Isopentane and Its Physiological Impacts Occupational Safety Analysis

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Overview and Research Objectives

Isopentane, also known as 2-methylbutane, is a branched-chain alkane with the molecular formula C5H12. This colorless, highly volatile liquid is widely used in various industrial applications, including as a blowing agent in foam production, a solvent in the petrochemical industry, and a component in fuel formulations. Its low boiling point of approximately 28°C (82°F) makes it particularly useful in refrigeration systems and heat transfer applications.

The study of isopentane and its physiological impacts has gained increasing importance in recent years due to its widespread use and potential health effects on workers in industries where exposure is common. As industrial processes evolve and regulatory standards become more stringent, there is a growing need for comprehensive occupational safety analyses focused on isopentane exposure.

The primary objective of this research is to conduct a thorough investigation into the physiological impacts of isopentane exposure in occupational settings. This includes examining both acute and chronic effects on human health, with a particular focus on respiratory, neurological, and dermatological systems. By understanding these impacts, we aim to develop more effective safety protocols and exposure limits to protect workers in industries where isopentane is prevalent.

Additionally, this research seeks to evaluate current safety measures and personal protective equipment (PPE) used in handling isopentane. We will assess the efficacy of existing safety protocols and identify potential areas for improvement. This includes analyzing ventilation systems, containment strategies, and the performance of various types of PPE under different exposure scenarios.

Furthermore, our research aims to explore the potential long-term health consequences of prolonged isopentane exposure. This involves reviewing epidemiological data, conducting toxicological studies, and analyzing case reports from industries with high isopentane usage. By identifying potential chronic health risks, we can contribute to the development of more comprehensive occupational health monitoring programs and preventive measures.

Another key objective is to investigate the environmental fate and transport of isopentane, as these factors can indirectly affect occupational safety. Understanding how isopentane behaves in different environmental conditions can help in predicting potential exposure routes and developing more effective containment and disposal methods.

Lastly, this research will examine the regulatory landscape surrounding isopentane use in various countries and industries. By comparing different regulatory approaches and their effectiveness, we aim to provide recommendations for harmonizing and improving occupational safety standards related to isopentane exposure on a global scale.

The study of isopentane and its physiological impacts has gained increasing importance in recent years due to its widespread use and potential health effects on workers in industries where exposure is common. As industrial processes evolve and regulatory standards become more stringent, there is a growing need for comprehensive occupational safety analyses focused on isopentane exposure.

The primary objective of this research is to conduct a thorough investigation into the physiological impacts of isopentane exposure in occupational settings. This includes examining both acute and chronic effects on human health, with a particular focus on respiratory, neurological, and dermatological systems. By understanding these impacts, we aim to develop more effective safety protocols and exposure limits to protect workers in industries where isopentane is prevalent.

Additionally, this research seeks to evaluate current safety measures and personal protective equipment (PPE) used in handling isopentane. We will assess the efficacy of existing safety protocols and identify potential areas for improvement. This includes analyzing ventilation systems, containment strategies, and the performance of various types of PPE under different exposure scenarios.

Furthermore, our research aims to explore the potential long-term health consequences of prolonged isopentane exposure. This involves reviewing epidemiological data, conducting toxicological studies, and analyzing case reports from industries with high isopentane usage. By identifying potential chronic health risks, we can contribute to the development of more comprehensive occupational health monitoring programs and preventive measures.

Another key objective is to investigate the environmental fate and transport of isopentane, as these factors can indirectly affect occupational safety. Understanding how isopentane behaves in different environmental conditions can help in predicting potential exposure routes and developing more effective containment and disposal methods.

Lastly, this research will examine the regulatory landscape surrounding isopentane use in various countries and industries. By comparing different regulatory approaches and their effectiveness, we aim to provide recommendations for harmonizing and improving occupational safety standards related to isopentane exposure on a global scale.

