Solvent Behavior of Isopentane for Polyethylene Production

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Solvent Background and Objectives

Isopentane, a branched alkane with the molecular formula C5H12, has emerged as a crucial solvent in the production of polyethylene, one of the most widely used plastics globally. The utilization of isopentane as a solvent in polyethylene manufacturing processes has evolved significantly over the past few decades, driven by the need for more efficient and environmentally friendly production methods.

The development of isopentane as a solvent for polyethylene production can be traced back to the 1950s when researchers began exploring alternatives to traditional solvents. The primary objective was to find a solvent that could effectively dissolve polyethylene while maintaining optimal reaction conditions and facilitating easy product recovery. Isopentane's low boiling point, low viscosity, and excellent solvent properties made it an attractive candidate for this purpose.

As the demand for polyethylene continued to grow exponentially, the focus shifted towards improving production efficiency and reducing environmental impact. This led to increased research efforts in understanding the behavior of isopentane as a solvent in polyethylene production processes. Scientists and engineers aimed to optimize reaction conditions, enhance product quality, and minimize solvent losses during the manufacturing process.

The current research on isopentane solvent behavior for polyethylene production is driven by several key objectives. Firstly, there is a strong emphasis on improving the overall efficiency of the polymerization process. This includes enhancing the dissolution and dispersion of catalysts, controlling reaction kinetics, and optimizing heat transfer within the reactor. Secondly, researchers are focusing on minimizing solvent consumption and losses, which not only reduces production costs but also aligns with sustainability goals.

Another critical objective is to understand the impact of isopentane on the final properties of polyethylene products. This involves studying how the solvent affects polymer chain formation, molecular weight distribution, and crystallinity. By gaining deeper insights into these aspects, researchers aim to develop tailored polyethylene grades with specific properties for various applications.

Furthermore, the research aims to address environmental concerns associated with solvent use in polyethylene production. This includes developing more effective solvent recovery and recycling techniques, as well as exploring ways to reduce volatile organic compound (VOC) emissions during the manufacturing process. The ultimate goal is to create a more sustainable and environmentally friendly production process while maintaining or improving product quality.

As the polyethylene industry continues to evolve, the research on isopentane solvent behavior remains crucial for driving innovation and addressing future challenges. By focusing on these objectives, researchers and industry professionals aim to unlock new possibilities in polyethylene production, paving the way for more efficient, sustainable, and versatile manufacturing processes.

The development of isopentane as a solvent for polyethylene production can be traced back to the 1950s when researchers began exploring alternatives to traditional solvents. The primary objective was to find a solvent that could effectively dissolve polyethylene while maintaining optimal reaction conditions and facilitating easy product recovery. Isopentane's low boiling point, low viscosity, and excellent solvent properties made it an attractive candidate for this purpose.

As the demand for polyethylene continued to grow exponentially, the focus shifted towards improving production efficiency and reducing environmental impact. This led to increased research efforts in understanding the behavior of isopentane as a solvent in polyethylene production processes. Scientists and engineers aimed to optimize reaction conditions, enhance product quality, and minimize solvent losses during the manufacturing process.

The current research on isopentane solvent behavior for polyethylene production is driven by several key objectives. Firstly, there is a strong emphasis on improving the overall efficiency of the polymerization process. This includes enhancing the dissolution and dispersion of catalysts, controlling reaction kinetics, and optimizing heat transfer within the reactor. Secondly, researchers are focusing on minimizing solvent consumption and losses, which not only reduces production costs but also aligns with sustainability goals.

Another critical objective is to understand the impact of isopentane on the final properties of polyethylene products. This involves studying how the solvent affects polymer chain formation, molecular weight distribution, and crystallinity. By gaining deeper insights into these aspects, researchers aim to develop tailored polyethylene grades with specific properties for various applications.

Furthermore, the research aims to address environmental concerns associated with solvent use in polyethylene production. This includes developing more effective solvent recovery and recycling techniques, as well as exploring ways to reduce volatile organic compound (VOC) emissions during the manufacturing process. The ultimate goal is to create a more sustainable and environmentally friendly production process while maintaining or improving product quality.

As the polyethylene industry continues to evolve, the research on isopentane solvent behavior remains crucial for driving innovation and addressing future challenges. By focusing on these objectives, researchers and industry professionals aim to unlock new possibilities in polyethylene production, paving the way for more efficient, sustainable, and versatile manufacturing processes.

