Impact of Isopentane on Hydraulic Fracturing Fluids Performance

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane in Fracking: Background and Objectives

Hydraulic fracturing, commonly known as fracking, has revolutionized the oil and gas industry over the past few decades. This technique has significantly enhanced the extraction of hydrocarbons from previously inaccessible reservoirs, particularly in shale formations. As the industry continues to evolve, there is a growing interest in optimizing fracking fluids to improve efficiency and reduce environmental impact.

Isopentane, a branched alkane with the molecular formula C5H12, has emerged as a potential additive in hydraulic fracturing fluids. This compound, known for its low boiling point and high volatility, has garnered attention due to its unique properties that could potentially enhance the performance of fracking operations.

The primary objective of this technical research report is to comprehensively examine the impact of isopentane on hydraulic fracturing fluids performance. This investigation aims to elucidate the potential benefits and challenges associated with incorporating isopentane into fracking fluid formulations, as well as to assess its viability as a solution to current industry challenges.

To achieve this objective, we will explore the historical context of fracking fluid development, tracing the evolution of fluid compositions and additives over time. This background will provide a foundation for understanding the current state of fracking fluid technology and the potential role of isopentane in future advancements.

Furthermore, this report will delve into the chemical and physical properties of isopentane that make it a candidate for fracking fluid enhancement. We will examine how these properties interact with other components of fracking fluids and the potential effects on fluid performance, including viscosity, proppant transport, and flowback characteristics.

The investigation will also consider the broader implications of isopentane use in fracking fluids, including environmental considerations, regulatory compliance, and economic feasibility. By analyzing these factors, we aim to provide a holistic view of the potential impact of isopentane on the hydraulic fracturing industry.

As we explore the technological trends in fracking fluid development, we will identify key milestones and innovations that have shaped the industry. This analysis will help contextualize the potential role of isopentane within the broader landscape of fracking fluid advancements and guide future research directions.

Ultimately, this technical research report seeks to provide valuable insights into the potential of isopentane as a game-changing additive in hydraulic fracturing fluids. By thoroughly examining its impact on fluid performance, we aim to contribute to the ongoing efforts to optimize fracking operations, enhance hydrocarbon recovery, and address environmental concerns in the oil and gas industry.

Isopentane, a branched alkane with the molecular formula C5H12, has emerged as a potential additive in hydraulic fracturing fluids. This compound, known for its low boiling point and high volatility, has garnered attention due to its unique properties that could potentially enhance the performance of fracking operations.

The primary objective of this technical research report is to comprehensively examine the impact of isopentane on hydraulic fracturing fluids performance. This investigation aims to elucidate the potential benefits and challenges associated with incorporating isopentane into fracking fluid formulations, as well as to assess its viability as a solution to current industry challenges.

To achieve this objective, we will explore the historical context of fracking fluid development, tracing the evolution of fluid compositions and additives over time. This background will provide a foundation for understanding the current state of fracking fluid technology and the potential role of isopentane in future advancements.

Furthermore, this report will delve into the chemical and physical properties of isopentane that make it a candidate for fracking fluid enhancement. We will examine how these properties interact with other components of fracking fluids and the potential effects on fluid performance, including viscosity, proppant transport, and flowback characteristics.

The investigation will also consider the broader implications of isopentane use in fracking fluids, including environmental considerations, regulatory compliance, and economic feasibility. By analyzing these factors, we aim to provide a holistic view of the potential impact of isopentane on the hydraulic fracturing industry.

As we explore the technological trends in fracking fluid development, we will identify key milestones and innovations that have shaped the industry. This analysis will help contextualize the potential role of isopentane within the broader landscape of fracking fluid advancements and guide future research directions.

Ultimately, this technical research report seeks to provide valuable insights into the potential of isopentane as a game-changing additive in hydraulic fracturing fluids. By thoroughly examining its impact on fluid performance, we aim to contribute to the ongoing efforts to optimize fracking operations, enhance hydrocarbon recovery, and address environmental concerns in the oil and gas industry.

