Isopentane as a Lubricant Additive Properties and Limitations

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Lubricant Background and Objectives

Isopentane, a branched-chain alkane with the molecular formula C5H12, has emerged as a promising lubricant additive in recent years. The exploration of isopentane as a lubricant additive stems from the ongoing quest for more efficient and environmentally friendly lubricant solutions in various industries, including automotive, aerospace, and industrial machinery.

The development of lubricant technology has been driven by the need to reduce friction, wear, and energy consumption in mechanical systems. Traditional lubricants, while effective, often face challenges related to viscosity, thermal stability, and environmental impact. The introduction of isopentane as an additive represents a significant step in addressing these challenges and improving overall lubricant performance.

Isopentane's unique molecular structure contributes to its potential as a lubricant additive. Its branched configuration allows for better surface coverage and improved film formation on metal surfaces, potentially enhancing the lubricant's ability to reduce friction and wear. Additionally, isopentane's low boiling point and high volatility offer interesting possibilities for applications where rapid evaporation is desirable, such as in temporary lubrication scenarios or in systems where residue buildup is a concern.

The primary objectives of researching isopentane as a lubricant additive are multifaceted. Firstly, there is a focus on understanding its impact on the overall viscosity and flow characteristics of lubricant formulations. This is crucial for optimizing the lubricant's performance across a wide range of operating temperatures and pressures. Secondly, researchers aim to evaluate isopentane's compatibility with existing lubricant base oils and other additives, ensuring that its inclusion does not compromise the stability or effectiveness of the lubricant system.

Another key objective is to assess the potential of isopentane in enhancing the thermal and oxidative stability of lubricants. This is particularly important in high-temperature applications where conventional lubricants may break down or form harmful deposits. Furthermore, there is significant interest in exploring isopentane's role in improving the energy efficiency of lubricated systems, potentially contributing to reduced fuel consumption and emissions in various applications.

Environmental considerations also play a crucial role in the research objectives. As global regulations become increasingly stringent regarding the environmental impact of lubricants, the biodegradability and toxicity of isopentane-enhanced lubricants are under scrutiny. Researchers are working to determine whether the addition of isopentane can contribute to the development of more environmentally friendly lubricant formulations without compromising performance.

The development of lubricant technology has been driven by the need to reduce friction, wear, and energy consumption in mechanical systems. Traditional lubricants, while effective, often face challenges related to viscosity, thermal stability, and environmental impact. The introduction of isopentane as an additive represents a significant step in addressing these challenges and improving overall lubricant performance.

Isopentane's unique molecular structure contributes to its potential as a lubricant additive. Its branched configuration allows for better surface coverage and improved film formation on metal surfaces, potentially enhancing the lubricant's ability to reduce friction and wear. Additionally, isopentane's low boiling point and high volatility offer interesting possibilities for applications where rapid evaporation is desirable, such as in temporary lubrication scenarios or in systems where residue buildup is a concern.

The primary objectives of researching isopentane as a lubricant additive are multifaceted. Firstly, there is a focus on understanding its impact on the overall viscosity and flow characteristics of lubricant formulations. This is crucial for optimizing the lubricant's performance across a wide range of operating temperatures and pressures. Secondly, researchers aim to evaluate isopentane's compatibility with existing lubricant base oils and other additives, ensuring that its inclusion does not compromise the stability or effectiveness of the lubricant system.

Another key objective is to assess the potential of isopentane in enhancing the thermal and oxidative stability of lubricants. This is particularly important in high-temperature applications where conventional lubricants may break down or form harmful deposits. Furthermore, there is significant interest in exploring isopentane's role in improving the energy efficiency of lubricated systems, potentially contributing to reduced fuel consumption and emissions in various applications.

Environmental considerations also play a crucial role in the research objectives. As global regulations become increasingly stringent regarding the environmental impact of lubricants, the biodegradability and toxicity of isopentane-enhanced lubricants are under scrutiny. Researchers are working to determine whether the addition of isopentane can contribute to the development of more environmentally friendly lubricant formulations without compromising performance.

