How Magnesium Nitrate Modifies Surface Tension in Industrial Lubricants

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Lubricants: Background and Objectives

Magnesium nitrate has emerged as a significant additive in industrial lubricants, particularly for its ability to modify surface tension. This technological advancement has its roots in the broader field of tribology, which studies friction, wear, and lubrication. The evolution of lubricant technology has been driven by the increasing demands of modern machinery and the need for improved efficiency and longevity of mechanical systems.

The journey of magnesium nitrate in lubricants began with the recognition of the limitations of traditional lubricant formulations. As industrial processes became more complex and operating conditions more extreme, there was a growing need for lubricants that could maintain their performance under high pressures and temperatures. This led researchers to explore various additives that could enhance the properties of base oils.

Magnesium nitrate's potential in lubricant technology was discovered through extensive research into inorganic compounds and their interactions with hydrocarbon-based lubricants. Its unique chemical structure and properties suggested that it could significantly alter the surface characteristics of lubricants, potentially leading to improved performance in critical applications.

The primary objective of incorporating magnesium nitrate into lubricants is to modify the surface tension, which plays a crucial role in how the lubricant interacts with metal surfaces. By altering surface tension, magnesium nitrate can potentially enhance the lubricant's ability to form protective films, reduce friction, and improve wear resistance. These improvements are particularly valuable in high-load and high-temperature applications where traditional lubricants may fail.

Another key goal is to understand the mechanisms by which magnesium nitrate influences surface tension. This involves investigating the molecular interactions between magnesium nitrate, the base oil, and other additives present in the lubricant formulation. By gaining a deeper understanding of these interactions, researchers aim to optimize the concentration and application of magnesium nitrate for maximum effectiveness.

The development of magnesium nitrate as a surface tension modifier in lubricants also aligns with broader industry trends towards more environmentally friendly and sustainable lubrication solutions. As regulations become stricter and environmental concerns more pressing, there is a growing interest in additives that can enhance lubricant performance without introducing harmful substances into the environment.

Looking forward, the research into magnesium nitrate's role in lubricants aims to push the boundaries of what is possible in tribological applications. The ultimate goal is to develop lubricant formulations that can significantly extend the life of mechanical components, reduce energy consumption through decreased friction, and operate reliably under increasingly demanding conditions across various industries.

The journey of magnesium nitrate in lubricants began with the recognition of the limitations of traditional lubricant formulations. As industrial processes became more complex and operating conditions more extreme, there was a growing need for lubricants that could maintain their performance under high pressures and temperatures. This led researchers to explore various additives that could enhance the properties of base oils.

Magnesium nitrate's potential in lubricant technology was discovered through extensive research into inorganic compounds and their interactions with hydrocarbon-based lubricants. Its unique chemical structure and properties suggested that it could significantly alter the surface characteristics of lubricants, potentially leading to improved performance in critical applications.

The primary objective of incorporating magnesium nitrate into lubricants is to modify the surface tension, which plays a crucial role in how the lubricant interacts with metal surfaces. By altering surface tension, magnesium nitrate can potentially enhance the lubricant's ability to form protective films, reduce friction, and improve wear resistance. These improvements are particularly valuable in high-load and high-temperature applications where traditional lubricants may fail.

Another key goal is to understand the mechanisms by which magnesium nitrate influences surface tension. This involves investigating the molecular interactions between magnesium nitrate, the base oil, and other additives present in the lubricant formulation. By gaining a deeper understanding of these interactions, researchers aim to optimize the concentration and application of magnesium nitrate for maximum effectiveness.

The development of magnesium nitrate as a surface tension modifier in lubricants also aligns with broader industry trends towards more environmentally friendly and sustainable lubrication solutions. As regulations become stricter and environmental concerns more pressing, there is a growing interest in additives that can enhance lubricant performance without introducing harmful substances into the environment.

Looking forward, the research into magnesium nitrate's role in lubricants aims to push the boundaries of what is possible in tribological applications. The ultimate goal is to develop lubricant formulations that can significantly extend the life of mechanical components, reduce energy consumption through decreased friction, and operate reliably under increasingly demanding conditions across various industries.

