How longitudinal waves affect fluid-solid interaction in pipes

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Longitudinal Wave Fundamentals and Objectives

Longitudinal waves play a crucial role in fluid-solid interaction within pipes, a phenomenon of significant importance in various engineering applications. These waves, characterized by particle motion parallel to the direction of wave propagation, have been the subject of extensive research due to their impact on pipe systems' performance and integrity.

The study of longitudinal waves in fluid-filled pipes dates back to the early 20th century, with pioneering work by Korteweg and Joukowsky. Their research laid the foundation for understanding the propagation of pressure waves in pipelines, a concept now known as water hammer. As technology advanced, the importance of these waves in industrial settings became increasingly apparent, leading to a surge in research efforts to comprehend their behavior and effects.

The primary objective in studying longitudinal waves in fluid-solid interaction is to develop a comprehensive understanding of how these waves influence the dynamic response of pipe systems. This includes analyzing wave propagation characteristics, energy dissipation mechanisms, and the coupling between fluid and structural dynamics. By gaining insights into these aspects, researchers aim to enhance the design, operation, and maintenance of pipeline systems across various industries.

One of the key goals is to accurately predict and mitigate the potential adverse effects of longitudinal waves on pipe structures. These effects may include excessive vibrations, fatigue damage, and even catastrophic failures in extreme cases. Understanding the wave-structure interaction allows engineers to implement effective countermeasures, such as optimizing pipe geometry, selecting appropriate materials, or incorporating damping mechanisms.

Another critical objective is to leverage the properties of longitudinal waves for beneficial applications. For instance, researchers explore the use of these waves in non-destructive testing methods for pipe integrity assessment. By analyzing the propagation and reflection of longitudinal waves, it becomes possible to detect defects, corrosion, or other anomalies in pipeline systems without the need for invasive inspections.

The evolution of computational methods and experimental techniques has significantly advanced the field, enabling more accurate modeling and analysis of longitudinal wave behavior in complex pipe systems. Modern research aims to develop sophisticated numerical models that can simulate the intricate interactions between fluid flow, pipe structure, and wave propagation. These models serve as valuable tools for predicting system response under various operating conditions and optimizing design parameters.

As industries continue to push the boundaries of operational efficiency and safety, the study of longitudinal waves in fluid-solid interaction remains at the forefront of engineering research. The ongoing objectives include refining theoretical models, improving experimental methodologies, and developing innovative technologies to harness the power of these waves for enhanced system performance and reliability.

The study of longitudinal waves in fluid-filled pipes dates back to the early 20th century, with pioneering work by Korteweg and Joukowsky. Their research laid the foundation for understanding the propagation of pressure waves in pipelines, a concept now known as water hammer. As technology advanced, the importance of these waves in industrial settings became increasingly apparent, leading to a surge in research efforts to comprehend their behavior and effects.

The primary objective in studying longitudinal waves in fluid-solid interaction is to develop a comprehensive understanding of how these waves influence the dynamic response of pipe systems. This includes analyzing wave propagation characteristics, energy dissipation mechanisms, and the coupling between fluid and structural dynamics. By gaining insights into these aspects, researchers aim to enhance the design, operation, and maintenance of pipeline systems across various industries.

One of the key goals is to accurately predict and mitigate the potential adverse effects of longitudinal waves on pipe structures. These effects may include excessive vibrations, fatigue damage, and even catastrophic failures in extreme cases. Understanding the wave-structure interaction allows engineers to implement effective countermeasures, such as optimizing pipe geometry, selecting appropriate materials, or incorporating damping mechanisms.

Another critical objective is to leverage the properties of longitudinal waves for beneficial applications. For instance, researchers explore the use of these waves in non-destructive testing methods for pipe integrity assessment. By analyzing the propagation and reflection of longitudinal waves, it becomes possible to detect defects, corrosion, or other anomalies in pipeline systems without the need for invasive inspections.

