How Isopentane Loads Affect Cellular Material Fire Resistance

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane and Fire Safety: Background and Objectives

Isopentane, a highly volatile hydrocarbon, has become increasingly prevalent in various industrial applications, particularly in the production of cellular materials. However, its flammable nature poses significant fire safety concerns, necessitating a comprehensive understanding of how isopentane loads impact the fire resistance of cellular materials. This technical research report aims to explore the historical development of isopentane usage, examine the evolving trends in fire safety technologies, and establish clear objectives for enhancing the fire resistance of isopentane-loaded cellular materials.

The use of isopentane in cellular materials can be traced back to the mid-20th century when it was first introduced as a blowing agent in the production of expanded polystyrene (EPS) and extruded polystyrene (XPS) foams. Its low boiling point and excellent expansion properties made it an ideal candidate for creating lightweight, insulating materials. However, the inherent fire risks associated with isopentane quickly became apparent, prompting the development of fire safety measures and regulations.

Over the past few decades, the cellular material industry has witnessed a continuous evolution in fire safety technologies. Early approaches focused primarily on the addition of flame retardants to the base polymer. These additives, while effective in reducing flame spread, often compromised the material's physical properties and raised environmental concerns. Subsequently, research shifted towards developing more sustainable and efficient fire-resistant solutions, including intumescent coatings, nanocomposites, and advanced polymer formulations.

The technological progression in this field has been driven by increasingly stringent fire safety regulations and a growing awareness of the importance of fire-resistant building materials. Notable milestones include the introduction of fire-resistant EPS in the 1980s, the development of halogen-free flame retardants in the 1990s, and the recent advancements in smart, reactive fire protection systems.

Current trends in isopentane-related fire safety research focus on understanding the complex interactions between isopentane loads and the cellular structure of materials. This includes investigating how varying concentrations of isopentane affect the ignition properties, flame spread rates, and smoke production of cellular materials. Additionally, there is a growing interest in developing predictive models that can accurately simulate the behavior of isopentane-loaded materials under fire conditions.

The primary objective of this technical research is to comprehensively analyze the relationship between isopentane loads and the fire resistance of cellular materials. This involves quantifying the impact of different isopentane concentrations on key fire performance indicators, such as time to ignition, heat release rate, and flame spread index. Furthermore, the research aims to identify innovative strategies for enhancing fire resistance without compromising the beneficial properties of isopentane as a blowing agent.

Another crucial goal is to develop advanced testing methodologies that can accurately assess the fire performance of isopentane-loaded cellular materials under realistic conditions. This includes simulating various fire scenarios and evaluating the effectiveness of different fire protection strategies. Ultimately, the research seeks to establish guidelines for optimizing isopentane usage in cellular materials, balancing fire safety requirements with material performance and environmental considerations.

The use of isopentane in cellular materials can be traced back to the mid-20th century when it was first introduced as a blowing agent in the production of expanded polystyrene (EPS) and extruded polystyrene (XPS) foams. Its low boiling point and excellent expansion properties made it an ideal candidate for creating lightweight, insulating materials. However, the inherent fire risks associated with isopentane quickly became apparent, prompting the development of fire safety measures and regulations.

Over the past few decades, the cellular material industry has witnessed a continuous evolution in fire safety technologies. Early approaches focused primarily on the addition of flame retardants to the base polymer. These additives, while effective in reducing flame spread, often compromised the material's physical properties and raised environmental concerns. Subsequently, research shifted towards developing more sustainable and efficient fire-resistant solutions, including intumescent coatings, nanocomposites, and advanced polymer formulations.

The technological progression in this field has been driven by increasingly stringent fire safety regulations and a growing awareness of the importance of fire-resistant building materials. Notable milestones include the introduction of fire-resistant EPS in the 1980s, the development of halogen-free flame retardants in the 1990s, and the recent advancements in smart, reactive fire protection systems.

Current trends in isopentane-related fire safety research focus on understanding the complex interactions between isopentane loads and the cellular structure of materials. This includes investigating how varying concentrations of isopentane affect the ignition properties, flame spread rates, and smoke production of cellular materials. Additionally, there is a growing interest in developing predictive models that can accurately simulate the behavior of isopentane-loaded materials under fire conditions.

