How Nichrome Equips Next-Gen Home Heating Technologies?

JUL 11, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in Home Heating: Evolution and Objectives

Nichrome, an alloy of nickel and chromium, has been a cornerstone in home heating technologies for over a century. Its journey from a simple resistive element to a key component in advanced heating systems reflects the evolution of domestic comfort and energy efficiency. The primary objective of nichrome in home heating has consistently been to provide reliable, efficient, and controllable heat generation.

The evolution of nichrome in home heating technologies can be traced back to the early 20th century when it was first used in electric heaters. Its high resistance to oxidation and ability to withstand high temperatures made it an ideal material for heating elements. As home heating demands grew more sophisticated, nichrome adapted to meet these changing needs, finding applications in various heating devices from simple space heaters to complex HVAC systems.

In recent decades, the objectives for nichrome in home heating have expanded beyond mere heat generation. Energy efficiency has become a paramount concern, driving the development of nichrome-based heating elements that can achieve higher temperatures with lower energy input. This shift aligns with global efforts to reduce energy consumption and carbon footprints in residential settings.

Another key objective in the evolution of nichrome for home heating has been to enhance user control and comfort. This has led to the integration of nichrome elements with smart home technologies, allowing for precise temperature regulation, zone-based heating, and remote operation. The goal is to provide homeowners with heating solutions that are not only efficient but also customizable to individual preferences and lifestyles.

Durability and safety have remained constant objectives throughout nichrome's evolution in home heating. Manufacturers have continually refined the composition and manufacturing processes of nichrome to improve its longevity and resistance to degradation under repeated heating cycles. Simultaneously, efforts have been made to enhance the safety features of nichrome-based heating systems, addressing concerns such as overheating and electrical safety.

Looking towards the future, the objectives for nichrome in next-generation home heating technologies are becoming even more ambitious. There is a growing focus on developing nichrome-based systems that can integrate seamlessly with renewable energy sources, such as solar and geothermal power. Additionally, research is being conducted to explore how nichrome can contribute to more sustainable heating solutions, potentially incorporating recycled materials or improving end-of-life recyclability.

The evolution of nichrome in home heating technologies can be traced back to the early 20th century when it was first used in electric heaters. Its high resistance to oxidation and ability to withstand high temperatures made it an ideal material for heating elements. As home heating demands grew more sophisticated, nichrome adapted to meet these changing needs, finding applications in various heating devices from simple space heaters to complex HVAC systems.

In recent decades, the objectives for nichrome in home heating have expanded beyond mere heat generation. Energy efficiency has become a paramount concern, driving the development of nichrome-based heating elements that can achieve higher temperatures with lower energy input. This shift aligns with global efforts to reduce energy consumption and carbon footprints in residential settings.

Another key objective in the evolution of nichrome for home heating has been to enhance user control and comfort. This has led to the integration of nichrome elements with smart home technologies, allowing for precise temperature regulation, zone-based heating, and remote operation. The goal is to provide homeowners with heating solutions that are not only efficient but also customizable to individual preferences and lifestyles.

Durability and safety have remained constant objectives throughout nichrome's evolution in home heating. Manufacturers have continually refined the composition and manufacturing processes of nichrome to improve its longevity and resistance to degradation under repeated heating cycles. Simultaneously, efforts have been made to enhance the safety features of nichrome-based heating systems, addressing concerns such as overheating and electrical safety.

Looking towards the future, the objectives for nichrome in next-generation home heating technologies are becoming even more ambitious. There is a growing focus on developing nichrome-based systems that can integrate seamlessly with renewable energy sources, such as solar and geothermal power. Additionally, research is being conducted to explore how nichrome can contribute to more sustainable heating solutions, potentially incorporating recycled materials or improving end-of-life recyclability.

Market Analysis: Smart Home Heating Demand

The smart home heating market is experiencing significant growth, driven by increasing consumer demand for energy-efficient, convenient, and technologically advanced heating solutions. This trend is particularly evident in developed countries where smart home adoption rates are high. The global smart thermostat market, a key component of smart home heating systems, is projected to reach $6.8 billion by 2026, growing at a CAGR of 20.3% from 2021 to 2026.

Consumer preferences are shifting towards more intelligent and connected heating systems that offer precise temperature control, energy savings, and remote operation capabilities. The integration of AI and machine learning algorithms in smart heating devices is enabling predictive heating patterns, further enhancing energy efficiency and user comfort. This shift is supported by the growing awareness of environmental issues and the need for sustainable living practices among consumers.