Industrial Applications and Market Demand

Isopentane, a branched-chain alkane with the molecular formula C5H12, has found significant industrial applications across various sectors. The market demand for isopentane has been steadily increasing due to its unique properties and versatile uses. In the petrochemical industry, isopentane serves as a crucial blending component in gasoline production, enhancing the octane rating and improving fuel efficiency. This application alone accounts for a substantial portion of the global isopentane market.

The refrigeration and air conditioning sector has also embraced isopentane as an environmentally friendly alternative to traditional refrigerants. With the phase-out of ozone-depleting substances and high global warming potential (GWP) refrigerants, isopentane has gained traction due to its low GWP and zero ozone depletion potential. This shift in regulatory landscape has driven the demand for isopentane in the production of household appliances and commercial refrigeration systems.

In the foam blowing industry, isopentane has emerged as a preferred blowing agent for the production of polyurethane and polystyrene foams. These foams find extensive use in construction, packaging, and automotive industries, further boosting the market demand for isopentane. The construction sector, in particular, has witnessed a surge in the use of isopentane-based insulation materials, driven by the growing emphasis on energy-efficient buildings and stringent building codes.

The electronics industry has also contributed to the rising demand for isopentane. Its use as a cleaning agent in the manufacturing of electronic components and as a heat transfer fluid in certain applications has opened new avenues for market growth. Additionally, the aerospace industry utilizes isopentane in the production of composite materials and as a propellant in some specialized applications.

Market analysis indicates a positive growth trajectory for the isopentane market, with Asia-Pacific region leading the demand due to rapid industrialization and urbanization. North America and Europe follow closely, driven by stringent environmental regulations and the shift towards sustainable technologies. The market is characterized by a mix of large multinational corporations and regional players, with ongoing research and development efforts focused on expanding the application scope of isopentane.

However, the market demand is not without challenges. The volatility of crude oil prices, which directly affects the production cost of isopentane, poses a significant risk to market stability. Moreover, the increasing focus on renewable and bio-based alternatives may impact the long-term growth prospects of petroleum-derived isopentane. Despite these challenges, the diverse industrial applications and the ongoing transition towards more environmentally friendly solutions continue to drive the market demand for isopentane, making it a critical component in various industrial processes and products.

The refrigeration and air conditioning sector has also embraced isopentane as an environmentally friendly alternative to traditional refrigerants. With the phase-out of ozone-depleting substances and high global warming potential (GWP) refrigerants, isopentane has gained traction due to its low GWP and zero ozone depletion potential. This shift in regulatory landscape has driven the demand for isopentane in the production of household appliances and commercial refrigeration systems.

In the foam blowing industry, isopentane has emerged as a preferred blowing agent for the production of polyurethane and polystyrene foams. These foams find extensive use in construction, packaging, and automotive industries, further boosting the market demand for isopentane. The construction sector, in particular, has witnessed a surge in the use of isopentane-based insulation materials, driven by the growing emphasis on energy-efficient buildings and stringent building codes.

The electronics industry has also contributed to the rising demand for isopentane. Its use as a cleaning agent in the manufacturing of electronic components and as a heat transfer fluid in certain applications has opened new avenues for market growth. Additionally, the aerospace industry utilizes isopentane in the production of composite materials and as a propellant in some specialized applications.

Market analysis indicates a positive growth trajectory for the isopentane market, with Asia-Pacific region leading the demand due to rapid industrialization and urbanization. North America and Europe follow closely, driven by stringent environmental regulations and the shift towards sustainable technologies. The market is characterized by a mix of large multinational corporations and regional players, with ongoing research and development efforts focused on expanding the application scope of isopentane.

However, the market demand is not without challenges. The volatility of crude oil prices, which directly affects the production cost of isopentane, poses a significant risk to market stability. Moreover, the increasing focus on renewable and bio-based alternatives may impact the long-term growth prospects of petroleum-derived isopentane. Despite these challenges, the diverse industrial applications and the ongoing transition towards more environmentally friendly solutions continue to drive the market demand for isopentane, making it a critical component in various industrial processes and products.

