Isopentane as a Calibration Gas for Analytical Devices

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Calibration Background and Objectives

Isopentane, a volatile organic compound with the chemical formula C5H12, has emerged as a crucial calibration gas for analytical devices in recent years. The evolution of this technology stems from the increasing demand for precise and reliable calibration methods in various industries, including environmental monitoring, petrochemical processing, and quality control in manufacturing.

The use of isopentane as a calibration gas has its roots in the broader field of gas chromatography and mass spectrometry. These analytical techniques have been instrumental in identifying and quantifying complex mixtures of organic compounds for decades. As the need for more accurate and sensitive measurements grew, so did the importance of reliable calibration standards.

Isopentane's unique properties make it an ideal candidate for calibration purposes. Its low boiling point, high vapor pressure, and chemical stability contribute to its effectiveness as a reference gas. These characteristics allow for consistent and reproducible results across a wide range of analytical instruments and environmental conditions.

The development of isopentane as a calibration gas has been driven by several factors. First, the increasing stringency of environmental regulations has necessitated more precise measurement techniques for volatile organic compounds. Second, advancements in analytical instrumentation have enabled the detection of ever-smaller concentrations of analytes, requiring equally precise calibration methods.

The primary objective of research into isopentane as a calibration gas is to enhance the accuracy and reliability of analytical measurements. This involves optimizing the preparation and delivery of isopentane calibration standards, as well as developing robust methodologies for its use across different types of analytical devices.

Another key goal is to expand the applicability of isopentane calibration to a broader range of analytical techniques and industries. This includes exploring its potential in emerging fields such as portable and real-time monitoring devices, which present unique challenges in terms of calibration stability and precision.

Furthermore, researchers aim to improve the long-term stability of isopentane calibration standards, ensuring consistent performance over extended periods. This is particularly important for applications requiring continuous or frequent calibration, such as in industrial process control or environmental monitoring stations.

As the field progresses, there is also a focus on developing multi-component calibration mixtures that include isopentane, allowing for simultaneous calibration of multiple analytes. This approach has the potential to streamline calibration processes and improve overall analytical efficiency.

In conclusion, the background and objectives of isopentane calibration research reflect a broader trend towards higher precision and reliability in analytical measurements. As technology continues to advance, the role of isopentane as a calibration gas is likely to evolve, opening new possibilities for improved analytical performance across a wide range of applications.

The use of isopentane as a calibration gas has its roots in the broader field of gas chromatography and mass spectrometry. These analytical techniques have been instrumental in identifying and quantifying complex mixtures of organic compounds for decades. As the need for more accurate and sensitive measurements grew, so did the importance of reliable calibration standards.

Isopentane's unique properties make it an ideal candidate for calibration purposes. Its low boiling point, high vapor pressure, and chemical stability contribute to its effectiveness as a reference gas. These characteristics allow for consistent and reproducible results across a wide range of analytical instruments and environmental conditions.

The development of isopentane as a calibration gas has been driven by several factors. First, the increasing stringency of environmental regulations has necessitated more precise measurement techniques for volatile organic compounds. Second, advancements in analytical instrumentation have enabled the detection of ever-smaller concentrations of analytes, requiring equally precise calibration methods.

The primary objective of research into isopentane as a calibration gas is to enhance the accuracy and reliability of analytical measurements. This involves optimizing the preparation and delivery of isopentane calibration standards, as well as developing robust methodologies for its use across different types of analytical devices.

Another key goal is to expand the applicability of isopentane calibration to a broader range of analytical techniques and industries. This includes exploring its potential in emerging fields such as portable and real-time monitoring devices, which present unique challenges in terms of calibration stability and precision.

Furthermore, researchers aim to improve the long-term stability of isopentane calibration standards, ensuring consistent performance over extended periods. This is particularly important for applications requiring continuous or frequent calibration, such as in industrial process control or environmental monitoring stations.

As the field progresses, there is also a focus on developing multi-component calibration mixtures that include isopentane, allowing for simultaneous calibration of multiple analytes. This approach has the potential to streamline calibration processes and improve overall analytical efficiency.

