases in facility size or workforce.

Energy efficiency is another area where robotic assembly excels. Modern robotic systems consume 25-30% less energy than traditional production lines, contributing to both cost savings and environmental sustainability goals. This aligns well with the eco-friendly image of PHEV production.

Workplace safety improvements are a crucial, often overlooked benefit. Robotic systems can handle hazardous tasks, reducing workplace injuries by up to 50%. This leads to lower insurance premiums and workers' compensation costs, as well as improved employee morale and retention.

The flexibility of robotic systems allows for rapid retooling and adaptation to new PHEV models or design changes. This agility can reduce time-to-market for new products by 20-30%, providing a competitive edge in the fast-evolving automotive market.

While the benefits are substantial, it's important to consider ongoing costs such as maintenance, software updates, and specialized training for operators. These typically amount to 10-15% of the initial investment annually but are essential for maintaining optimal performance and longevity of the robotic systems.

Labor cost reduction is a primary benefit of robotic integration. Automated assembly lines can operate 24/7 with minimal human intervention, potentially reducing labor costs by 40-60% over traditional assembly methods. This is particularly significant in high-wage regions where labor expenses constitute a major portion of production costs.

Quality improvements and consistency in production are additional advantages. Robots can perform repetitive tasks with high precision, reducing error rates by up to 80% compared to manual assembly. This leads to fewer defects, less waste, and lower warranty claim costs, which can result in savings of 2-5% of total production costs annually.

Increased production speed and throughput are notable benefits of robotic PHEV assembly. Automated lines can achieve cycle time reductions of 30-50%, significantly boosting overall production capacity. This allows manufacturers to meet growing demand for PHEVs without proportional increases in facility size or workforce.

Energy efficiency is another area where robotic assembly excels. Modern robotic systems consume 25-30% less energy than traditional production lines, contributing to both cost savings and environmental sustainability goals. This aligns well with the eco-friendly image of PHEV production.

Workplace safety improvements are a crucial, often overlooked benefit. Robotic systems can handle hazardous tasks, reducing workplace injuries by up to 50%. This leads to lower insurance premiums and workers' compensation costs, as well as improved employee morale and retention.

The flexibility of robotic systems allows for rapid retooling and adaptation to new PHEV models or design changes. This agility can reduce time-to-market for new products by 20-30%, providing a competitive edge in the fast-evolving automotive market.

While the benefits are substantial, it's important to consider ongoing costs such as maintenance, software updates, and specialized training for operators. These typically amount to 10-15% of the initial investment annually but are essential for maintaining optimal performance and longevity of the robotic systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!