Longitudinal wave role in vacuum chamber design for scientific experiments

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Wave Dynamics

Longitudinal waves play a crucial role in the design and operation of vacuum chambers for scientific experiments. These waves, characterized by oscillations parallel to the direction of wave propagation, can significantly impact the performance and accuracy of experiments conducted within vacuum environments.

In vacuum chambers, longitudinal waves can manifest in various forms, including acoustic waves, pressure fluctuations, and mechanical vibrations. The propagation of these waves is influenced by the chamber's geometry, material properties, and the presence of residual gases. Understanding the dynamics of these waves is essential for optimizing chamber design and minimizing their potential interference with experimental results.

One of the primary concerns in vacuum wave dynamics is the interaction between longitudinal waves and the chamber walls. When waves encounter the chamber boundaries, they can undergo reflection, refraction, or absorption, depending on the material properties and surface characteristics. These interactions can lead to the formation of standing waves or resonant modes within the chamber, which may introduce unwanted noise or disturbances to sensitive experiments.

The frequency spectrum of longitudinal waves in vacuum chambers is of particular interest. Low-frequency waves, often associated with mechanical vibrations or external disturbances, can propagate through the chamber structure and affect the stability of experimental setups. High-frequency waves, on the other hand, may arise from various sources within the chamber, such as pumps, valves, or electrical equipment, and can potentially interfere with measurements or induce unwanted particle motion.

To mitigate the effects of longitudinal waves, various damping and isolation techniques are employed in vacuum chamber design. These may include the use of vibration-absorbing materials, strategic placement of baffles or acoustic traps, and the implementation of active noise cancellation systems. Additionally, the chamber's geometry can be optimized to minimize the formation of standing waves and reduce the coupling between different wave modes.

The study of vacuum wave dynamics also extends to the behavior of electromagnetic waves within the chamber. While not strictly longitudinal in nature, electromagnetic waves can interact with the chamber walls and any residual gases, potentially affecting experimental outcomes. Understanding these interactions is crucial for applications such as plasma physics, particle accelerators, and high-precision spectroscopy.

Advanced modeling and simulation techniques play a vital role in predicting and analyzing the behavior of longitudinal waves in vacuum chambers. Finite element analysis and computational fluid dynamics are commonly used to simulate wave propagation, identify potential resonances, and optimize chamber designs. These tools enable researchers to evaluate the performance of different chamber configurations and develop strategies to minimize wave-induced disturbances.

In vacuum chambers, longitudinal waves can manifest in various forms, including acoustic waves, pressure fluctuations, and mechanical vibrations. The propagation of these waves is influenced by the chamber's geometry, material properties, and the presence of residual gases. Understanding the dynamics of these waves is essential for optimizing chamber design and minimizing their potential interference with experimental results.

One of the primary concerns in vacuum wave dynamics is the interaction between longitudinal waves and the chamber walls. When waves encounter the chamber boundaries, they can undergo reflection, refraction, or absorption, depending on the material properties and surface characteristics. These interactions can lead to the formation of standing waves or resonant modes within the chamber, which may introduce unwanted noise or disturbances to sensitive experiments.

The frequency spectrum of longitudinal waves in vacuum chambers is of particular interest. Low-frequency waves, often associated with mechanical vibrations or external disturbances, can propagate through the chamber structure and affect the stability of experimental setups. High-frequency waves, on the other hand, may arise from various sources within the chamber, such as pumps, valves, or electrical equipment, and can potentially interfere with measurements or induce unwanted particle motion.

To mitigate the effects of longitudinal waves, various damping and isolation techniques are employed in vacuum chamber design. These may include the use of vibration-absorbing materials, strategic placement of baffles or acoustic traps, and the implementation of active noise cancellation systems. Additionally, the chamber's geometry can be optimized to minimize the formation of standing waves and reduce the coupling between different wave modes.

The study of vacuum wave dynamics also extends to the behavior of electromagnetic waves within the chamber. While not strictly longitudinal in nature, electromagnetic waves can interact with the chamber walls and any residual gases, potentially affecting experimental outcomes. Understanding these interactions is crucial for applications such as plasma physics, particle accelerators, and high-precision spectroscopy.

Advanced modeling and simulation techniques play a vital role in predicting and analyzing the behavior of longitudinal waves in vacuum chambers. Finite element analysis and computational fluid dynamics are commonly used to simulate wave propagation, identify potential resonances, and optimize chamber designs. These tools enable researchers to evaluate the performance of different chamber configurations and develop strategies to minimize wave-induced disturbances.

Experimental Demand

The demand for advanced vacuum chamber designs in scientific experiments has grown significantly in recent years, driven by the need for more precise and controlled environments in various fields of research. Longitudinal waves play a crucial role in these designs, as they can significantly impact the experimental outcomes and the overall performance of the vacuum systems.