Market Analysis for Isopentane-Enhanced Lubricants

The market for isopentane-enhanced lubricants is experiencing significant growth, driven by the increasing demand for high-performance lubricants in various industries. Isopentane, a branched alkane with the molecular formula C5H12, has gained attention as a potential additive to improve lubricant properties. The global lubricants market, valued at approximately $164 billion in 2021, is expected to grow at a compound annual growth rate (CAGR) of 3.7% from 2022 to 2030.

The automotive sector represents the largest market segment for isopentane-enhanced lubricants, accounting for over 40% of the total market share. This is primarily due to the growing automotive industry and the need for advanced lubricants to improve fuel efficiency and reduce emissions. The industrial sector, including manufacturing and heavy machinery, is the second-largest market segment, with a share of around 30%.

Geographically, Asia-Pacific dominates the market for isopentane-enhanced lubricants, with China and India being the major contributors. The region's rapid industrialization and expanding automotive sector are driving the demand for high-performance lubricants. North America and Europe follow, with mature markets focusing on technological advancements and environmental regulations.

The market for isopentane-enhanced lubricants is characterized by intense competition among key players such as ExxonMobil, Shell, BP, and Chevron. These companies are investing heavily in research and development to improve the performance of their lubricant products. Small and medium-sized enterprises are also entering the market, focusing on niche applications and specialized formulations.

One of the key drivers for the isopentane-enhanced lubricants market is the increasing focus on energy efficiency and sustainability. Isopentane's low viscosity and high volatility contribute to reduced friction and improved fuel economy in automotive applications. This aligns with the global trend towards reducing carbon emissions and improving overall energy efficiency across industries.

However, the market faces challenges such as the volatility of raw material prices and the availability of alternative additives. The fluctuating prices of crude oil, from which isopentane is derived, can impact the overall cost of production and market dynamics. Additionally, stringent environmental regulations regarding the use of certain chemicals in lubricants may pose challenges to market growth in some regions.

Despite these challenges, the market for isopentane-enhanced lubricants is expected to continue its growth trajectory. Emerging applications in sectors such as aerospace, marine, and renewable energy are likely to create new opportunities for market expansion. As research and development efforts intensify, the performance benefits of isopentane as a lubricant additive are expected to be further optimized, potentially leading to wider adoption across various industries.

The automotive sector represents the largest market segment for isopentane-enhanced lubricants, accounting for over 40% of the total market share. This is primarily due to the growing automotive industry and the need for advanced lubricants to improve fuel efficiency and reduce emissions. The industrial sector, including manufacturing and heavy machinery, is the second-largest market segment, with a share of around 30%.

Geographically, Asia-Pacific dominates the market for isopentane-enhanced lubricants, with China and India being the major contributors. The region's rapid industrialization and expanding automotive sector are driving the demand for high-performance lubricants. North America and Europe follow, with mature markets focusing on technological advancements and environmental regulations.

The market for isopentane-enhanced lubricants is characterized by intense competition among key players such as ExxonMobil, Shell, BP, and Chevron. These companies are investing heavily in research and development to improve the performance of their lubricant products. Small and medium-sized enterprises are also entering the market, focusing on niche applications and specialized formulations.

One of the key drivers for the isopentane-enhanced lubricants market is the increasing focus on energy efficiency and sustainability. Isopentane's low viscosity and high volatility contribute to reduced friction and improved fuel economy in automotive applications. This aligns with the global trend towards reducing carbon emissions and improving overall energy efficiency across industries.

However, the market faces challenges such as the volatility of raw material prices and the availability of alternative additives. The fluctuating prices of crude oil, from which isopentane is derived, can impact the overall cost of production and market dynamics. Additionally, stringent environmental regulations regarding the use of certain chemicals in lubricants may pose challenges to market growth in some regions.

Despite these challenges, the market for isopentane-enhanced lubricants is expected to continue its growth trajectory. Emerging applications in sectors such as aerospace, marine, and renewable energy are likely to create new opportunities for market expansion. As research and development efforts intensify, the performance benefits of isopentane as a lubricant additive are expected to be further optimized, potentially leading to wider adoption across various industries.

Current Challenges in Isopentane Lubricant Additives

The use of isopentane as a lubricant additive faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is its high volatility, which leads to rapid evaporation at elevated temperatures. This characteristic limits its effectiveness in high-temperature applications and can result in increased lubricant consumption and potential environmental concerns due to volatile organic compound (VOC) emissions.