The evolution of computational methods and experimental techniques has significantly advanced the field, enabling more accurate modeling and analysis of longitudinal wave behavior in complex pipe systems. Modern research aims to develop sophisticated numerical models that can simulate the intricate interactions between fluid flow, pipe structure, and wave propagation. These models serve as valuable tools for predicting system response under various operating conditions and optimizing design parameters.

As industries continue to push the boundaries of operational efficiency and safety, the study of longitudinal waves in fluid-solid interaction remains at the forefront of engineering research. The ongoing objectives include refining theoretical models, improving experimental methodologies, and developing innovative technologies to harness the power of these waves for enhanced system performance and reliability.

Market Applications of Fluid-Solid Interaction Analysis

The analysis of fluid-solid interaction in pipes has significant market applications across various industries, driven by the need for improved efficiency, safety, and performance in fluid transport systems. In the oil and gas sector, understanding how longitudinal waves affect fluid-solid interaction is crucial for optimizing pipeline design and operation. This knowledge enables companies to enhance the structural integrity of pipelines, reduce the risk of leaks, and improve overall system reliability. The market for advanced pipeline monitoring and management solutions is expected to grow substantially as energy companies seek to minimize environmental risks and operational costs.

In the water management industry, fluid-solid interaction analysis plays a vital role in designing and maintaining water distribution networks. Municipalities and water utilities can leverage this technology to predict and prevent pipe failures, reduce water loss through leaks, and optimize pump operations. The growing focus on sustainable water management and infrastructure resilience is driving increased investment in smart water technologies, including those that utilize fluid-solid interaction models.

The chemical processing industry also benefits from advancements in fluid-solid interaction analysis. By understanding how longitudinal waves affect the behavior of fluids and solids within reactor vessels and transport pipes, companies can improve process efficiency, reduce material waste, and enhance product quality. This application is particularly valuable in the production of specialty chemicals and pharmaceuticals, where precise control over reaction conditions is critical.

In the aerospace and automotive sectors, fluid-solid interaction analysis is essential for designing fuel systems, hydraulic components, and cooling systems. The ability to model and predict the effects of longitudinal waves on these systems allows manufacturers to develop more efficient and reliable vehicles. This technology is increasingly important in the development of electric and hybrid vehicles, where thermal management and battery cooling systems are critical components.

The biomedical field represents an emerging market for fluid-solid interaction analysis, particularly in the design of medical devices and artificial organs. Understanding how longitudinal waves affect blood flow in artificial blood vessels or dialysis machines can lead to improved treatment outcomes and reduced complications for patients. As the global population ages and the demand for advanced medical technologies grows, this application area is expected to expand significantly.

In the renewable energy sector, fluid-solid interaction analysis is valuable for optimizing the design of wind turbines, hydroelectric systems, and wave energy converters. By modeling how longitudinal waves affect the interaction between fluids and solid structures, engineers can develop more efficient and durable energy generation systems. This application is particularly relevant as countries worldwide increase their investments in renewable energy infrastructure to meet climate change mitigation goals.

In the water management industry, fluid-solid interaction analysis plays a vital role in designing and maintaining water distribution networks. Municipalities and water utilities can leverage this technology to predict and prevent pipe failures, reduce water loss through leaks, and optimize pump operations. The growing focus on sustainable water management and infrastructure resilience is driving increased investment in smart water technologies, including those that utilize fluid-solid interaction models.

The chemical processing industry also benefits from advancements in fluid-solid interaction analysis. By understanding how longitudinal waves affect the behavior of fluids and solids within reactor vessels and transport pipes, companies can improve process efficiency, reduce material waste, and enhance product quality. This application is particularly valuable in the production of specialty chemicals and pharmaceuticals, where precise control over reaction conditions is critical.

In the aerospace and automotive sectors, fluid-solid interaction analysis is essential for designing fuel systems, hydraulic components, and cooling systems. The ability to model and predict the effects of longitudinal waves on these systems allows manufacturers to develop more efficient and reliable vehicles. This technology is increasingly important in the development of electric and hybrid vehicles, where thermal management and battery cooling systems are critical components.

