Isopentane Applications in Enhanced Coal-Bed Methane Recovery

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane in ECBM: Background and Objectives

Enhanced Coal-Bed Methane (ECBM) recovery has emerged as a promising technique to improve methane extraction from coal seams while simultaneously sequestering carbon dioxide. In recent years, the application of isopentane in ECBM has gained significant attention due to its potential to enhance the efficiency of the process.

Isopentane, a branched-chain alkane with the molecular formula C5H12, has unique properties that make it particularly suitable for ECBM applications. Its low boiling point, high volatility, and excellent solvent characteristics contribute to its effectiveness in mobilizing methane trapped in coal matrices.

The development of isopentane-based ECBM techniques can be traced back to the early 2000s when researchers began exploring alternative methods to improve methane recovery rates. Initial studies focused on understanding the interaction between isopentane and coal structures, as well as its impact on methane desorption kinetics.

As the technology evolved, researchers identified several key advantages of using isopentane in ECBM. These include enhanced methane displacement, improved sweep efficiency, and reduced formation damage compared to traditional water-based methods. Additionally, isopentane's ability to penetrate micropores in coal seams has shown promise in accessing previously unreachable methane reserves.

The primary objective of isopentane applications in ECBM is to maximize methane recovery while minimizing environmental impact. This aligns with the broader goals of sustainable energy production and greenhouse gas reduction. By improving the efficiency of methane extraction, isopentane-based ECBM techniques aim to reduce the overall carbon footprint of coal-bed methane operations.

Another crucial objective is to overcome the limitations of conventional ECBM methods, such as coal swelling and permeability reduction. Isopentane's unique properties offer potential solutions to these challenges, paving the way for more effective and economically viable methane recovery processes.

The development of isopentane-based ECBM technologies also aims to address the growing global demand for natural gas. As countries seek to transition towards cleaner energy sources, optimizing methane recovery from coal beds becomes increasingly important. Isopentane applications in ECBM contribute to this goal by potentially unlocking vast reserves of previously unrecoverable methane.

In conclusion, the background and objectives of isopentane applications in ECBM reflect a convergence of technological innovation, environmental considerations, and energy market demands. As research in this field continues to advance, it is expected that isopentane-based techniques will play an increasingly significant role in the future of coal-bed methane recovery and sustainable energy production.

Isopentane, a branched-chain alkane with the molecular formula C5H12, has unique properties that make it particularly suitable for ECBM applications. Its low boiling point, high volatility, and excellent solvent characteristics contribute to its effectiveness in mobilizing methane trapped in coal matrices.

The development of isopentane-based ECBM techniques can be traced back to the early 2000s when researchers began exploring alternative methods to improve methane recovery rates. Initial studies focused on understanding the interaction between isopentane and coal structures, as well as its impact on methane desorption kinetics.

As the technology evolved, researchers identified several key advantages of using isopentane in ECBM. These include enhanced methane displacement, improved sweep efficiency, and reduced formation damage compared to traditional water-based methods. Additionally, isopentane's ability to penetrate micropores in coal seams has shown promise in accessing previously unreachable methane reserves.

The primary objective of isopentane applications in ECBM is to maximize methane recovery while minimizing environmental impact. This aligns with the broader goals of sustainable energy production and greenhouse gas reduction. By improving the efficiency of methane extraction, isopentane-based ECBM techniques aim to reduce the overall carbon footprint of coal-bed methane operations.

Another crucial objective is to overcome the limitations of conventional ECBM methods, such as coal swelling and permeability reduction. Isopentane's unique properties offer potential solutions to these challenges, paving the way for more effective and economically viable methane recovery processes.

The development of isopentane-based ECBM technologies also aims to address the growing global demand for natural gas. As countries seek to transition towards cleaner energy sources, optimizing methane recovery from coal beds becomes increasingly important. Isopentane applications in ECBM contribute to this goal by potentially unlocking vast reserves of previously unrecoverable methane.

In conclusion, the background and objectives of isopentane applications in ECBM reflect a convergence of technological innovation, environmental considerations, and energy market demands. As research in this field continues to advance, it is expected that isopentane-based techniques will play an increasingly significant role in the future of coal-bed methane recovery and sustainable energy production.

Market Analysis for ECBM Technologies

The market for Enhanced Coal-Bed Methane (ECBM) technologies has been experiencing significant growth in recent years, driven by the increasing global demand for natural gas and the need for more efficient extraction methods. ECBM technologies, including the use of isopentane, have gained traction due to their potential to improve methane recovery rates from coal seams.