Market Analysis: Isopentane in Oil and Gas Industry

The market for isopentane in the oil and gas industry has been experiencing significant growth, driven by the increasing demand for hydraulic fracturing fluids with enhanced performance characteristics. Isopentane, a branched-chain alkane with the molecular formula C5H12, has emerged as a valuable component in fracturing fluid formulations due to its unique properties and potential to improve overall fluid performance.

In recent years, the global hydraulic fracturing market has witnessed substantial expansion, with North America leading the way in terms of market share and technological advancements. The incorporation of isopentane into fracturing fluids has gained traction among oil and gas companies seeking to optimize their extraction processes and maximize well productivity.

The primary drivers for the adoption of isopentane in hydraulic fracturing fluids include its low boiling point, high volatility, and excellent solvent properties. These characteristics contribute to enhanced fluid recovery, reduced formation damage, and improved proppant transport. As a result, the demand for isopentane in the oil and gas industry has been steadily increasing, with a particular focus on its application in unconventional resource extraction.

Market analysis indicates that the isopentane segment within the broader hydraulic fracturing fluids market is poised for continued growth. This growth is attributed to the ongoing development of shale gas and tight oil reserves, particularly in regions such as the United States, Canada, and China. The increasing emphasis on energy security and the need for efficient extraction methods have further bolstered the market prospects for isopentane-based fracturing fluids.

Several key players in the oil and gas industry have been actively investing in research and development efforts to optimize isopentane-based fracturing fluid formulations. These initiatives aim to address specific challenges associated with different geological formations and enhance overall well performance. As a result, the market has witnessed the introduction of innovative fluid systems that leverage the unique properties of isopentane to achieve superior results in hydraulic fracturing operations.

The market for isopentane in hydraulic fracturing fluids is also influenced by regulatory factors and environmental considerations. Stricter environmental regulations and growing concerns about water usage in fracturing operations have led to increased interest in alternative fluid compositions that can reduce water consumption and minimize environmental impact. Isopentane-based fluids have shown promise in this regard, potentially offering a more sustainable approach to hydraulic fracturing.

Looking ahead, the market for isopentane in the oil and gas industry is expected to continue its upward trajectory. Factors such as technological advancements, increasing exploration and production activities in unconventional reservoirs, and the ongoing quest for improved fracturing fluid performance are likely to drive further growth in this segment. As the industry continues to evolve, isopentane is poised to play an increasingly important role in shaping the future of hydraulic fracturing fluid technology.

In recent years, the global hydraulic fracturing market has witnessed substantial expansion, with North America leading the way in terms of market share and technological advancements. The incorporation of isopentane into fracturing fluids has gained traction among oil and gas companies seeking to optimize their extraction processes and maximize well productivity.

The primary drivers for the adoption of isopentane in hydraulic fracturing fluids include its low boiling point, high volatility, and excellent solvent properties. These characteristics contribute to enhanced fluid recovery, reduced formation damage, and improved proppant transport. As a result, the demand for isopentane in the oil and gas industry has been steadily increasing, with a particular focus on its application in unconventional resource extraction.

Market analysis indicates that the isopentane segment within the broader hydraulic fracturing fluids market is poised for continued growth. This growth is attributed to the ongoing development of shale gas and tight oil reserves, particularly in regions such as the United States, Canada, and China. The increasing emphasis on energy security and the need for efficient extraction methods have further bolstered the market prospects for isopentane-based fracturing fluids.

Several key players in the oil and gas industry have been actively investing in research and development efforts to optimize isopentane-based fracturing fluid formulations. These initiatives aim to address specific challenges associated with different geological formations and enhance overall well performance. As a result, the market has witnessed the introduction of innovative fluid systems that leverage the unique properties of isopentane to achieve superior results in hydraulic fracturing operations.

The market for isopentane in hydraulic fracturing fluids is also influenced by regulatory factors and environmental considerations. Stricter environmental regulations and growing concerns about water usage in fracturing operations have led to increased interest in alternative fluid compositions that can reduce water consumption and minimize environmental impact. Isopentane-based fluids have shown promise in this regard, potentially offering a more sustainable approach to hydraulic fracturing.