The biomedical field represents an emerging market for fluid-solid interaction analysis, particularly in the design of medical devices and artificial organs. Understanding how longitudinal waves affect blood flow in artificial blood vessels or dialysis machines can lead to improved treatment outcomes and reduced complications for patients. As the global population ages and the demand for advanced medical technologies grows, this application area is expected to expand significantly.

In the renewable energy sector, fluid-solid interaction analysis is valuable for optimizing the design of wind turbines, hydroelectric systems, and wave energy converters. By modeling how longitudinal waves affect the interaction between fluids and solid structures, engineers can develop more efficient and durable energy generation systems. This application is particularly relevant as countries worldwide increase their investments in renewable energy infrastructure to meet climate change mitigation goals.

Current Challenges in Pipe Fluid-Solid Interaction Modeling

The modeling of fluid-solid interaction in pipes presents several significant challenges, particularly when considering the effects of longitudinal waves. One of the primary difficulties lies in accurately capturing the complex interplay between the fluid dynamics and the structural response of the pipe. Traditional models often struggle to account for the full spectrum of wave propagation phenomena, especially in scenarios involving high-frequency excitations or non-linear behavior.

A major challenge is the accurate representation of energy transfer between the fluid and the solid structure. Longitudinal waves can induce vibrations in the pipe wall, which in turn affect the fluid flow. This bidirectional coupling is difficult to model precisely, as it involves intricate feedback mechanisms that can lead to resonance or damping effects. Current numerical methods often require significant computational resources to resolve these interactions at multiple time and spatial scales.

Another hurdle is the incorporation of material nonlinearities and geometric complexities. Pipes in real-world applications may have varying cross-sections, bends, or material properties that change under stress. These factors can significantly alter the propagation of longitudinal waves and their interaction with the fluid. Existing models frequently rely on simplifying assumptions that may not hold true in all operational conditions, leading to discrepancies between predicted and observed behavior.

The treatment of boundary conditions and interfaces poses additional challenges. At pipe junctions, valves, or other discontinuities, the behavior of longitudinal waves becomes particularly complex. Current modeling approaches often struggle to accurately represent these transition zones, where wave reflection, transmission, and mode conversion occur. This limitation can lead to inaccuracies in predicting system response, especially in networks of interconnected pipes.

Furthermore, the multiphysics nature of fluid-solid interaction in pipes complicates the development of comprehensive models. Thermal effects, chemical reactions, and multiphase flows may all play roles in real-world scenarios, yet integrating these phenomena into a unified model remains challenging. The coupling of these various physical processes with longitudinal wave propagation requires sophisticated numerical techniques that are still evolving.

Lastly, validation of fluid-solid interaction models for pipes under longitudinal wave excitation presents its own set of challenges. Experimental data for complex pipe systems under realistic operating conditions is often limited or difficult to obtain. This scarcity of benchmark data hampers the refinement and verification of advanced modeling techniques, making it challenging to assess the accuracy and reliability of simulation results across a wide range of operational scenarios.

A major challenge is the accurate representation of energy transfer between the fluid and the solid structure. Longitudinal waves can induce vibrations in the pipe wall, which in turn affect the fluid flow. This bidirectional coupling is difficult to model precisely, as it involves intricate feedback mechanisms that can lead to resonance or damping effects. Current numerical methods often require significant computational resources to resolve these interactions at multiple time and spatial scales.

Another hurdle is the incorporation of material nonlinearities and geometric complexities. Pipes in real-world applications may have varying cross-sections, bends, or material properties that change under stress. These factors can significantly alter the propagation of longitudinal waves and their interaction with the fluid. Existing models frequently rely on simplifying assumptions that may not hold true in all operational conditions, leading to discrepancies between predicted and observed behavior.

The treatment of boundary conditions and interfaces poses additional challenges. At pipe junctions, valves, or other discontinuities, the behavior of longitudinal waves becomes particularly complex. Current modeling approaches often struggle to accurately represent these transition zones, where wave reflection, transmission, and mode conversion occur. This limitation can lead to inaccuracies in predicting system response, especially in networks of interconnected pipes.

