Isopentane Thermal Safety Guidelines for On-Site Application

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Safety Overview

Isopentane, a highly volatile and flammable hydrocarbon, presents significant safety challenges in on-site applications. This overview focuses on the thermal safety aspects of isopentane, which are crucial for preventing accidents and ensuring proper handling in industrial settings.

Isopentane has a low boiling point of approximately 28°C (82°F), making it prone to rapid vaporization at ambient temperatures. This property necessitates careful consideration of thermal management strategies to prevent uncontrolled vapor release. The compound's high vapor pressure contributes to its flammability, with a flash point of -51°C (-60°F), creating a constant risk of fire or explosion if not properly contained and managed.

The auto-ignition temperature of isopentane is relatively low at 420°C (788°F), which means that it can spontaneously ignite without an external ignition source if exposed to sufficiently high temperatures. This characteristic underscores the importance of strict temperature control in storage and processing environments. Additionally, isopentane has a wide flammable range, with lower and upper explosive limits of 1.4% and 7.6% by volume in air, respectively, further emphasizing the need for robust safety measures.

Thermal expansion is another critical factor in isopentane safety. As a liquid, isopentane expands significantly with temperature increases, potentially leading to overpressurization of storage tanks or process equipment if not properly accounted for. This expansion can result in equipment failure, leaks, or ruptures, creating hazardous situations.

Heat transfer properties of isopentane also play a crucial role in safety considerations. Its low specific heat capacity and high thermal conductivity mean that it can quickly absorb or release heat, potentially leading to rapid temperature changes in storage or process systems. This characteristic requires careful design of heating and cooling systems to maintain stable and safe operating conditions.

In the context of on-site applications, the thermal stability of isopentane under various process conditions must be thoroughly understood. Prolonged exposure to high temperatures or the presence of catalytic materials can lead to decomposition or polymerization reactions, potentially altering the compound's properties and creating new safety hazards.

Given these thermal safety considerations, comprehensive guidelines for on-site application of isopentane typically include strict temperature monitoring and control systems, pressure relief mechanisms, inert gas blanketing, and robust ventilation systems. Personal protective equipment (PPE) requirements often include thermal-resistant clothing and respiratory protection to safeguard workers against potential exposure to vapors or liquid contact.

Isopentane has a low boiling point of approximately 28°C (82°F), making it prone to rapid vaporization at ambient temperatures. This property necessitates careful consideration of thermal management strategies to prevent uncontrolled vapor release. The compound's high vapor pressure contributes to its flammability, with a flash point of -51°C (-60°F), creating a constant risk of fire or explosion if not properly contained and managed.

The auto-ignition temperature of isopentane is relatively low at 420°C (788°F), which means that it can spontaneously ignite without an external ignition source if exposed to sufficiently high temperatures. This characteristic underscores the importance of strict temperature control in storage and processing environments. Additionally, isopentane has a wide flammable range, with lower and upper explosive limits of 1.4% and 7.6% by volume in air, respectively, further emphasizing the need for robust safety measures.

Thermal expansion is another critical factor in isopentane safety. As a liquid, isopentane expands significantly with temperature increases, potentially leading to overpressurization of storage tanks or process equipment if not properly accounted for. This expansion can result in equipment failure, leaks, or ruptures, creating hazardous situations.

Heat transfer properties of isopentane also play a crucial role in safety considerations. Its low specific heat capacity and high thermal conductivity mean that it can quickly absorb or release heat, potentially leading to rapid temperature changes in storage or process systems. This characteristic requires careful design of heating and cooling systems to maintain stable and safe operating conditions.

In the context of on-site applications, the thermal stability of isopentane under various process conditions must be thoroughly understood. Prolonged exposure to high temperatures or the presence of catalytic materials can lead to decomposition or polymerization reactions, potentially altering the compound's properties and creating new safety hazards.

Given these thermal safety considerations, comprehensive guidelines for on-site application of isopentane typically include strict temperature monitoring and control systems, pressure relief mechanisms, inert gas blanketing, and robust ventilation systems. Personal protective equipment (PPE) requirements often include thermal-resistant clothing and respiratory protection to safeguard workers against potential exposure to vapors or liquid contact.

