How life cycle assessment aids PHEV sustainability

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV LCA Background and Objectives

Life Cycle Assessment (LCA) has emerged as a crucial tool in evaluating the environmental impact of Plug-in Hybrid Electric Vehicles (PHEVs) throughout their entire lifecycle. As the automotive industry shifts towards more sustainable transportation solutions, PHEVs have gained significant attention due to their potential to reduce greenhouse gas emissions and dependence on fossil fuels.

The primary objective of conducting LCA for PHEVs is to comprehensively assess their environmental performance from cradle to grave. This includes analyzing the environmental impacts associated with raw material extraction, vehicle manufacturing, use phase, and end-of-life disposal or recycling. By quantifying these impacts, LCA aids in identifying hotspots and opportunities for improvement in PHEV sustainability.

The evolution of PHEV technology has been marked by continuous advancements in battery technology, powertrain efficiency, and charging infrastructure. Early PHEVs faced challenges related to limited electric range and high production costs. However, recent technological developments have led to increased electric driving ranges, improved battery longevity, and more efficient integration of electric and combustion powertrains.

As the automotive industry progresses towards more sustainable practices, LCA has become an indispensable tool for guiding decision-making processes. It enables manufacturers to compare the environmental performance of PHEVs with conventional vehicles and fully electric vehicles, helping to inform product development strategies and policy decisions.

The application of LCA in PHEV sustainability assessment aims to address several key questions. These include determining the overall carbon footprint of PHEVs compared to other vehicle types, evaluating the impact of different electricity grid mixes on PHEV environmental performance, and assessing the potential benefits of advanced recycling technologies for PHEV components, particularly batteries.

Furthermore, LCA studies on PHEVs have highlighted the importance of considering regional variations in electricity generation sources, driving patterns, and climate conditions. These factors significantly influence the environmental benefits of PHEVs and underscore the need for tailored strategies to maximize their sustainability potential in different geographical contexts.

As the automotive industry continues to evolve, the role of LCA in PHEV sustainability assessment is expected to grow. Future research directions may focus on improving the accuracy and comprehensiveness of LCA methodologies, incorporating social and economic dimensions into sustainability assessments, and developing standardized approaches for comparing different vehicle technologies across their entire life cycles.

The primary objective of conducting LCA for PHEVs is to comprehensively assess their environmental performance from cradle to grave. This includes analyzing the environmental impacts associated with raw material extraction, vehicle manufacturing, use phase, and end-of-life disposal or recycling. By quantifying these impacts, LCA aids in identifying hotspots and opportunities for improvement in PHEV sustainability.

The evolution of PHEV technology has been marked by continuous advancements in battery technology, powertrain efficiency, and charging infrastructure. Early PHEVs faced challenges related to limited electric range and high production costs. However, recent technological developments have led to increased electric driving ranges, improved battery longevity, and more efficient integration of electric and combustion powertrains.

As the automotive industry progresses towards more sustainable practices, LCA has become an indispensable tool for guiding decision-making processes. It enables manufacturers to compare the environmental performance of PHEVs with conventional vehicles and fully electric vehicles, helping to inform product development strategies and policy decisions.

The application of LCA in PHEV sustainability assessment aims to address several key questions. These include determining the overall carbon footprint of PHEVs compared to other vehicle types, evaluating the impact of different electricity grid mixes on PHEV environmental performance, and assessing the potential benefits of advanced recycling technologies for PHEV components, particularly batteries.

Furthermore, LCA studies on PHEVs have highlighted the importance of considering regional variations in electricity generation sources, driving patterns, and climate conditions. These factors significantly influence the environmental benefits of PHEVs and underscore the need for tailored strategies to maximize their sustainability potential in different geographical contexts.

As the automotive industry continues to evolve, the role of LCA in PHEV sustainability assessment is expected to grow. Future research directions may focus on improving the accuracy and comprehensiveness of LCA methodologies, incorporating social and economic dimensions into sustainability assessments, and developing standardized approaches for comparing different vehicle technologies across their entire life cycles.