Furthermore, the multiphysics nature of fluid-solid interaction in pipes complicates the development of comprehensive models. Thermal effects, chemical reactions, and multiphase flows may all play roles in real-world scenarios, yet integrating these phenomena into a unified model remains challenging. The coupling of these various physical processes with longitudinal wave propagation requires sophisticated numerical techniques that are still evolving.

Lastly, validation of fluid-solid interaction models for pipes under longitudinal wave excitation presents its own set of challenges. Experimental data for complex pipe systems under realistic operating conditions is often limited or difficult to obtain. This scarcity of benchmark data hampers the refinement and verification of advanced modeling techniques, making it challenging to assess the accuracy and reliability of simulation results across a wide range of operational scenarios.

Existing Methods for Analyzing Longitudinal Wave Effects

01 Acoustic wave propagation in fluid-solid systems

This area focuses on the study of longitudinal wave propagation in systems involving both fluids and solids. It includes the analysis of wave behavior at fluid-solid interfaces, energy transfer between mediums, and the effects of material properties on wave characteristics. Applications range from medical ultrasound to seismic exploration.- Acoustic wave propagation in fluid-solid systems: This area focuses on the study of longitudinal wave propagation in systems involving both fluids and solids. It includes the analysis of wave behavior at fluid-solid interfaces, energy transfer between mediums, and the effects of material properties on wave characteristics. Applications range from medical ultrasound to seismic exploration.

- Sensors and transducers for fluid-solid interaction: Development of specialized sensors and transducers for detecting and measuring longitudinal waves in fluid-solid systems. These devices are designed to capture the complex interactions between fluids and solids, enabling accurate data collection for various applications such as non-destructive testing and structural health monitoring.

- Numerical modeling and simulation techniques: Advanced computational methods for modeling longitudinal wave propagation in fluid-solid systems. These techniques include finite element analysis, boundary element methods, and coupled fluid-structure interaction models. They enable researchers and engineers to predict wave behavior in complex geometries and material compositions.

- Applications in geophysics and seismology: Utilization of longitudinal wave fluid-solid interaction principles in geophysical exploration and seismological studies. This includes techniques for analyzing seismic wave propagation through layered earth structures, borehole acoustics, and marine seismic surveys. These applications are crucial for resource exploration and natural hazard assessment.

- Acoustic metamaterials for wave control: Design and development of acoustic metamaterials that can manipulate longitudinal waves in fluid-solid systems. These engineered materials possess unique properties that allow for precise control of wave propagation, including wave focusing, redirection, and attenuation. Applications include noise control, acoustic cloaking, and enhanced sensing technologies.

02 Sensors and transducers for fluid-solid interaction

Development of specialized sensors and transducers to detect and measure longitudinal waves in fluid-solid systems. These devices are crucial for various applications, including non-destructive testing, underwater acoustics, and structural health monitoring. Innovations focus on improving sensitivity, accuracy, and robustness in challenging environments.Expand Specific Solutions03 Numerical modeling and simulation techniques

Advanced computational methods for modeling longitudinal wave propagation in complex fluid-solid systems. These techniques enable researchers and engineers to predict wave behavior, optimize designs, and analyze complex interactions without extensive physical testing. Key areas include finite element analysis, boundary element methods, and multi-physics simulations.Expand Specific Solutions04 Applications in geophysics and seismology

Utilization of longitudinal wave fluid-solid interaction principles in geophysical exploration and seismological studies. This includes techniques for subsurface imaging, oil and gas exploration, and earthquake analysis. Innovations focus on improving data acquisition, processing, and interpretation methods for complex geological structures.Expand Specific Solutions05 Acoustic metamaterials for wave control

Development of engineered materials and structures to manipulate longitudinal wave propagation in fluid-solid systems. These acoustic metamaterials can be designed to achieve unique properties such as negative refraction, cloaking, or enhanced wave focusing. Applications include noise control, improved sensing, and novel acoustic devices.Expand Specific Solutions