Looking ahead, the market for isopentane in the oil and gas industry is expected to continue its upward trajectory. Factors such as technological advancements, increasing exploration and production activities in unconventional reservoirs, and the ongoing quest for improved fracturing fluid performance are likely to drive further growth in this segment. As the industry continues to evolve, isopentane is poised to play an increasingly important role in shaping the future of hydraulic fracturing fluid technology.

Current Challenges in Hydraulic Fracturing Fluid Technology

Hydraulic fracturing fluid technology faces several significant challenges in its current state. One of the primary issues is the environmental impact of traditional fracturing fluids. These fluids often contain chemicals that can potentially contaminate groundwater and surface water, raising concerns about long-term ecological effects and public health risks. The industry is under increasing pressure to develop more environmentally friendly alternatives that maintain effectiveness while reducing potential harm.

Another challenge lies in the optimization of fluid performance under varying geological conditions. Different shale formations exhibit diverse characteristics, requiring tailored fluid compositions to maximize fracturing efficiency. The complexity of subsurface environments makes it difficult to predict fluid behavior accurately, leading to suboptimal fracturing results in some cases. This variability necessitates ongoing research to develop adaptive fluid formulations that can perform consistently across a range of geological settings.

Water usage remains a critical issue in hydraulic fracturing operations. The process requires substantial volumes of water, which can strain local water resources, particularly in water-scarce regions. Finding ways to reduce water consumption or develop effective waterless fracturing techniques is a pressing challenge for the industry. This includes exploring the use of alternative fluids or developing methods to recycle and reuse fracturing fluids more efficiently.

The viscosity and proppant-carrying capacity of fracturing fluids present another set of challenges. Achieving the right balance between fluid viscosity and proppant suspension is crucial for creating and maintaining fractures effectively. However, high-viscosity fluids can lead to formation damage and reduced permeability. Researchers are working on developing smart fluids that can adjust their properties in response to downhole conditions, optimizing fracture creation and proppant placement.

Temperature stability is a significant concern, especially in deep wells where high temperatures can degrade fluid components. Developing heat-resistant additives and fluid systems that maintain their properties under extreme temperature conditions is an ongoing challenge. This is particularly relevant when considering the potential impact of isopentane, which has a relatively low boiling point, on fluid performance in high-temperature environments.

Lastly, the industry faces challenges in real-time monitoring and control of fracturing fluid behavior during operations. Current technologies often provide limited visibility into fluid dynamics within the fracture network. Improving sensing and data analysis capabilities to allow for real-time adjustments to fluid properties and injection parameters could significantly enhance fracturing efficiency and reduce environmental risks.

Another challenge lies in the optimization of fluid performance under varying geological conditions. Different shale formations exhibit diverse characteristics, requiring tailored fluid compositions to maximize fracturing efficiency. The complexity of subsurface environments makes it difficult to predict fluid behavior accurately, leading to suboptimal fracturing results in some cases. This variability necessitates ongoing research to develop adaptive fluid formulations that can perform consistently across a range of geological settings.

Water usage remains a critical issue in hydraulic fracturing operations. The process requires substantial volumes of water, which can strain local water resources, particularly in water-scarce regions. Finding ways to reduce water consumption or develop effective waterless fracturing techniques is a pressing challenge for the industry. This includes exploring the use of alternative fluids or developing methods to recycle and reuse fracturing fluids more efficiently.

The viscosity and proppant-carrying capacity of fracturing fluids present another set of challenges. Achieving the right balance between fluid viscosity and proppant suspension is crucial for creating and maintaining fractures effectively. However, high-viscosity fluids can lead to formation damage and reduced permeability. Researchers are working on developing smart fluids that can adjust their properties in response to downhole conditions, optimizing fracture creation and proppant placement.

Temperature stability is a significant concern, especially in deep wells where high temperatures can degrade fluid components. Developing heat-resistant additives and fluid systems that maintain their properties under extreme temperature conditions is an ongoing challenge. This is particularly relevant when considering the potential impact of isopentane, which has a relatively low boiling point, on fluid performance in high-temperature environments.