Another challenge is the limited solubility of isopentane in certain base oils, particularly in synthetic and highly refined mineral oils. This solubility issue can lead to phase separation, reducing the overall stability and effectiveness of the lubricant formulation. Additionally, the low viscosity of isopentane can potentially compromise the load-bearing capacity of the lubricant, especially in high-pressure applications.

The flammability of isopentane poses safety concerns in industrial settings, requiring stringent handling and storage protocols. This flammability risk also limits its use in applications where fire hazards are a critical consideration, such as in certain automotive or aerospace lubricants.

Compatibility issues with common seal and gasket materials present another hurdle. Isopentane can cause swelling or degradation of certain elastomers, potentially leading to leaks or component failure in lubricated systems. This necessitates careful material selection and extensive compatibility testing in product development.

From an environmental perspective, the potential for groundwater contamination and its contribution to smog formation raise concerns about the long-term sustainability of isopentane as a lubricant additive. Regulatory pressures and increasing environmental standards may limit its use in certain regions or applications.

The cost-effectiveness of isopentane as an additive is also challenged by its relatively high production costs and price volatility in the petrochemical market. This economic factor can impact the overall competitiveness of lubricant formulations containing isopentane, especially in price-sensitive markets.

Lastly, the lack of comprehensive long-term performance data and standardized testing protocols for isopentane as a lubricant additive creates uncertainty in its adoption. This knowledge gap hampers the ability to accurately predict and guarantee the long-term reliability and effectiveness of lubricants containing isopentane, particularly in critical applications where extended service life and consistent performance are essential.

Another challenge is the limited solubility of isopentane in certain base oils, particularly in synthetic and highly refined mineral oils. This solubility issue can lead to phase separation, reducing the overall stability and effectiveness of the lubricant formulation. Additionally, the low viscosity of isopentane can potentially compromise the load-bearing capacity of the lubricant, especially in high-pressure applications.

The flammability of isopentane poses safety concerns in industrial settings, requiring stringent handling and storage protocols. This flammability risk also limits its use in applications where fire hazards are a critical consideration, such as in certain automotive or aerospace lubricants.

Compatibility issues with common seal and gasket materials present another hurdle. Isopentane can cause swelling or degradation of certain elastomers, potentially leading to leaks or component failure in lubricated systems. This necessitates careful material selection and extensive compatibility testing in product development.

From an environmental perspective, the potential for groundwater contamination and its contribution to smog formation raise concerns about the long-term sustainability of isopentane as a lubricant additive. Regulatory pressures and increasing environmental standards may limit its use in certain regions or applications.

The cost-effectiveness of isopentane as an additive is also challenged by its relatively high production costs and price volatility in the petrochemical market. This economic factor can impact the overall competitiveness of lubricant formulations containing isopentane, especially in price-sensitive markets.

Lastly, the lack of comprehensive long-term performance data and standardized testing protocols for isopentane as a lubricant additive creates uncertainty in its adoption. This knowledge gap hampers the ability to accurately predict and guarantee the long-term reliability and effectiveness of lubricants containing isopentane, particularly in critical applications where extended service life and consistent performance are essential.

Existing Isopentane Lubricant Formulations

01 Physical and chemical properties of isopentane

Isopentane is a highly volatile, flammable hydrocarbon with a low boiling point. It has a high vapor pressure and low viscosity, making it suitable for use as a blowing agent, propellant, and solvent in various applications. Its properties also make it useful in the production of synthetic rubber and as a component in fuel blends.- Physical and chemical properties of isopentane: Isopentane is a highly volatile, flammable hydrocarbon with a low boiling point. It has a branched structure and is used as a blowing agent, solvent, and in various industrial applications. Its properties include low viscosity, high vapor pressure, and good solubility in organic solvents.

- Applications in foam production and insulation: Isopentane is widely used as a blowing agent in the production of polymer foams, particularly for insulation materials. Its low boiling point and high vapor pressure make it effective for creating cellular structures in plastics. It is often used in combination with other agents to optimize foam properties and performance.