Industrial Demand Analysis

The industrial demand for isopentane thermal safety guidelines in on-site applications has been steadily increasing due to the growing use of isopentane in various sectors. Isopentane, a highly volatile and flammable hydrocarbon, is widely utilized in the production of foam insulation, refrigerants, and as a blowing agent in the manufacturing of polystyrene foam products. The expanding construction and automotive industries have significantly contributed to the rising demand for isopentane-based products, consequently elevating the need for robust safety protocols.

In the construction sector, the push for energy-efficient buildings has led to a surge in the use of foam insulation materials, many of which rely on isopentane as a key component. This trend is particularly evident in regions with stringent energy conservation regulations, such as the European Union and North America. The automotive industry's shift towards lightweight materials for improved fuel efficiency has also boosted the demand for isopentane-based foam products in vehicle manufacturing.

The refrigeration and air conditioning industry represents another significant market driver for isopentane safety guidelines. As countries phase out hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) due to environmental concerns, isopentane has emerged as a promising alternative refrigerant. This transition has created a pressing need for comprehensive thermal safety guidelines to ensure the safe handling and use of isopentane in cooling systems.

The chemical processing industry, where isopentane is used as a solvent and in the production of various chemicals, has also contributed to the increased demand for safety protocols. As production volumes grow, so does the necessity for stringent safety measures to prevent accidents and ensure worker protection during on-site handling and storage of isopentane.

Furthermore, the oil and gas sector utilizes isopentane in natural gas processing and as a fuel additive, creating additional demand for thermal safety guidelines. The expansion of natural gas infrastructure in developing economies has amplified this need, as new facilities require up-to-date safety standards for isopentane handling.

The global focus on workplace safety and environmental protection has intensified regulatory scrutiny on the use of volatile organic compounds like isopentane. This has prompted industries to seek comprehensive guidelines that address not only thermal safety but also environmental impact and occupational health concerns. The demand for such guidelines is particularly acute in emerging markets where rapid industrialization is occurring alongside evolving safety standards.

As industries continue to innovate and find new applications for isopentane, the complexity of safety requirements increases. This has led to a growing market for specialized consulting services and training programs focused on isopentane thermal safety, further underscoring the industrial demand for comprehensive and adaptable guidelines.

In the construction sector, the push for energy-efficient buildings has led to a surge in the use of foam insulation materials, many of which rely on isopentane as a key component. This trend is particularly evident in regions with stringent energy conservation regulations, such as the European Union and North America. The automotive industry's shift towards lightweight materials for improved fuel efficiency has also boosted the demand for isopentane-based foam products in vehicle manufacturing.

The refrigeration and air conditioning industry represents another significant market driver for isopentane safety guidelines. As countries phase out hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) due to environmental concerns, isopentane has emerged as a promising alternative refrigerant. This transition has created a pressing need for comprehensive thermal safety guidelines to ensure the safe handling and use of isopentane in cooling systems.

The chemical processing industry, where isopentane is used as a solvent and in the production of various chemicals, has also contributed to the increased demand for safety protocols. As production volumes grow, so does the necessity for stringent safety measures to prevent accidents and ensure worker protection during on-site handling and storage of isopentane.

Furthermore, the oil and gas sector utilizes isopentane in natural gas processing and as a fuel additive, creating additional demand for thermal safety guidelines. The expansion of natural gas infrastructure in developing economies has amplified this need, as new facilities require up-to-date safety standards for isopentane handling.

The global focus on workplace safety and environmental protection has intensified regulatory scrutiny on the use of volatile organic compounds like isopentane. This has prompted industries to seek comprehensive guidelines that address not only thermal safety but also environmental impact and occupational health concerns. The demand for such guidelines is particularly acute in emerging markets where rapid industrialization is occurring alongside evolving safety standards.

As industries continue to innovate and find new applications for isopentane, the complexity of safety requirements increases. This has led to a growing market for specialized consulting services and training programs focused on isopentane thermal safety, further underscoring the industrial demand for comprehensive and adaptable guidelines.