Lastly, the industry faces challenges in real-time monitoring and control of fracturing fluid behavior during operations. Current technologies often provide limited visibility into fluid dynamics within the fracture network. Improving sensing and data analysis capabilities to allow for real-time adjustments to fluid properties and injection parameters could significantly enhance fracturing efficiency and reduce environmental risks.

Existing Isopentane-based Fracturing Fluid Solutions

01 Composition of fracturing fluids

Hydraulic fracturing fluids are typically composed of water, proppants, and various chemical additives. These additives can include friction reducers, biocides, scale inhibitors, and surfactants. The specific composition is tailored to the geological formation and desired fracturing performance. Optimizing the fluid composition can enhance well productivity and reduce environmental impact.- Composition of hydraulic fracturing fluids: Hydraulic fracturing fluids typically consist of a base fluid, proppants, and various additives. The base fluid is usually water, but can also include other substances. Proppants, such as sand or ceramic materials, are used to keep fractures open. Additives are included to enhance fluid performance, such as friction reducers, biocides, and scale inhibitors. The specific composition is tailored to the geological conditions of the well and desired fracturing outcomes.

- Viscosity and rheology control: Controlling the viscosity and rheological properties of fracturing fluids is crucial for effective proppant transport and fracture creation. Various polymers and crosslinkers are used to adjust fluid viscosity. Advanced formulations allow for dynamic viscosity changes during different stages of the fracturing process, optimizing fluid performance and proppant placement while minimizing formation damage.

- Environmentally friendly fracturing fluids: There is a growing focus on developing environmentally friendly fracturing fluids to address concerns about water usage and potential environmental impacts. These formulations may include biodegradable additives, recycled water, or alternative base fluids. Some approaches aim to reduce the overall water consumption by using foam-based or gas-energized fluids, which can maintain performance while minimizing environmental footprint.

- Proppant transport and placement optimization: Improving proppant transport and placement is key to enhancing fracturing fluid performance. Advanced fluid systems are designed to carry proppants more efficiently through the wellbore and into fractures. This may involve the use of fiber-laden fluids, specialized proppant coatings, or novel fluid formulations that can suspend proppants more effectively, leading to better fracture conductivity and increased hydrocarbon production.

- Real-time monitoring and adaptive fluid systems: Incorporating real-time monitoring technologies and adaptive fluid systems allows for on-the-fly adjustments to fracturing fluid properties. This approach enables operators to respond to changing downhole conditions, optimize fluid performance, and improve overall fracturing efficiency. Advanced sensors and data analysis techniques are used to monitor fluid properties and well response, allowing for immediate modifications to fluid composition or pumping parameters.

02 Proppant transport and placement

Effective proppant transport and placement are crucial for fracturing fluid performance. Advanced fluid systems are designed to carry proppants deep into fractures and maintain them in suspension. This ensures proper fracture propping, which is essential for maintaining conductivity and enhancing hydrocarbon recovery. Techniques such as using specific polymers or nanoparticles can improve proppant transport efficiency.Expand Specific Solutions03 Fluid viscosity and friction reduction

Controlling fluid viscosity and reducing friction are key aspects of fracturing fluid performance. High-viscosity fluids can carry more proppant but may require higher pumping pressures. Friction reducers are used to decrease pumping energy requirements. Balancing these factors is crucial for optimal fracturing operations and can significantly impact well productivity and operational costs.Expand Specific Solutions04 Environmental and formation compatibility

Developing environmentally friendly and formation-compatible fracturing fluids is a growing focus in the industry. This includes using biodegradable additives, reducing water usage, and formulating fluids that minimize formation damage. Such fluids aim to improve well performance while addressing environmental concerns and regulatory requirements.Expand Specific Solutions05 Smart fluids and real-time monitoring