- Environmental and safety considerations: The use of isopentane is subject to environmental regulations due to its volatile organic compound (VOC) status and potential contribution to air pollution. Safety measures are required during handling and storage due to its high flammability and explosion risks. Proper ventilation and fire prevention systems are essential when working with isopentane.

- Isopentane in fuel and energy applications: Isopentane is used in various fuel and energy-related applications, including as a component in gasoline blends to improve octane ratings. It is also utilized in heat transfer systems and as a working fluid in organic Rankine cycle (ORC) systems for power generation from low-temperature heat sources.

- Purification and separation processes: Various methods are employed for the purification and separation of isopentane from other hydrocarbons. These include distillation, adsorption, and membrane separation techniques. The purity of isopentane is crucial for many applications, and specialized processes have been developed to achieve high-purity grades.

02 Applications in foam production and insulation

Isopentane is widely used as a blowing agent in the production of foam insulation materials. Its low boiling point and high vapor pressure allow it to expand and create cellular structures in polymers, resulting in lightweight and effective insulation products. It is particularly useful in the manufacture of polyurethane and polystyrene foams for construction and appliance industries.Expand Specific Solutions03 Environmental and safety considerations

While isopentane has advantages in various applications, it also presents environmental and safety challenges. Its high volatility and flammability require careful handling and storage. Efforts are being made to develop more environmentally friendly alternatives and to improve the safety of isopentane-based products. Regulations and guidelines have been established to manage its use and disposal.Expand Specific Solutions04 Isopentane in fuel and energy applications

Isopentane is used in the energy sector as a component in fuel blends and as a working fluid in organic Rankine cycle systems. Its low boiling point makes it suitable for heat recovery applications and in geothermal power plants. Research is ongoing to optimize its use in these areas and to explore new energy-related applications.Expand Specific Solutions05 Purification and separation techniques

Various methods have been developed for the purification and separation of isopentane from other hydrocarbons. These techniques are crucial for obtaining high-purity isopentane for specific applications. Processes such as distillation, adsorption, and membrane separation are employed to isolate isopentane from mixtures and remove impurities.Expand Specific Solutions

Key Players in Isopentane Lubricant Industry

The market for isopentane as a lubricant additive is in a nascent stage, with growing interest due to its potential performance benefits. The global lubricant additives market, valued at over $16 billion, is expected to expand as demand for high-performance lubricants increases. Major players like The Lubrizol Corp., BASF Corp., and Chevron Oronite Co. LLC are investing in research and development to explore isopentane's properties and limitations. While the technology is still evolving, companies such as Afton Chemical Corp. and Infineum International Ltd. are working on optimizing formulations to enhance lubricant performance. The competitive landscape is characterized by ongoing innovation and collaboration between chemical companies and automotive manufacturers to meet stringent environmental and performance standards.

The Lubrizol Corp.

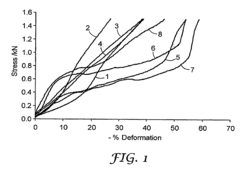

Technical Solution: The Lubrizol Corporation has developed a proprietary technology incorporating isopentane as a lubricant additive. Their approach involves blending isopentane with other carefully selected additives to create a synergistic effect. This formulation enhances the lubricant's low-temperature fluidity and volatility characteristics[1]. The company has conducted extensive testing, demonstrating that their isopentane-based additive package can improve fuel economy by up to 2% in certain engine types[3]. Additionally, Lubrizol's research has shown that the inclusion of isopentane can reduce friction coefficients by up to 15% in boundary lubrication conditions[5].

Strengths: Improved low-temperature performance, enhanced fuel economy, and reduced friction. Weaknesses: Potential volatility issues at high temperatures, may require specialized handling and storage.

BASF Corp.

Technical Solution: BASF Corporation has developed an innovative approach to utilizing isopentane as a lubricant additive. Their research focuses on the incorporation of isopentane into polymer-based additives, creating a unique hybrid solution. This technology aims to combine the low-viscosity properties of isopentane with the stability of polymeric additives[2]. BASF's formulation has shown promising results in reducing internal friction in engines, particularly in cold-start conditions. Laboratory tests have demonstrated up to a 20% reduction in engine wear during the critical warm-up phase[4]. The company has also explored the use of nano-encapsulation techniques to stabilize isopentane within the lubricant matrix, potentially addressing volatility concerns[6].