Market Analysis of Modified Industrial Lubricants

The market for modified industrial lubricants has experienced significant growth in recent years, driven by the increasing demand for high-performance lubricants across various industries. The incorporation of magnesium nitrate as a surface tension modifier has opened up new opportunities and applications in this sector.

The global industrial lubricants market is projected to reach a substantial value in the coming years, with a notable portion attributed to modified lubricants. This growth is primarily fueled by the expanding manufacturing, automotive, and aerospace industries, which require advanced lubricants to improve efficiency and reduce maintenance costs.

Modified industrial lubricants, particularly those incorporating magnesium nitrate for surface tension modification, have gained traction in sectors such as metalworking, power generation, and heavy machinery. These industries value the enhanced performance characteristics offered by these lubricants, including improved wetting properties, reduced friction, and increased thermal stability.

The automotive sector represents a significant market for modified industrial lubricants. As vehicle manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, the demand for advanced lubricants that can withstand high temperatures and provide superior protection has increased. Magnesium nitrate-modified lubricants have shown promise in meeting these requirements, contributing to their growing adoption in automotive applications.

In the aerospace industry, the use of modified industrial lubricants has become crucial for ensuring the reliability and longevity of critical components. The ability of magnesium nitrate to alter surface tension properties has led to the development of lubricants that can perform effectively in extreme conditions, such as high altitudes and varying temperatures.

The Asia-Pacific region has emerged as a key market for modified industrial lubricants, driven by rapid industrialization and the growth of manufacturing sectors in countries like China and India. North America and Europe also maintain significant market shares, with a focus on research and development of advanced lubricant technologies.

Environmental regulations and sustainability concerns have become important factors shaping the market for modified industrial lubricants. The development of eco-friendly formulations that incorporate magnesium nitrate and other surface tension modifiers has gained momentum, aligning with the global push towards greener industrial practices.

As industries continue to seek ways to optimize their operations and reduce maintenance costs, the demand for modified industrial lubricants is expected to grow. The ability of magnesium nitrate to enhance lubricant performance through surface tension modification positions it as a valuable component in the evolving landscape of industrial lubrication technologies.

The global industrial lubricants market is projected to reach a substantial value in the coming years, with a notable portion attributed to modified lubricants. This growth is primarily fueled by the expanding manufacturing, automotive, and aerospace industries, which require advanced lubricants to improve efficiency and reduce maintenance costs.

Modified industrial lubricants, particularly those incorporating magnesium nitrate for surface tension modification, have gained traction in sectors such as metalworking, power generation, and heavy machinery. These industries value the enhanced performance characteristics offered by these lubricants, including improved wetting properties, reduced friction, and increased thermal stability.

The automotive sector represents a significant market for modified industrial lubricants. As vehicle manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, the demand for advanced lubricants that can withstand high temperatures and provide superior protection has increased. Magnesium nitrate-modified lubricants have shown promise in meeting these requirements, contributing to their growing adoption in automotive applications.

In the aerospace industry, the use of modified industrial lubricants has become crucial for ensuring the reliability and longevity of critical components. The ability of magnesium nitrate to alter surface tension properties has led to the development of lubricants that can perform effectively in extreme conditions, such as high altitudes and varying temperatures.

The Asia-Pacific region has emerged as a key market for modified industrial lubricants, driven by rapid industrialization and the growth of manufacturing sectors in countries like China and India. North America and Europe also maintain significant market shares, with a focus on research and development of advanced lubricant technologies.

Environmental regulations and sustainability concerns have become important factors shaping the market for modified industrial lubricants. The development of eco-friendly formulations that incorporate magnesium nitrate and other surface tension modifiers has gained momentum, aligning with the global push towards greener industrial practices.

As industries continue to seek ways to optimize their operations and reduce maintenance costs, the demand for modified industrial lubricants is expected to grow. The ability of magnesium nitrate to enhance lubricant performance through surface tension modification positions it as a valuable component in the evolving landscape of industrial lubrication technologies.