In particle physics experiments, such as those conducted at CERN's Large Hadron Collider, vacuum chambers are essential for maintaining the integrity of particle beams. The presence of longitudinal waves in these chambers can lead to beam instabilities and reduced collision rates. Consequently, there is a pressing need for vacuum chamber designs that can effectively mitigate the effects of these waves, ensuring more accurate and reliable experimental results.

Materials science research also heavily relies on vacuum chambers for processes like thin film deposition and surface analysis. In these applications, longitudinal waves can interfere with the uniformity of deposited layers or the accuracy of surface measurements. As a result, researchers are seeking innovative chamber designs that can minimize wave-induced disturbances and enhance the precision of their experiments.

The field of quantum computing presents another area where vacuum chamber design is critical. Quantum bits, or qubits, are highly sensitive to environmental disturbances, including those caused by longitudinal waves. To achieve longer coherence times and more stable quantum states, there is a growing demand for vacuum chambers that can effectively isolate qubits from wave-induced perturbations.

In space technology development, vacuum chambers are used to simulate the conditions of outer space for testing spacecraft components and materials. Longitudinal waves in these chambers can introduce unwanted vibrations and thermal fluctuations, potentially compromising the validity of test results. This has led to increased interest in chamber designs that can better replicate the wave-free environment of space.

The pharmaceutical industry also utilizes vacuum chambers for processes such as freeze-drying and sterilization. Longitudinal waves can affect the uniformity of these processes, potentially impacting drug quality and efficacy. As a result, there is a demand for chamber designs that can ensure consistent and reliable results in pharmaceutical manufacturing.

To address these diverse experimental demands, researchers and engineers are exploring various approaches to vacuum chamber design. These include the development of advanced damping systems, the use of novel materials with wave-absorbing properties, and the implementation of active control mechanisms to counteract wave effects. The ultimate goal is to create vacuum chambers that can provide the stable, controlled environments necessary for cutting-edge scientific experiments across multiple disciplines.

In particle physics experiments, such as those conducted at CERN's Large Hadron Collider, vacuum chambers are essential for maintaining the integrity of particle beams. The presence of longitudinal waves in these chambers can lead to beam instabilities and reduced collision rates. Consequently, there is a pressing need for vacuum chamber designs that can effectively mitigate the effects of these waves, ensuring more accurate and reliable experimental results.

Materials science research also heavily relies on vacuum chambers for processes like thin film deposition and surface analysis. In these applications, longitudinal waves can interfere with the uniformity of deposited layers or the accuracy of surface measurements. As a result, researchers are seeking innovative chamber designs that can minimize wave-induced disturbances and enhance the precision of their experiments.

The field of quantum computing presents another area where vacuum chamber design is critical. Quantum bits, or qubits, are highly sensitive to environmental disturbances, including those caused by longitudinal waves. To achieve longer coherence times and more stable quantum states, there is a growing demand for vacuum chambers that can effectively isolate qubits from wave-induced perturbations.

In space technology development, vacuum chambers are used to simulate the conditions of outer space for testing spacecraft components and materials. Longitudinal waves in these chambers can introduce unwanted vibrations and thermal fluctuations, potentially compromising the validity of test results. This has led to increased interest in chamber designs that can better replicate the wave-free environment of space.

The pharmaceutical industry also utilizes vacuum chambers for processes such as freeze-drying and sterilization. Longitudinal waves can affect the uniformity of these processes, potentially impacting drug quality and efficacy. As a result, there is a demand for chamber designs that can ensure consistent and reliable results in pharmaceutical manufacturing.

To address these diverse experimental demands, researchers and engineers are exploring various approaches to vacuum chamber design. These include the development of advanced damping systems, the use of novel materials with wave-absorbing properties, and the implementation of active control mechanisms to counteract wave effects. The ultimate goal is to create vacuum chambers that can provide the stable, controlled environments necessary for cutting-edge scientific experiments across multiple disciplines.

Challenges in Design

The design of vacuum chambers for scientific experiments involving longitudinal waves presents several significant challenges. One of the primary difficulties lies in maintaining the integrity of the vacuum environment while allowing for the propagation and measurement of longitudinal waves. The materials used in chamber construction must be carefully selected to minimize outgassing and ensure long-term vacuum stability, while simultaneously possessing the necessary properties to support wave transmission.

Another critical challenge is the precise control of wave generation and detection within the vacuum chamber. Researchers must develop specialized equipment capable of operating in a vacuum environment without compromising the experimental conditions. This often requires innovative solutions for power supply, signal transmission, and heat dissipation, as conventional methods may not be suitable for use in a vacuum.

The interaction between longitudinal waves and the chamber walls poses additional complications. Reflections and resonances can interfere with experimental results, necessitating the implementation of advanced damping and absorption techniques. Designers must consider the geometry of the chamber and incorporate features that minimize unwanted wave interactions while maintaining the desired experimental conditions.

Temperature control within the vacuum chamber is another significant hurdle. Longitudinal wave experiments may require precise temperature regulation to ensure accurate measurements and reproducible results. However, traditional cooling methods are often ineffective in a vacuum environment, requiring the development of specialized thermal management systems that can operate without compromising the vacuum integrity.