The COVID-19 pandemic has accelerated the adoption of smart home technologies, including heating systems, as people spend more time at home and seek to optimize their living spaces. This has led to an increased focus on indoor air quality and comfort, driving demand for advanced heating solutions that can be easily controlled and monitored remotely.

Government initiatives and regulations promoting energy efficiency in buildings are also contributing to the growth of the smart home heating market. For instance, the European Union's Energy Performance of Buildings Directive (EPBD) requires all new buildings to be nearly zero-energy by 2021, which is boosting the adoption of smart heating technologies.

The market is seeing a rise in demand for multi-functional heating systems that integrate with other smart home devices and platforms. Consumers are looking for seamless integration with voice assistants, smartphones, and home automation systems, creating opportunities for manufacturers to develop more interconnected and user-friendly products.

Emerging technologies such as geofencing and occupancy sensing are gaining traction in the smart home heating sector. These technologies allow heating systems to automatically adjust based on user presence and preferences, further enhancing energy efficiency and comfort.

The retrofit market for smart heating solutions is also expanding, as homeowners seek to upgrade existing heating systems with smart controls and sensors. This presents a significant opportunity for manufacturers to develop products that can be easily integrated into existing infrastructure.

Consumer preferences are shifting towards more intelligent and connected heating systems that offer precise temperature control, energy savings, and remote operation capabilities. The integration of AI and machine learning algorithms in smart heating devices is enabling predictive heating patterns, further enhancing energy efficiency and user comfort. This shift is supported by the growing awareness of environmental issues and the need for sustainable living practices among consumers.

The COVID-19 pandemic has accelerated the adoption of smart home technologies, including heating systems, as people spend more time at home and seek to optimize their living spaces. This has led to an increased focus on indoor air quality and comfort, driving demand for advanced heating solutions that can be easily controlled and monitored remotely.

Government initiatives and regulations promoting energy efficiency in buildings are also contributing to the growth of the smart home heating market. For instance, the European Union's Energy Performance of Buildings Directive (EPBD) requires all new buildings to be nearly zero-energy by 2021, which is boosting the adoption of smart heating technologies.

The market is seeing a rise in demand for multi-functional heating systems that integrate with other smart home devices and platforms. Consumers are looking for seamless integration with voice assistants, smartphones, and home automation systems, creating opportunities for manufacturers to develop more interconnected and user-friendly products.

Emerging technologies such as geofencing and occupancy sensing are gaining traction in the smart home heating sector. These technologies allow heating systems to automatically adjust based on user presence and preferences, further enhancing energy efficiency and comfort.

The retrofit market for smart heating solutions is also expanding, as homeowners seek to upgrade existing heating systems with smart controls and sensors. This presents a significant opportunity for manufacturers to develop products that can be easily integrated into existing infrastructure.

Nichrome Technology: Current State and Challenges

Nichrome technology has reached a mature state in home heating applications, but it still faces several challenges in adapting to next-generation heating systems. Currently, nichrome is widely used in electric heaters, toasters, and other household appliances due to its high electrical resistance and ability to generate heat efficiently. The alloy's composition, typically 80% nickel and 20% chromium, provides excellent oxidation resistance and stability at high temperatures.

One of the primary challenges for nichrome in next-generation home heating technologies is improving energy efficiency. While nichrome is effective at generating heat, there is a growing demand for heating solutions that consume less energy. This has led to research into optimizing nichrome wire configurations and exploring new alloy compositions to enhance heat distribution and reduce power consumption.

Another significant challenge is the integration of nichrome elements with smart home systems. As the Internet of Things (IoT) becomes more prevalent in household appliances, there is a need to develop nichrome-based heating elements that can seamlessly interface with digital controls and sensors. This requires advancements in the design of heating elements to incorporate connectivity features without compromising performance or safety.

Durability and longevity of nichrome elements in high-use scenarios remain areas of concern. While nichrome is known for its resistance to oxidation, prolonged exposure to high temperatures can still lead to degradation over time. Researchers are exploring ways to enhance the material's lifespan through surface treatments and protective coatings, aiming to extend the operational life of heating appliances.

Environmental considerations also pose challenges for nichrome technology. As global initiatives push for more sustainable and eco-friendly solutions, there is pressure to develop heating technologies with lower environmental impact. This includes reducing the carbon footprint of nichrome production and exploring recycling methods for used nichrome elements.

Miniaturization is another frontier for nichrome technology in home heating. As appliances become more compact and multifunctional, there is a need to design smaller, more efficient nichrome heating elements. This challenge involves balancing heat output with size constraints while maintaining safety standards.