The global ECBM market is projected to expand at a compound annual growth rate (CAGR) of over 5% during the forecast period of 2021-2026. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the shift towards cleaner energy sources. The Asia-Pacific region, led by countries such as China and India, is expected to dominate the market due to their vast coal reserves and increasing focus on unconventional gas resources.

North America, particularly the United States, remains a key player in the ECBM market, with significant investments in research and development of advanced extraction technologies. Europe is also showing growing interest in ECBM technologies as part of its efforts to reduce dependence on imported natural gas and meet climate change targets.

The application of isopentane in ECBM recovery is gaining attention due to its potential to enhance methane production rates and overall recovery efficiency. Isopentane, when used as an injection fluid, can improve the displacement of methane from coal matrices, leading to higher recovery rates compared to traditional CO2 injection methods.

Market trends indicate a growing preference for environmentally friendly ECBM technologies. This has led to increased research and development activities focused on optimizing isopentane-based ECBM processes to minimize environmental impact while maximizing methane recovery. The market is also witnessing collaborations between energy companies and technology providers to develop innovative ECBM solutions.

Challenges in the ECBM market include the high initial investment costs associated with implementing advanced technologies and the environmental concerns related to potential groundwater contamination. However, ongoing technological advancements and stricter environmental regulations are expected to address these challenges, further driving market growth.

The competitive landscape of the ECBM market is characterized by the presence of both large multinational energy companies and specialized technology providers. Key players are focusing on strategic partnerships and acquisitions to strengthen their market position and expand their technological capabilities in isopentane-based ECBM recovery.

In conclusion, the market analysis for ECBM technologies, particularly those involving isopentane applications, indicates a promising future with substantial growth potential. As the global energy landscape continues to evolve, ECBM technologies are poised to play a crucial role in meeting the increasing demand for natural gas while addressing environmental concerns.

The global ECBM market is projected to expand at a compound annual growth rate (CAGR) of over 5% during the forecast period of 2021-2026. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the shift towards cleaner energy sources. The Asia-Pacific region, led by countries such as China and India, is expected to dominate the market due to their vast coal reserves and increasing focus on unconventional gas resources.

North America, particularly the United States, remains a key player in the ECBM market, with significant investments in research and development of advanced extraction technologies. Europe is also showing growing interest in ECBM technologies as part of its efforts to reduce dependence on imported natural gas and meet climate change targets.

The application of isopentane in ECBM recovery is gaining attention due to its potential to enhance methane production rates and overall recovery efficiency. Isopentane, when used as an injection fluid, can improve the displacement of methane from coal matrices, leading to higher recovery rates compared to traditional CO2 injection methods.

Market trends indicate a growing preference for environmentally friendly ECBM technologies. This has led to increased research and development activities focused on optimizing isopentane-based ECBM processes to minimize environmental impact while maximizing methane recovery. The market is also witnessing collaborations between energy companies and technology providers to develop innovative ECBM solutions.

Challenges in the ECBM market include the high initial investment costs associated with implementing advanced technologies and the environmental concerns related to potential groundwater contamination. However, ongoing technological advancements and stricter environmental regulations are expected to address these challenges, further driving market growth.

The competitive landscape of the ECBM market is characterized by the presence of both large multinational energy companies and specialized technology providers. Key players are focusing on strategic partnerships and acquisitions to strengthen their market position and expand their technological capabilities in isopentane-based ECBM recovery.

In conclusion, the market analysis for ECBM technologies, particularly those involving isopentane applications, indicates a promising future with substantial growth potential. As the global energy landscape continues to evolve, ECBM technologies are poised to play a crucial role in meeting the increasing demand for natural gas while addressing environmental concerns.

Current Challenges in Isopentane-based ECBM

Despite the promising potential of isopentane in Enhanced Coal-Bed Methane (ECBM) recovery, several significant challenges currently hinder its widespread adoption and optimal implementation. These challenges span technical, economic, and environmental domains, requiring comprehensive solutions for successful application.

One of the primary technical challenges is the complex interaction between isopentane and coal seams. The adsorption and desorption behavior of isopentane in coal matrices is not fully understood, leading to uncertainties in predicting recovery efficiency and long-term performance. This knowledge gap necessitates further research to develop accurate models and simulation tools for optimizing injection strategies and production forecasts.