In conclusion, the background and objectives of isopentane calibration research reflect a broader trend towards higher precision and reliability in analytical measurements. As technology continues to advance, the role of isopentane as a calibration gas is likely to evolve, opening new possibilities for improved analytical performance across a wide range of applications.

Market Analysis for Analytical Device Calibration

The market for analytical device calibration is experiencing significant growth, driven by the increasing demand for accurate and reliable measurements across various industries. The global analytical instrument market, which includes calibration devices, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that reflects the industry's robust expansion.

Key factors contributing to this market growth include stringent regulatory requirements in industries such as pharmaceuticals, environmental monitoring, and food safety. These regulations necessitate regular calibration of analytical devices to ensure compliance and maintain product quality. Additionally, the growing emphasis on quality control and assurance in manufacturing processes has led to increased adoption of calibration services and equipment.

The market for isopentane as a calibration gas is a niche but essential segment within the broader analytical device calibration market. Isopentane is particularly valuable for calibrating gas chromatographs and other analytical instruments used in petrochemical, environmental, and industrial applications. Its stability and well-defined chemical properties make it an ideal calibration standard for many analytical procedures.

Geographically, North America and Europe currently dominate the analytical device calibration market, owing to their advanced industrial infrastructure and stringent regulatory environments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing industrialization, expanding research and development activities, and growing awareness of quality standards in countries like China and India.

The end-user segments for analytical device calibration, including isopentane calibration gas, span across multiple industries. The pharmaceutical and biotechnology sectors are major consumers, given the critical nature of their products and the need for precise measurements. Environmental monitoring agencies and laboratories also constitute a significant market share, as they require accurate calibration for air and water quality assessments. The oil and gas industry, particularly in refining and petrochemical applications, represents another key market for isopentane calibration gas.

Looking ahead, the market for analytical device calibration is expected to continue its upward trajectory. Technological advancements, such as the integration of IoT and AI in calibration processes, are likely to drive further market expansion. The trend towards automation and remote calibration services is also anticipated to shape the market landscape, potentially reducing costs and improving efficiency for end-users.

Key factors contributing to this market growth include stringent regulatory requirements in industries such as pharmaceuticals, environmental monitoring, and food safety. These regulations necessitate regular calibration of analytical devices to ensure compliance and maintain product quality. Additionally, the growing emphasis on quality control and assurance in manufacturing processes has led to increased adoption of calibration services and equipment.

The market for isopentane as a calibration gas is a niche but essential segment within the broader analytical device calibration market. Isopentane is particularly valuable for calibrating gas chromatographs and other analytical instruments used in petrochemical, environmental, and industrial applications. Its stability and well-defined chemical properties make it an ideal calibration standard for many analytical procedures.

Geographically, North America and Europe currently dominate the analytical device calibration market, owing to their advanced industrial infrastructure and stringent regulatory environments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing industrialization, expanding research and development activities, and growing awareness of quality standards in countries like China and India.

The end-user segments for analytical device calibration, including isopentane calibration gas, span across multiple industries. The pharmaceutical and biotechnology sectors are major consumers, given the critical nature of their products and the need for precise measurements. Environmental monitoring agencies and laboratories also constitute a significant market share, as they require accurate calibration for air and water quality assessments. The oil and gas industry, particularly in refining and petrochemical applications, represents another key market for isopentane calibration gas.

Looking ahead, the market for analytical device calibration is expected to continue its upward trajectory. Technological advancements, such as the integration of IoT and AI in calibration processes, are likely to drive further market expansion. The trend towards automation and remote calibration services is also anticipated to shape the market landscape, potentially reducing costs and improving efficiency for end-users.

Current Challenges in Isopentane Calibration

Despite the widespread use of isopentane as a calibration gas for analytical devices, several challenges persist in its application. One of the primary issues is the stability of isopentane under varying environmental conditions. Temperature fluctuations can significantly affect the vapor pressure of isopentane, leading to inconsistencies in calibration results. This sensitivity to temperature requires precise control of environmental parameters during the calibration process, which can be difficult to maintain in diverse laboratory settings.

Another challenge lies in the purity of isopentane used for calibration purposes. Even trace amounts of impurities can skew calibration results, potentially leading to inaccurate measurements in subsequent analyses. Ensuring and maintaining high-purity isopentane for calibration is both costly and technically demanding, requiring sophisticated purification techniques and storage methods.