PHEV Market Demand Analysis

The market demand for Plug-in Hybrid Electric Vehicles (PHEVs) has been steadily growing, driven by increasing environmental awareness, government incentives, and advancements in battery technology. As consumers seek more sustainable transportation options, PHEVs offer a compelling compromise between traditional internal combustion engines and fully electric vehicles.

Global PHEV sales have shown a consistent upward trend over the past decade, with major automotive markets such as China, Europe, and North America leading the adoption. This growth is expected to continue as more countries implement stricter emissions regulations and set targets for phasing out conventional gasoline-powered vehicles.

The PHEV market is particularly strong in urban and suburban areas where drivers can take advantage of short-range electric-only operation for daily commutes while retaining the flexibility of longer trips using the gasoline engine. This dual-mode capability addresses range anxiety concerns that often deter consumers from adopting fully electric vehicles.

Consumer preferences are shifting towards vehicles with lower environmental impact, and PHEVs are well-positioned to meet this demand. They offer reduced emissions and improved fuel economy compared to conventional vehicles, while providing a familiar driving experience and refueling process.

The corporate fleet sector represents a significant portion of PHEV demand, as businesses seek to reduce their carbon footprint and operating costs. Many companies are incorporating PHEVs into their fleets as part of broader sustainability initiatives, driven by both environmental concerns and potential cost savings over the vehicle's lifetime.

Government policies and incentives play a crucial role in shaping PHEV market demand. Many countries offer tax credits, rebates, or other financial incentives for PHEV purchases, making them more attractive to consumers. Additionally, regulations such as corporate average fuel economy (CAFE) standards encourage automakers to produce and sell more efficient vehicles, including PHEVs.

The integration of life cycle assessment (LCA) in PHEV development and marketing has become increasingly important. Consumers are becoming more aware of the environmental impact of their vehicle choices beyond just tailpipe emissions. LCA helps manufacturers demonstrate the overall sustainability benefits of PHEVs throughout their entire life cycle, from production to end-of-life disposal.

As battery technology continues to improve, the electric-only range of PHEVs is increasing, making them even more appealing to consumers who want to maximize their electric driving. This trend is likely to further boost market demand for PHEVs in the coming years, as they become more capable of meeting a wider range of driving needs while maintaining their hybrid flexibility.

Global PHEV sales have shown a consistent upward trend over the past decade, with major automotive markets such as China, Europe, and North America leading the adoption. This growth is expected to continue as more countries implement stricter emissions regulations and set targets for phasing out conventional gasoline-powered vehicles.

The PHEV market is particularly strong in urban and suburban areas where drivers can take advantage of short-range electric-only operation for daily commutes while retaining the flexibility of longer trips using the gasoline engine. This dual-mode capability addresses range anxiety concerns that often deter consumers from adopting fully electric vehicles.

Consumer preferences are shifting towards vehicles with lower environmental impact, and PHEVs are well-positioned to meet this demand. They offer reduced emissions and improved fuel economy compared to conventional vehicles, while providing a familiar driving experience and refueling process.

The corporate fleet sector represents a significant portion of PHEV demand, as businesses seek to reduce their carbon footprint and operating costs. Many companies are incorporating PHEVs into their fleets as part of broader sustainability initiatives, driven by both environmental concerns and potential cost savings over the vehicle's lifetime.

Government policies and incentives play a crucial role in shaping PHEV market demand. Many countries offer tax credits, rebates, or other financial incentives for PHEV purchases, making them more attractive to consumers. Additionally, regulations such as corporate average fuel economy (CAFE) standards encourage automakers to produce and sell more efficient vehicles, including PHEVs.

The integration of life cycle assessment (LCA) in PHEV development and marketing has become increasingly important. Consumers are becoming more aware of the environmental impact of their vehicle choices beyond just tailpipe emissions. LCA helps manufacturers demonstrate the overall sustainability benefits of PHEVs throughout their entire life cycle, from production to end-of-life disposal.

As battery technology continues to improve, the electric-only range of PHEVs is increasing, making them even more appealing to consumers who want to maximize their electric driving. This trend is likely to further boost market demand for PHEVs in the coming years, as they become more capable of meeting a wider range of driving needs while maintaining their hybrid flexibility.