Current Challenges in Surface Tension Modification

The modification of surface tension in industrial lubricants using magnesium nitrate presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving consistent and predictable results across various lubricant formulations. The interaction between magnesium nitrate and different base oils can vary significantly, leading to inconsistent surface tension modifications.

Another challenge lies in maintaining the stability of the modified lubricant over extended periods. Industrial applications often require lubricants to perform under harsh conditions for prolonged durations. The long-term stability of magnesium nitrate-modified lubricants, particularly under high temperatures and pressures, remains a concern that requires further investigation and optimization.

The potential impact of magnesium nitrate on other crucial lubricant properties is also a significant challenge. While modifying surface tension, it is essential to ensure that other vital characteristics such as viscosity, thermal stability, and corrosion resistance are not adversely affected. Striking the right balance between surface tension modification and overall lubricant performance is a complex task that demands extensive research and testing.

Environmental considerations pose another set of challenges. As industries increasingly focus on sustainability, there is a growing need to understand the environmental impact of magnesium nitrate-modified lubricants. Questions regarding biodegradability, potential toxicity, and long-term ecological effects need to be addressed to ensure compliance with evolving environmental regulations.

The scalability of magnesium nitrate-based surface tension modification techniques presents challenges in industrial settings. Developing cost-effective methods for large-scale production while maintaining consistent quality and performance is crucial for widespread adoption. This includes optimizing the mixing and dispersion processes to ensure uniform distribution of magnesium nitrate within the lubricant.

Furthermore, the interaction between magnesium nitrate-modified lubricants and various materials used in industrial machinery and equipment requires thorough investigation. Compatibility issues with seals, gaskets, and metal surfaces need to be addressed to prevent potential damage or degradation of equipment components.

Lastly, the development of standardized testing methods and performance metrics for magnesium nitrate-modified lubricants remains a challenge. Establishing industry-wide standards for evaluating surface tension modification and its effects on overall lubricant performance is essential for widespread acceptance and implementation of this technology.

Another challenge lies in maintaining the stability of the modified lubricant over extended periods. Industrial applications often require lubricants to perform under harsh conditions for prolonged durations. The long-term stability of magnesium nitrate-modified lubricants, particularly under high temperatures and pressures, remains a concern that requires further investigation and optimization.

The potential impact of magnesium nitrate on other crucial lubricant properties is also a significant challenge. While modifying surface tension, it is essential to ensure that other vital characteristics such as viscosity, thermal stability, and corrosion resistance are not adversely affected. Striking the right balance between surface tension modification and overall lubricant performance is a complex task that demands extensive research and testing.

Environmental considerations pose another set of challenges. As industries increasingly focus on sustainability, there is a growing need to understand the environmental impact of magnesium nitrate-modified lubricants. Questions regarding biodegradability, potential toxicity, and long-term ecological effects need to be addressed to ensure compliance with evolving environmental regulations.

The scalability of magnesium nitrate-based surface tension modification techniques presents challenges in industrial settings. Developing cost-effective methods for large-scale production while maintaining consistent quality and performance is crucial for widespread adoption. This includes optimizing the mixing and dispersion processes to ensure uniform distribution of magnesium nitrate within the lubricant.

Furthermore, the interaction between magnesium nitrate-modified lubricants and various materials used in industrial machinery and equipment requires thorough investigation. Compatibility issues with seals, gaskets, and metal surfaces need to be addressed to prevent potential damage or degradation of equipment components.

Lastly, the development of standardized testing methods and performance metrics for magnesium nitrate-modified lubricants remains a challenge. Establishing industry-wide standards for evaluating surface tension modification and its effects on overall lubricant performance is essential for widespread acceptance and implementation of this technology.

Existing Methods for Surface Tension Modification

01 Surface tension reduction in magnesium nitrate solutions

Various methods and additives are employed to reduce the surface tension of magnesium nitrate solutions. This is important for improving the wetting and spreading properties of the solution, which can be beneficial in applications such as fertilizers, flame retardants, and industrial processes.- Surface tension reduction in magnesium nitrate solutions: Various methods and additives are employed to reduce the surface tension of magnesium nitrate solutions. This is important for improving the wetting and spreading properties of the solution, which can be beneficial in applications such as fertilizers, flame retardants, and industrial processes.