The reactivity of isopentane poses additional complications. Its tendency to oxidize when exposed to air can alter its chemical composition over time, affecting its reliability as a calibration standard. This necessitates careful handling and storage procedures to minimize exposure to oxygen and other reactive substances, adding complexity to the calibration process.

Furthermore, the volatility of isopentane presents safety concerns in laboratory environments. Its low boiling point and high flammability require stringent safety protocols and specialized equipment for handling and storage, which can be challenging to implement consistently across different research facilities.

Achieving precise and reproducible concentrations of isopentane in calibration mixtures is another significant challenge. The high volatility of isopentane makes it difficult to prepare and maintain stable gas mixtures at specific concentrations, particularly at low levels. This can lead to variations in calibration curves and reduced accuracy in analytical measurements.

Lastly, the environmental impact of isopentane use in calibration processes is a growing concern. As a volatile organic compound (VOC), isopentane contributes to air pollution and has a high global warming potential. Balancing the need for accurate calibration with environmental responsibility presents an ongoing challenge for researchers and analytical laboratories.

These challenges collectively underscore the need for continued research and innovation in isopentane calibration techniques. Addressing these issues is crucial for improving the accuracy, reliability, and sustainability of analytical measurements across various scientific and industrial applications.

Another challenge lies in the purity of isopentane used for calibration purposes. Even trace amounts of impurities can skew calibration results, potentially leading to inaccurate measurements in subsequent analyses. Ensuring and maintaining high-purity isopentane for calibration is both costly and technically demanding, requiring sophisticated purification techniques and storage methods.

The reactivity of isopentane poses additional complications. Its tendency to oxidize when exposed to air can alter its chemical composition over time, affecting its reliability as a calibration standard. This necessitates careful handling and storage procedures to minimize exposure to oxygen and other reactive substances, adding complexity to the calibration process.

Furthermore, the volatility of isopentane presents safety concerns in laboratory environments. Its low boiling point and high flammability require stringent safety protocols and specialized equipment for handling and storage, which can be challenging to implement consistently across different research facilities.

Achieving precise and reproducible concentrations of isopentane in calibration mixtures is another significant challenge. The high volatility of isopentane makes it difficult to prepare and maintain stable gas mixtures at specific concentrations, particularly at low levels. This can lead to variations in calibration curves and reduced accuracy in analytical measurements.

Lastly, the environmental impact of isopentane use in calibration processes is a growing concern. As a volatile organic compound (VOC), isopentane contributes to air pollution and has a high global warming potential. Balancing the need for accurate calibration with environmental responsibility presents an ongoing challenge for researchers and analytical laboratories.

These challenges collectively underscore the need for continued research and innovation in isopentane calibration techniques. Addressing these issues is crucial for improving the accuracy, reliability, and sustainability of analytical measurements across various scientific and industrial applications.

Existing Isopentane Calibration Methods

01 Production and purification of isopentane

Various methods for producing and purifying isopentane are described, including separation from hydrocarbon mixtures, isomerization processes, and distillation techniques. These processes aim to obtain high-purity isopentane for industrial applications.- Production and purification of isopentane: Various methods for producing and purifying isopentane are described, including separation from hydrocarbon mixtures, isomerization processes, and distillation techniques. These processes aim to obtain high-purity isopentane for industrial applications.

- Use of isopentane in polymer production: Isopentane is utilized as a blowing agent or solvent in the production of polymers, particularly in the manufacture of expandable polystyrene beads and other foam materials. Its low boiling point and inert nature make it suitable for these applications.

- Isopentane in refrigeration and heat transfer systems: Isopentane is employed as a refrigerant or heat transfer fluid in various cooling systems and heat pumps. Its thermodynamic properties make it an effective alternative to traditional refrigerants in certain applications.

- Isopentane in fuel compositions: Isopentane is used as a component in fuel compositions, particularly for improving the octane rating of gasoline and enhancing the performance of internal combustion engines. It may also be used in the production of synthetic fuels.