Scaling presents yet another challenge in vacuum chamber design for longitudinal wave experiments. As researchers aim to study phenomena at different scales, from microscopic to macroscopic, the chamber design must be adaptable to accommodate various experimental setups while maintaining consistent performance across different sizes and configurations.

Furthermore, the integration of diagnostic and measurement instruments into the vacuum chamber design adds complexity. These instruments must be capable of accurately detecting and analyzing longitudinal waves without introducing disturbances or compromising the vacuum environment. This often requires the development of custom sensors and data acquisition systems specifically tailored to the unique constraints of vacuum-based experiments.

Lastly, ensuring the long-term reliability and maintainability of vacuum chambers for longitudinal wave experiments is crucial. The design must allow for periodic maintenance, calibration, and upgrades without compromising the chamber's performance or requiring extensive downtime. This necessitates careful consideration of access points, sealing mechanisms, and modular components that can be easily replaced or serviced.

Another critical challenge is the precise control of wave generation and detection within the vacuum chamber. Researchers must develop specialized equipment capable of operating in a vacuum environment without compromising the experimental conditions. This often requires innovative solutions for power supply, signal transmission, and heat dissipation, as conventional methods may not be suitable for use in a vacuum.

The interaction between longitudinal waves and the chamber walls poses additional complications. Reflections and resonances can interfere with experimental results, necessitating the implementation of advanced damping and absorption techniques. Designers must consider the geometry of the chamber and incorporate features that minimize unwanted wave interactions while maintaining the desired experimental conditions.

Temperature control within the vacuum chamber is another significant hurdle. Longitudinal wave experiments may require precise temperature regulation to ensure accurate measurements and reproducible results. However, traditional cooling methods are often ineffective in a vacuum environment, requiring the development of specialized thermal management systems that can operate without compromising the vacuum integrity.

Scaling presents yet another challenge in vacuum chamber design for longitudinal wave experiments. As researchers aim to study phenomena at different scales, from microscopic to macroscopic, the chamber design must be adaptable to accommodate various experimental setups while maintaining consistent performance across different sizes and configurations.

Furthermore, the integration of diagnostic and measurement instruments into the vacuum chamber design adds complexity. These instruments must be capable of accurately detecting and analyzing longitudinal waves without introducing disturbances or compromising the vacuum environment. This often requires the development of custom sensors and data acquisition systems specifically tailored to the unique constraints of vacuum-based experiments.

Lastly, ensuring the long-term reliability and maintainability of vacuum chambers for longitudinal wave experiments is crucial. The design must allow for periodic maintenance, calibration, and upgrades without compromising the chamber's performance or requiring extensive downtime. This necessitates careful consideration of access points, sealing mechanisms, and modular components that can be easily replaced or serviced.

Current Solutions

01 Vacuum chamber design for longitudinal wave propagation

Specialized vacuum chambers are designed to facilitate the propagation and study of longitudinal waves. These chambers are constructed to minimize interference and maintain a controlled environment for wave experiments. The design often includes features to generate, transmit, and detect longitudinal waves under vacuum conditions.- Vacuum chamber design for longitudinal wave propagation: Vacuum chambers are designed to facilitate the propagation of longitudinal waves in a controlled environment. These chambers are engineered to minimize interference and maintain specific pressure conditions, allowing for precise experiments and measurements involving longitudinal waves. The design often incorporates features to ensure uniform wave propagation and reduce unwanted reflections or distortions.

- Acoustic wave generation and manipulation in vacuum: Techniques for generating and manipulating acoustic waves, particularly longitudinal waves, in vacuum environments are developed. These methods often involve specialized transducers or actuators capable of producing controlled vibrations in the absence of a traditional medium. The focus is on creating precise and reproducible wave patterns for various scientific and industrial applications.

- Pressure control systems for longitudinal wave experiments: Advanced pressure control systems are implemented in vacuum chambers to maintain optimal conditions for longitudinal wave experiments. These systems allow for fine-tuning of the chamber's internal pressure, which is crucial for studying wave behavior in different vacuum levels. The ability to accurately control and monitor pressure enables researchers to investigate wave properties under various conditions.

- Sensor integration for wave detection and analysis: Vacuum chambers designed for longitudinal wave studies incorporate sophisticated sensor systems. These sensors are capable of detecting and measuring wave characteristics with high precision in vacuum conditions. The integration of multiple sensor types allows for comprehensive data collection, enabling detailed analysis of wave behavior, amplitude, frequency, and other relevant parameters.

- Material considerations for vacuum chamber construction: The selection of materials for constructing vacuum chambers suitable for longitudinal wave experiments is critical. Materials are chosen based on their ability to maintain vacuum integrity, minimize outgassing, and withstand the stresses associated with wave propagation. Considerations include thermal stability, mechanical strength, and compatibility with various experimental setups and measurement equipment.