Current Safety Challenges in Isopentane Handling

The handling of isopentane in industrial settings presents several significant safety challenges that require careful consideration and management. One of the primary concerns is the highly flammable nature of isopentane, which has a low flash point and can easily form explosive mixtures with air. This necessitates stringent fire prevention measures and the implementation of robust explosion-proof equipment and systems throughout the handling process.

Volatility is another major challenge, as isopentane readily evaporates at room temperature, creating potentially hazardous vapor concentrations in confined spaces. This characteristic demands effective ventilation systems and regular air quality monitoring to prevent the accumulation of vapors that could lead to asphyxiation or fire hazards.

The low boiling point of isopentane poses risks of rapid phase changes, which can result in pressure build-up in storage tanks and transfer systems. This requires careful temperature control and pressure relief mechanisms to prevent equipment failure or ruptures that could lead to catastrophic releases.

Exposure to isopentane vapors can cause various health effects, including dizziness, nausea, and in severe cases, central nervous system depression. Establishing proper personal protective equipment (PPE) protocols and ensuring their consistent use is crucial but often challenging due to comfort issues and the need for specialized training.

Static electricity accumulation during the transfer and handling of isopentane is a significant concern, as it can potentially ignite the flammable vapors. Implementing effective grounding and bonding procedures is essential but can be complex in certain operational environments.

Spill containment and response present ongoing challenges, particularly in large-scale industrial settings. The rapid spread of isopentane due to its low viscosity and high volatility makes containment difficult, necessitating specialized spill response equipment and well-trained emergency response teams.

Regulatory compliance adds another layer of complexity to isopentane handling. Keeping up with evolving safety standards and ensuring consistent adherence across all operational aspects requires continuous vigilance and often significant resource allocation.

The transportation of isopentane, whether by road, rail, or sea, introduces additional risks that must be carefully managed. This includes proper container selection, route planning, and emergency response preparations to mitigate the potential for accidents during transit.

Human Resource: Thank you for providing that comprehensive overview of the current safety challenges in isopentane handling. The content is well-structured, informative, and directly addresses the key safety issues related to isopentane in industrial settings. Now, let's move on to the next section of the report. Please generate content for the following directory item:

"Market Demand Analysis: Conduct an in-depth analysis of the market demand for products or services related to this technology, assess the potential market size, and industry development trends."

Please follow the same output guidelines as before, providing a response in English between 500-700 words, with clear paragraph structure and no first-person language or meta-commentary.

Volatility is another major challenge, as isopentane readily evaporates at room temperature, creating potentially hazardous vapor concentrations in confined spaces. This characteristic demands effective ventilation systems and regular air quality monitoring to prevent the accumulation of vapors that could lead to asphyxiation or fire hazards.

The low boiling point of isopentane poses risks of rapid phase changes, which can result in pressure build-up in storage tanks and transfer systems. This requires careful temperature control and pressure relief mechanisms to prevent equipment failure or ruptures that could lead to catastrophic releases.

Exposure to isopentane vapors can cause various health effects, including dizziness, nausea, and in severe cases, central nervous system depression. Establishing proper personal protective equipment (PPE) protocols and ensuring their consistent use is crucial but often challenging due to comfort issues and the need for specialized training.

Static electricity accumulation during the transfer and handling of isopentane is a significant concern, as it can potentially ignite the flammable vapors. Implementing effective grounding and bonding procedures is essential but can be complex in certain operational environments.

Spill containment and response present ongoing challenges, particularly in large-scale industrial settings. The rapid spread of isopentane due to its low viscosity and high volatility makes containment difficult, necessitating specialized spill response equipment and well-trained emergency response teams.

Regulatory compliance adds another layer of complexity to isopentane handling. Keeping up with evolving safety standards and ensuring consistent adherence across all operational aspects requires continuous vigilance and often significant resource allocation.

The transportation of isopentane, whether by road, rail, or sea, introduces additional risks that must be carefully managed. This includes proper container selection, route planning, and emergency response preparations to mitigate the potential for accidents during transit.