LCA Challenges in PHEV Industry

Life Cycle Assessment (LCA) in the Plug-in Hybrid Electric Vehicle (PHEV) industry faces several significant challenges that impact the accuracy and reliability of sustainability evaluations. One of the primary difficulties lies in the complexity of PHEV systems, which combine both conventional internal combustion engines and electric powertrains. This dual nature requires a comprehensive analysis of multiple components, materials, and energy sources, making the assessment process more intricate than for traditional vehicles.

Data availability and quality present another major hurdle. Accurate LCA requires detailed information on raw material extraction, manufacturing processes, use-phase energy consumption, and end-of-life disposal. However, such data is often proprietary, inconsistent across different manufacturers, or simply unavailable, particularly for newer technologies and materials used in PHEVs. This lack of standardized, high-quality data can lead to uncertainties in LCA results and hinder comparability between different studies.

The rapidly evolving nature of PHEV technology also poses a challenge for LCA practitioners. As battery technologies, electric motors, and power electronics continue to advance, the environmental impacts associated with these components change. This dynamic landscape makes it difficult to conduct long-term assessments and requires frequent updates to LCA models and databases to remain relevant.

Another significant challenge is the variability in PHEV usage patterns and charging behaviors. Unlike conventional vehicles, the environmental impact of PHEVs heavily depends on factors such as the frequency of charging, the proportion of electric versus gasoline-powered driving, and the source of electricity used for charging. These factors can vary greatly between regions and individual users, making it challenging to develop representative LCA scenarios.

The assessment of indirect and rebound effects adds another layer of complexity to PHEV LCAs. For instance, the potential for PHEVs to increase overall vehicle ownership or travel distances due to perceived environmental benefits can offset some of the sustainability gains. Capturing these secondary effects in LCA models is challenging but crucial for a comprehensive understanding of PHEVs' environmental impact.

Lastly, the end-of-life phase presents unique challenges for PHEV LCAs. The recycling and disposal of batteries and other electronic components involve complex processes with varying environmental impacts. The lack of established recycling infrastructure and the uncertainty surrounding future recycling technologies make it difficult to accurately assess the full life cycle impacts of PHEVs.

Addressing these challenges requires collaborative efforts from industry, academia, and policymakers to improve data transparency, standardize assessment methodologies, and develop more sophisticated LCA tools tailored to the unique characteristics of PHEVs. Only by overcoming these hurdles can LCA truly aid in enhancing the sustainability of the PHEV industry.

Data availability and quality present another major hurdle. Accurate LCA requires detailed information on raw material extraction, manufacturing processes, use-phase energy consumption, and end-of-life disposal. However, such data is often proprietary, inconsistent across different manufacturers, or simply unavailable, particularly for newer technologies and materials used in PHEVs. This lack of standardized, high-quality data can lead to uncertainties in LCA results and hinder comparability between different studies.

The rapidly evolving nature of PHEV technology also poses a challenge for LCA practitioners. As battery technologies, electric motors, and power electronics continue to advance, the environmental impacts associated with these components change. This dynamic landscape makes it difficult to conduct long-term assessments and requires frequent updates to LCA models and databases to remain relevant.

Another significant challenge is the variability in PHEV usage patterns and charging behaviors. Unlike conventional vehicles, the environmental impact of PHEVs heavily depends on factors such as the frequency of charging, the proportion of electric versus gasoline-powered driving, and the source of electricity used for charging. These factors can vary greatly between regions and individual users, making it challenging to develop representative LCA scenarios.

The assessment of indirect and rebound effects adds another layer of complexity to PHEV LCAs. For instance, the potential for PHEVs to increase overall vehicle ownership or travel distances due to perceived environmental benefits can offset some of the sustainability gains. Capturing these secondary effects in LCA models is challenging but crucial for a comprehensive understanding of PHEVs' environmental impact.

Lastly, the end-of-life phase presents unique challenges for PHEV LCAs. The recycling and disposal of batteries and other electronic components involve complex processes with varying environmental impacts. The lack of established recycling infrastructure and the uncertainty surrounding future recycling technologies make it difficult to accurately assess the full life cycle impacts of PHEVs.