The primary objective of this technical research is to comprehensively analyze the relationship between isopentane loads and the fire resistance of cellular materials. This involves quantifying the impact of different isopentane concentrations on key fire performance indicators, such as time to ignition, heat release rate, and flame spread index. Furthermore, the research aims to identify innovative strategies for enhancing fire resistance without compromising the beneficial properties of isopentane as a blowing agent.

Another crucial goal is to develop advanced testing methodologies that can accurately assess the fire performance of isopentane-loaded cellular materials under realistic conditions. This includes simulating various fire scenarios and evaluating the effectiveness of different fire protection strategies. Ultimately, the research seeks to establish guidelines for optimizing isopentane usage in cellular materials, balancing fire safety requirements with material performance and environmental considerations.

Market Analysis: Flame-Retardant Cellular Materials

The market for flame-retardant cellular materials has experienced significant growth in recent years, driven by increasing safety regulations and a growing awareness of fire safety across various industries. The global flame retardant market size was valued at USD 7.4 billion in 2020 and is projected to reach USD 10.6 billion by 2025, with a compound annual growth rate (CAGR) of 7.5% during the forecast period.

The construction industry remains the largest consumer of flame-retardant cellular materials, accounting for approximately 30% of the market share. This is primarily due to stringent building codes and regulations aimed at improving fire safety in residential and commercial structures. The automotive sector follows closely, with a market share of around 25%, as manufacturers seek to enhance passenger safety and comply with vehicle safety standards.

In terms of regional distribution, North America and Europe dominate the flame-retardant cellular materials market, collectively accounting for over 60% of the global market share. This is attributed to strict fire safety regulations and the presence of major manufacturers in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing safety awareness in countries like China and India.

The market is characterized by intense competition among key players, including BASF SE, Dow Chemical Company, and Huntsman Corporation. These companies are investing heavily in research and development to innovate new flame-retardant solutions that are not only effective but also environmentally friendly. This trend is partly driven by growing concerns over the environmental impact of traditional halogenated flame retardants.

A notable shift in the market is the increasing demand for bio-based and sustainable flame-retardant solutions. This trend is driven by both consumer preferences and regulatory pressures to reduce the use of potentially harmful chemicals. As a result, manufacturers are exploring natural and renewable sources for flame-retardant additives, which is expected to create new opportunities in the market.

The impact of isopentane loads on cellular material fire resistance is becoming a crucial factor in market dynamics. As isopentane is commonly used as a blowing agent in the production of cellular materials, understanding its effect on fire resistance is vital for manufacturers to meet safety standards and consumer expectations. This has led to increased research and development efforts focused on optimizing the balance between material performance and fire safety.

The construction industry remains the largest consumer of flame-retardant cellular materials, accounting for approximately 30% of the market share. This is primarily due to stringent building codes and regulations aimed at improving fire safety in residential and commercial structures. The automotive sector follows closely, with a market share of around 25%, as manufacturers seek to enhance passenger safety and comply with vehicle safety standards.

In terms of regional distribution, North America and Europe dominate the flame-retardant cellular materials market, collectively accounting for over 60% of the global market share. This is attributed to strict fire safety regulations and the presence of major manufacturers in these regions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing safety awareness in countries like China and India.

The market is characterized by intense competition among key players, including BASF SE, Dow Chemical Company, and Huntsman Corporation. These companies are investing heavily in research and development to innovate new flame-retardant solutions that are not only effective but also environmentally friendly. This trend is partly driven by growing concerns over the environmental impact of traditional halogenated flame retardants.

A notable shift in the market is the increasing demand for bio-based and sustainable flame-retardant solutions. This trend is driven by both consumer preferences and regulatory pressures to reduce the use of potentially harmful chemicals. As a result, manufacturers are exploring natural and renewable sources for flame-retardant additives, which is expected to create new opportunities in the market.

The impact of isopentane loads on cellular material fire resistance is becoming a crucial factor in market dynamics. As isopentane is commonly used as a blowing agent in the production of cellular materials, understanding its effect on fire resistance is vital for manufacturers to meet safety standards and consumer expectations. This has led to increased research and development efforts focused on optimizing the balance between material performance and fire safety.

Current Challenges in Isopentane-Loaded Material Fire Resistance

The fire resistance of isopentane-loaded cellular materials presents several significant challenges in current research and industrial applications. One of the primary concerns is the inherent flammability of isopentane, which serves as a blowing agent in the production of cellular materials such as expanded polystyrene (EPS) and extruded polystyrene (XPS). The presence of isopentane within the cellular structure can significantly increase the fire risk and reduce the overall fire resistance of the material.