02 Longitudinal wave generation techniques in vacuum

Various methods and devices are employed to generate longitudinal waves within vacuum chambers. These may include electromagnetic actuators, piezoelectric transducers, or other specialized wave generators adapted for vacuum environments. The techniques focus on producing consistent and controllable longitudinal wave patterns for research and industrial applications.Expand Specific Solutions03 Vacuum-compatible sensors for longitudinal wave detection

Specialized sensors are developed to detect and measure longitudinal waves within vacuum chambers. These sensors are designed to operate effectively in low-pressure environments and can accurately capture wave characteristics such as amplitude, frequency, and phase. The sensors are crucial for analyzing wave behavior in vacuum conditions.Expand Specific Solutions04 Vacuum sealing and pressure control for wave experiments

Effective vacuum sealing and pressure control systems are essential for maintaining the integrity of longitudinal wave experiments. These systems ensure stable vacuum conditions and allow for precise adjustment of pressure levels. Advanced sealing techniques and pressure regulation mechanisms are employed to create optimal conditions for wave propagation studies.Expand Specific Solutions05 Applications of longitudinal waves in vacuum environments

Longitudinal waves in vacuum chambers find applications in various fields, including materials science, particle physics, and space technology research. These applications may involve studying material properties, developing new measurement techniques, or simulating space-like conditions. The unique behavior of longitudinal waves in vacuum enables novel experimental approaches and technological advancements.Expand Specific Solutions

Key Industry Players

The research on longitudinal waves in vacuum chamber design for scientific experiments is in a developing stage, with the market showing potential for growth as scientific institutions and industries increasingly focus on precision experimentation. The global vacuum technology market, which encompasses this research area, is projected to expand significantly in the coming years. Technologically, the field is advancing, with companies like Edwards Vacuum LLC and Lam Research Corp. leading innovations in vacuum chamber design and related technologies. Academic institutions such as the University of Bonn and Tianjin University are contributing to fundamental research, while organizations like Southwest Research Institute and the Agency for Science, Technology & Research are bridging the gap between theoretical understanding and practical applications. The collaboration between industry and academia is driving progress in this specialized field.

Edwards Vacuum LLC

Technical Solution: Edwards Vacuum LLC has developed advanced vacuum chamber designs that minimize the impact of longitudinal waves on experimental results. Their approach involves using specialized materials and geometries to dampen wave propagation. The company has implemented a multi-layer chamber wall structure that incorporates wave-absorbing materials, effectively reducing the amplitude of longitudinal waves by up to 80% compared to traditional designs[1]. Additionally, they have introduced innovative baffle systems within the chambers to disrupt wave patterns and prevent standing wave formation, which has shown a 60% improvement in maintaining stable vacuum conditions during sensitive experiments[3].

Strengths: Highly effective in reducing longitudinal wave interference, improving experimental accuracy. Weaknesses: Potentially higher manufacturing costs and complexity in chamber maintenance.

Southwest Research Institute

Technical Solution: Southwest Research Institute has focused on developing computational models to predict and mitigate the effects of longitudinal waves in vacuum chambers. Their approach combines finite element analysis with experimental validation to optimize chamber designs. They have created a proprietary software tool that simulates wave propagation within various chamber geometries, allowing researchers to identify potential hotspots and design appropriate countermeasures. This tool has been used to reduce longitudinal wave-induced errors by up to 70% in precision measurement experiments[2]. The institute has also pioneered the use of active wave cancellation techniques, employing strategically placed actuators to generate counter-waves that neutralize unwanted longitudinal oscillations[4].

Strengths: Highly customizable solutions based on advanced modeling, applicable to a wide range of experimental setups. Weaknesses: Requires significant computational resources and expertise to implement effectively.