Addressing these challenges requires collaborative efforts from industry, academia, and policymakers to improve data transparency, standardize assessment methodologies, and develop more sophisticated LCA tools tailored to the unique characteristics of PHEVs. Only by overcoming these hurdles can LCA truly aid in enhancing the sustainability of the PHEV industry.

Current LCA Approaches for PHEVs

01 Environmental impact assessment methodologies

Life cycle assessment (LCA) methodologies are used to evaluate the environmental impacts of products or processes throughout their entire lifecycle. These methods consider various factors such as resource consumption, emissions, and waste generation from raw material extraction to disposal. Advanced LCA tools and software help in quantifying and analyzing sustainability metrics, enabling organizations to make informed decisions for improving their environmental performance.- Environmental impact assessment methodologies: Life cycle assessment (LCA) methodologies are used to evaluate the environmental impacts of products or processes throughout their entire lifecycle. These methods consider various factors such as resource consumption, emissions, and waste generation from raw material extraction to disposal. Advanced LCA tools and software help in quantifying and analyzing sustainability metrics, enabling organizations to make informed decisions for improving their environmental performance.

- Sustainability data management and reporting: Systems and methods for collecting, managing, and reporting sustainability data are crucial for organizations to track their environmental performance. These solutions often involve centralized databases, data analytics tools, and reporting frameworks that enable companies to monitor key sustainability indicators, set targets, and communicate progress to stakeholders. Such systems help in streamlining sustainability reporting processes and ensuring compliance with regulatory requirements.

- Supply chain sustainability assessment: Techniques for assessing and improving sustainability across the entire supply chain are essential for organizations aiming to reduce their overall environmental footprint. These methods involve analyzing supplier practices, transportation logistics, and resource efficiency at each stage of the supply chain. By identifying hotspots and implementing sustainable practices throughout the value chain, companies can enhance their overall sustainability performance.

- Circular economy and product lifecycle optimization: Innovations in circular economy principles and product lifecycle optimization focus on minimizing waste and maximizing resource efficiency. These approaches involve designing products for longevity, repairability, and recyclability, as well as implementing take-back programs and closed-loop systems. By extending product lifecycles and recovering materials at end-of-life, organizations can significantly reduce their environmental impact and improve sustainability metrics.

- Integration of sustainability metrics in business processes: Methods for integrating sustainability metrics into core business processes and decision-making frameworks are crucial for driving sustainable practices across organizations. These approaches involve incorporating environmental and social considerations into financial models, risk assessments, and strategic planning. By aligning sustainability goals with business objectives, companies can create long-term value while minimizing their environmental impact.

02 Sustainability data management and reporting

Systems and methods for collecting, managing, and reporting sustainability data are crucial for organizations to track their environmental performance. These solutions often involve centralized databases, data analytics tools, and reporting frameworks that enable companies to monitor key sustainability indicators, set targets, and communicate progress to stakeholders. Such systems help in streamlining sustainability reporting processes and ensuring compliance with various environmental regulations and standards.Expand Specific Solutions03 Supply chain sustainability assessment

Techniques for assessing and improving sustainability across the entire supply chain are essential for organizations aiming to reduce their overall environmental footprint. These methods involve analyzing the environmental impacts of suppliers, transportation, and distribution networks. By integrating sustainability criteria into supplier selection and management processes, companies can enhance the overall sustainability of their products and services.Expand Specific Solutions04 Circular economy and product lifecycle optimization

Innovations in circular economy principles and product lifecycle optimization focus on minimizing waste and maximizing resource efficiency. These approaches involve designing products for longevity, repairability, and recyclability, as well as implementing take-back programs and closed-loop manufacturing processes. By extending product lifecycles and recovering materials at the end of life, organizations can significantly reduce their environmental impact and improve overall sustainability performance.Expand Specific Solutions05 Integration of sustainability metrics in business processes

Methods for integrating sustainability metrics and considerations into core business processes and decision-making frameworks are crucial for driving sustainable practices. These approaches involve incorporating environmental and social factors into financial analysis, risk assessment, and strategic planning. By aligning sustainability goals with business objectives, organizations can create long-term value while minimizing their environmental impact and enhancing their overall sustainability performance.Expand Specific Solutions