A major challenge lies in maintaining the desired thermal insulation properties of the cellular material while simultaneously improving its fire resistance. The cellular structure that provides excellent insulation also traps isopentane, creating potential fuel pockets that can rapidly spread fire once ignited. This contradiction between insulation performance and fire safety poses a complex problem for material scientists and engineers.

Another critical issue is the variability in isopentane load across different batches of cellular materials. Inconsistencies in manufacturing processes can lead to uneven distribution of isopentane within the material, resulting in unpredictable fire behavior. This variability makes it difficult to establish standardized fire resistance ratings and complicates the development of effective fire safety strategies.

The release of toxic fumes during combustion of isopentane-loaded materials is an additional concern. When exposed to fire, these materials can emit harmful gases, posing severe health risks to occupants and firefighters. Developing solutions that address both fire resistance and toxicity reduction is a multifaceted challenge that requires innovative approaches.

Furthermore, the interaction between isopentane and fire retardants presents another layer of complexity. Traditional fire retardants may not be as effective in materials with high isopentane loads, necessitating the development of new, compatible fire-retardant systems. This challenge is compounded by the need to maintain other material properties such as mechanical strength and durability while incorporating these new fire-resistant solutions.

Environmental concerns also play a role in the challenges faced by researchers and manufacturers. As regulations on volatile organic compounds (VOCs) and greenhouse gases become more stringent, there is increasing pressure to reduce or eliminate the use of isopentane in cellular materials. However, finding alternative blowing agents that offer similar performance without compromising fire resistance or other material properties remains a significant hurdle.

Lastly, the cost-effectiveness of implementing advanced fire resistance solutions in isopentane-loaded materials is a persistent challenge. Balancing the need for improved fire safety with economic viability is crucial for widespread adoption in construction and other industries. This economic factor often limits the implementation of more effective but expensive fire resistance technologies, particularly in price-sensitive markets.

A major challenge lies in maintaining the desired thermal insulation properties of the cellular material while simultaneously improving its fire resistance. The cellular structure that provides excellent insulation also traps isopentane, creating potential fuel pockets that can rapidly spread fire once ignited. This contradiction between insulation performance and fire safety poses a complex problem for material scientists and engineers.

Another critical issue is the variability in isopentane load across different batches of cellular materials. Inconsistencies in manufacturing processes can lead to uneven distribution of isopentane within the material, resulting in unpredictable fire behavior. This variability makes it difficult to establish standardized fire resistance ratings and complicates the development of effective fire safety strategies.

The release of toxic fumes during combustion of isopentane-loaded materials is an additional concern. When exposed to fire, these materials can emit harmful gases, posing severe health risks to occupants and firefighters. Developing solutions that address both fire resistance and toxicity reduction is a multifaceted challenge that requires innovative approaches.

Furthermore, the interaction between isopentane and fire retardants presents another layer of complexity. Traditional fire retardants may not be as effective in materials with high isopentane loads, necessitating the development of new, compatible fire-retardant systems. This challenge is compounded by the need to maintain other material properties such as mechanical strength and durability while incorporating these new fire-resistant solutions.

Environmental concerns also play a role in the challenges faced by researchers and manufacturers. As regulations on volatile organic compounds (VOCs) and greenhouse gases become more stringent, there is increasing pressure to reduce or eliminate the use of isopentane in cellular materials. However, finding alternative blowing agents that offer similar performance without compromising fire resistance or other material properties remains a significant hurdle.

Lastly, the cost-effectiveness of implementing advanced fire resistance solutions in isopentane-loaded materials is a persistent challenge. Balancing the need for improved fire safety with economic viability is crucial for widespread adoption in construction and other industries. This economic factor often limits the implementation of more effective but expensive fire resistance technologies, particularly in price-sensitive markets.

Existing Fire Resistance Solutions for Isopentane-Loaded Materials

01 Fire-resistant cellular materials

Development of cellular materials with inherent fire-resistant properties. These materials are designed to withstand high temperatures and prevent or slow down the spread of fire. They may incorporate flame retardants or be made from naturally fire-resistant substances.- Fire-resistant cellular materials: Development of cellular materials with inherent fire resistance properties. These materials are designed to withstand high temperatures and prevent or slow down the spread of fire. They may incorporate flame retardant additives or be made from naturally fire-resistant substances.