Key Players in Fluid Dynamics and Pipe Engineering

The field of longitudinal wave effects on fluid-solid interaction in pipes is in a mature development stage, with ongoing research and industrial applications. The market size is substantial, driven by the oil and gas, water management, and manufacturing sectors. Technologically, the field is well-established but continues to evolve. Companies like Shell Internationale Research Maatschappij BV and Schlumberger are at the forefront, leveraging their expertise in fluid dynamics and materials science. ContiTech Schlauch GmbH and Eisenbau Krämer GmbH contribute specialized knowledge in pipe systems and large-diameter steel pipes, respectively. Academic institutions such as Southwest Jiaotong University and the University of Jinan are advancing theoretical understanding, while research organizations like Southwest Research Institute bridge the gap between academia and industry applications.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed innovative approaches to address longitudinal wave effects in fluid-solid interactions for oil and gas pipeline systems. Their research focuses on advanced numerical modeling techniques that incorporate multi-phase flow dynamics, structural mechanics, and wave propagation theories. Shell's proprietary software utilizes adaptive mesh refinement and parallel computing to simulate complex wave phenomena in long-distance pipelines with high accuracy[8]. The company has also invested in developing smart pipeline monitoring systems that use distributed acoustic sensing (DAS) technology to detect and analyze longitudinal wave patterns in real-time, enabling proactive maintenance and risk mitigation strategies[9].

Strengths: Extensive experience in oil and gas applications, advanced numerical modeling capabilities, integration with smart monitoring systems. Weaknesses: Solutions may be highly specialized for hydrocarbon transport, potentially limiting applicability in other industries.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed a suite of advanced simulation tools and experimental techniques to study longitudinal wave effects in fluid-solid interactions within pipes. Their approach combines multi-physics modeling with high-fidelity experimental validation. SwRI's proprietary software incorporates fluid dynamics, structural mechanics, and acoustic wave propagation to predict the behavior of complex pipe systems under various operating conditions[4]. The institute has also pioneered non-invasive measurement techniques using ultrasonic transducers to characterize longitudinal wave patterns in operational pipelines, providing crucial data for model validation and system health monitoring[5].

Strengths: Strong integration of computational and experimental methods, expertise in non-invasive measurement techniques. Weaknesses: Potential limitations in scaling solutions for very large or complex pipeline networks.

Innovative Approaches in Fluid-Solid Coupling Analysis

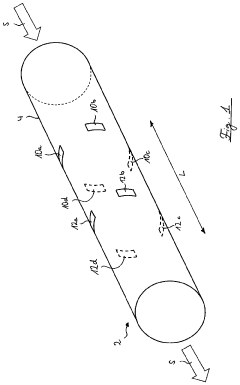

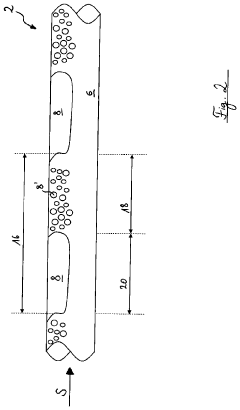

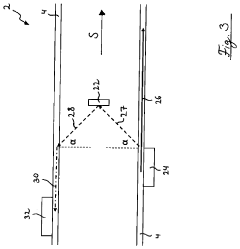

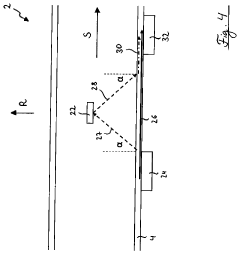

Method and device for non-invasively determining properties of a multiphase flow

PatentActiveUS20210381866A1

Innovation

- A non-invasive method using a single setup of EMAT transducers to determine properties such as velocity and flow cross-section fraction of gaseous and liquid fractions by spatially correlating signals and evaluating waves reflected or transmitted through the multiphase flow, allowing for efficient measurement with minimal equipment and space requirements.