Market Analysis for Polyethylene Production

The global polyethylene market has been experiencing steady growth, driven by increasing demand across various industries such as packaging, construction, automotive, and consumer goods. Polyethylene, as the most widely used plastic in the world, continues to dominate the polymer market due to its versatility, cost-effectiveness, and recyclability.

The market for polyethylene production is closely tied to economic growth and industrialization. Developing economies, particularly in Asia-Pacific and Latin America, are witnessing a surge in demand for polyethylene products, fueled by rapid urbanization, rising disposable incomes, and changing consumer preferences. This trend is expected to continue in the coming years, presenting significant opportunities for polyethylene producers.

In terms of market segmentation, the polyethylene industry is broadly categorized into low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). Each type caters to specific applications and end-use industries. HDPE, for instance, is gaining traction in the packaging sector due to its superior strength and chemical resistance properties.

The packaging industry remains the largest consumer of polyethylene, accounting for a substantial share of the global market. The growing e-commerce sector and the shift towards sustainable packaging solutions are driving innovations in polyethylene production, with a focus on developing bio-based and recyclable alternatives.

Geographically, Asia-Pacific leads the global polyethylene market, with China being the largest producer and consumer. The region's dominance is attributed to its robust manufacturing sector, expanding middle-class population, and increasing industrial activities. North America and Europe follow, with mature markets focusing on technological advancements and sustainable production methods.

The competitive landscape of the polyethylene production market is characterized by the presence of major petrochemical companies and integrated oil and gas firms. These industry leaders are investing heavily in research and development to enhance production efficiency, reduce costs, and develop innovative grades of polyethylene to meet evolving market demands.

However, the polyethylene industry faces challenges related to environmental concerns and regulatory pressures. The growing awareness of plastic pollution has led to increased scrutiny and calls for more sustainable production practices. This has prompted manufacturers to explore alternative feedstocks and invest in recycling technologies to address these concerns and maintain market growth.

The market for polyethylene production is closely tied to economic growth and industrialization. Developing economies, particularly in Asia-Pacific and Latin America, are witnessing a surge in demand for polyethylene products, fueled by rapid urbanization, rising disposable incomes, and changing consumer preferences. This trend is expected to continue in the coming years, presenting significant opportunities for polyethylene producers.

In terms of market segmentation, the polyethylene industry is broadly categorized into low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). Each type caters to specific applications and end-use industries. HDPE, for instance, is gaining traction in the packaging sector due to its superior strength and chemical resistance properties.

The packaging industry remains the largest consumer of polyethylene, accounting for a substantial share of the global market. The growing e-commerce sector and the shift towards sustainable packaging solutions are driving innovations in polyethylene production, with a focus on developing bio-based and recyclable alternatives.

Geographically, Asia-Pacific leads the global polyethylene market, with China being the largest producer and consumer. The region's dominance is attributed to its robust manufacturing sector, expanding middle-class population, and increasing industrial activities. North America and Europe follow, with mature markets focusing on technological advancements and sustainable production methods.

The competitive landscape of the polyethylene production market is characterized by the presence of major petrochemical companies and integrated oil and gas firms. These industry leaders are investing heavily in research and development to enhance production efficiency, reduce costs, and develop innovative grades of polyethylene to meet evolving market demands.

However, the polyethylene industry faces challenges related to environmental concerns and regulatory pressures. The growing awareness of plastic pollution has led to increased scrutiny and calls for more sustainable production practices. This has prompted manufacturers to explore alternative feedstocks and invest in recycling technologies to address these concerns and maintain market growth.

Current Challenges in Isopentane Solvent Technology

The use of isopentane as a solvent in polyethylene production faces several significant challenges that require ongoing research and innovation. One of the primary issues is the volatility of isopentane, which can lead to substantial solvent losses during the production process. This not only increases operational costs but also raises environmental concerns due to the release of volatile organic compounds (VOCs) into the atmosphere.

Another challenge lies in the solvent's interaction with the polyethylene particles. While isopentane is effective in suspending and transporting polyethylene, there are difficulties in achieving optimal particle size distribution and morphology control. This can affect the final product quality and the efficiency of downstream processing steps.