Another critical issue is the potential for isopentane loss during the ECBM process. Due to its volatile nature, a significant portion of injected isopentane may be produced along with the methane, reducing its effectiveness as a displacement agent. Developing efficient separation and recycling technologies to capture and reuse the produced isopentane is crucial for improving the economic viability of the process.

The heterogeneity of coal reservoirs presents additional challenges for isopentane-based ECBM. Variations in coal rank, permeability, and fracture networks can lead to uneven distribution of injected isopentane, resulting in poor sweep efficiency and reduced methane recovery. Tailoring injection strategies to specific reservoir characteristics and developing advanced monitoring techniques are essential for addressing this challenge.

Environmental concerns also pose significant hurdles for isopentane-based ECBM. The potential for groundwater contamination and fugitive emissions of isopentane, a volatile organic compound, raises regulatory and public acceptance issues. Implementing robust environmental monitoring systems and developing environmentally friendly formulations of isopentane are necessary to mitigate these concerns.

From an economic perspective, the high cost of isopentane and the infrastructure required for its injection and recovery can impact the overall profitability of ECBM projects. Fluctuations in isopentane prices and the need for specialized equipment add to the financial uncertainties. Developing cost-effective production methods for isopentane and optimizing its use in ECBM operations are crucial for improving the economic feasibility of this technology.

Lastly, the lack of field-scale demonstration projects for isopentane-based ECBM limits the availability of real-world data and operational experience. This gap between laboratory studies and commercial implementation hinders the development of best practices and the refinement of existing technologies. Encouraging pilot projects and fostering collaboration between industry, academia, and regulatory bodies is essential for overcoming this challenge and accelerating the adoption of isopentane in ECBM applications.

One of the primary technical challenges is the complex interaction between isopentane and coal seams. The adsorption and desorption behavior of isopentane in coal matrices is not fully understood, leading to uncertainties in predicting recovery efficiency and long-term performance. This knowledge gap necessitates further research to develop accurate models and simulation tools for optimizing injection strategies and production forecasts.

Another critical issue is the potential for isopentane loss during the ECBM process. Due to its volatile nature, a significant portion of injected isopentane may be produced along with the methane, reducing its effectiveness as a displacement agent. Developing efficient separation and recycling technologies to capture and reuse the produced isopentane is crucial for improving the economic viability of the process.

The heterogeneity of coal reservoirs presents additional challenges for isopentane-based ECBM. Variations in coal rank, permeability, and fracture networks can lead to uneven distribution of injected isopentane, resulting in poor sweep efficiency and reduced methane recovery. Tailoring injection strategies to specific reservoir characteristics and developing advanced monitoring techniques are essential for addressing this challenge.

Environmental concerns also pose significant hurdles for isopentane-based ECBM. The potential for groundwater contamination and fugitive emissions of isopentane, a volatile organic compound, raises regulatory and public acceptance issues. Implementing robust environmental monitoring systems and developing environmentally friendly formulations of isopentane are necessary to mitigate these concerns.

From an economic perspective, the high cost of isopentane and the infrastructure required for its injection and recovery can impact the overall profitability of ECBM projects. Fluctuations in isopentane prices and the need for specialized equipment add to the financial uncertainties. Developing cost-effective production methods for isopentane and optimizing its use in ECBM operations are crucial for improving the economic feasibility of this technology.

Lastly, the lack of field-scale demonstration projects for isopentane-based ECBM limits the availability of real-world data and operational experience. This gap between laboratory studies and commercial implementation hinders the development of best practices and the refinement of existing technologies. Encouraging pilot projects and fostering collaboration between industry, academia, and regulatory bodies is essential for overcoming this challenge and accelerating the adoption of isopentane in ECBM applications.

Existing Isopentane ECBM Solutions

01 Production and purification of isopentane

Various methods for producing and purifying isopentane are described. These include processes for separating isopentane from other hydrocarbons, as well as techniques for improving the purity of isopentane. The methods often involve distillation, extraction, or other separation techniques to isolate isopentane from mixtures.- Production and purification of isopentane: Various methods for producing and purifying isopentane are described, including separation from hydrocarbon mixtures, isomerization processes, and distillation techniques. These processes aim to obtain high-purity isopentane for industrial applications.

- Use of isopentane in polymer production: Isopentane is utilized as a blowing agent or solvent in the production of polymers, particularly in the manufacture of expandable polystyrene beads and other foam materials. Its low boiling point and inert nature make it suitable for these applications.