Thermal Hazards Assessment

Isopentane, a highly volatile and flammable hydrocarbon, presents significant thermal hazards in on-site applications. A comprehensive thermal hazards assessment is crucial for ensuring safety and preventing potential accidents. This assessment begins with identifying the physical and chemical properties of isopentane that contribute to its thermal risks, including its low boiling point, high vapor pressure, and wide flammability range.

The primary thermal hazards associated with isopentane include rapid vaporization, vapor cloud formation, and potential for fire and explosion. When exposed to heat or ignition sources, isopentane can quickly transition from a liquid to a vapor state, creating a potentially explosive atmosphere. The vapor, being heavier than air, can accumulate in low-lying areas, increasing the risk of fire or explosion if an ignition source is present.

Thermal expansion is another critical factor to consider. As isopentane heats up, it expands significantly, which can lead to overpressurization in closed containers or systems. This expansion can result in equipment failure, leaks, or even catastrophic ruptures if proper pressure relief mechanisms are not in place.

The assessment must also consider the potential for rapid phase transitions (RPT) when isopentane comes into contact with water or other incompatible substances. These transitions can lead to sudden pressure increases and violent reactions, posing severe risks to personnel and equipment.

Heat transfer characteristics of isopentane play a crucial role in thermal hazard assessment. Its low specific heat capacity and high thermal conductivity mean that it can quickly absorb and transfer heat, potentially leading to rapid temperature increases in storage or process equipment. This property necessitates careful consideration of cooling systems and temperature control measures.

Environmental factors such as ambient temperature, sunlight exposure, and proximity to heat sources must be evaluated as part of the thermal hazards assessment. High ambient temperatures can increase vapor pressure and evaporation rates, exacerbating the risks associated with isopentane handling and storage.

The assessment should include a detailed analysis of potential ignition sources in the vicinity of isopentane storage and handling areas. This includes electrical equipment, static electricity, hot surfaces, and open flames. Implementing proper grounding and bonding procedures, using explosion-proof equipment, and establishing exclusion zones are essential mitigation strategies.

Lastly, the thermal hazards assessment must consider the potential for domino effects, where a thermal incident involving isopentane could trigger cascading failures or accidents in nearby equipment or processes. This requires a holistic approach to risk assessment and the development of comprehensive emergency response plans.

The primary thermal hazards associated with isopentane include rapid vaporization, vapor cloud formation, and potential for fire and explosion. When exposed to heat or ignition sources, isopentane can quickly transition from a liquid to a vapor state, creating a potentially explosive atmosphere. The vapor, being heavier than air, can accumulate in low-lying areas, increasing the risk of fire or explosion if an ignition source is present.

Thermal expansion is another critical factor to consider. As isopentane heats up, it expands significantly, which can lead to overpressurization in closed containers or systems. This expansion can result in equipment failure, leaks, or even catastrophic ruptures if proper pressure relief mechanisms are not in place.

The assessment must also consider the potential for rapid phase transitions (RPT) when isopentane comes into contact with water or other incompatible substances. These transitions can lead to sudden pressure increases and violent reactions, posing severe risks to personnel and equipment.

Heat transfer characteristics of isopentane play a crucial role in thermal hazard assessment. Its low specific heat capacity and high thermal conductivity mean that it can quickly absorb and transfer heat, potentially leading to rapid temperature increases in storage or process equipment. This property necessitates careful consideration of cooling systems and temperature control measures.

Environmental factors such as ambient temperature, sunlight exposure, and proximity to heat sources must be evaluated as part of the thermal hazards assessment. High ambient temperatures can increase vapor pressure and evaporation rates, exacerbating the risks associated with isopentane handling and storage.

The assessment should include a detailed analysis of potential ignition sources in the vicinity of isopentane storage and handling areas. This includes electrical equipment, static electricity, hot surfaces, and open flames. Implementing proper grounding and bonding procedures, using explosion-proof equipment, and establishing exclusion zones are essential mitigation strategies.

Lastly, the thermal hazards assessment must consider the potential for domino effects, where a thermal incident involving isopentane could trigger cascading failures or accidents in nearby equipment or processes. This requires a holistic approach to risk assessment and the development of comprehensive emergency response plans.