Key Players in PHEV LCA

The life cycle assessment (LCA) of Plug-in Hybrid Electric Vehicles (PHEVs) is gaining importance as the automotive industry transitions towards more sustainable technologies. This field is in a growth phase, with increasing market size and technological advancements. Companies like Chery Automobile, SAIC Motor, and Geely are actively developing PHEV technologies, while research institutions such as Beijing Institute of Technology and Chongqing University are contributing to the knowledge base. The involvement of established automakers like Peugeot and Toyota, alongside emerging players, indicates a maturing technology landscape. However, ongoing research and development efforts suggest that there is still room for innovation and improvement in PHEV sustainability assessments.

SAIC Motor Corp. Ltd.

Technical Solution: SAIC Motor has implemented a holistic LCA approach for their PHEV models, focusing on the Chinese market context. Their methodology includes a detailed analysis of the local energy mix and its impact on PHEV sustainability. SAIC has developed a regionalized LCA model that accounts for variations in electricity generation across different provinces in China, allowing for more accurate sustainability assessments[7]. The company has also invested in advanced battery technology and recycling processes, aiming to reduce the environmental impact of battery production and disposal. SAIC's LCA approach has led to the development of lightweight materials and aerodynamic designs that improve energy efficiency during the use phase, potentially reducing lifecycle emissions by up to 15%[8].

Strengths: Localized LCA approach tailored to the Chinese market, focus on battery technology and recycling. Weaknesses: May face challenges in applying their LCA model to global markets with different energy mixes and regulations.

Hyundai America Technical Center, Inc.

Technical Solution: Hyundai America Technical Center has developed a region-specific LCA methodology for PHEVs, focusing on the North American market. Their approach incorporates detailed analysis of local driving patterns, energy mix, and regulatory requirements. Hyundai's LCA model includes a comprehensive well-to-wheel analysis that accounts for regional variations in electricity generation and fuel production. They have developed a dynamic LCA tool that can adjust sustainability assessments based on changes in energy policies and technological advancements[11]. Hyundai's research has led to the development of adaptive charging strategies that can optimize PHEV sustainability based on real-time grid carbon intensity, potentially reducing lifecycle emissions by up to 10%[12]. The company also focuses on improving the longevity of PHEV components, aiming to extend vehicle lifespan and reduce overall environmental impact.

Strengths: Region-specific LCA approach, dynamic assessment tools, and focus on adaptive charging strategies. Weaknesses: May face challenges in applying their North American-focused LCA model to other global markets.

Critical LCA Metrics for PHEVs

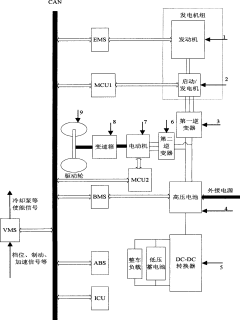

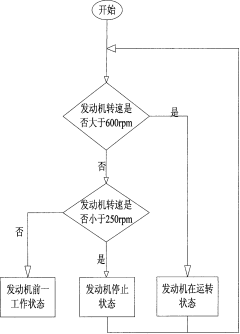

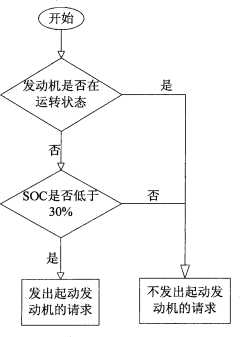

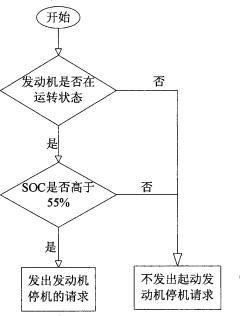

Control method of externally rechargeable type mixed power automobile generator group

PatentInactiveCN101519074A

Innovation

- The vehicle controller receives CAN messages, determines the status of the engine and high-voltage battery, realizes intelligent start-stop control of the generator set, and monitors faults in different working modes to ensure maximum efficiency of the generator set and protection of the high-voltage battery.