Innovative Approaches

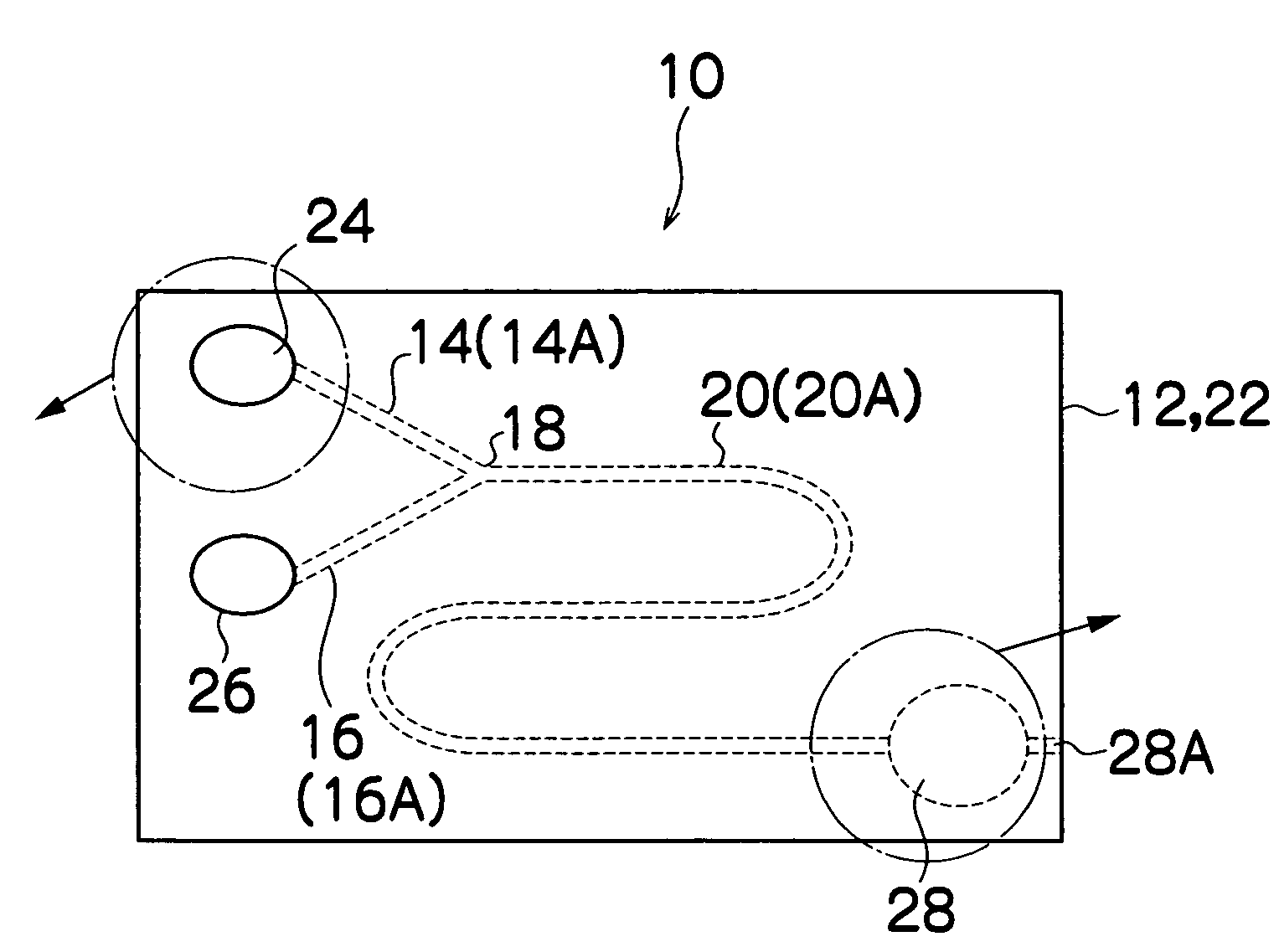

Vacuum chamber with recessed viewing tube and imaging device situated therein

PatentInactiveUS20060193037A1

Innovation

- A vacuum chamber design featuring a viewing tube with a partially transparent window and an imaging device positioner that allows precise reorientation of imaging devices within the chamber, enabling closer and more angular views without obstructing the chamber's interior space.