Current Safety Protocols

01 Thermal stability and safety measures

Isopentane's thermal stability and safety are crucial considerations in various applications. Measures are implemented to prevent thermal runaway and ensure safe handling. This includes proper storage conditions, temperature monitoring, and the use of safety relief systems to manage potential pressure build-up during thermal events.- Thermal stability and safety measures for isopentane: Isopentane's thermal stability and safety are crucial considerations in various applications. Measures are taken to prevent thermal runaway and ensure safe handling. This includes proper storage conditions, temperature control systems, and safety equipment to mitigate risks associated with its flammability and volatility.

- Isopentane in heat transfer and cooling systems: Isopentane is utilized in heat transfer and cooling systems due to its favorable thermodynamic properties. Its low boiling point and high vapor pressure make it suitable for applications requiring efficient heat dissipation. Special attention is given to system design and safety features to prevent leaks and ensure thermal stability.

- Fire safety and explosion prevention for isopentane: Given isopentane's high flammability, fire safety and explosion prevention are critical. This involves implementing proper ventilation systems, using explosion-proof equipment, and establishing emergency protocols. Specialized storage and handling procedures are developed to minimize the risk of fire and explosions in industrial settings.

- Isopentane in chemical processes and reactions: Isopentane is used in various chemical processes and reactions, where thermal management is crucial. Reactor design, process control, and safety systems are implemented to maintain optimal temperature ranges and prevent runaway reactions. Careful consideration is given to the thermal behavior of isopentane during these processes to ensure safety and efficiency.

- Environmental and health considerations for isopentane use: The use of isopentane requires attention to environmental and health impacts. This includes measures to prevent atmospheric emissions, proper disposal methods, and personal protective equipment for workers. Thermal safety considerations extend to potential environmental releases and exposure scenarios, with a focus on minimizing risks to human health and the environment.

02 Fire suppression and explosion prevention

Due to isopentane's flammability, fire suppression and explosion prevention techniques are essential. This involves the use of specialized fire extinguishing systems, inert gas blanketing, and the implementation of explosion-proof equipment in areas where isopentane is handled or stored.Expand Specific Solutions03 Heat transfer and cooling systems

Efficient heat transfer and cooling systems are crucial for maintaining isopentane's thermal safety in various processes. This includes the design of heat exchangers, cooling jackets, and temperature control systems to manage heat generation and dissipation effectively.Expand Specific Solutions04 Process monitoring and control

Advanced process monitoring and control systems are implemented to ensure the thermal safety of isopentane in industrial applications. This involves real-time temperature and pressure monitoring, automated shutdown systems, and the use of process analytical technology to detect and respond to potential thermal hazards.Expand Specific Solutions05 Material compatibility and storage

Ensuring material compatibility and proper storage conditions is essential for isopentane's thermal safety. This includes the selection of appropriate container materials, storage tank design, and the implementation of vapor recovery systems to minimize the risk of leaks and thermal incidents during storage and transportation.Expand Specific Solutions

Key Industry Stakeholders

The competitive landscape for "Isopentane Thermal Safety Guidelines for On-Site Application" is characterized by a mature market with established players and growing demand for safety solutions in petrochemical industries. The market is in a growth phase, driven by increasing safety regulations and awareness. Key players like China Petroleum & Chemical Corp., PetroChina Co., Ltd., and Sinopec Research Institute of Petroleum Processing dominate the sector, leveraging their extensive industry experience and research capabilities. The technology is relatively mature, with ongoing refinements focused on improving safety protocols and efficiency. Companies such as Wanhua Chemical Group and Sinopec Safety Engineering Research Institute are actively contributing to advancements in thermal safety guidelines, indicating a competitive environment for innovation in this specialized field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive Isopentane Thermal Safety Guidelines for on-site applications. Their approach includes advanced risk assessment methodologies, incorporating Hazard and Operability (HAZOP) studies and Quantitative Risk Assessment (QRA) techniques[1]. Sinopec's guidelines emphasize the importance of proper storage conditions, maintaining isopentane at temperatures below its flash point of approximately -51°C[2]. They have implemented a multi-layered safety system, including advanced leak detection systems, emergency shutdown procedures, and fire suppression systems specifically designed for isopentane's unique properties[3]. Sinopec also focuses on personnel training, ensuring that all on-site staff are well-versed in the handling and emergency response procedures for isopentane.