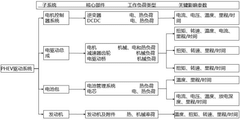

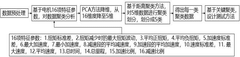

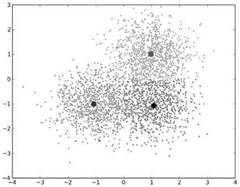

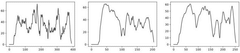

Method for testing and detecting reliability of whole plug-in hybrid electric automobile

PatentPendingCN119915526A

Innovation

- A special vehicle reliability test and detection method is designed, including vehicle structure test and detection, power and transmission test and environmental test test parts. Through market user surveys and real user load spectrum data analysis, the reliability target of PHEV cars is determined, and K-mean clustering analysis technology is used to construct typical test conditions to ensure that the test method is equivalent to user requirements.

Environmental Regulations Impact

Environmental regulations play a crucial role in shaping the sustainability landscape for Plug-in Hybrid Electric Vehicles (PHEVs). These regulations are designed to mitigate the environmental impact of transportation and promote the adoption of cleaner technologies. In recent years, governments worldwide have implemented increasingly stringent emissions standards and fuel efficiency requirements, directly influencing the development and market penetration of PHEVs.

One of the primary regulatory frameworks affecting PHEVs is the Corporate Average Fuel Economy (CAFE) standards in the United States. These standards set specific targets for automakers to improve the overall fuel efficiency of their vehicle fleets. PHEVs, with their ability to operate on both electric power and conventional fuel, contribute significantly to meeting these requirements. Similarly, the European Union's CO2 emissions targets for new vehicles have been a driving force behind the increased production and sales of PHEVs in the region.

China, the world's largest automotive market, has also implemented policies to promote new energy vehicles, including PHEVs. The country's dual-credit policy system rewards manufacturers for producing low-emission vehicles while penalizing those who fail to meet targets. This regulatory approach has led to a surge in PHEV development and adoption within the Chinese market.

Environmental regulations have also influenced the lifecycle assessment (LCA) methodologies used to evaluate PHEV sustainability. Many jurisdictions now require manufacturers to consider the entire lifecycle of vehicles, from raw material extraction to end-of-life disposal. This comprehensive approach has led to improvements in battery technology, recycling processes, and the use of sustainable materials in PHEV production.

The impact of these regulations extends beyond vehicle manufacturing. Grid decarbonization efforts, driven by environmental policies, are enhancing the sustainability of PHEVs by reducing the carbon intensity of electricity used for charging. Additionally, regulations promoting the development of charging infrastructure are addressing one of the key barriers to PHEV adoption.

Looking ahead, evolving environmental regulations are likely to continue shaping the PHEV landscape. Proposed bans on internal combustion engine vehicles in various countries may accelerate the transition to fully electric vehicles, potentially impacting the long-term viability of PHEVs. However, in the near term, PHEVs remain an important transitional technology, benefiting from regulatory frameworks that recognize their role in reducing emissions and fostering sustainable transportation solutions.

One of the primary regulatory frameworks affecting PHEVs is the Corporate Average Fuel Economy (CAFE) standards in the United States. These standards set specific targets for automakers to improve the overall fuel efficiency of their vehicle fleets. PHEVs, with their ability to operate on both electric power and conventional fuel, contribute significantly to meeting these requirements. Similarly, the European Union's CO2 emissions targets for new vehicles have been a driving force behind the increased production and sales of PHEVs in the region.

China, the world's largest automotive market, has also implemented policies to promote new energy vehicles, including PHEVs. The country's dual-credit policy system rewards manufacturers for producing low-emission vehicles while penalizing those who fail to meet targets. This regulatory approach has led to a surge in PHEV development and adoption within the Chinese market.

Environmental regulations have also influenced the lifecycle assessment (LCA) methodologies used to evaluate PHEV sustainability. Many jurisdictions now require manufacturers to consider the entire lifecycle of vehicles, from raw material extraction to end-of-life disposal. This comprehensive approach has led to improvements in battery technology, recycling processes, and the use of sustainable materials in PHEV production.