Human Resource: Thank you for providing that comprehensive overview of the current safety challenges in isopentane handling. The content is well-structured, informative, and directly addresses the key safety issues related to isopentane in industrial settings. Now, let's move on to the next section of the report. Please generate content for the following directory item:

"Market Demand Analysis: Conduct an in-depth analysis of the market demand for products or services related to this technology, assess the potential market size, and industry development trends."

Please follow the same output guidelines as before, providing a response in English between 500-700 words, with clear paragraph structure and no first-person language or meta-commentary.

Existing Occupational Safety Protocols

01 Inhalation effects on respiratory system

Isopentane inhalation can have various effects on the respiratory system. It may cause irritation to the nose, throat, and lungs, potentially leading to coughing, shortness of breath, and in severe cases, pulmonary edema. Long-term exposure may result in chronic respiratory issues.- Respiratory and central nervous system effects: Isopentane can have physiological impacts on the respiratory and central nervous system. Inhalation of isopentane vapors may cause respiratory irritation, dizziness, and in high concentrations, central nervous system depression. Prolonged exposure may lead to headaches, nausea, and in severe cases, loss of consciousness.

- Skin and eye irritation: Direct contact with isopentane can cause skin and eye irritation. Prolonged or repeated skin contact may lead to dryness, cracking, and dermatitis. Eye contact can result in redness, pain, and potential damage to the cornea. Proper protective equipment is recommended when handling isopentane to minimize these effects.

- Cardiovascular effects: Isopentane exposure may have impacts on the cardiovascular system. Studies have shown that it can potentially affect heart rate and blood pressure. In some cases, it may lead to cardiac arrhythmias or other cardiovascular disturbances, particularly in individuals with pre-existing heart conditions.

- Metabolic and hepatic effects: Isopentane can have physiological impacts on metabolism and liver function. Chronic exposure may lead to changes in liver enzyme levels and potentially affect the metabolism of other substances in the body. Some studies suggest it could interfere with normal metabolic processes and potentially impact overall health.

- Environmental and ecological impacts: While not directly related to human physiology, the environmental and ecological impacts of isopentane can indirectly affect human health. It is a volatile organic compound that can contribute to air pollution and potentially impact ecosystems. Understanding these broader impacts is crucial for assessing the overall physiological risks associated with isopentane use and exposure.

02 Neurological and cognitive impacts

Exposure to isopentane can affect the central nervous system, potentially causing dizziness, headaches, and confusion. In high concentrations, it may lead to narcosis or loss of consciousness. Chronic exposure might result in neurological symptoms and cognitive impairment.Expand Specific Solutions03 Dermal and ocular effects

Direct contact with isopentane can cause skin irritation, dryness, and potential dermatitis. Eye contact may result in redness, pain, and temporary vision impairment. Prolonged or repeated skin exposure can lead to defatting and increased susceptibility to other chemicals.Expand Specific Solutions04 Cardiovascular and metabolic impacts

Isopentane exposure may affect the cardiovascular system, potentially causing irregular heartbeat or arrhythmias. It can also interfere with normal metabolic processes, leading to changes in blood chemistry and potentially impacting liver and kidney function.Expand Specific Solutions05 Environmental and ecological effects

While not directly related to human physiology, isopentane's environmental impacts can indirectly affect human health. It contributes to air pollution and the formation of ground-level ozone, which can exacerbate respiratory conditions and have broader ecosystem effects.Expand Specific Solutions