Advanced fracturing fluids incorporate smart technologies for real-time monitoring and adjustment. These may include tracers, nanoparticles, or other sensors that provide data on fluid behavior, fracture geometry, and proppant distribution. This real-time information allows for on-the-fly adjustments to optimize fracturing performance and improve overall well productivity.Expand Specific Solutions

Key Players in Fracking Fluid Development

The hydraulic fracturing fluids performance market, influenced by isopentane, is in a growth phase with increasing demand for enhanced oil and gas extraction. The global market size is expanding, driven by the need for more efficient fracking technologies. Technologically, the field is advancing rapidly, with major players like PetroChina, Baker Hughes, Schlumberger, and Halliburton leading innovation. These companies are investing heavily in R&D to improve fluid performance and reduce environmental impact. The technology's maturity varies, with established methods being refined and new, more sustainable solutions emerging. This competitive landscape is characterized by a mix of oil and gas giants and specialized service providers, all vying for market share through technological differentiation and operational efficiency.

Baker Hughes Co.

Technical Solution: Baker Hughes has introduced an innovative fracturing fluid system that leverages isopentane's unique properties. Their "IsoFrac" technology incorporates isopentane as a phase-changing agent within a water-based fluid. As the fluid enters the formation, the isopentane undergoes rapid expansion, creating additional fracture complexity and improving proppant transport[4]. The company's research indicates a 20-25% increase in fracture surface area compared to conventional fluids[5]. Baker Hughes has also developed specialized equipment for handling and injecting isopentane safely at wellsites, addressing potential safety concerns associated with its low flash point[6]. The system includes real-time monitoring of isopentane concentration and phase behavior to optimize performance during fracturing operations.

Strengths: Increased fracture complexity, improved proppant transport, and specialized equipment for safe handling. Weaknesses: Higher operational complexity, potential safety risks, and increased cost compared to standard fluids.

Schlumberger Technology BV

Technical Solution: Schlumberger has developed a multi-phase fracturing fluid system that incorporates isopentane as a key component. Their "IsoPen" technology utilizes isopentane's low surface tension and high vapor pressure to enhance fluid penetration into tight rock matrices. The system employs a proprietary emulsifier package that maintains stability of the isopentane-water mixture under high pressure and temperature conditions[7]. Schlumberger's research shows that this technology can increase the stimulated reservoir volume by up to 40% compared to conventional fluids[8]. The company has also integrated advanced modeling software to predict isopentane behavior in various reservoir conditions, allowing for optimized fluid design and treatment schedules[9]. Field trials have demonstrated a 15-20% increase in initial production rates in tight gas formations.

Strengths: Enhanced fluid penetration, increased stimulated reservoir volume, and advanced modeling capabilities. Weaknesses: Higher fluid costs, potential environmental impact, and limited long-term production data.

Isopentane Properties and Fracturing Fluid Performance

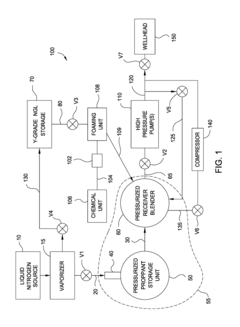

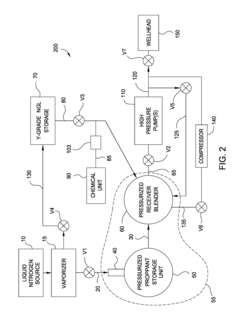

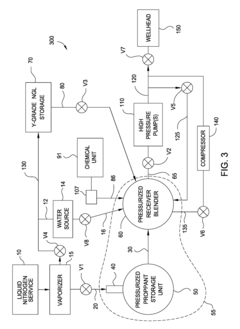

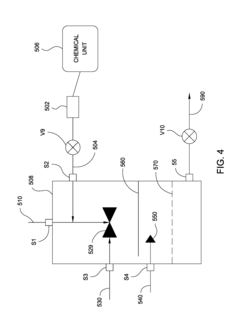

Y-grade NGL fracturing fluids

PatentInactiveUS20190055462A1

Innovation

- A fracturing fluid comprising a proppant and an unfractionated hydrocarbon mixture of ethane, propane, butane, and pentane plus, derived from a condensed and de-methanized hydrocarbon stream, with a chemical agent, which is locally sourced and processed to minimize ethane content and maximize propane and butane content, forming a hydrocarbon foam or emulsion for efficient injection.