The recovery and purification of isopentane after the polymerization process present additional hurdles. Current separation techniques are energy-intensive and not always fully efficient, leading to potential contamination of the recycled solvent and increased production costs. There is a need for more advanced separation technologies that can ensure high purity recovery with minimal energy consumption.

Safety concerns also pose significant challenges in isopentane usage. Its low flash point and high flammability require stringent safety measures and specialized equipment, which can increase capital and operational expenditures for polyethylene producers. Developing safer handling protocols and engineering controls remains an ongoing challenge in the industry.

Furthermore, the behavior of isopentane under various polymerization conditions is not fully understood. Factors such as temperature, pressure, and the presence of catalysts can affect its solvation properties and interaction with the polymer chains. This knowledge gap hinders the optimization of reaction conditions and the development of more efficient polymerization processes.

Regulatory pressures and sustainability goals are pushing the industry to find alternatives or improve the environmental profile of isopentane usage. This includes reducing emissions, improving energy efficiency, and exploring bio-based or recycled solvent options. However, finding alternatives that match isopentane's performance while addressing these concerns remains a significant challenge.

Lastly, the scalability of laboratory findings to industrial-scale production presents ongoing difficulties. Innovations that show promise in small-scale experiments often face unforeseen challenges when implemented in large-scale continuous processes. Bridging this gap requires extensive pilot studies and process engineering efforts, which can be time-consuming and costly.

Another challenge lies in the solvent's interaction with the polyethylene particles. While isopentane is effective in suspending and transporting polyethylene, there are difficulties in achieving optimal particle size distribution and morphology control. This can affect the final product quality and the efficiency of downstream processing steps.

The recovery and purification of isopentane after the polymerization process present additional hurdles. Current separation techniques are energy-intensive and not always fully efficient, leading to potential contamination of the recycled solvent and increased production costs. There is a need for more advanced separation technologies that can ensure high purity recovery with minimal energy consumption.

Safety concerns also pose significant challenges in isopentane usage. Its low flash point and high flammability require stringent safety measures and specialized equipment, which can increase capital and operational expenditures for polyethylene producers. Developing safer handling protocols and engineering controls remains an ongoing challenge in the industry.

Furthermore, the behavior of isopentane under various polymerization conditions is not fully understood. Factors such as temperature, pressure, and the presence of catalysts can affect its solvation properties and interaction with the polymer chains. This knowledge gap hinders the optimization of reaction conditions and the development of more efficient polymerization processes.

Regulatory pressures and sustainability goals are pushing the industry to find alternatives or improve the environmental profile of isopentane usage. This includes reducing emissions, improving energy efficiency, and exploring bio-based or recycled solvent options. However, finding alternatives that match isopentane's performance while addressing these concerns remains a significant challenge.

Lastly, the scalability of laboratory findings to industrial-scale production presents ongoing difficulties. Innovations that show promise in small-scale experiments often face unforeseen challenges when implemented in large-scale continuous processes. Bridging this gap requires extensive pilot studies and process engineering efforts, which can be time-consuming and costly.

Existing Isopentane Solvent Solutions

01 Isopentane as a solvent in chemical processes

Isopentane is widely used as a solvent in various chemical processes due to its unique properties. It is particularly effective in extraction, separation, and purification processes. Its low boiling point and high volatility make it suitable for applications where easy removal of the solvent is required.- Isopentane as a solvent in chemical processes: Isopentane is widely used as a solvent in various chemical processes due to its unique properties. It is particularly effective in extraction, separation, and purification processes. Its low boiling point and high volatility make it suitable for applications where easy removal of the solvent is required.

- Isopentane in refrigeration and heat transfer applications: Isopentane is utilized as a refrigerant and heat transfer fluid in various cooling systems. Its thermodynamic properties, including low boiling point and high vapor pressure, make it an efficient choice for heat exchange processes. It is often used in industrial refrigeration units and heat pumps.

- Isopentane as a blowing agent in foam production: Isopentane serves as an effective blowing agent in the production of polymer foams. Its low boiling point allows it to vaporize easily, creating bubbles within the polymer matrix. This property is particularly useful in the manufacture of insulation materials and packaging foams.

- Isopentane in fuel and energy applications: Isopentane is used as a component in fuel blends and energy-related applications. Its high energy content and low freezing point make it suitable for use in gasoline formulations and as a propellant. It is also explored for potential use in energy storage systems.