Lastly, cost-effectiveness remains a persistent challenge. While nichrome is relatively inexpensive compared to some alternative heating technologies, there is ongoing research to further reduce production costs and improve manufacturing processes. This is crucial for maintaining nichrome's competitive edge in the market, especially as new heating technologies emerge.

One of the primary challenges for nichrome in next-generation home heating technologies is improving energy efficiency. While nichrome is effective at generating heat, there is a growing demand for heating solutions that consume less energy. This has led to research into optimizing nichrome wire configurations and exploring new alloy compositions to enhance heat distribution and reduce power consumption.

Another significant challenge is the integration of nichrome elements with smart home systems. As the Internet of Things (IoT) becomes more prevalent in household appliances, there is a need to develop nichrome-based heating elements that can seamlessly interface with digital controls and sensors. This requires advancements in the design of heating elements to incorporate connectivity features without compromising performance or safety.

Durability and longevity of nichrome elements in high-use scenarios remain areas of concern. While nichrome is known for its resistance to oxidation, prolonged exposure to high temperatures can still lead to degradation over time. Researchers are exploring ways to enhance the material's lifespan through surface treatments and protective coatings, aiming to extend the operational life of heating appliances.

Environmental considerations also pose challenges for nichrome technology. As global initiatives push for more sustainable and eco-friendly solutions, there is pressure to develop heating technologies with lower environmental impact. This includes reducing the carbon footprint of nichrome production and exploring recycling methods for used nichrome elements.

Miniaturization is another frontier for nichrome technology in home heating. As appliances become more compact and multifunctional, there is a need to design smaller, more efficient nichrome heating elements. This challenge involves balancing heat output with size constraints while maintaining safety standards.

Lastly, cost-effectiveness remains a persistent challenge. While nichrome is relatively inexpensive compared to some alternative heating technologies, there is ongoing research to further reduce production costs and improve manufacturing processes. This is crucial for maintaining nichrome's competitive edge in the market, especially as new heating technologies emerge.

Current Nichrome Applications in Home Heating

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Manufacturing processes for nichrome components: Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes aim to achieve specific dimensions, surface properties, and performance characteristics required for different applications.

- Applications in heating elements and resistors: Nichrome is widely used in the production of heating elements for appliances, industrial equipment, and laboratory instruments. It is also employed in the manufacture of precision resistors for electronic circuits, where its stable resistance properties are advantageous.

- Nichrome in thin film and microelectronic applications: Nichrome thin films are utilized in microelectronics and semiconductor industries for various purposes, including resistive elements, interconnects, and as adhesion layers for other metallic films. The deposition and patterning of nichrome films are crucial in these applications.

- Innovations in nichrome-based materials and coatings: Ongoing research focuses on improving the properties of nichrome-based materials through alloying, surface treatments, and composite formations. These innovations aim to enhance performance in specific applications, such as improved oxidation resistance or tailored electrical properties.

02 Nichrome in heating elements and electrical resistors

Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and stability at high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's properties allow for efficient and reliable heat generation in these applications.Expand Specific Solutions03 Nichrome in thin film technology

Nichrome is utilized in thin film technology for various electronic applications. It can be deposited as a thin film using techniques such as sputtering or evaporation. These thin films are used in the production of resistors, sensors, and other electronic components where precise resistance values and stability are required.Expand Specific Solutions04 Nichrome in aerospace and high-temperature applications

The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that need to withstand extreme heat, such as rocket nozzles, furnace elements, and high-temperature sensors. The alloy's ability to maintain its properties under harsh conditions contributes to its popularity in these fields.Expand Specific Solutions05 Surface treatment and coating of nichrome

Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from environmental factors. These treatments can improve corrosion resistance, reduce oxidation, or modify the surface characteristics for specific applications. Coatings may include ceramic materials, precious metals, or other protective layers to extend the lifespan and performance of nichrome components.Expand Specific Solutions

Key Players in Nichrome-based Heating Solutions

The market for next-generation home heating technologies is in a growth phase, driven by increasing demand for energy-efficient and environmentally friendly solutions. The global smart home heating market is expected to expand significantly in the coming years, with a projected market size reaching billions of dollars. Technologically, the field is rapidly evolving, with companies like Toyota Motor Corp. and Honda Motor Co., Ltd. leveraging their expertise in automotive technologies to develop innovative heating solutions. Established HVAC manufacturers such as BSH Hausgeräte GmbH and Addison HVAC LLC are also advancing their offerings, while specialized firms like Adagio Medical, Inc. are exploring novel approaches to thermal management. The involvement of diverse players indicates a maturing technology landscape with potential for further breakthroughs.