- Isopentane in chemical synthesis and industrial processes: Isopentane serves as a raw material or intermediate in various chemical synthesis processes and industrial applications. It is used in the production of other chemicals, as a solvent in extraction processes, and in the manufacture of specialty products.

02 Use of isopentane in polymer production

Isopentane is utilized as a blowing agent or solvent in the production of polymers, particularly in the manufacture of expandable polystyrene beads and other foam materials. Its low boiling point and inert nature make it suitable for these applications.Expand Specific Solutions03 Isopentane in refrigeration and heat transfer systems

Isopentane is employed as a refrigerant or heat transfer fluid in various cooling systems and heat pumps. Its thermodynamic properties make it an effective alternative to traditional refrigerants in certain applications.Expand Specific Solutions04 Isopentane in fuel compositions

Isopentane is used as a component in fuel compositions, particularly for improving the octane rating and volatility of gasoline blends. It can also be used in the production of high-energy density fuels for specialized applications.Expand Specific Solutions05 Isopentane in chemical synthesis and industrial processes

Isopentane serves as a raw material or intermediate in various chemical synthesis routes and industrial processes. It is used in the production of other chemicals, as a solvent in extraction processes, and as a component in specialty chemical formulations.Expand Specific Solutions

Key Players in Analytical Device Calibration

The research on isopentane as a calibration gas for analytical devices is in a mature stage of development, with a significant market presence and established applications. The global market for calibration gases is substantial, driven by increasing demand for accurate analytical measurements across various industries. Companies like Horiba Ltd., Thermo Fisher Scientific, and Air Liquide SA are key players in this field, leveraging their expertise in analytical instrumentation and gas production. These firms, along with others such as Airgas, Inc. and Air Products & Chemicals, Inc., have developed sophisticated calibration gas products and services, indicating a high level of technological maturity. The competitive landscape is characterized by ongoing innovation in gas purity, stability, and application-specific formulations, with a focus on meeting stringent regulatory requirements and enhancing measurement accuracy.

Horiba Ltd.

Technical Solution: Horiba Ltd. has developed advanced analytical devices utilizing isopentane as a calibration gas. Their approach involves a high-precision gas chromatography system with a flame ionization detector (GC-FID) specifically optimized for isopentane detection[1]. The system employs a specialized column coating and temperature programming to achieve superior separation and quantification of isopentane from other hydrocarbons. Horiba's calibration method includes a multi-point calibration curve using certified isopentane standards, ensuring accuracy across a wide concentration range[3]. They have also integrated automated calibration routines into their software, allowing for frequent system checks and adjustments to maintain long-term stability and reliability[5].

Strengths: High precision and accuracy in isopentane detection, automated calibration for improved reliability. Weaknesses: Potentially higher cost compared to simpler systems, may require specialized training for operation and maintenance.

Thermo Fisher Scientific (Bremen) GmbH

Technical Solution: Thermo Fisher Scientific has engineered a mass spectrometry-based solution for isopentane calibration in analytical devices. Their approach utilizes a quadrupole mass spectrometer coupled with a specialized ionization source optimized for volatile organic compounds[2]. The system employs a unique ion trap design that allows for enhanced sensitivity and selectivity for isopentane molecules. Thermo Fisher's calibration protocol involves isotope dilution techniques, using deuterated isopentane as an internal standard to achieve high accuracy and precision[4]. They have also developed a proprietary software algorithm that compensates for matrix effects and potential interferences, ensuring robust calibration across various sample types[6].

Strengths: High selectivity and sensitivity, ability to handle complex matrices. Weaknesses: Higher initial investment, requires more complex sample preparation compared to some other techniques.

Innovations in Isopentane Gas Calibration

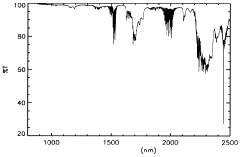

Calibration system of wavelengths covering the near infrared

PatentWO2011073474A2

Innovation

- A mixture of gases including 1-Butene, trans-2-Butene, cis-2-Butene, nitrous oxide, Chloromethane, Dichloromethane, Ammonia, and Acetylene is used in transparent cells to provide a well-characterized set of absorption lines, increasing the number of absorption peaks and enhancing calibration precision by being arranged in the optical path between light sources and spectrograph focal planes.