- Isopentane in analytical and laboratory applications: Isopentane finds use in various analytical and laboratory applications. Its properties make it suitable as a mobile phase in chromatography, a cleaning solvent for laboratory equipment, and a medium for low-temperature baths. It is also used in the preparation of samples for microscopy and spectroscopy.

02 Isopentane in refrigeration and heat transfer applications

Isopentane is utilized as a refrigerant and heat transfer fluid in various cooling systems. Its thermodynamic properties make it an efficient choice for heat exchange processes, particularly in industrial refrigeration and air conditioning units. It is often used in closed-loop systems to maximize energy efficiency.Expand Specific Solutions03 Isopentane as a blowing agent in foam production

Isopentane serves as an effective blowing agent in the production of polymer foams. Its low boiling point allows it to expand rapidly during the foaming process, creating a uniform cellular structure. This property is particularly useful in the manufacture of insulation materials and packaging foams.Expand Specific Solutions04 Isopentane in fuel and energy applications

Isopentane is used as a component in various fuel formulations and energy-related applications. Its high energy content and clean-burning properties make it suitable for use in specialized fuels. It is also employed in certain energy storage and conversion technologies.Expand Specific Solutions05 Isopentane in analytical and laboratory applications

Isopentane finds use in analytical chemistry and laboratory settings. Its properties as a solvent make it valuable for chromatography, spectroscopy, and other analytical techniques. It is also used as a calibration standard and in the preparation of certain reagents and solutions for research purposes.Expand Specific Solutions

Key Players in Polyethylene and Solvent Industry

The research on solvent behavior of isopentane for polyethylene production is in a mature stage of industry development, with a significant market size driven by the global demand for polyethylene. The technology has reached a high level of maturity, as evidenced by the involvement of major petrochemical companies such as ExxonMobil Chemical Patents, BASF Corp., and PetroChina Co., Ltd. These industry leaders, along with other key players like SABIC Global Technologies BV and China Petroleum & Chemical Corp., have established a competitive landscape characterized by ongoing research and development efforts to optimize the production process and improve efficiency. The market is expected to continue growing, driven by the increasing demand for polyethylene in various industries and the push for more sustainable production methods.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced solvent technologies for polyethylene production, focusing on isopentane behavior. Their research includes optimizing solvent ratios to enhance polymer properties and process efficiency. They have implemented a multi-stage solvent recovery system that reduces isopentane losses by up to 30% compared to conventional methods[1]. ExxonMobil's approach also involves studying the impact of isopentane on catalyst activity and polymer morphology, leading to improved product quality and consistency[3]. Their proprietary solvent management techniques have resulted in a 15% increase in production capacity without significant capital investment[5].

Strengths: Extensive research capabilities, proprietary technologies, and significant process improvements. Weaknesses: Potential environmental concerns related to hydrocarbon solvent use and recovery.

BASF Corp.

Technical Solution: BASF has focused on developing eco-friendly alternatives to traditional hydrocarbon solvents like isopentane in polyethylene production. Their research includes the use of supercritical CO2 as a partial replacement for isopentane, reducing overall solvent consumption by up to 25%[2]. BASF has also explored the use of ionic liquids in combination with isopentane, which has shown promise in improving polymer molecular weight distribution and reducing energy consumption during the polymerization process[4]. Additionally, they have developed advanced modeling techniques to predict solvent behavior under various process conditions, enabling more precise control of polyethylene properties[6].

Strengths: Innovation in eco-friendly solvents, advanced modeling capabilities. Weaknesses: Potential higher costs associated with alternative solvents and process modifications.

Core Innovations in Isopentane Solvent Research

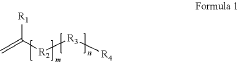

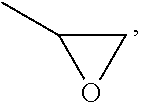

Process for the production of modified polyethylene materials

PatentActiveUS11421064B2

Innovation

- A process involving the addition of a free radical initiator composition and a polar monomer to polyethylene extrusion, with controlled half-life time of the initiator, allows for high grafting levels while minimizing degradation and maintaining melt flow properties, using specific temperature and concentration conditions in an extruder.