Strengths: Comprehensive risk assessment, advanced safety systems, and extensive industry experience. Weaknesses: Potential high implementation costs and complexity in retrofitting existing facilities.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed a robust set of Isopentane Thermal Safety Guidelines for on-site applications, focusing on a holistic approach to safety management. Their guidelines incorporate real-time monitoring systems that track temperature, pressure, and vapor concentrations in storage and handling areas[4]. PetroChina's approach includes the use of double-walled storage tanks with inert gas blanketing to minimize the risk of explosions[5]. They have also implemented advanced process control systems that automatically adjust operating parameters to maintain safe conditions. PetroChina's guidelines emphasize the importance of regular safety audits and continuous improvement processes to ensure the ongoing effectiveness of their safety measures[6].

Strengths: Advanced real-time monitoring, innovative storage solutions, and emphasis on continuous improvement. Weaknesses: Potential high initial investment costs and complexity in integrating systems across diverse operational sites.

Innovative Safety Measures

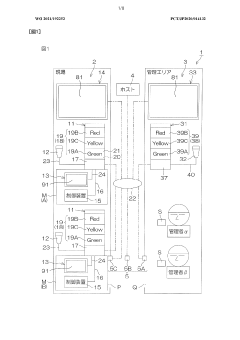

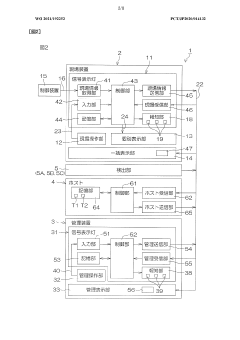

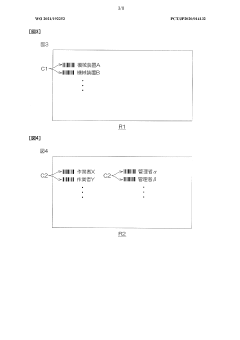

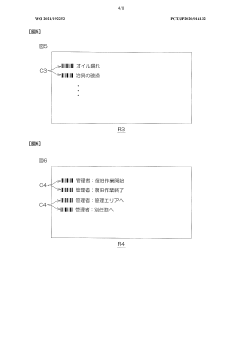

User interactive on-site job management system and uses thereof

PatentWO2016100469A1

Innovation

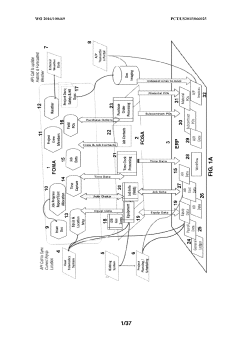

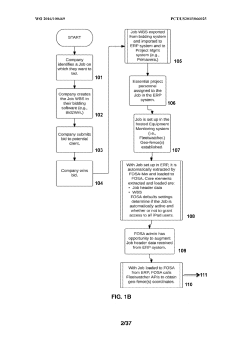

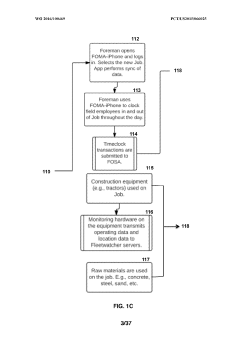

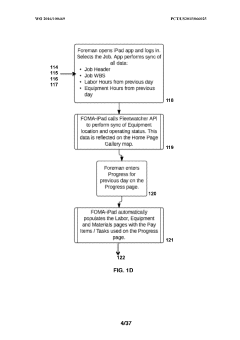

- A user interactive on-site job management system that integrates a mobile device with a server, incorporating an equipment monitoring system, interactive mobile tool, enterprise resource planning system, project planning system, and document imaging system, enabling real-time data synchronization and allocation of labor, equipment, and materials, along with weather and geo-fencing features.