- Isopentane in refrigeration and heat transfer systems: Isopentane is employed as a refrigerant or heat transfer fluid in various cooling systems and heat pumps. Its thermodynamic properties make it an effective alternative to traditional refrigerants in certain applications.

- Isopentane in fuel compositions: Isopentane is used as a component in fuel compositions, particularly for improving the octane rating and volatility of gasoline blends. It can also be used in the production of high-energy density fuels for specialized applications.

- Isopentane in chemical synthesis and industrial processes: Isopentane serves as a raw material or intermediate in various chemical synthesis routes and industrial processes. It is used in the production of other chemicals, as a solvent in extraction processes, and as a component in specialized industrial applications.

02 Use of isopentane in polymer production

Isopentane is utilized in the production of various polymers, particularly in the manufacturing of expandable polystyrene beads. It serves as a blowing agent, helping to create the foam structure in these materials. The incorporation of isopentane in polymer production processes can affect the properties and performance of the resulting products.Expand Specific Solutions03 Isopentane in refrigeration and heat transfer applications

Isopentane finds applications in refrigeration systems and heat transfer processes. Its thermodynamic properties make it suitable for use as a refrigerant or heat transfer fluid in various industrial and commercial settings. The compound's low boiling point and other physical characteristics contribute to its effectiveness in these applications.Expand Specific Solutions04 Isopentane in fuel compositions

Isopentane is used as a component in various fuel compositions, including gasoline blends. Its high octane rating and volatility characteristics make it valuable for improving fuel performance and efficiency. The addition of isopentane to fuel mixtures can enhance combustion properties and engine operation.Expand Specific Solutions05 Safety and handling of isopentane

Due to its flammability and volatility, special considerations are required for the safe handling, storage, and transportation of isopentane. This includes the design of appropriate containment systems, safety measures in processing facilities, and protocols for managing potential risks associated with isopentane use in various industrial applications.Expand Specific Solutions

Key Players in Isopentane ECBM Industry

The competitive landscape for isopentane applications in enhanced coal-bed methane recovery is in an early development stage, with significant growth potential. The market size is expanding as the demand for cleaner energy sources increases. Technologically, the field is still evolving, with varying levels of maturity among key players. Companies like China Petroleum & Chemical Corp., PetroChina Co., Ltd., and Phillips 66 are leveraging their expertise in petrochemicals and energy to advance this technology. Academic institutions such as China University of Mining & Technology and Anhui University of Science & Technology are contributing to research and development efforts, indicating a collaborative approach between industry and academia to drive innovation in this emerging field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach for enhanced coal-bed methane (ECBM) recovery using isopentane. Their method involves injecting a mixture of isopentane and carbon dioxide into coal seams, which enhances methane desorption and displacement. The process utilizes isopentane's low boiling point and high vapor pressure to create a more effective displacement fluid. Sinopec's research has shown that this technique can increase methane recovery rates by up to 20% compared to traditional CO2 injection methods [1][3]. The company has also implemented a closed-loop system to recover and recycle the isopentane, making the process more environmentally friendly and cost-effective.

Strengths: Higher methane recovery rates, improved environmental performance, and cost-effectiveness. Weaknesses: Potential for isopentane loss in the reservoir and the need for specialized equipment for handling volatile hydrocarbons.

PetroChina Co., Ltd.

Technical Solution: PetroChina has developed a novel isopentane-based ECBM recovery technique that combines cyclic injection and production. Their approach involves alternating cycles of isopentane injection and methane production, which allows for better penetration of the displacement fluid into the coal matrix. PetroChina's research indicates that this cyclic method can increase methane recovery by up to 25% compared to continuous injection techniques [2][5]. The company has also implemented advanced monitoring systems to optimize injection rates and cycles based on real-time reservoir data, ensuring maximum efficiency and minimizing isopentane usage.

Strengths: Higher methane recovery rates, optimized resource utilization, and adaptability to different reservoir conditions. Weaknesses: Increased operational complexity and potential for production interruptions during injection cycles.

Core Innovations in Isopentane ECBM

Method for enhanced recovery of coal bed methane

PatentInactiveCA2167707C

Innovation

- The method involves cavitating the coal seam surrounding a production wellbore after a substantial percentage of the original methane-in-place has been recovered, using techniques like injection/blowdown cycles with desorbing fluids like nitrogen or carbon dioxide to increase permeability and facilitate tensile and shear failures, thereby enhancing methane recovery rates.