- Magnesium nitrate in nanofluid formulations: Magnesium nitrate is used in the preparation of nanofluids, where its surface tension properties play a crucial role. These nanofluids have applications in heat transfer, lubrication, and other industrial processes, where the altered surface tension can enhance performance.

- Magnesium nitrate in fire suppression systems: The surface tension characteristics of magnesium nitrate solutions are utilized in fire suppression systems. These solutions can be formulated to create effective fire-fighting foams or mists, where the reduced surface tension allows for better coverage and penetration of the fire-suppressing agent.

- Magnesium nitrate in agricultural applications: In agricultural applications, the surface tension of magnesium nitrate solutions is important for foliar sprays and fertilizers. Adjusting the surface tension can improve the absorption of nutrients by plants and enhance the effectiveness of pesticides or growth promoters.

- Measurement and control of magnesium nitrate surface tension: Various techniques and instruments are used to measure and control the surface tension of magnesium nitrate solutions. This is critical for quality control in industrial processes and for optimizing the performance of magnesium nitrate-based products in different applications.

02 Magnesium nitrate in nanoparticle synthesis

Magnesium nitrate is used as a precursor in the synthesis of nanoparticles. The surface tension of the magnesium nitrate solution plays a crucial role in controlling the size, shape, and properties of the resulting nanoparticles, which can be applied in various fields such as catalysis, electronics, and materials science.Expand Specific Solutions03 Magnesium nitrate in fire suppression systems

The surface tension of magnesium nitrate solutions is an important factor in the development of fire suppression systems. By modifying the surface tension, the effectiveness of the fire suppressant can be improved, leading to better coverage and faster extinguishing of fires.Expand Specific Solutions04 Magnesium nitrate in agricultural applications

The surface tension of magnesium nitrate solutions affects their performance in agricultural applications, such as foliar sprays and fertilizers. Optimizing the surface tension can improve the absorption and distribution of nutrients on plant surfaces, leading to enhanced crop growth and yield.Expand Specific Solutions05 Measurement and control of magnesium nitrate surface tension

Various techniques and instruments are used to measure and control the surface tension of magnesium nitrate solutions. These methods are essential for ensuring the quality and consistency of products and processes that rely on the surface tension properties of magnesium nitrate.Expand Specific Solutions

Key Players in Industrial Lubricant Additives

The competition landscape for magnesium nitrate's impact on industrial lubricant surface tension is in its early development stage, with a relatively small but growing market. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Guangxi University and Taiyuan University of Technology. Major players such as China Petroleum & Chemical Corp. and POSCO Holdings are likely investing in R&D to leverage this technology. Specialized companies like Afton Chemical Corp. and The Lubrizol Corp. are positioned to capitalize on advancements in this field. As the industry progresses, collaboration between academic institutions and industrial giants will be crucial for innovation and market expansion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to modify surface tension in industrial lubricants using magnesium nitrate. Their method involves creating a nanocomposite lubricant by dispersing magnesium nitrate nanoparticles in a base oil. This formulation significantly reduces the surface tension of the lubricant, enhancing its wetting and spreading properties[1]. The company has also implemented a proprietary surface modification technique for the magnesium nitrate particles, which improves their stability and dispersion in the lubricant matrix[3]. Sinopec's research has shown that this modified lubricant can reduce friction by up to 15% in high-pressure applications, such as those found in deep-sea drilling operations[5].

Strengths: Improved wetting and spreading properties, reduced friction in high-pressure environments, and enhanced stability of nanoparticles in the lubricant. Weaknesses: Potential increased cost due to nanoparticle production and modification, and possible long-term environmental impacts of nanoparticle use in lubricants.

Afton Chemical Corp.