On-site assistance system

PatentWO2021192252A1

Innovation

- A site support system comprising on-site and management area devices that transmit and receive behavior information, allowing on-site personnel to grasp the manager's actions and status, including location, enabling informed task allocation and improved resource management.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing isopentane thermal safety guidelines for on-site applications. The use of isopentane, a highly flammable hydrocarbon, is subject to stringent regulations and standards to ensure the safety of personnel, equipment, and the environment. Compliance with these regulations is mandatory for organizations handling isopentane in their operations.

At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) sets forth requirements for the safe handling and storage of flammable liquids, including isopentane. OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandates proper labeling, safety data sheets, and employee training on the hazards associated with isopentane. Additionally, OSHA's Process Safety Management (PSM) standard (29 CFR 1910.119) may apply to facilities using large quantities of isopentane, requiring a comprehensive management system to prevent catastrophic releases.

The Environmental Protection Agency (EPA) regulates isopentane under the Clean Air Act as a volatile organic compound (VOC). Facilities must comply with emission standards and reporting requirements, particularly in areas designated as non-attainment for ozone. The EPA's Risk Management Program (RMP) rule (40 CFR Part 68) may also apply, necessitating the development of risk management plans for facilities storing significant quantities of isopentane.

At the state and local levels, regulations can vary significantly. Many states have adopted more stringent requirements than federal standards, particularly in areas prone to air quality issues. Local fire codes often dictate specific storage and handling practices for flammable liquids like isopentane. Compliance with these local regulations is essential and may require additional safety measures beyond federal standards.

Internationally, organizations must navigate a complex landscape of regulations. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the CLP (Classification, Labelling, and Packaging) regulation govern the use of isopentane in EU member states. In Asia, countries like China and Japan have their own sets of chemical management regulations that must be adhered to when handling isopentane.

Industry standards also play a crucial role in regulatory compliance. The National Fire Protection Association (NFPA) provides guidelines for the storage and handling of flammable liquids (NFPA 30), which are often incorporated into local fire codes. The American Petroleum Institute (API) offers standards specific to the petroleum industry that may apply to isopentane handling in certain applications.

Compliance with these regulations requires a comprehensive approach, including regular risk assessments, implementation of engineering controls, development of standard operating procedures, and ongoing employee training. Organizations must stay informed about regulatory changes and update their compliance strategies accordingly to ensure continued safe operations with isopentane.

At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) sets forth requirements for the safe handling and storage of flammable liquids, including isopentane. OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandates proper labeling, safety data sheets, and employee training on the hazards associated with isopentane. Additionally, OSHA's Process Safety Management (PSM) standard (29 CFR 1910.119) may apply to facilities using large quantities of isopentane, requiring a comprehensive management system to prevent catastrophic releases.

The Environmental Protection Agency (EPA) regulates isopentane under the Clean Air Act as a volatile organic compound (VOC). Facilities must comply with emission standards and reporting requirements, particularly in areas designated as non-attainment for ozone. The EPA's Risk Management Program (RMP) rule (40 CFR Part 68) may also apply, necessitating the development of risk management plans for facilities storing significant quantities of isopentane.

At the state and local levels, regulations can vary significantly. Many states have adopted more stringent requirements than federal standards, particularly in areas prone to air quality issues. Local fire codes often dictate specific storage and handling practices for flammable liquids like isopentane. Compliance with these local regulations is essential and may require additional safety measures beyond federal standards.

Internationally, organizations must navigate a complex landscape of regulations. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the CLP (Classification, Labelling, and Packaging) regulation govern the use of isopentane in EU member states. In Asia, countries like China and Japan have their own sets of chemical management regulations that must be adhered to when handling isopentane.

Industry standards also play a crucial role in regulatory compliance. The National Fire Protection Association (NFPA) provides guidelines for the storage and handling of flammable liquids (NFPA 30), which are often incorporated into local fire codes. The American Petroleum Institute (API) offers standards specific to the petroleum industry that may apply to isopentane handling in certain applications.

Compliance with these regulations requires a comprehensive approach, including regular risk assessments, implementation of engineering controls, development of standard operating procedures, and ongoing employee training. Organizations must stay informed about regulatory changes and update their compliance strategies accordingly to ensure continued safe operations with isopentane.