Transporting fluids through a conduit

PatentWO2005057023A1

Innovation

- Estimating and maintaining a critical modified Froude number above 15 by introducing a buffer fluid with a density between the first and second fluids, ensuring a gradual density profile along the conduit to prevent stratification, using a mixture of the first and second fluids as the buffer, and employing linear or stepwise density profiles to bridge the density gap without exceeding maximum allowable density steps.

Regulatory Standards for Pipe System Design

Regulatory standards for pipe system design play a crucial role in ensuring the safety, reliability, and efficiency of fluid transport systems. These standards address the impact of longitudinal waves on fluid-solid interactions in pipes, recognizing the potential for structural damage and operational inefficiencies. The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) have developed comprehensive guidelines that incorporate considerations for wave-induced vibrations and stress.

ASME B31.3, the Process Piping Code, provides specific requirements for the design of piping systems subjected to dynamic loads, including those caused by longitudinal waves. It mandates the use of appropriate stress analysis techniques to account for the effects of fluid-induced vibrations on pipe integrity. The standard emphasizes the importance of considering both steady-state and transient conditions in the design process, as longitudinal waves can significantly impact system performance during pressure surges or rapid flow changes.

ISO 13628-7, which focuses on completion/workover riser systems, includes provisions for the design of subsea piping systems exposed to various environmental loads, including wave-induced forces. This standard requires engineers to evaluate the potential for vortex-induced vibrations and fatigue damage caused by longitudinal waves, particularly in offshore applications where wave action is more pronounced.

The American Petroleum Institute (API) has also developed relevant standards, such as API RP 1111 for the design, construction, operation, and maintenance of offshore hydrocarbon pipelines. This recommended practice addresses the need to consider wave-induced loads and their impact on fluid-solid interactions in subsea pipeline design. It provides guidance on the selection of appropriate materials and wall thicknesses to withstand the cyclic stresses caused by longitudinal waves.

Regulatory bodies, such as the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA), enforce these standards through regulations like 49 CFR Part 192 for gas pipelines and 49 CFR Part 195 for hazardous liquid pipelines. These regulations require operators to implement design measures that mitigate the risks associated with longitudinal wave effects, including the use of appropriate support systems and vibration dampening technologies.

In the European Union, the Pressure Equipment Directive (PED) 2014/68/EU sets out essential safety requirements for pressure equipment, including pipes subjected to internal pressure. This directive mandates the consideration of all relevant load cases, including those arising from fluid-solid interactions due to longitudinal waves, in the design and manufacturing processes of piping systems.

ASME B31.3, the Process Piping Code, provides specific requirements for the design of piping systems subjected to dynamic loads, including those caused by longitudinal waves. It mandates the use of appropriate stress analysis techniques to account for the effects of fluid-induced vibrations on pipe integrity. The standard emphasizes the importance of considering both steady-state and transient conditions in the design process, as longitudinal waves can significantly impact system performance during pressure surges or rapid flow changes.

ISO 13628-7, which focuses on completion/workover riser systems, includes provisions for the design of subsea piping systems exposed to various environmental loads, including wave-induced forces. This standard requires engineers to evaluate the potential for vortex-induced vibrations and fatigue damage caused by longitudinal waves, particularly in offshore applications where wave action is more pronounced.

The American Petroleum Institute (API) has also developed relevant standards, such as API RP 1111 for the design, construction, operation, and maintenance of offshore hydrocarbon pipelines. This recommended practice addresses the need to consider wave-induced loads and their impact on fluid-solid interactions in subsea pipeline design. It provides guidance on the selection of appropriate materials and wall thicknesses to withstand the cyclic stresses caused by longitudinal waves.

Regulatory bodies, such as the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA), enforce these standards through regulations like 49 CFR Part 192 for gas pipelines and 49 CFR Part 195 for hazardous liquid pipelines. These regulations require operators to implement design measures that mitigate the risks associated with longitudinal wave effects, including the use of appropriate support systems and vibration dampening technologies.

In the European Union, the Pressure Equipment Directive (PED) 2014/68/EU sets out essential safety requirements for pressure equipment, including pipes subjected to internal pressure. This directive mandates the consideration of all relevant load cases, including those arising from fluid-solid interactions due to longitudinal waves, in the design and manufacturing processes of piping systems.