The impact of these regulations extends beyond vehicle manufacturing. Grid decarbonization efforts, driven by environmental policies, are enhancing the sustainability of PHEVs by reducing the carbon intensity of electricity used for charging. Additionally, regulations promoting the development of charging infrastructure are addressing one of the key barriers to PHEV adoption.

Looking ahead, evolving environmental regulations are likely to continue shaping the PHEV landscape. Proposed bans on internal combustion engine vehicles in various countries may accelerate the transition to fully electric vehicles, potentially impacting the long-term viability of PHEVs. However, in the near term, PHEVs remain an important transitional technology, benefiting from regulatory frameworks that recognize their role in reducing emissions and fostering sustainable transportation solutions.

Circular Economy in PHEV Design

The concept of circular economy is gaining traction in the automotive industry, particularly in the design and production of Plug-in Hybrid Electric Vehicles (PHEVs). This approach aims to minimize waste, maximize resource efficiency, and extend the lifecycle of vehicles and their components.

In PHEV design, circular economy principles are applied throughout the vehicle's lifecycle, from material selection to end-of-life management. Manufacturers are increasingly focusing on using recycled and recyclable materials in vehicle production. For instance, some PHEV models incorporate recycled plastics in interior components and utilize sustainable materials for seat fabrics and carpeting.

Design for disassembly is another key aspect of circular economy in PHEV production. Engineers are developing modular designs that facilitate easier repair, replacement, and recycling of components. This approach not only extends the vehicle's lifespan but also simplifies the recycling process at the end of its life.

Battery technology is a critical area where circular economy principles are being implemented. PHEV batteries are designed with recyclability in mind, and manufacturers are establishing recycling programs to recover valuable materials such as lithium, cobalt, and nickel. Some companies are exploring second-life applications for PHEV batteries, repurposing them for energy storage in residential or commercial settings after their automotive life cycle.

The circular economy approach also extends to the manufacturing process itself. PHEV production facilities are increasingly adopting closed-loop systems, where water and materials are recycled and reused within the factory. Energy efficiency measures and the use of renewable energy sources in manufacturing further contribute to the circular economy goals.

Maintenance and repair strategies for PHEVs are evolving to align with circular economy principles. Manufacturers are developing advanced diagnostics and predictive maintenance systems to extend component life and reduce waste. Additionally, the promotion of remanufactured parts for repairs helps to reduce the demand for new components and minimize waste.

As the PHEV market matures, the implementation of circular economy principles in vehicle design and production is expected to become more sophisticated. This evolution will likely lead to increased sustainability, reduced environmental impact, and potentially lower costs for consumers over the long term.

In PHEV design, circular economy principles are applied throughout the vehicle's lifecycle, from material selection to end-of-life management. Manufacturers are increasingly focusing on using recycled and recyclable materials in vehicle production. For instance, some PHEV models incorporate recycled plastics in interior components and utilize sustainable materials for seat fabrics and carpeting.

Design for disassembly is another key aspect of circular economy in PHEV production. Engineers are developing modular designs that facilitate easier repair, replacement, and recycling of components. This approach not only extends the vehicle's lifespan but also simplifies the recycling process at the end of its life.

Battery technology is a critical area where circular economy principles are being implemented. PHEV batteries are designed with recyclability in mind, and manufacturers are establishing recycling programs to recover valuable materials such as lithium, cobalt, and nickel. Some companies are exploring second-life applications for PHEV batteries, repurposing them for energy storage in residential or commercial settings after their automotive life cycle.

The circular economy approach also extends to the manufacturing process itself. PHEV production facilities are increasingly adopting closed-loop systems, where water and materials are recycled and reused within the factory. Energy efficiency measures and the use of renewable energy sources in manufacturing further contribute to the circular economy goals.

Maintenance and repair strategies for PHEVs are evolving to align with circular economy principles. Manufacturers are developing advanced diagnostics and predictive maintenance systems to extend component life and reduce waste. Additionally, the promotion of remanufactured parts for repairs helps to reduce the demand for new components and minimize waste.

As the PHEV market matures, the implementation of circular economy principles in vehicle design and production is expected to become more sophisticated. This evolution will likely lead to increased sustainability, reduced environmental impact, and potentially lower costs for consumers over the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!