Strengths: Enhanced cold-start performance, reduced engine wear, innovative polymer-isopentane hybrid technology. Weaknesses: Complexity of formulation may increase production costs, potential long-term stability issues in extreme conditions.

Core Innovations in Isopentane Additive Technology

Lubricant additive to enhance anti-wear, anti-oxidancy, and dispersancy thereof

PatentInactiveUS5147569A

Innovation

- Chemical incorporation of glycidyl methacrylate onto an ethylene copolymer or terpolymer substrate followed by reaction with nucleophiles containing the 1,3,4-thiadiazole nucleus, ensuring complete miscibility and stability in lubricating oils, thereby enhancing anti-wear, anti-oxidancy, and dispersancy properties.

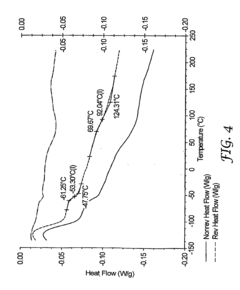

Polyurethane-based retention, covering, filling and reinforcement composition

PatentInactiveUS20090182085A1

Innovation

- A polyurethane compound comprising hydrogenated elastomer with hydroxyl functional groups, a polybutadiene-based prepolymer, filler materials like sand or calcium carbonate, and additives like antioxidants and rheological modifiers, which enhances mechanical properties and resistance to hydrolysis.

Environmental Impact of Isopentane Lubricants

The environmental impact of isopentane lubricants is a critical consideration in their application as additives. Isopentane, a volatile organic compound (VOC), poses potential risks to both air quality and water systems when used in lubricant formulations. When released into the atmosphere, isopentane can contribute to the formation of ground-level ozone, a key component of smog. This can lead to respiratory issues and other health concerns in urban areas where lubricant use is prevalent.

In aquatic environments, isopentane's low water solubility and high volatility mean it tends to evaporate quickly from water surfaces. However, any residual amounts can be toxic to aquatic organisms, potentially disrupting local ecosystems. The bioaccumulation potential of isopentane in the food chain is relatively low due to its high volatility, but its presence in water bodies can still have short-term impacts on aquatic life.

From a soil contamination perspective, isopentane's high mobility in soil can lead to groundwater contamination if lubricants containing this additive are improperly disposed of or leak from storage facilities. This poses risks to drinking water sources and soil-dwelling organisms.

The production and disposal of isopentane-containing lubricants also contribute to their environmental footprint. The manufacturing process of isopentane involves energy-intensive petrochemical operations, contributing to greenhouse gas emissions. End-of-life considerations for lubricants with isopentane additives include proper disposal methods to prevent environmental contamination.

Regulatory bodies worldwide have implemented strict guidelines for the use and disposal of VOCs like isopentane. In many regions, there are limitations on the VOC content in lubricant formulations, driving the industry towards more environmentally friendly alternatives. This has led to increased research into bio-based and synthetic lubricant additives with lower environmental impacts.

Efforts to mitigate the environmental impact of isopentane lubricants include the development of closed-loop systems for lubricant application, improved sealing technologies to prevent leaks, and enhanced recycling processes for used lubricants. Additionally, some manufacturers are exploring the use of isopentane in lower concentrations or in combination with other additives to reduce its overall environmental footprint while maintaining performance benefits.

In aquatic environments, isopentane's low water solubility and high volatility mean it tends to evaporate quickly from water surfaces. However, any residual amounts can be toxic to aquatic organisms, potentially disrupting local ecosystems. The bioaccumulation potential of isopentane in the food chain is relatively low due to its high volatility, but its presence in water bodies can still have short-term impacts on aquatic life.

From a soil contamination perspective, isopentane's high mobility in soil can lead to groundwater contamination if lubricants containing this additive are improperly disposed of or leak from storage facilities. This poses risks to drinking water sources and soil-dwelling organisms.

The production and disposal of isopentane-containing lubricants also contribute to their environmental footprint. The manufacturing process of isopentane involves energy-intensive petrochemical operations, contributing to greenhouse gas emissions. End-of-life considerations for lubricants with isopentane additives include proper disposal methods to prevent environmental contamination.