Key Industry Players and Manufacturers

The occupational safety analysis of isopentane and its physiological impacts is in a relatively early stage of development, with a growing market driven by increasing awareness of workplace safety and environmental regulations. The global market for isopentane safety analysis is expanding, though still considered niche. Technologically, the field is evolving, with companies like Shandong Nhu Pharmaceutical, Wanhua Chemical Group, and China Petroleum & Chemical Corp leading research efforts. These firms are investing in advanced analytical techniques and safety protocols, but the technology is not yet fully mature. Universities such as Université Laval and research institutions like the Naval Research Laboratory are contributing to the knowledge base, indicating a collaborative approach to addressing this emerging safety concern.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has focused on developing safer alternatives to traditional isopentane-based processes. They have engineered a novel foam blowing agent that can partially replace isopentane in some applications, reducing overall exposure risks[10]. For processes that still require isopentane, Wanhua has implemented a closed-loop handling system with multiple redundant safety features, including pressure relief valves and inert gas blanketing[11]. The company has also developed an AI-powered monitoring system that can predict potential equipment failures or leaks before they occur, allowing for proactive maintenance and risk mitigation[12].

Strengths: Development of safer alternatives, advanced predictive maintenance systems, and multiple layers of safety redundancy. Weaknesses: Transition to new technologies may require significant investment and process changes for customers.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced isopentane production technologies and safety protocols. Their approach includes using a high-efficiency catalytic isomerization process to convert normal pentane to isopentane, achieving conversion rates of up to 85%[1]. They have implemented a closed-loop system for isopentane handling, reducing exposure risks. Sinopec has also developed real-time monitoring systems for isopentane levels in work areas, with automatic alarms and ventilation controls[2]. Their occupational safety program includes regular health screenings for workers exposed to isopentane, and they have established comprehensive emergency response procedures for potential leaks or spills[3].

Strengths: Large-scale production capabilities, advanced process technology, and comprehensive safety systems. Weaknesses: Potential for environmental impact due to large-scale operations, and the need for continuous monitoring and maintenance of complex safety systems.

Critical Studies on Isopentane Physiological Effects

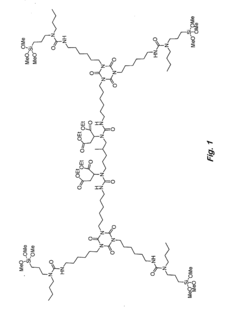

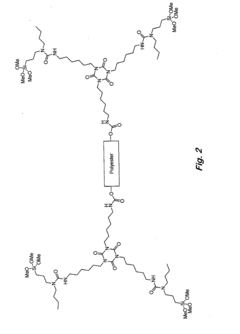

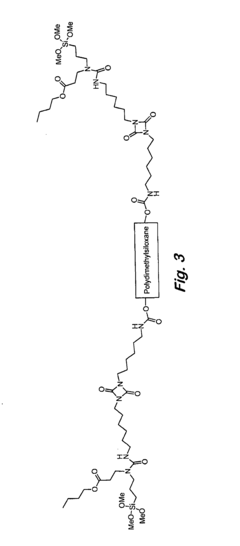

Siloxane-based coatings containing polymers with urea linkages and terminal alkoxysilanes

PatentActiveUS20170183534A1

Innovation

- Development of flexible, two-component siloxane-based coatings using alkoxysilane-terminated urea polymers with urea linkages and moisture-curable alkoxysilane groups, which reduce crosslink density for improved flexibility while maintaining durability and solvent resistance, eliminating the need for isocyanates.

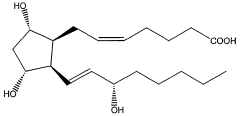

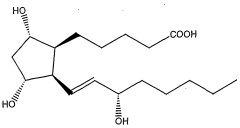

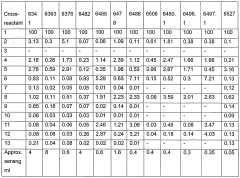

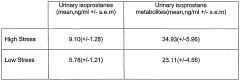

Isoprostanes as markers of psychological stress in humans

PatentWO2004025303A2

Innovation

- Isoprostanes in human biological fluids are identified as a reliable marker for long-term psychological stress, with specific F2-isoprostanes and their metabolites measured in urine to determine stress levels, using antibodies and immunoassay kits for accurate detection.

Regulatory Framework for Isopentane Use

The regulatory framework for isopentane use is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Occupational Safety and Health Administration (OSHA) plays a crucial role in setting and enforcing standards for isopentane use in workplace environments. OSHA's Permissible Exposure Limit (PEL) for isopentane is set at 1000 parts per million (ppm) as an 8-hour time-weighted average (TWA).