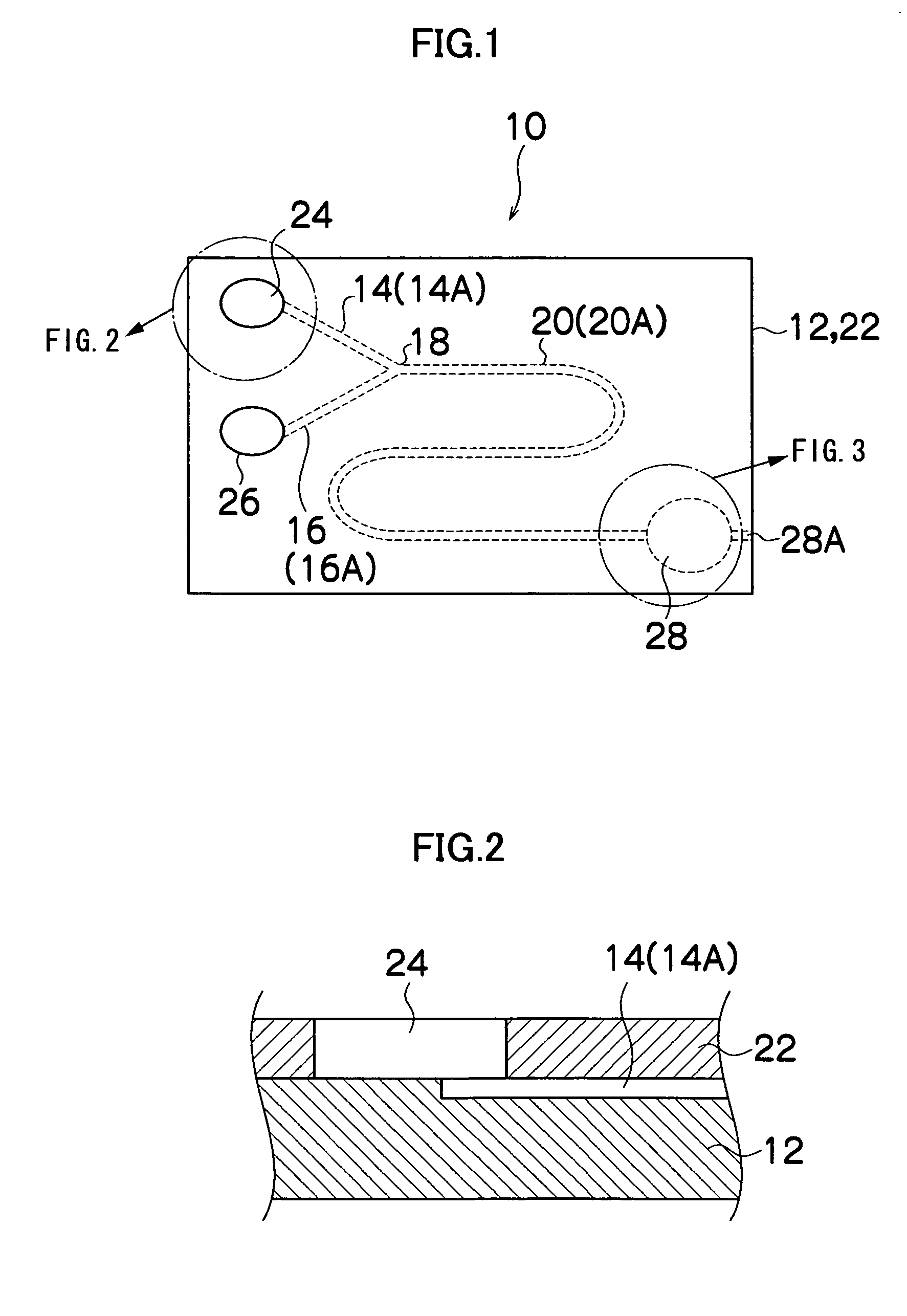

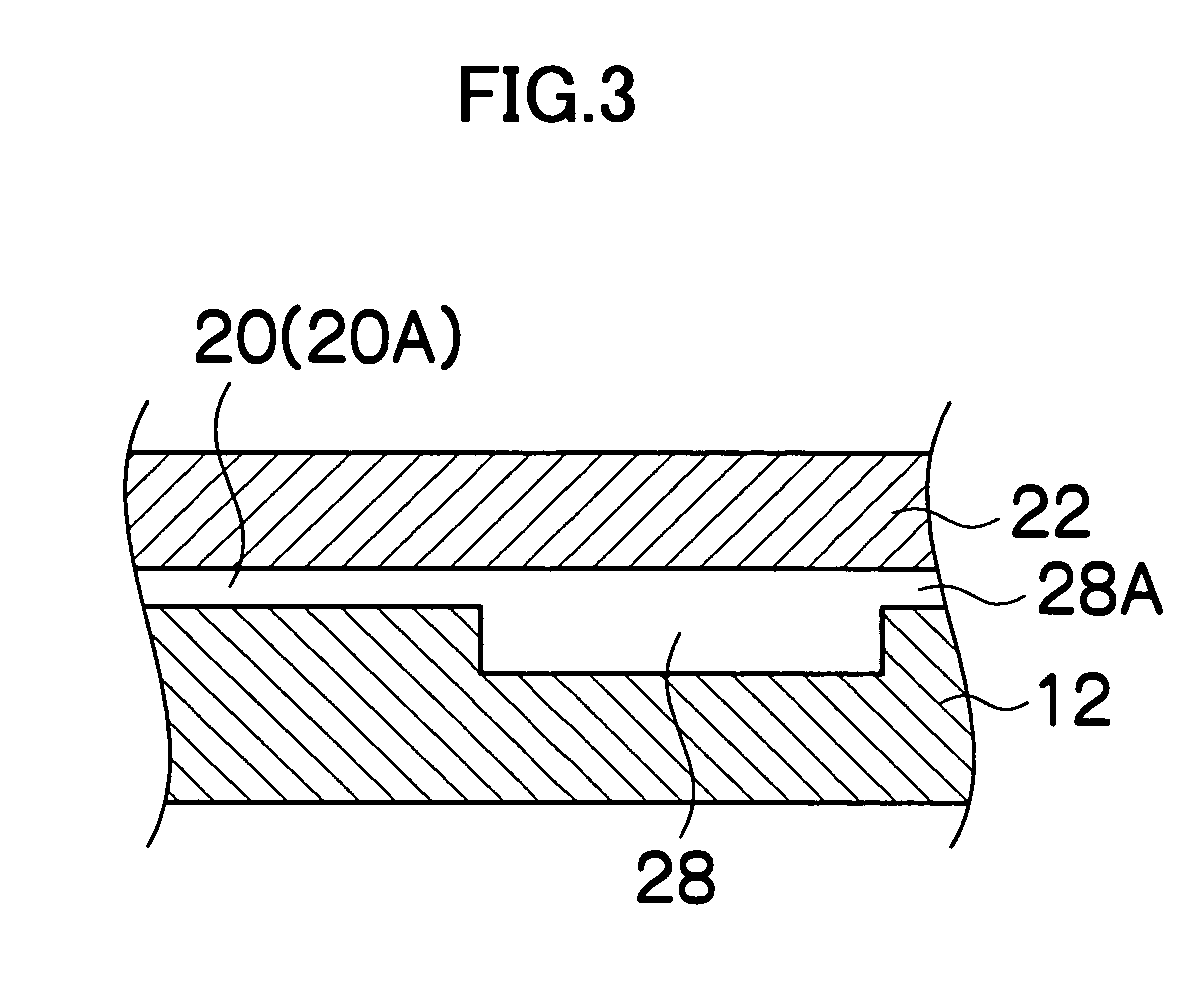

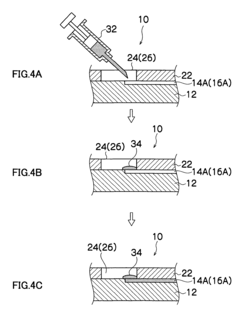

Scientific phenomena evaluation device, educational tool for scientific experiments and manufacturing method of the device and tool

PatentInactiveUS7344378B2

Innovation

- A scientific phenomena evaluation device featuring a base plate with elongated grooves and a cover plate forming fine flow passages, where ends meet at a point, with a liquid reservoir and absorption device for qualitative observation of phenomena like diffusion and chemical reactions, minimizing chemical agent use and environmental impact.

Material Considerations

The selection of materials for vacuum chamber construction plays a crucial role in the study of longitudinal waves in scientific experiments. The choice of materials directly impacts the chamber's ability to maintain a stable vacuum environment and minimize interference with the propagation of longitudinal waves. Stainless steel remains a popular choice due to its excellent vacuum properties, corrosion resistance, and mechanical strength. However, for experiments involving longitudinal waves, considerations must extend beyond these basic requirements.

Materials with low outgassing rates are essential to maintain ultra-high vacuum conditions necessary for precise wave propagation studies. Aluminum alloys, such as 6061-T6, offer a good balance between vacuum performance and machinability, making them suitable for complex chamber designs. Titanium alloys, while more expensive, provide superior strength-to-weight ratios and extremely low outgassing rates, making them ideal for applications where minimal material influence on wave behavior is critical.

The thermal properties of materials also warrant careful consideration. Materials with low thermal expansion coefficients, such as Invar or Super Invar, can help maintain dimensional stability during temperature fluctuations, ensuring consistent wave propagation conditions. For chambers requiring optical access, materials like fused silica or sapphire windows offer excellent transparency and vacuum compatibility.