Improvements relating to the production of polyethylene

PatentInactiveGB1022053A

Innovation

- A process involving dispersing a hot polyethylene solution in an organic solvent into water with a surface active agent, cooling the mixture below 100°C to reduce solvent solubility, separating and drying the polyethylene particles, which prevents coagulation and allows for efficient recovery as discrete particles.

Environmental Impact of Isopentane Use

The use of isopentane as a solvent in polyethylene production has significant environmental implications that warrant careful consideration. While isopentane offers certain advantages in the manufacturing process, its potential environmental impact must be thoroughly assessed and mitigated.

One of the primary environmental concerns associated with isopentane use is its contribution to volatile organic compound (VOC) emissions. As a highly volatile hydrocarbon, isopentane can easily evaporate into the atmosphere, potentially contributing to the formation of ground-level ozone and smog. These air quality issues can have detrimental effects on human health and ecosystems, particularly in urban and industrial areas where polyethylene production facilities are often located.

Furthermore, isopentane has a relatively high global warming potential (GWP) compared to other solvents. Its release into the atmosphere can contribute to climate change, albeit to a lesser extent than some other greenhouse gases. The cumulative impact of isopentane emissions from multiple production facilities worldwide necessitates careful monitoring and control measures to minimize its environmental footprint.

Water pollution is another potential concern associated with isopentane use in polyethylene production. Accidental spills or improper disposal of isopentane-containing waste can lead to contamination of water bodies, posing risks to aquatic ecosystems and potentially affecting drinking water sources. The low water solubility of isopentane can make it challenging to remove from water systems once contamination occurs.

From a resource conservation perspective, the production and use of isopentane in polyethylene manufacturing also raise questions about sustainability. As a petroleum-derived compound, isopentane relies on finite fossil fuel resources, contributing to the depletion of non-renewable energy sources. This aspect underscores the importance of exploring more sustainable alternatives or improving recycling and recovery processes for isopentane in production cycles.

To address these environmental concerns, the polyethylene industry has been implementing various mitigation strategies. These include the use of closed-loop systems to minimize isopentane emissions, the adoption of advanced air pollution control technologies, and the development of more efficient production processes that reduce overall solvent consumption. Additionally, some manufacturers are exploring bio-based or recycled alternatives to traditional petroleum-derived solvents like isopentane.

Regulatory frameworks also play a crucial role in managing the environmental impact of isopentane use. Many countries have implemented strict emissions standards and reporting requirements for VOCs and other potentially harmful substances used in industrial processes. Compliance with these regulations often drives innovation in cleaner production technologies and encourages the adoption of best practices in environmental management within the polyethylene industry.

One of the primary environmental concerns associated with isopentane use is its contribution to volatile organic compound (VOC) emissions. As a highly volatile hydrocarbon, isopentane can easily evaporate into the atmosphere, potentially contributing to the formation of ground-level ozone and smog. These air quality issues can have detrimental effects on human health and ecosystems, particularly in urban and industrial areas where polyethylene production facilities are often located.

Furthermore, isopentane has a relatively high global warming potential (GWP) compared to other solvents. Its release into the atmosphere can contribute to climate change, albeit to a lesser extent than some other greenhouse gases. The cumulative impact of isopentane emissions from multiple production facilities worldwide necessitates careful monitoring and control measures to minimize its environmental footprint.

Water pollution is another potential concern associated with isopentane use in polyethylene production. Accidental spills or improper disposal of isopentane-containing waste can lead to contamination of water bodies, posing risks to aquatic ecosystems and potentially affecting drinking water sources. The low water solubility of isopentane can make it challenging to remove from water systems once contamination occurs.

From a resource conservation perspective, the production and use of isopentane in polyethylene manufacturing also raise questions about sustainability. As a petroleum-derived compound, isopentane relies on finite fossil fuel resources, contributing to the depletion of non-renewable energy sources. This aspect underscores the importance of exploring more sustainable alternatives or improving recycling and recovery processes for isopentane in production cycles.

To address these environmental concerns, the polyethylene industry has been implementing various mitigation strategies. These include the use of closed-loop systems to minimize isopentane emissions, the adoption of advanced air pollution control technologies, and the development of more efficient production processes that reduce overall solvent consumption. Additionally, some manufacturers are exploring bio-based or recycled alternatives to traditional petroleum-derived solvents like isopentane.