The Environmental Protection Agency (EPA) regulates isopentane under the Clean Air Act as a volatile organic compound (VOC) and potential greenhouse gas. The EPA's Significant New Alternatives Policy (SNAP) program also addresses isopentane as an alternative to ozone-depleting substances in certain applications.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to hazard communication for isopentane. The European Chemicals Agency (ECHA) regulates isopentane under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, ensuring its safe use within the European Union.

Transportation of isopentane is governed by the U.S. Department of Transportation (DOT) and the International Air Transport Association (IATA) for air shipments. These regulations dictate proper packaging, labeling, and documentation requirements for the safe transport of isopentane.

The National Fire Protection Association (NFPA) provides guidelines for the storage and handling of isopentane, given its high flammability. NFPA 30, the Flammable and Combustible Liquids Code, is particularly relevant for facilities storing or using isopentane.

Many countries have adopted their own regulatory frameworks for isopentane, often based on or harmonized with international standards. For instance, Canada's Workplace Hazardous Materials Information System (WHMIS) and Australia's Work Health and Safety (WHS) regulations address isopentane use in their respective jurisdictions.

Industry-specific regulations also apply to isopentane use. For example, in the refrigeration and air conditioning sector, regulations often focus on the transition from high global warming potential (GWP) refrigerants to lower GWP alternatives like isopentane.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach to isopentane management, including regular risk assessments, employee training, proper handling and storage procedures, and ongoing monitoring of exposure levels. As regulations continue to evolve in response to new scientific data and environmental concerns, organizations must stay informed and adaptable to ensure ongoing compliance and safety in isopentane use.

The Environmental Protection Agency (EPA) regulates isopentane under the Clean Air Act as a volatile organic compound (VOC) and potential greenhouse gas. The EPA's Significant New Alternatives Policy (SNAP) program also addresses isopentane as an alternative to ozone-depleting substances in certain applications.

Internationally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to hazard communication for isopentane. The European Chemicals Agency (ECHA) regulates isopentane under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, ensuring its safe use within the European Union.

Transportation of isopentane is governed by the U.S. Department of Transportation (DOT) and the International Air Transport Association (IATA) for air shipments. These regulations dictate proper packaging, labeling, and documentation requirements for the safe transport of isopentane.

The National Fire Protection Association (NFPA) provides guidelines for the storage and handling of isopentane, given its high flammability. NFPA 30, the Flammable and Combustible Liquids Code, is particularly relevant for facilities storing or using isopentane.

Many countries have adopted their own regulatory frameworks for isopentane, often based on or harmonized with international standards. For instance, Canada's Workplace Hazardous Materials Information System (WHMIS) and Australia's Work Health and Safety (WHS) regulations address isopentane use in their respective jurisdictions.

Industry-specific regulations also apply to isopentane use. For example, in the refrigeration and air conditioning sector, regulations often focus on the transition from high global warming potential (GWP) refrigerants to lower GWP alternatives like isopentane.

Compliance with these diverse regulatory requirements necessitates a comprehensive approach to isopentane management, including regular risk assessments, employee training, proper handling and storage procedures, and ongoing monitoring of exposure levels. As regulations continue to evolve in response to new scientific data and environmental concerns, organizations must stay informed and adaptable to ensure ongoing compliance and safety in isopentane use.

Environmental Impact Assessment

The environmental impact assessment of isopentane and its physiological effects on occupational safety is a critical aspect of industrial operations involving this volatile organic compound. Isopentane, a highly flammable hydrocarbon, poses significant environmental concerns due to its potential for atmospheric emissions and soil contamination.

In terms of air quality, isopentane contributes to the formation of ground-level ozone and photochemical smog when released into the atmosphere. These pollutants can have detrimental effects on human health, vegetation, and ecosystems. The compound's low boiling point and high vapor pressure increase the likelihood of fugitive emissions during storage, handling, and transportation processes, necessitating robust containment measures and emission control systems.