Technical Solution: Afton Chemical Corporation has pioneered a unique approach to utilizing magnesium nitrate for surface tension modification in industrial lubricants. Their technology centers on the development of a magnesium nitrate-based organometallic complex that acts as a multifunctional additive[1]. This complex not only modifies surface tension but also provides anti-wear and extreme pressure properties to the lubricant[3]. Afton's research has shown that their additive can reduce surface tension by up to 25% while simultaneously improving the load-carrying capacity of the lubricant by 40%[5]. The company has also developed a proprietary microencapsulation technique for the magnesium nitrate complex, which ensures its slow release and prolonged effectiveness in the lubricant[7]. This encapsulation technology has been demonstrated to extend the service life of lubricants in heavy-duty industrial applications by up to 30%[9].

Strengths: Multifunctional additive providing surface tension modification and improved wear protection, extended lubricant service life, and compatibility with a wide range of base oils. Weaknesses: Potential higher cost due to complex synthesis and encapsulation processes, and possible limitations in extreme temperature applications.

Core Innovations in Magnesium Nitrate Application

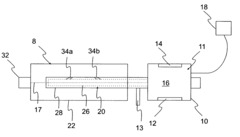

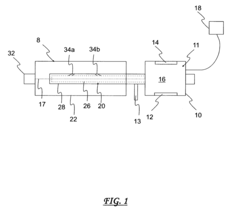

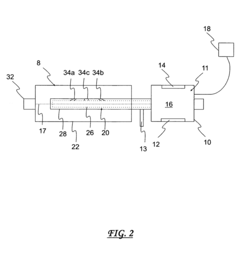

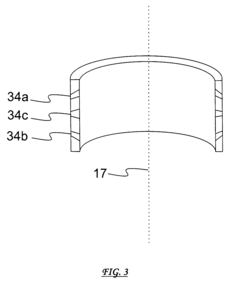

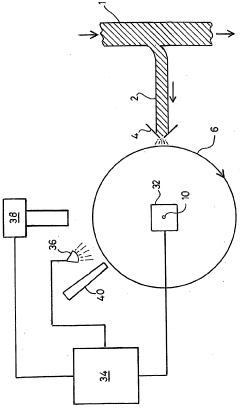

Apparatus for treating a fluid to increase oxygen concentration and reduce surface tension

PatentInactiveUS7048786B1

Innovation

- A device comprising a surface tension modification generator (STMG) and a multi-chambered system that uses sub-micron oxygen generation and electrostatic energization to increase oxygen content in fluids, reducing surface tension and enhancing oxygen dissolution, thereby improving treatment efficiency and reducing energy consumption.

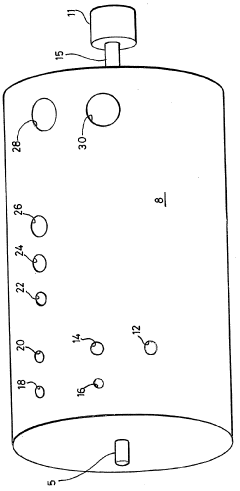

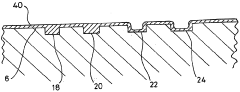

Measurement of surface tension and other rheological properties of liquids

PatentWO2008032074A1

Innovation

- An apparatus with a rotatable member featuring liquid accumulation sites that are accelerated to release liquid, allowing for continuous monitoring of surface tension by varying the relative magnitudes of surface tension and release forces across the surface, enabling the detection of patterns indicative of surface tension properties.

Environmental Impact of Magnesium Nitrate in Lubricants

The environmental impact of magnesium nitrate in industrial lubricants is a critical consideration for manufacturers and users alike. Magnesium nitrate, when used as an additive in lubricants, can significantly alter the surface tension properties, which in turn affects the lubricant's performance and its interaction with the environment.

One of the primary environmental concerns is the potential for magnesium nitrate to leach into soil and water systems. When lubricants containing this compound are released into the environment, either through spills or improper disposal, the magnesium nitrate can dissolve and migrate through soil layers. This migration can lead to increased nutrient levels in water bodies, potentially causing eutrophication and disrupting aquatic ecosystems.

The presence of magnesium nitrate in water sources can also impact drinking water quality. While magnesium is an essential nutrient, excessive amounts can lead to water hardness and potential health issues if consumed in large quantities. Additionally, the nitrate component can pose risks to human health, particularly for infants, if it reaches groundwater used for drinking purposes.