Surface finish and treatment of the chosen materials significantly impact vacuum performance and wave interaction. Electropolishing stainless steel surfaces can reduce outgassing and improve vacuum quality. For materials prone to hydrogen outgassing, such as aluminum, special surface treatments or coatings may be necessary to mitigate this effect and ensure stable longitudinal wave propagation.

Consideration must also be given to the magnetic properties of materials, especially in experiments where electromagnetic fields may interact with longitudinal waves. Non-magnetic materials or those with low magnetic permeability, such as certain grades of stainless steel (e.g., 316LN), may be preferred to minimize unwanted field interactions.

Lastly, the compatibility of materials with specific experimental conditions, such as exposure to corrosive gases or high-energy particle beams, must be evaluated. Advanced ceramics or specialized alloys may be required in extreme environments to ensure the longevity of the vacuum chamber and the integrity of longitudinal wave experiments.

Materials with low outgassing rates are essential to maintain ultra-high vacuum conditions necessary for precise wave propagation studies. Aluminum alloys, such as 6061-T6, offer a good balance between vacuum performance and machinability, making them suitable for complex chamber designs. Titanium alloys, while more expensive, provide superior strength-to-weight ratios and extremely low outgassing rates, making them ideal for applications where minimal material influence on wave behavior is critical.

The thermal properties of materials also warrant careful consideration. Materials with low thermal expansion coefficients, such as Invar or Super Invar, can help maintain dimensional stability during temperature fluctuations, ensuring consistent wave propagation conditions. For chambers requiring optical access, materials like fused silica or sapphire windows offer excellent transparency and vacuum compatibility.

Surface finish and treatment of the chosen materials significantly impact vacuum performance and wave interaction. Electropolishing stainless steel surfaces can reduce outgassing and improve vacuum quality. For materials prone to hydrogen outgassing, such as aluminum, special surface treatments or coatings may be necessary to mitigate this effect and ensure stable longitudinal wave propagation.