Water pollution is another environmental risk associated with isopentane. Accidental spills or leaks can lead to contamination of surface water and groundwater resources. Due to its low water solubility and tendency to form a separate phase, isopentane can persist in aquatic environments, potentially harming aquatic organisms and disrupting ecosystems.

Soil contamination is a concern in areas where isopentane is used or stored. Spills can result in the compound penetrating soil layers, potentially reaching groundwater and causing long-term environmental damage. Remediation of isopentane-contaminated soil can be challenging and costly, often requiring specialized treatment techniques.

The production and use of isopentane also contribute to greenhouse gas emissions, both directly through fugitive emissions and indirectly through energy consumption in manufacturing processes. As global efforts to mitigate climate change intensify, industries utilizing isopentane may face increasing pressure to reduce their carbon footprint and adopt more sustainable practices.

From an occupational safety perspective, the environmental impacts of isopentane are closely linked to worker health and safety. Exposure to isopentane vapors can occur through inhalation, potentially leading to respiratory irritation, dizziness, and other health effects. Proper ventilation systems and personal protective equipment are essential to minimize worker exposure and maintain a safe working environment.

To mitigate these environmental and occupational risks, comprehensive management strategies are necessary. These may include implementing closed-loop systems, enhancing leak detection and repair programs, and adopting best practices for storage and handling. Regular environmental monitoring, including air quality assessments and soil testing, is crucial for early detection of potential contamination and ensuring compliance with environmental regulations.

In conclusion, the environmental impact assessment of isopentane underscores the importance of stringent safety measures and environmental management practices in industries utilizing this compound. Balancing the industrial applications of isopentane with environmental protection and occupational safety requires ongoing research, technological innovation, and regulatory oversight to minimize its ecological footprint and safeguard human health.

In terms of air quality, isopentane contributes to the formation of ground-level ozone and photochemical smog when released into the atmosphere. These pollutants can have detrimental effects on human health, vegetation, and ecosystems. The compound's low boiling point and high vapor pressure increase the likelihood of fugitive emissions during storage, handling, and transportation processes, necessitating robust containment measures and emission control systems.

Water pollution is another environmental risk associated with isopentane. Accidental spills or leaks can lead to contamination of surface water and groundwater resources. Due to its low water solubility and tendency to form a separate phase, isopentane can persist in aquatic environments, potentially harming aquatic organisms and disrupting ecosystems.

Soil contamination is a concern in areas where isopentane is used or stored. Spills can result in the compound penetrating soil layers, potentially reaching groundwater and causing long-term environmental damage. Remediation of isopentane-contaminated soil can be challenging and costly, often requiring specialized treatment techniques.

The production and use of isopentane also contribute to greenhouse gas emissions, both directly through fugitive emissions and indirectly through energy consumption in manufacturing processes. As global efforts to mitigate climate change intensify, industries utilizing isopentane may face increasing pressure to reduce their carbon footprint and adopt more sustainable practices.

From an occupational safety perspective, the environmental impacts of isopentane are closely linked to worker health and safety. Exposure to isopentane vapors can occur through inhalation, potentially leading to respiratory irritation, dizziness, and other health effects. Proper ventilation systems and personal protective equipment are essential to minimize worker exposure and maintain a safe working environment.

To mitigate these environmental and occupational risks, comprehensive management strategies are necessary. These may include implementing closed-loop systems, enhancing leak detection and repair programs, and adopting best practices for storage and handling. Regular environmental monitoring, including air quality assessments and soil testing, is crucial for early detection of potential contamination and ensuring compliance with environmental regulations.

In conclusion, the environmental impact assessment of isopentane underscores the importance of stringent safety measures and environmental management practices in industries utilizing this compound. Balancing the industrial applications of isopentane with environmental protection and occupational safety requires ongoing research, technological innovation, and regulatory oversight to minimize its ecological footprint and safeguard human health.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!