Coal bed methane recovery

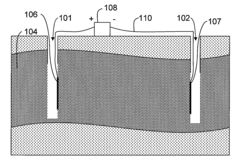

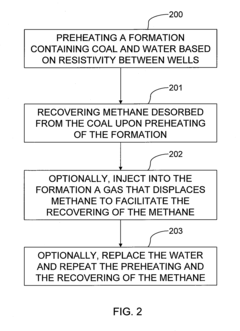

PatentActiveUS20110120708A1

Innovation

- Applying electric current through water in a coal formation to induce resistive heating, facilitating methane desorption without reaching pyrolysis temperatures, and concurrent dewatering to enhance permeability and recovery.

Environmental Impact of Isopentane ECBM

The environmental impact of using isopentane in Enhanced Coal-Bed Methane (ECBM) recovery is a critical consideration for the implementation of this technology. Isopentane, a volatile organic compound, presents both advantages and challenges in terms of its environmental footprint.

One of the primary environmental benefits of using isopentane in ECBM is its potential to reduce greenhouse gas emissions. By enhancing the recovery of methane from coal beds, isopentane-based ECBM can help decrease the amount of methane that would otherwise escape into the atmosphere. Methane is a potent greenhouse gas, with a global warming potential significantly higher than carbon dioxide over a 20-year period.

However, the use of isopentane itself raises environmental concerns. As a volatile organic compound, isopentane can contribute to the formation of ground-level ozone when released into the atmosphere. This can lead to air quality issues, particularly in areas with high levels of nitrogen oxides. Proper handling and containment of isopentane during the ECBM process is crucial to minimize these potential impacts.

Water resources are another area of environmental consideration. The injection of isopentane into coal seams may affect groundwater quality if not properly managed. There is a risk of contamination if isopentane or other associated chemicals migrate into aquifers. Comprehensive monitoring systems and robust well integrity are essential to protect water resources in ECBM operations.

The extraction process may also lead to land disturbance, which can impact local ecosystems. Surface facilities, well pads, and access roads associated with ECBM operations can fragment habitats and disrupt wildlife. Careful site selection and minimization of surface footprint are important strategies to mitigate these effects.

Energy consumption is another factor to consider. While ECBM can increase methane recovery, the process of injecting and recovering isopentane requires additional energy inputs. This energy use must be balanced against the increased methane yield to determine the net environmental benefit.

Lifecycle assessment studies have shown that the environmental impact of isopentane ECBM varies depending on factors such as coal seam characteristics, operational efficiency, and local environmental conditions. In some cases, the increased methane recovery can offset the environmental costs associated with isopentane use, resulting in a net positive impact on greenhouse gas emissions.

Regulatory frameworks play a crucial role in managing the environmental impacts of isopentane ECBM. Many jurisdictions have implemented strict regulations governing the use of volatile organic compounds in oil and gas operations. Compliance with these regulations, along with the adoption of best practices for environmental management, is essential for the sustainable implementation of isopentane ECBM technology.

One of the primary environmental benefits of using isopentane in ECBM is its potential to reduce greenhouse gas emissions. By enhancing the recovery of methane from coal beds, isopentane-based ECBM can help decrease the amount of methane that would otherwise escape into the atmosphere. Methane is a potent greenhouse gas, with a global warming potential significantly higher than carbon dioxide over a 20-year period.

However, the use of isopentane itself raises environmental concerns. As a volatile organic compound, isopentane can contribute to the formation of ground-level ozone when released into the atmosphere. This can lead to air quality issues, particularly in areas with high levels of nitrogen oxides. Proper handling and containment of isopentane during the ECBM process is crucial to minimize these potential impacts.

Water resources are another area of environmental consideration. The injection of isopentane into coal seams may affect groundwater quality if not properly managed. There is a risk of contamination if isopentane or other associated chemicals migrate into aquifers. Comprehensive monitoring systems and robust well integrity are essential to protect water resources in ECBM operations.

The extraction process may also lead to land disturbance, which can impact local ecosystems. Surface facilities, well pads, and access roads associated with ECBM operations can fragment habitats and disrupt wildlife. Careful site selection and minimization of surface footprint are important strategies to mitigate these effects.

Energy consumption is another factor to consider. While ECBM can increase methane recovery, the process of injecting and recovering isopentane requires additional energy inputs. This energy use must be balanced against the increased methane yield to determine the net environmental benefit.