Consideration must also be given to the magnetic properties of materials, especially in experiments where electromagnetic fields may interact with longitudinal waves. Non-magnetic materials or those with low magnetic permeability, such as certain grades of stainless steel (e.g., 316LN), may be preferred to minimize unwanted field interactions.

Lastly, the compatibility of materials with specific experimental conditions, such as exposure to corrosive gases or high-energy particle beams, must be evaluated. Advanced ceramics or specialized alloys may be required in extreme environments to ensure the longevity of the vacuum chamber and the integrity of longitudinal wave experiments.

Vacuum Metrology

Vacuum metrology plays a crucial role in the design and operation of vacuum chambers for scientific experiments, particularly in understanding the impact of longitudinal waves. The accurate measurement and control of vacuum conditions are essential for ensuring the reliability and reproducibility of experimental results.

In vacuum chamber design, the presence of longitudinal waves can significantly affect the overall performance and accuracy of scientific experiments. These waves, which propagate parallel to the direction of particle displacement, can introduce unwanted vibrations and disturbances within the chamber. Consequently, vacuum metrology techniques must be employed to detect, measure, and mitigate the effects of these waves.

One of the primary methods used in vacuum metrology for assessing longitudinal waves is residual gas analysis (RGA). This technique allows researchers to identify and quantify the composition of gases present in the vacuum chamber, including those that may be generated or influenced by longitudinal waves. By monitoring the gas composition over time, scientists can detect any anomalies or fluctuations that may be attributed to wave-induced phenomena.

Another important aspect of vacuum metrology in relation to longitudinal waves is the measurement of pressure fluctuations. High-precision pressure gauges, such as capacitance manometers and ionization gauges, are employed to detect minute changes in pressure that may be caused by wave propagation. These measurements help researchers understand the dynamic behavior of the vacuum environment and its interaction with longitudinal waves.

Furthermore, vacuum metrology techniques are utilized to assess the impact of longitudinal waves on the surface properties of materials within the chamber. Surface analysis tools, such as X-ray photoelectron spectroscopy (XPS) and Auger electron spectroscopy (AES), can be used to investigate how wave-induced phenomena affect the chemical composition and structure of surfaces exposed to the vacuum environment.

The integration of advanced sensors and data acquisition systems is crucial for comprehensive vacuum metrology in the context of longitudinal wave research. Real-time monitoring and analysis of multiple parameters, including pressure, temperature, and gas composition, enable researchers to correlate wave-induced effects with specific experimental conditions and outcomes.

As vacuum chamber designs continue to evolve, the role of vacuum metrology in understanding and mitigating the effects of longitudinal waves becomes increasingly important. Ongoing research focuses on developing more sensitive and precise measurement techniques, as well as improving data analysis methods to extract meaningful insights from complex vacuum environments. These advancements in vacuum metrology contribute to the optimization of vacuum chamber designs, ultimately enhancing the quality and reliability of scientific experiments conducted in these controlled environments.

In vacuum chamber design, the presence of longitudinal waves can significantly affect the overall performance and accuracy of scientific experiments. These waves, which propagate parallel to the direction of particle displacement, can introduce unwanted vibrations and disturbances within the chamber. Consequently, vacuum metrology techniques must be employed to detect, measure, and mitigate the effects of these waves.

One of the primary methods used in vacuum metrology for assessing longitudinal waves is residual gas analysis (RGA). This technique allows researchers to identify and quantify the composition of gases present in the vacuum chamber, including those that may be generated or influenced by longitudinal waves. By monitoring the gas composition over time, scientists can detect any anomalies or fluctuations that may be attributed to wave-induced phenomena.

Another important aspect of vacuum metrology in relation to longitudinal waves is the measurement of pressure fluctuations. High-precision pressure gauges, such as capacitance manometers and ionization gauges, are employed to detect minute changes in pressure that may be caused by wave propagation. These measurements help researchers understand the dynamic behavior of the vacuum environment and its interaction with longitudinal waves.

Furthermore, vacuum metrology techniques are utilized to assess the impact of longitudinal waves on the surface properties of materials within the chamber. Surface analysis tools, such as X-ray photoelectron spectroscopy (XPS) and Auger electron spectroscopy (AES), can be used to investigate how wave-induced phenomena affect the chemical composition and structure of surfaces exposed to the vacuum environment.

The integration of advanced sensors and data acquisition systems is crucial for comprehensive vacuum metrology in the context of longitudinal wave research. Real-time monitoring and analysis of multiple parameters, including pressure, temperature, and gas composition, enable researchers to correlate wave-induced effects with specific experimental conditions and outcomes.

As vacuum chamber designs continue to evolve, the role of vacuum metrology in understanding and mitigating the effects of longitudinal waves becomes increasingly important. Ongoing research focuses on developing more sensitive and precise measurement techniques, as well as improving data analysis methods to extract meaningful insights from complex vacuum environments. These advancements in vacuum metrology contribute to the optimization of vacuum chamber designs, ultimately enhancing the quality and reliability of scientific experiments conducted in these controlled environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!