- Coatings and treatments for fire resistance: Application of fire-resistant coatings or treatments to cellular materials to enhance their fire resistance. These coatings can form a protective barrier when exposed to heat, preventing the underlying material from igniting or burning.

- Composite cellular structures for fire resistance: Creation of composite structures using cellular materials combined with other fire-resistant components. These composites can provide enhanced fire resistance while maintaining the lightweight and insulating properties of cellular materials.

- Fire-resistant foams and insulation: Development of fire-resistant foams and insulation materials with cellular structures. These materials are designed to provide thermal insulation while also offering protection against fire spread.

- Testing and certification of fire-resistant cellular materials: Methods and systems for testing and certifying the fire resistance of cellular materials. This includes standardized testing procedures to evaluate the performance of these materials under fire conditions and ensure compliance with safety regulations.

02 Coatings and treatments for fire resistance

Application of fire-resistant coatings or treatments to cellular materials to enhance their fire resistance. These coatings can form a protective barrier when exposed to heat, preventing the underlying material from igniting or burning.Expand Specific Solutions03 Composite cellular structures for fire resistance

Creation of composite cellular structures that combine different materials to achieve improved fire resistance. These composites may include layers of fire-resistant materials or incorporate fire-resistant fibers or particles within the cellular structure.Expand Specific Solutions04 Fire-resistant foams and insulation

Development of fire-resistant foams and insulation materials with cellular structures. These materials are designed to provide thermal insulation while also offering fire resistance, making them suitable for use in construction and other applications where fire safety is crucial.Expand Specific Solutions05 Testing and certification of fire-resistant cellular materials

Methods and systems for testing and certifying the fire resistance of cellular materials. This includes standardized testing procedures to evaluate the performance of these materials under fire conditions and ensure they meet safety requirements for various applications.Expand Specific Solutions

Key Players in Fire-Resistant Cellular Material Industry

The competitive landscape for research on isopentane's impact on cellular material fire resistance is in an early development stage, with a relatively small but growing market. The technology's maturity is still evolving, with key players like BASF Corp., Bayer AG, and Mitsubishi Materials Corp. leading research efforts. These companies, along with academic institutions such as Sichuan University and Vanderbilt University, are driving innovation in this niche field. The market size is expected to expand as fire safety regulations become more stringent across industries. Companies like H.B. Fuller Co. and Firestone Building Products Co. LLC are likely to leverage this technology for developing advanced fire-resistant materials, indicating potential for significant growth and commercial applications in the near future.

BASF Corp.

Technical Solution: BASF has developed advanced flame retardant solutions for cellular materials exposed to isopentane. Their approach involves incorporating halogen-free flame retardants into polymer matrices, which create a protective char layer when exposed to fire. This char layer acts as a barrier, reducing heat transfer and oxygen diffusion[1]. BASF's technology also includes synergistic combinations of phosphorus and nitrogen-based additives, which enhance the overall fire resistance of isopentane-loaded cellular materials[2]. The company has conducted extensive testing, demonstrating that their solutions can achieve UL94 V-0 ratings in various foam densities[3].

Strengths: Environmentally friendly halogen-free solutions, proven effectiveness in various foam densities. Weaknesses: May require higher loadings of additives, potentially affecting material properties.

DSM IP Assets BV

Technical Solution: DSM has innovated in the field of fire-resistant cellular materials with their proprietary Diablo technology. This approach focuses on creating intrinsically flame-retardant polymers that maintain their fire resistance even when loaded with isopentane. The technology involves modifying the polymer backbone with flame-retardant moieties, ensuring uniform distribution throughout the material[4]. DSM's solution has shown remarkable performance in maintaining structural integrity during fire events, with reduced heat release rates and smoke generation[5]. Their materials have been successfully applied in automotive and construction industries, where isopentane is commonly used as a blowing agent[6].

Strengths: Intrinsic flame retardancy, reduced smoke generation, and broad industry application. Weaknesses: Potentially higher production costs and limited to specific polymer types.