Environmental Impact of Wave-Induced Pipe Failures

The environmental impact of wave-induced pipe failures is a critical concern in the context of fluid-solid interactions in pipes. Longitudinal waves propagating through pipes can lead to structural damage, leaks, and potential environmental hazards. These failures often result in the release of transported fluids, which can have severe consequences for surrounding ecosystems and human populations.

One of the primary environmental risks associated with pipe failures is soil and groundwater contamination. When pipes carrying hazardous materials such as oil, chemicals, or wastewater rupture due to wave-induced stress, these substances can seep into the surrounding soil and eventually reach groundwater aquifers. This contamination can persist for years, affecting plant life, wildlife, and potentially entering the human food chain through contaminated crops or water sources.

In marine environments, pipe failures can have devastating effects on aquatic ecosystems. Offshore oil and gas pipelines are particularly vulnerable to wave-induced damage, and leaks can result in oil spills that harm marine life, damage coral reefs, and disrupt entire food chains. The long-term effects of such incidents can include reduced biodiversity, altered ecosystem dynamics, and economic losses for coastal communities dependent on fishing and tourism.

Air pollution is another significant environmental concern related to pipe failures. When pipes carrying natural gas or other volatile substances rupture, the released gases can contribute to air quality degradation and increase greenhouse gas emissions. In urban areas, these leaks can pose immediate health risks to nearby populations and exacerbate existing air pollution problems.

The environmental impact of wave-induced pipe failures extends beyond immediate contamination events. The energy and resources required for cleanup operations, pipe repairs, and environmental restoration efforts contribute to increased carbon footprints and resource depletion. Moreover, the disposal of damaged pipe materials and contaminated soil can create additional waste management challenges and potential environmental hazards.

To mitigate these environmental risks, ongoing research focuses on improving pipe design, materials, and monitoring systems to better withstand longitudinal wave effects. Advanced sensing technologies and predictive maintenance strategies are being developed to detect potential failures before they occur, reducing the likelihood of environmental incidents. Additionally, stricter regulations and industry standards are being implemented to ensure more robust pipe installations and maintenance practices, particularly in environmentally sensitive areas.

One of the primary environmental risks associated with pipe failures is soil and groundwater contamination. When pipes carrying hazardous materials such as oil, chemicals, or wastewater rupture due to wave-induced stress, these substances can seep into the surrounding soil and eventually reach groundwater aquifers. This contamination can persist for years, affecting plant life, wildlife, and potentially entering the human food chain through contaminated crops or water sources.

In marine environments, pipe failures can have devastating effects on aquatic ecosystems. Offshore oil and gas pipelines are particularly vulnerable to wave-induced damage, and leaks can result in oil spills that harm marine life, damage coral reefs, and disrupt entire food chains. The long-term effects of such incidents can include reduced biodiversity, altered ecosystem dynamics, and economic losses for coastal communities dependent on fishing and tourism.

Air pollution is another significant environmental concern related to pipe failures. When pipes carrying natural gas or other volatile substances rupture, the released gases can contribute to air quality degradation and increase greenhouse gas emissions. In urban areas, these leaks can pose immediate health risks to nearby populations and exacerbate existing air pollution problems.

The environmental impact of wave-induced pipe failures extends beyond immediate contamination events. The energy and resources required for cleanup operations, pipe repairs, and environmental restoration efforts contribute to increased carbon footprints and resource depletion. Moreover, the disposal of damaged pipe materials and contaminated soil can create additional waste management challenges and potential environmental hazards.

To mitigate these environmental risks, ongoing research focuses on improving pipe design, materials, and monitoring systems to better withstand longitudinal wave effects. Advanced sensing technologies and predictive maintenance strategies are being developed to detect potential failures before they occur, reducing the likelihood of environmental incidents. Additionally, stricter regulations and industry standards are being implemented to ensure more robust pipe installations and maintenance practices, particularly in environmentally sensitive areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!