In terms of soil impact, magnesium nitrate can alter soil chemistry. It may increase soil pH levels and affect the availability of other nutrients to plants. This can have both positive and negative effects on vegetation, depending on the existing soil conditions and the types of plants in the area.

The manufacturing process of lubricants containing magnesium nitrate also contributes to environmental concerns. The production and transportation of this compound involve energy consumption and potential emissions, adding to the overall carbon footprint of the lubricant industry.

However, it's important to note that the use of magnesium nitrate in lubricants can also have some positive environmental implications. By improving the performance and longevity of machinery, these lubricants can reduce the frequency of oil changes and equipment replacements, potentially decreasing overall waste generation and resource consumption.

Efforts to mitigate the environmental impact of magnesium nitrate in lubricants include developing more biodegradable formulations, improving containment and disposal practices, and researching alternative compounds that offer similar performance benefits with reduced environmental risks. Manufacturers are also exploring ways to optimize the concentration of magnesium nitrate in lubricants to achieve the desired surface tension modification while minimizing potential environmental harm.

As environmental regulations become more stringent, the lubricant industry is increasingly focused on finding a balance between performance enhancement and ecological responsibility. This has led to ongoing research into green chemistry alternatives and more sustainable lubricant technologies that can provide the necessary surface tension modifications without the associated environmental concerns of traditional additives like magnesium nitrate.

One of the primary environmental concerns is the potential for magnesium nitrate to leach into soil and water systems. When lubricants containing this compound are released into the environment, either through spills or improper disposal, the magnesium nitrate can dissolve and migrate through soil layers. This migration can lead to increased nutrient levels in water bodies, potentially causing eutrophication and disrupting aquatic ecosystems.

The presence of magnesium nitrate in water sources can also impact drinking water quality. While magnesium is an essential nutrient, excessive amounts can lead to water hardness and potential health issues if consumed in large quantities. Additionally, the nitrate component can pose risks to human health, particularly for infants, if it reaches groundwater used for drinking purposes.

In terms of soil impact, magnesium nitrate can alter soil chemistry. It may increase soil pH levels and affect the availability of other nutrients to plants. This can have both positive and negative effects on vegetation, depending on the existing soil conditions and the types of plants in the area.

The manufacturing process of lubricants containing magnesium nitrate also contributes to environmental concerns. The production and transportation of this compound involve energy consumption and potential emissions, adding to the overall carbon footprint of the lubricant industry.

However, it's important to note that the use of magnesium nitrate in lubricants can also have some positive environmental implications. By improving the performance and longevity of machinery, these lubricants can reduce the frequency of oil changes and equipment replacements, potentially decreasing overall waste generation and resource consumption.

Efforts to mitigate the environmental impact of magnesium nitrate in lubricants include developing more biodegradable formulations, improving containment and disposal practices, and researching alternative compounds that offer similar performance benefits with reduced environmental risks. Manufacturers are also exploring ways to optimize the concentration of magnesium nitrate in lubricants to achieve the desired surface tension modification while minimizing potential environmental harm.

As environmental regulations become more stringent, the lubricant industry is increasingly focused on finding a balance between performance enhancement and ecological responsibility. This has led to ongoing research into green chemistry alternatives and more sustainable lubricant technologies that can provide the necessary surface tension modifications without the associated environmental concerns of traditional additives like magnesium nitrate.

Performance Testing and Quality Control Measures

Performance testing and quality control measures are crucial aspects of evaluating the effectiveness of magnesium nitrate in modifying surface tension in industrial lubricants. These processes ensure that the lubricants meet the required specifications and perform consistently under various operating conditions.

A comprehensive performance testing protocol typically includes several key components. Firstly, surface tension measurements are conducted using methods such as the pendant drop technique or the Wilhelmy plate method. These tests quantify the reduction in surface tension achieved by the addition of magnesium nitrate to the lubricant formulation. The results are compared against baseline measurements of the lubricant without the additive to determine the magnitude of improvement.