Innovative Approaches to Enhance Fire Resistance with Isopentane

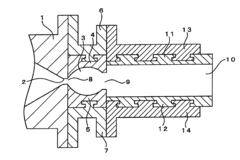

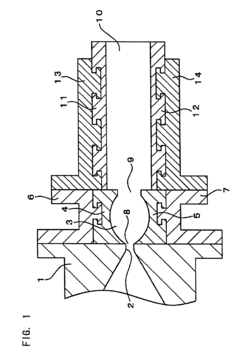

Method for production of extruded, polystyrene-based resin foam plate and extruded foam plate obtained thereby

PatentInactiveUS7008578B2

Innovation

- A method for producing extruded polystyrene-based resin foam plates using a blowing agent composition comprising 25-65% isobutane, 5-70% dimethyl ether, and 5-55% carbon dioxide, along with a flame retardant and nucleating agent, to create a foam with low thermal conductivity and excellent flame retardancy, while minimizing environmental impact.

Method for production of extruded, polystyrene-based resin foam plate and extruded foam plate obtained thereby

PatentInactiveUS7008578B2

Innovation

- A method for producing extruded polystyrene-based resin foam plates using a blowing agent composition comprising 25-65% isobutane, 5-70% dimethyl ether, and 5-55% carbon dioxide, along with a flame retardant and nucleating agent, to create a foam with low thermal conductivity and excellent flame retardancy, while minimizing environmental impact.

Environmental Impact of Fire-Resistant Cellular Materials

The environmental impact of fire-resistant cellular materials, particularly those containing isopentane, is a critical consideration in the development and application of these materials. As the demand for fire-resistant materials grows, it is essential to evaluate their long-term effects on ecosystems and human health.

Isopentane, a volatile organic compound used in the production of cellular materials, plays a significant role in enhancing fire resistance. However, its release into the environment during manufacturing, use, and disposal of these materials can have far-reaching consequences. When exposed to sunlight, isopentane can react with nitrogen oxides to form ground-level ozone, a major component of smog that can harm human respiratory systems and vegetation.

The production process of fire-resistant cellular materials often involves the use of chemical blowing agents, including isopentane. These processes can result in emissions of greenhouse gases and other pollutants, contributing to climate change and air quality degradation. Furthermore, the energy-intensive nature of manufacturing these materials adds to their overall carbon footprint.

During fires, the combustion of isopentane-loaded cellular materials can release toxic fumes and particulate matter. While these materials are designed to resist fire, when they do burn, they may produce more harmful emissions compared to their non-fire-resistant counterparts. This poses risks not only to firefighters and building occupants but also to the surrounding environment.

The disposal of fire-resistant cellular materials at the end of their lifecycle presents another environmental challenge. Many of these materials are not biodegradable and can persist in landfills for extended periods. The potential leaching of chemical components, including isopentane residues, into soil and groundwater is a concern that requires careful management and monitoring.

On the positive side, the improved fire resistance of these materials can lead to reduced fire incidents and associated environmental damage. By preventing or slowing the spread of fires, these materials can indirectly contribute to lower emissions of smoke and toxic combustion products that would otherwise be released during large-scale fires.

Efforts to mitigate the environmental impact of fire-resistant cellular materials are ongoing. Research into more sustainable production methods, the use of bio-based alternatives to isopentane, and improved recycling techniques are areas of active development. Additionally, life cycle assessments are being conducted to better understand and quantify the overall environmental impact of these materials from production to disposal.

Isopentane, a volatile organic compound used in the production of cellular materials, plays a significant role in enhancing fire resistance. However, its release into the environment during manufacturing, use, and disposal of these materials can have far-reaching consequences. When exposed to sunlight, isopentane can react with nitrogen oxides to form ground-level ozone, a major component of smog that can harm human respiratory systems and vegetation.

The production process of fire-resistant cellular materials often involves the use of chemical blowing agents, including isopentane. These processes can result in emissions of greenhouse gases and other pollutants, contributing to climate change and air quality degradation. Furthermore, the energy-intensive nature of manufacturing these materials adds to their overall carbon footprint.

During fires, the combustion of isopentane-loaded cellular materials can release toxic fumes and particulate matter. While these materials are designed to resist fire, when they do burn, they may produce more harmful emissions compared to their non-fire-resistant counterparts. This poses risks not only to firefighters and building occupants but also to the surrounding environment.

The disposal of fire-resistant cellular materials at the end of their lifecycle presents another environmental challenge. Many of these materials are not biodegradable and can persist in landfills for extended periods. The potential leaching of chemical components, including isopentane residues, into soil and groundwater is a concern that requires careful management and monitoring.

On the positive side, the improved fire resistance of these materials can lead to reduced fire incidents and associated environmental damage. By preventing or slowing the spread of fires, these materials can indirectly contribute to lower emissions of smoke and toxic combustion products that would otherwise be released during large-scale fires.