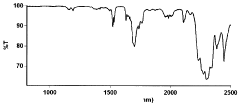

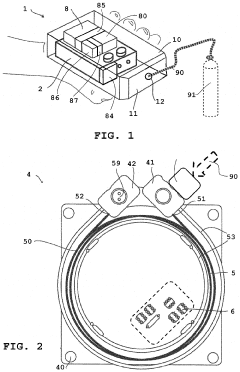

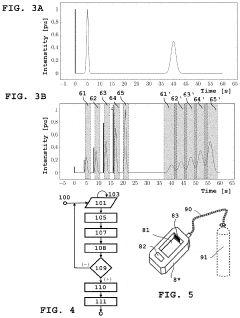

Method and device for calibrating a gas detection

PatentActiveUS20220236240A1

Innovation

- A method and device for calibrating gas detection devices using a sequence of consecutive partial injections with pauses in between, generating measurement signals that allow for automatic calibration, even with non-linear transfer functions, by varying injection amounts and times to determine key parameters like response factor and non-linearity exponent.

Environmental Impact of Isopentane Use

The use of isopentane as a calibration gas for analytical devices raises important environmental considerations. As a volatile organic compound (VOC), isopentane can contribute to air pollution and the formation of ground-level ozone when released into the atmosphere. This impact is particularly significant in urban areas with high concentrations of industrial activities and vehicular emissions.

Isopentane has a relatively high global warming potential compared to carbon dioxide, making it a concern for climate change mitigation efforts. Its atmospheric lifetime is estimated to be around 10 days, during which it can participate in various chemical reactions that affect air quality and climate. The photochemical reactivity of isopentane in the troposphere can lead to the production of secondary pollutants, including ozone and particulate matter.

In terms of ecosystem effects, isopentane can have indirect impacts through its contribution to smog formation and acid rain. These phenomena can harm vegetation, disrupt aquatic ecosystems, and affect biodiversity. While direct toxicity to plants and animals is generally low at ambient concentrations, prolonged exposure to elevated levels may cause adverse effects on sensitive species.

The production and handling of isopentane also present environmental risks. Industrial processes involving isopentane can result in fugitive emissions, potentially leading to localized air quality issues. Proper containment and handling procedures are crucial to minimize these releases and protect both workers and the surrounding environment.

From a regulatory perspective, isopentane is subject to various environmental regulations, including emission control standards and reporting requirements. Many countries classify it as a hazardous air pollutant, necessitating strict management practices in industrial settings. The use of isopentane in calibration processes must adhere to these regulations to ensure compliance and minimize environmental impact.

Efforts to mitigate the environmental impact of isopentane use in analytical device calibration include the development of closed-loop systems, improved leak detection methods, and the exploration of alternative calibration gases with lower environmental footprints. Research into more environmentally friendly substitutes is ongoing, with a focus on compounds that offer similar calibration properties but with reduced atmospheric reactivity and global warming potential.

Isopentane has a relatively high global warming potential compared to carbon dioxide, making it a concern for climate change mitigation efforts. Its atmospheric lifetime is estimated to be around 10 days, during which it can participate in various chemical reactions that affect air quality and climate. The photochemical reactivity of isopentane in the troposphere can lead to the production of secondary pollutants, including ozone and particulate matter.

In terms of ecosystem effects, isopentane can have indirect impacts through its contribution to smog formation and acid rain. These phenomena can harm vegetation, disrupt aquatic ecosystems, and affect biodiversity. While direct toxicity to plants and animals is generally low at ambient concentrations, prolonged exposure to elevated levels may cause adverse effects on sensitive species.

The production and handling of isopentane also present environmental risks. Industrial processes involving isopentane can result in fugitive emissions, potentially leading to localized air quality issues. Proper containment and handling procedures are crucial to minimize these releases and protect both workers and the surrounding environment.

From a regulatory perspective, isopentane is subject to various environmental regulations, including emission control standards and reporting requirements. Many countries classify it as a hazardous air pollutant, necessitating strict management practices in industrial settings. The use of isopentane in calibration processes must adhere to these regulations to ensure compliance and minimize environmental impact.