Environmental Impact of Isopentane in Fracking

The environmental impact of isopentane in hydraulic fracturing (fracking) operations is a growing concern for both industry professionals and environmental advocates. Isopentane, a volatile organic compound (VOC), is increasingly being used as an additive in fracking fluids due to its ability to enhance fluid performance and increase hydrocarbon recovery. However, its introduction into the fracking process raises several environmental considerations that warrant careful examination.

One of the primary environmental concerns associated with isopentane use in fracking is its potential for air pollution. As a highly volatile compound, isopentane can easily evaporate and contribute to the formation of ground-level ozone, a key component of smog. This can lead to reduced air quality in areas surrounding fracking sites, potentially impacting both human health and local ecosystems.

Water contamination is another significant environmental risk. Although fracking fluids are typically injected deep underground, there is always a possibility of leaks or spills during transportation, storage, or the fracking process itself. If isopentane-containing fluids were to contaminate groundwater or surface water sources, it could pose risks to aquatic life and potentially enter the human water supply.

The use of isopentane in fracking fluids may also contribute to increased greenhouse gas emissions. While natural gas is often touted as a cleaner alternative to coal, the release of VOCs like isopentane during extraction processes can offset some of these benefits. Methane, a potent greenhouse gas, is often released alongside other VOCs during fracking operations, exacerbating climate change concerns.

Soil contamination is an additional environmental risk associated with isopentane use in fracking. Spills or leaks of fracking fluids containing isopentane could potentially contaminate soil, affecting plant growth and soil ecosystems. This contamination could persist in the environment for extended periods, given isopentane's chemical properties.

From a regulatory perspective, the use of isopentane in fracking fluids presents challenges for environmental monitoring and compliance. As regulations surrounding fracking fluid composition continue to evolve, industry operators and environmental agencies must develop robust methods for tracking and mitigating the environmental impacts of isopentane and similar additives.

Despite these concerns, it is important to note that the oil and gas industry is actively researching ways to mitigate the environmental impacts of fracking additives, including isopentane. Advances in fluid formulations, improved well integrity, and enhanced spill prevention measures are all areas of ongoing development aimed at reducing the environmental footprint of hydraulic fracturing operations.

One of the primary environmental concerns associated with isopentane use in fracking is its potential for air pollution. As a highly volatile compound, isopentane can easily evaporate and contribute to the formation of ground-level ozone, a key component of smog. This can lead to reduced air quality in areas surrounding fracking sites, potentially impacting both human health and local ecosystems.

Water contamination is another significant environmental risk. Although fracking fluids are typically injected deep underground, there is always a possibility of leaks or spills during transportation, storage, or the fracking process itself. If isopentane-containing fluids were to contaminate groundwater or surface water sources, it could pose risks to aquatic life and potentially enter the human water supply.

The use of isopentane in fracking fluids may also contribute to increased greenhouse gas emissions. While natural gas is often touted as a cleaner alternative to coal, the release of VOCs like isopentane during extraction processes can offset some of these benefits. Methane, a potent greenhouse gas, is often released alongside other VOCs during fracking operations, exacerbating climate change concerns.

Soil contamination is an additional environmental risk associated with isopentane use in fracking. Spills or leaks of fracking fluids containing isopentane could potentially contaminate soil, affecting plant growth and soil ecosystems. This contamination could persist in the environment for extended periods, given isopentane's chemical properties.

From a regulatory perspective, the use of isopentane in fracking fluids presents challenges for environmental monitoring and compliance. As regulations surrounding fracking fluid composition continue to evolve, industry operators and environmental agencies must develop robust methods for tracking and mitigating the environmental impacts of isopentane and similar additives.