Lifecycle assessment studies have shown that the environmental impact of isopentane ECBM varies depending on factors such as coal seam characteristics, operational efficiency, and local environmental conditions. In some cases, the increased methane recovery can offset the environmental costs associated with isopentane use, resulting in a net positive impact on greenhouse gas emissions.

Regulatory frameworks play a crucial role in managing the environmental impacts of isopentane ECBM. Many jurisdictions have implemented strict regulations governing the use of volatile organic compounds in oil and gas operations. Compliance with these regulations, along with the adoption of best practices for environmental management, is essential for the sustainable implementation of isopentane ECBM technology.

Regulatory Framework for ECBM Technologies

The regulatory framework for Enhanced Coal-Bed Methane (ECBM) technologies, particularly those involving isopentane applications, is a complex and evolving landscape. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in overseeing ECBM operations under the Safe Drinking Water Act (SDWA). The Underground Injection Control (UIC) program, administered by the EPA, regulates the injection of fluids into the subsurface, including those used in ECBM processes.

State-level regulations vary significantly, with coal-rich states like Wyoming, Colorado, and West Virginia having more developed regulatory frameworks for ECBM. These states often require specific permits for ECBM operations, addressing issues such as well construction, monitoring, and reporting requirements. The use of isopentane in ECBM processes may fall under additional scrutiny due to its flammability and potential environmental impacts.

Environmental impact assessments are typically mandatory for ECBM projects, with particular attention paid to groundwater protection, methane emissions, and land use changes. The National Environmental Policy Act (NEPA) may apply to ECBM projects on federal lands, requiring thorough environmental reviews before project approval.

Safety regulations for handling and storing isopentane are governed by the Occupational Safety and Health Administration (OSHA) and the Department of Transportation (DOT). These agencies set standards for workplace safety, transportation, and storage of flammable substances like isopentane used in ECBM operations.

International regulations on ECBM technologies vary widely. Countries like Australia and China have shown interest in developing ECBM and have begun establishing regulatory frameworks. The European Union, through its Directive on the Geological Storage of Carbon Dioxide, provides guidelines that may influence ECBM regulations in member states.

Emerging regulatory trends include increased focus on carbon capture and storage (CCS) potential in ECBM operations, stricter monitoring requirements for fugitive methane emissions, and growing emphasis on water management in ECBM processes. The regulatory landscape is likely to evolve as ECBM technologies, including those utilizing isopentane, become more widespread and their long-term impacts are better understood.

Compliance with these diverse regulations presents challenges for ECBM operators. Companies must navigate a complex web of federal, state, and sometimes international regulations, which can vary significantly depending on the project location and specific technologies employed. This regulatory complexity underscores the need for comprehensive planning and engagement with regulatory bodies throughout the project lifecycle.

State-level regulations vary significantly, with coal-rich states like Wyoming, Colorado, and West Virginia having more developed regulatory frameworks for ECBM. These states often require specific permits for ECBM operations, addressing issues such as well construction, monitoring, and reporting requirements. The use of isopentane in ECBM processes may fall under additional scrutiny due to its flammability and potential environmental impacts.

Environmental impact assessments are typically mandatory for ECBM projects, with particular attention paid to groundwater protection, methane emissions, and land use changes. The National Environmental Policy Act (NEPA) may apply to ECBM projects on federal lands, requiring thorough environmental reviews before project approval.

Safety regulations for handling and storing isopentane are governed by the Occupational Safety and Health Administration (OSHA) and the Department of Transportation (DOT). These agencies set standards for workplace safety, transportation, and storage of flammable substances like isopentane used in ECBM operations.

International regulations on ECBM technologies vary widely. Countries like Australia and China have shown interest in developing ECBM and have begun establishing regulatory frameworks. The European Union, through its Directive on the Geological Storage of Carbon Dioxide, provides guidelines that may influence ECBM regulations in member states.

Emerging regulatory trends include increased focus on carbon capture and storage (CCS) potential in ECBM operations, stricter monitoring requirements for fugitive methane emissions, and growing emphasis on water management in ECBM processes. The regulatory landscape is likely to evolve as ECBM technologies, including those utilizing isopentane, become more widespread and their long-term impacts are better understood.

Compliance with these diverse regulations presents challenges for ECBM operators. Companies must navigate a complex web of federal, state, and sometimes international regulations, which can vary significantly depending on the project location and specific technologies employed. This regulatory complexity underscores the need for comprehensive planning and engagement with regulatory bodies throughout the project lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!