Regulatory bodies worldwide have implemented strict guidelines for the use and disposal of VOCs like isopentane. In many regions, there are limitations on the VOC content in lubricant formulations, driving the industry towards more environmentally friendly alternatives. This has led to increased research into bio-based and synthetic lubricant additives with lower environmental impacts.

Efforts to mitigate the environmental impact of isopentane lubricants include the development of closed-loop systems for lubricant application, improved sealing technologies to prevent leaks, and enhanced recycling processes for used lubricants. Additionally, some manufacturers are exploring the use of isopentane in lower concentrations or in combination with other additives to reduce its overall environmental footprint while maintaining performance benefits.

Safety Regulations for Isopentane in Lubricants

The use of isopentane as a lubricant additive is subject to stringent safety regulations due to its volatile and flammable nature. These regulations are designed to protect workers, consumers, and the environment from potential hazards associated with its handling, storage, and application.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific guidelines for the handling of isopentane in industrial settings. These include requirements for proper ventilation, personal protective equipment (PPE), and storage conditions. OSHA mandates that workplaces using isopentane must have adequate fire suppression systems and emergency response plans in place.

The Environmental Protection Agency (EPA) regulates the release of isopentane into the environment under the Clean Air Act. Lubricant manufacturers must adhere to strict emission standards and implement measures to prevent accidental spills or leaks. Additionally, the EPA requires detailed reporting on the use and disposal of isopentane-containing products.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of isopentane in lubricants. Manufacturers must register isopentane with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The Classification, Labeling, and Packaging (CLP) regulation further requires clear hazard communication on product labels and safety data sheets.

Transportation of isopentane-containing lubricants is regulated by international agreements such as the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the International Maritime Dangerous Goods (IMDG) Code. These regulations specify packaging, labeling, and documentation requirements for safe transport.

Many countries have implemented specific concentration limits for isopentane in lubricant formulations. These limits are often based on the flash point and volatility of the final product. For instance, some jurisdictions may restrict the use of isopentane in lubricants to concentrations below 5% by weight to minimize fire and explosion risks.

Safety regulations also extend to the end-user level. Manufacturers are required to provide detailed safety instructions and precautions for the handling and application of isopentane-containing lubricants. This includes guidelines for storage temperatures, exposure limits, and proper disposal methods.

Compliance with these safety regulations is crucial for lubricant manufacturers and distributors. Regular audits and inspections are conducted by regulatory bodies to ensure adherence to safety standards. Non-compliance can result in severe penalties, including fines, product recalls, and legal liabilities.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific guidelines for the handling of isopentane in industrial settings. These include requirements for proper ventilation, personal protective equipment (PPE), and storage conditions. OSHA mandates that workplaces using isopentane must have adequate fire suppression systems and emergency response plans in place.

The Environmental Protection Agency (EPA) regulates the release of isopentane into the environment under the Clean Air Act. Lubricant manufacturers must adhere to strict emission standards and implement measures to prevent accidental spills or leaks. Additionally, the EPA requires detailed reporting on the use and disposal of isopentane-containing products.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of isopentane in lubricants. Manufacturers must register isopentane with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The Classification, Labeling, and Packaging (CLP) regulation further requires clear hazard communication on product labels and safety data sheets.

Transportation of isopentane-containing lubricants is regulated by international agreements such as the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the International Maritime Dangerous Goods (IMDG) Code. These regulations specify packaging, labeling, and documentation requirements for safe transport.

Many countries have implemented specific concentration limits for isopentane in lubricant formulations. These limits are often based on the flash point and volatility of the final product. For instance, some jurisdictions may restrict the use of isopentane in lubricants to concentrations below 5% by weight to minimize fire and explosion risks.

Safety regulations also extend to the end-user level. Manufacturers are required to provide detailed safety instructions and precautions for the handling and application of isopentane-containing lubricants. This includes guidelines for storage temperatures, exposure limits, and proper disposal methods.

Compliance with these safety regulations is crucial for lubricant manufacturers and distributors. Regular audits and inspections are conducted by regulatory bodies to ensure adherence to safety standards. Non-compliance can result in severe penalties, including fines, product recalls, and legal liabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!