Efforts to mitigate the environmental impact of fire-resistant cellular materials are ongoing. Research into more sustainable production methods, the use of bio-based alternatives to isopentane, and improved recycling techniques are areas of active development. Additionally, life cycle assessments are being conducted to better understand and quantify the overall environmental impact of these materials from production to disposal.

Regulatory Framework for Isopentane-Containing Building Materials

The regulatory framework for isopentane-containing building materials is a complex and evolving landscape that aims to ensure the safety and fire resistance of structures while accommodating innovative materials. At the federal level, the U.S. Consumer Product Safety Commission (CPSC) and the Environmental Protection Agency (EPA) play crucial roles in setting standards and guidelines for the use of isopentane in building materials.

The CPSC focuses on consumer safety and has established flammability standards for various building materials, including those containing isopentane. These standards typically require manufacturers to conduct rigorous testing and provide detailed safety information for their products. The EPA, on the other hand, regulates the environmental impact of isopentane and other volatile organic compounds (VOCs) used in construction materials.

At the state and local levels, building codes and fire safety regulations vary, but many jurisdictions have adopted the International Building Code (IBC) or similar standards. These codes often include specific provisions for the use of foam insulation materials, which may contain isopentane as a blowing agent. The IBC typically requires that such materials meet certain fire resistance ratings and undergo standardized testing procedures.

The National Fire Protection Association (NFPA) also plays a significant role in shaping regulations for fire-resistant building materials. Their standards, particularly NFPA 285, which addresses fire testing of exterior wall assemblies, are widely referenced in building codes and regulations pertaining to isopentane-containing materials.

Industry associations, such as the Polyisocyanurate Insulation Manufacturers Association (PIMA) and the Extruded Polystyrene Foam Association (XPSA), work closely with regulatory bodies to develop guidelines and best practices for the safe use of isopentane in insulation materials. These organizations often conduct research and advocate for balanced regulations that promote both safety and innovation.

Internationally, the European Union has implemented the Construction Products Regulation (CPR), which includes specific requirements for the fire performance of building materials. This regulation has influenced global standards and may impact U.S. manufacturers seeking to export isopentane-containing products.

As research continues to shed light on the fire resistance properties of cellular materials containing isopentane, regulatory frameworks are likely to evolve. Future regulations may focus on more nuanced aspects of fire performance, such as smoke production and toxicity, in addition to traditional fire resistance metrics. This ongoing development underscores the need for continued collaboration between researchers, industry stakeholders, and regulatory bodies to ensure that safety standards keep pace with technological advancements in building materials.

The CPSC focuses on consumer safety and has established flammability standards for various building materials, including those containing isopentane. These standards typically require manufacturers to conduct rigorous testing and provide detailed safety information for their products. The EPA, on the other hand, regulates the environmental impact of isopentane and other volatile organic compounds (VOCs) used in construction materials.

At the state and local levels, building codes and fire safety regulations vary, but many jurisdictions have adopted the International Building Code (IBC) or similar standards. These codes often include specific provisions for the use of foam insulation materials, which may contain isopentane as a blowing agent. The IBC typically requires that such materials meet certain fire resistance ratings and undergo standardized testing procedures.

The National Fire Protection Association (NFPA) also plays a significant role in shaping regulations for fire-resistant building materials. Their standards, particularly NFPA 285, which addresses fire testing of exterior wall assemblies, are widely referenced in building codes and regulations pertaining to isopentane-containing materials.

Industry associations, such as the Polyisocyanurate Insulation Manufacturers Association (PIMA) and the Extruded Polystyrene Foam Association (XPSA), work closely with regulatory bodies to develop guidelines and best practices for the safe use of isopentane in insulation materials. These organizations often conduct research and advocate for balanced regulations that promote both safety and innovation.

Internationally, the European Union has implemented the Construction Products Regulation (CPR), which includes specific requirements for the fire performance of building materials. This regulation has influenced global standards and may impact U.S. manufacturers seeking to export isopentane-containing products.

As research continues to shed light on the fire resistance properties of cellular materials containing isopentane, regulatory frameworks are likely to evolve. Future regulations may focus on more nuanced aspects of fire performance, such as smoke production and toxicity, in addition to traditional fire resistance metrics. This ongoing development underscores the need for continued collaboration between researchers, industry stakeholders, and regulatory bodies to ensure that safety standards keep pace with technological advancements in building materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!