Efforts to mitigate the environmental impact of isopentane use in analytical device calibration include the development of closed-loop systems, improved leak detection methods, and the exploration of alternative calibration gases with lower environmental footprints. Research into more environmentally friendly substitutes is ongoing, with a focus on compounds that offer similar calibration properties but with reduced atmospheric reactivity and global warming potential.

Regulatory Framework for Calibration Gases

The regulatory framework for calibration gases plays a crucial role in ensuring the accuracy and reliability of analytical devices across various industries. In the context of using isopentane as a calibration gas, it is essential to understand the complex web of regulations and standards that govern its use.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established guidelines for the production, handling, and use of calibration gases. These standards provide a foundation for quality assurance and traceability in analytical measurements.

In the United States, the Environmental Protection Agency (EPA) and the National Institute of Standards and Technology (NIST) are key regulatory bodies overseeing the use of calibration gases. The EPA's Method 21, for instance, outlines specific requirements for calibration gases used in leak detection and repair programs. NIST, on the other hand, provides certified reference materials and calibration services to ensure the accuracy of analytical instruments.

The European Union has implemented the Measuring Instruments Directive (MID) and the In Vitro Diagnostic Medical Devices Regulation (IVDR), which set stringent requirements for calibration gases used in various applications. These regulations emphasize the importance of metrological traceability and the use of certified reference materials.

Specific to isopentane, its use as a calibration gas must comply with safety regulations due to its flammable nature. The Occupational Safety and Health Administration (OSHA) in the U.S. and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and handling guidelines for isopentane in workplace settings.

Industry-specific regulations also come into play when considering isopentane as a calibration gas. For instance, in the petrochemical industry, standards set by the American Petroleum Institute (API) and the American Society for Testing and Materials (ASTM) must be adhered to when using isopentane for calibration purposes.

The pharmaceutical industry, governed by Good Manufacturing Practice (GMP) regulations, requires strict adherence to calibration gas standards to ensure the quality and safety of drug products. Similarly, the food and beverage industry must comply with regulations set by the Food and Drug Administration (FDA) in the U.S. and the European Food Safety Authority (EFSA) in the EU.

As environmental concerns continue to grow, regulations surrounding the use of volatile organic compounds (VOCs) like isopentane are becoming increasingly stringent. Many countries have implemented emissions control regulations that impact the use and handling of isopentane as a calibration gas.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established guidelines for the production, handling, and use of calibration gases. These standards provide a foundation for quality assurance and traceability in analytical measurements.

In the United States, the Environmental Protection Agency (EPA) and the National Institute of Standards and Technology (NIST) are key regulatory bodies overseeing the use of calibration gases. The EPA's Method 21, for instance, outlines specific requirements for calibration gases used in leak detection and repair programs. NIST, on the other hand, provides certified reference materials and calibration services to ensure the accuracy of analytical instruments.

The European Union has implemented the Measuring Instruments Directive (MID) and the In Vitro Diagnostic Medical Devices Regulation (IVDR), which set stringent requirements for calibration gases used in various applications. These regulations emphasize the importance of metrological traceability and the use of certified reference materials.

Specific to isopentane, its use as a calibration gas must comply with safety regulations due to its flammable nature. The Occupational Safety and Health Administration (OSHA) in the U.S. and the European Agency for Safety and Health at Work (EU-OSHA) have established exposure limits and handling guidelines for isopentane in workplace settings.

Industry-specific regulations also come into play when considering isopentane as a calibration gas. For instance, in the petrochemical industry, standards set by the American Petroleum Institute (API) and the American Society for Testing and Materials (ASTM) must be adhered to when using isopentane for calibration purposes.

The pharmaceutical industry, governed by Good Manufacturing Practice (GMP) regulations, requires strict adherence to calibration gas standards to ensure the quality and safety of drug products. Similarly, the food and beverage industry must comply with regulations set by the Food and Drug Administration (FDA) in the U.S. and the European Food Safety Authority (EFSA) in the EU.

As environmental concerns continue to grow, regulations surrounding the use of volatile organic compounds (VOCs) like isopentane are becoming increasingly stringent. Many countries have implemented emissions control regulations that impact the use and handling of isopentane as a calibration gas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!