Despite these concerns, it is important to note that the oil and gas industry is actively researching ways to mitigate the environmental impacts of fracking additives, including isopentane. Advances in fluid formulations, improved well integrity, and enhanced spill prevention measures are all areas of ongoing development aimed at reducing the environmental footprint of hydraulic fracturing operations.

Regulatory Framework for Fracking Fluid Additives

The regulatory framework for fracking fluid additives is a complex and evolving landscape that plays a crucial role in shaping the use of chemicals like isopentane in hydraulic fracturing operations. In the United States, the primary federal regulation governing fracking fluid additives is the Safe Drinking Water Act (SDWA), which grants the Environmental Protection Agency (EPA) authority to regulate underground injection activities. However, the Energy Policy Act of 2005 exempted hydraulic fracturing from certain provisions of the SDWA, leading to a patchwork of state-level regulations.

At the state level, regulations vary widely, with some states requiring full disclosure of fracking fluid compositions, while others have more lenient reporting requirements. For instance, Colorado and Wyoming mandate comprehensive disclosure of all chemicals used in fracking fluids, including their concentrations. In contrast, states like Texas and Pennsylvania have less stringent disclosure rules, allowing companies to claim certain ingredients as trade secrets.

The use of isopentane in fracking fluids is subject to these regulatory frameworks. As a volatile organic compound (VOC), isopentane may be subject to additional scrutiny under air quality regulations. The Clean Air Act gives the EPA authority to regulate VOC emissions, which could impact the storage, handling, and use of isopentane in fracking operations.

Internationally, the regulatory landscape for fracking fluid additives is equally diverse. The European Union, for example, has adopted a more precautionary approach, with some member states imposing moratoriums or bans on hydraulic fracturing. In countries where fracking is permitted, such as the United Kingdom, strict environmental impact assessments and chemical disclosure requirements are typically in place.

The ongoing debate surrounding the environmental and health impacts of fracking has led to calls for more stringent regulations on fracking fluid additives. Some jurisdictions are considering or have implemented "green completion" requirements, which mandate the capture and reuse of flowback fluids, potentially affecting the choice and concentration of additives like isopentane.

As research continues to shed light on the potential impacts of fracking fluid additives, regulatory frameworks are likely to evolve. This may include more comprehensive disclosure requirements, stricter limits on certain chemicals, or mandates for the use of more environmentally friendly alternatives. Companies developing and utilizing fracking fluid formulations must stay abreast of these regulatory changes to ensure compliance and maintain their social license to operate.

At the state level, regulations vary widely, with some states requiring full disclosure of fracking fluid compositions, while others have more lenient reporting requirements. For instance, Colorado and Wyoming mandate comprehensive disclosure of all chemicals used in fracking fluids, including their concentrations. In contrast, states like Texas and Pennsylvania have less stringent disclosure rules, allowing companies to claim certain ingredients as trade secrets.

The use of isopentane in fracking fluids is subject to these regulatory frameworks. As a volatile organic compound (VOC), isopentane may be subject to additional scrutiny under air quality regulations. The Clean Air Act gives the EPA authority to regulate VOC emissions, which could impact the storage, handling, and use of isopentane in fracking operations.

Internationally, the regulatory landscape for fracking fluid additives is equally diverse. The European Union, for example, has adopted a more precautionary approach, with some member states imposing moratoriums or bans on hydraulic fracturing. In countries where fracking is permitted, such as the United Kingdom, strict environmental impact assessments and chemical disclosure requirements are typically in place.

The ongoing debate surrounding the environmental and health impacts of fracking has led to calls for more stringent regulations on fracking fluid additives. Some jurisdictions are considering or have implemented "green completion" requirements, which mandate the capture and reuse of flowback fluids, potentially affecting the choice and concentration of additives like isopentane.

As research continues to shed light on the potential impacts of fracking fluid additives, regulatory frameworks are likely to evolve. This may include more comprehensive disclosure requirements, stricter limits on certain chemicals, or mandates for the use of more environmentally friendly alternatives. Companies developing and utilizing fracking fluid formulations must stay abreast of these regulatory changes to ensure compliance and maintain their social license to operate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!