Environmental Impact

The environmental impact of isopentane thermal safety guidelines for on-site application is a critical consideration in the implementation of these protocols. Isopentane, a volatile organic compound (VOC), poses potential risks to the environment if not properly managed during its use in thermal applications.

One of the primary environmental concerns associated with isopentane is its contribution to air pollution. When released into the atmosphere, isopentane can react with other pollutants to form ground-level ozone, a key component of smog. This can lead to respiratory issues in humans and damage to vegetation. Additionally, isopentane has a high global warming potential, making it a significant contributor to climate change if released in large quantities.

Water contamination is another potential environmental impact of isopentane use. Improper handling or accidental spills can result in the infiltration of isopentane into groundwater or surface water bodies. This can have detrimental effects on aquatic ecosystems and potentially contaminate drinking water sources.

Soil contamination is also a concern, particularly in cases of leaks or spills during on-site applications. Isopentane can persist in soil for extended periods, potentially affecting soil microorganisms and plant growth. This can lead to long-term ecological impacts and require costly remediation efforts.

To mitigate these environmental risks, thermal safety guidelines for isopentane should incorporate stringent measures for containment, handling, and disposal. This includes the use of sealed systems, proper ventilation, and leak detection technologies to minimize atmospheric emissions. Implementing spill prevention and response protocols is crucial to protect soil and water resources.

The guidelines should also address the importance of proper storage and transportation of isopentane to reduce the risk of accidental releases. This may involve using specialized containers, maintaining appropriate temperature and pressure conditions, and following strict safety protocols during transfer operations.

Furthermore, the environmental impact assessment should consider the entire lifecycle of isopentane use in thermal applications. This includes evaluating the energy efficiency of the processes involved and exploring potential alternatives with lower environmental footprints. Implementing heat recovery systems and optimizing thermal processes can help reduce overall isopentane consumption and associated environmental risks.

Monitoring and reporting mechanisms should be integrated into the guidelines to track emissions, spills, and other environmental indicators. This data can inform continuous improvement efforts and ensure compliance with environmental regulations. Regular environmental audits and impact assessments should be conducted to evaluate the effectiveness of the safety measures and identify areas for enhancement.

One of the primary environmental concerns associated with isopentane is its contribution to air pollution. When released into the atmosphere, isopentane can react with other pollutants to form ground-level ozone, a key component of smog. This can lead to respiratory issues in humans and damage to vegetation. Additionally, isopentane has a high global warming potential, making it a significant contributor to climate change if released in large quantities.

Water contamination is another potential environmental impact of isopentane use. Improper handling or accidental spills can result in the infiltration of isopentane into groundwater or surface water bodies. This can have detrimental effects on aquatic ecosystems and potentially contaminate drinking water sources.

Soil contamination is also a concern, particularly in cases of leaks or spills during on-site applications. Isopentane can persist in soil for extended periods, potentially affecting soil microorganisms and plant growth. This can lead to long-term ecological impacts and require costly remediation efforts.

To mitigate these environmental risks, thermal safety guidelines for isopentane should incorporate stringent measures for containment, handling, and disposal. This includes the use of sealed systems, proper ventilation, and leak detection technologies to minimize atmospheric emissions. Implementing spill prevention and response protocols is crucial to protect soil and water resources.

The guidelines should also address the importance of proper storage and transportation of isopentane to reduce the risk of accidental releases. This may involve using specialized containers, maintaining appropriate temperature and pressure conditions, and following strict safety protocols during transfer operations.

Furthermore, the environmental impact assessment should consider the entire lifecycle of isopentane use in thermal applications. This includes evaluating the energy efficiency of the processes involved and exploring potential alternatives with lower environmental footprints. Implementing heat recovery systems and optimizing thermal processes can help reduce overall isopentane consumption and associated environmental risks.

Monitoring and reporting mechanisms should be integrated into the guidelines to track emissions, spills, and other environmental indicators. This data can inform continuous improvement efforts and ensure compliance with environmental regulations. Regular environmental audits and impact assessments should be conducted to evaluate the effectiveness of the safety measures and identify areas for enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!