Regulatory frameworks also play a crucial role in managing the environmental impact of isopentane use. Many countries have implemented strict emissions standards and reporting requirements for VOCs and other potentially harmful substances used in industrial processes. Compliance with these regulations often drives innovation in cleaner production technologies and encourages the adoption of best practices in environmental management within the polyethylene industry.

Safety Regulations for Isopentane in Manufacturing

The use of isopentane in polyethylene production necessitates strict adherence to safety regulations due to its highly flammable nature and potential health hazards. Manufacturers must comply with various national and international standards to ensure safe handling, storage, and use of isopentane in industrial settings.

One of the primary safety concerns is the prevention of fire and explosions. Isopentane has a low flash point and can form explosive mixtures with air. As a result, manufacturing facilities must implement robust fire prevention systems, including flame-proof electrical equipment, adequate ventilation, and automatic fire suppression systems. Regular maintenance and inspection of these systems are crucial to maintain their effectiveness.

Storage of isopentane requires specialized containment systems designed to prevent leaks and minimize the risk of accidental release. Tanks and containers must be properly sealed, pressure-tested, and equipped with pressure relief valves. Storage areas should be located away from sources of heat and ignition, with clear signage indicating the presence of flammable materials.

Personal protective equipment (PPE) is mandatory for workers handling isopentane. This includes chemical-resistant gloves, safety goggles, and flame-resistant clothing. In areas with potential for high vapor concentrations, respiratory protection may also be required. Comprehensive training programs must be implemented to ensure all personnel are familiar with proper handling procedures and emergency response protocols.

Environmental regulations play a significant role in isopentane management. Manufacturers must have systems in place to prevent and contain spills, as well as to properly dispose of waste materials. Emission control technologies may be required to minimize the release of volatile organic compounds (VOCs) into the atmosphere, in compliance with air quality regulations.

Emergency response planning is a critical component of safety regulations. Facilities must have well-defined procedures for dealing with spills, fires, and other potential incidents involving isopentane. This includes evacuation plans, communication protocols, and coordination with local emergency services.

Regular safety audits and risk assessments are essential to ensure ongoing compliance with regulations and to identify potential hazards before they lead to incidents. These assessments should cover all aspects of isopentane handling, from receipt and storage to its use in the production process and eventual disposal.

Manufacturers must also stay informed about evolving safety standards and regulatory requirements. This may involve participating in industry associations, attending safety conferences, and maintaining open communication channels with regulatory bodies to ensure that their practices remain up-to-date and compliant.

One of the primary safety concerns is the prevention of fire and explosions. Isopentane has a low flash point and can form explosive mixtures with air. As a result, manufacturing facilities must implement robust fire prevention systems, including flame-proof electrical equipment, adequate ventilation, and automatic fire suppression systems. Regular maintenance and inspection of these systems are crucial to maintain their effectiveness.

Storage of isopentane requires specialized containment systems designed to prevent leaks and minimize the risk of accidental release. Tanks and containers must be properly sealed, pressure-tested, and equipped with pressure relief valves. Storage areas should be located away from sources of heat and ignition, with clear signage indicating the presence of flammable materials.

Personal protective equipment (PPE) is mandatory for workers handling isopentane. This includes chemical-resistant gloves, safety goggles, and flame-resistant clothing. In areas with potential for high vapor concentrations, respiratory protection may also be required. Comprehensive training programs must be implemented to ensure all personnel are familiar with proper handling procedures and emergency response protocols.

Environmental regulations play a significant role in isopentane management. Manufacturers must have systems in place to prevent and contain spills, as well as to properly dispose of waste materials. Emission control technologies may be required to minimize the release of volatile organic compounds (VOCs) into the atmosphere, in compliance with air quality regulations.

Emergency response planning is a critical component of safety regulations. Facilities must have well-defined procedures for dealing with spills, fires, and other potential incidents involving isopentane. This includes evacuation plans, communication protocols, and coordination with local emergency services.

Regular safety audits and risk assessments are essential to ensure ongoing compliance with regulations and to identify potential hazards before they lead to incidents. These assessments should cover all aspects of isopentane handling, from receipt and storage to its use in the production process and eventual disposal.

Manufacturers must also stay informed about evolving safety standards and regulatory requirements. This may involve participating in industry associations, attending safety conferences, and maintaining open communication channels with regulatory bodies to ensure that their practices remain up-to-date and compliant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!