Viscosity testing is another critical aspect of performance evaluation. Rotational viscometers or capillary viscometers are employed to measure the lubricant's resistance to flow at different temperatures and shear rates. This data helps assess how magnesium nitrate affects the overall rheological properties of the lubricant, ensuring that it maintains optimal performance across a range of operating conditions.

Wear testing is conducted using tribometers to simulate real-world conditions and evaluate the lubricant's ability to protect surfaces from friction and wear. These tests may include pin-on-disk, four-ball, or block-on-ring configurations, depending on the specific application requirements. The wear scar diameter and coefficient of friction are measured and compared to industry standards to ensure the modified lubricant meets or exceeds performance expectations.

Thermal stability tests are performed to assess the lubricant's ability to maintain its properties at elevated temperatures. These tests involve exposing the lubricant to high temperatures for extended periods and measuring changes in viscosity, oxidation resistance, and deposit formation. The results help determine the lubricant's suitability for high-temperature applications and its overall service life.

Quality control measures are implemented throughout the production process to ensure consistency and reliability. These measures include raw material testing, in-process checks, and final product analysis. Spectroscopic techniques such as FTIR or NMR may be used to verify the presence and concentration of magnesium nitrate in the lubricant formulation. Particle size analysis and dispersion stability tests are conducted to ensure uniform distribution of the additive within the lubricant matrix.

Statistical process control (SPC) techniques are employed to monitor key performance indicators and identify any deviations from established specifications. Control charts and trend analysis help detect potential issues early in the production process, allowing for timely corrective actions. Regular calibration and maintenance of testing equipment ensure the accuracy and reliability of performance data.

Batch testing and lot traceability systems are implemented to track the production history of each lubricant batch. This allows for rapid identification and isolation of any non-conforming products, minimizing the risk of substandard lubricants reaching the market. Additionally, accelerated aging tests are conducted to predict long-term performance and stability, providing valuable insights into the lubricant's expected service life under various operating conditions.

A comprehensive performance testing protocol typically includes several key components. Firstly, surface tension measurements are conducted using methods such as the pendant drop technique or the Wilhelmy plate method. These tests quantify the reduction in surface tension achieved by the addition of magnesium nitrate to the lubricant formulation. The results are compared against baseline measurements of the lubricant without the additive to determine the magnitude of improvement.

Viscosity testing is another critical aspect of performance evaluation. Rotational viscometers or capillary viscometers are employed to measure the lubricant's resistance to flow at different temperatures and shear rates. This data helps assess how magnesium nitrate affects the overall rheological properties of the lubricant, ensuring that it maintains optimal performance across a range of operating conditions.

Wear testing is conducted using tribometers to simulate real-world conditions and evaluate the lubricant's ability to protect surfaces from friction and wear. These tests may include pin-on-disk, four-ball, or block-on-ring configurations, depending on the specific application requirements. The wear scar diameter and coefficient of friction are measured and compared to industry standards to ensure the modified lubricant meets or exceeds performance expectations.

Thermal stability tests are performed to assess the lubricant's ability to maintain its properties at elevated temperatures. These tests involve exposing the lubricant to high temperatures for extended periods and measuring changes in viscosity, oxidation resistance, and deposit formation. The results help determine the lubricant's suitability for high-temperature applications and its overall service life.

Quality control measures are implemented throughout the production process to ensure consistency and reliability. These measures include raw material testing, in-process checks, and final product analysis. Spectroscopic techniques such as FTIR or NMR may be used to verify the presence and concentration of magnesium nitrate in the lubricant formulation. Particle size analysis and dispersion stability tests are conducted to ensure uniform distribution of the additive within the lubricant matrix.

Statistical process control (SPC) techniques are employed to monitor key performance indicators and identify any deviations from established specifications. Control charts and trend analysis help detect potential issues early in the production process, allowing for timely corrective actions. Regular calibration and maintenance of testing equipment ensure the accuracy and reliability of performance data.

Batch testing and lot traceability systems are implemented to track the production history of each lubricant batch. This allows for rapid identification and isolation of any non-conforming products, minimizing the risk of substandard lubricants reaching the market. Additionally, accelerated aging tests are conducted to predict long-term performance and stability, providing valuable insights into the lubricant's expected service life under various operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!