Yancheng Xinyang Electric Heating Material Co., Ltd.

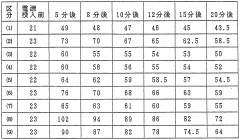

Technical Solution: Yancheng Xinyang specializes in nichrome-based heating solutions for various applications, including home heating. They have developed a high-purity nichrome alloy that offers superior resistance to oxidation at elevated temperatures, making it ideal for long-lasting heating elements in home appliances[5]. The company's manufacturing process includes precision winding techniques that allow for the creation of nichrome elements with consistent resistance across their length, ensuring even heat distribution. Yancheng Xinyang has also introduced a range of nichrome mesh products that provide larger surface areas for heat transfer, improving the efficiency of space heaters and other home heating devices[6].

Strengths: High-purity alloy composition, oxidation resistance, consistent heat distribution, and versatile product range. Weaknesses: Potential limitations in customization for specific appliance designs.

De Luca Oven Technologies LLC

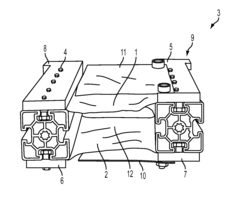

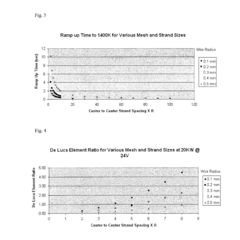

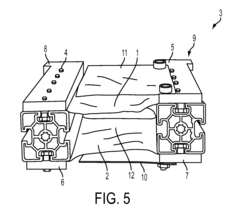

Technical Solution: De Luca Oven Technologies has developed advanced nichrome-based heating elements for next-generation home ovens. Their proprietary design incorporates a high-density nichrome wire configuration that allows for rapid and uniform heating across the oven cavity. The company has implemented a precision control system that adjusts power input to the nichrome elements in real-time, based on temperature sensors distributed throughout the oven[1]. This results in more accurate temperature maintenance and reduced energy consumption. Additionally, De Luca has engineered a protective coating for their nichrome elements that extends their lifespan and prevents degradation at high temperatures[2].

Strengths: Rapid and uniform heating, precise temperature control, energy efficiency, and extended element lifespan. Weaknesses: Potentially higher initial cost due to advanced technology and specialized coatings.

Innovative Nichrome Alloys and Manufacturing Techniques

Electric heater and heat exchanger employing the same

PatentWO1985000084A1

Innovation

- A bare nichrome wire is immersed in silicone oil, which provides rapid temperature rise, excellent insulation, oxidation resistance, and durability, preventing oxidation and ensuring safety by using silicone oil with good thermal and electrical properties.

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

Energy Efficiency and Environmental Impact

Nichrome's role in next-generation home heating technologies is closely tied to energy efficiency and environmental impact considerations. As a key component in many heating elements, nichrome wire contributes significantly to the overall performance and sustainability of modern heating systems.

The energy efficiency of nichrome-based heating technologies has seen substantial improvements in recent years. Advanced nichrome alloys and innovative coil designs have led to faster heat-up times and more uniform heat distribution. This results in reduced energy consumption during the initial heating phase and more consistent temperature maintenance. Some cutting-edge nichrome heating elements can achieve up to 95% energy efficiency, a marked improvement over older technologies.

Environmental impact is another crucial factor in the development of nichrome-equipped heating systems. The durability and corrosion resistance of nichrome allow for longer-lasting heating elements, reducing the need for frequent replacements and minimizing waste. Additionally, the ability of nichrome to operate efficiently at high temperatures enables the use of lower wattage heating elements, further reducing energy consumption and associated carbon emissions.

Nichrome's compatibility with smart home technologies has opened new avenues for energy optimization. Integration with IoT devices and AI-driven control systems allows for precise temperature regulation based on occupancy patterns, weather forecasts, and user preferences. This intelligent heating approach can lead to energy savings of up to 30% compared to traditional thermostat-controlled systems.

The recyclability of nichrome is another environmental advantage. At the end of a heating system's life cycle, the nichrome components can be easily separated and recycled, contributing to a circular economy approach in the HVAC industry. This recyclability, combined with the material's longevity, significantly reduces the overall environmental footprint of home heating systems.

Recent innovations in nichrome coating technologies have further enhanced its environmental profile. Nano-coatings applied to nichrome wires can improve heat transfer efficiency and reduce the formation of oxide layers, extending the operational life of heating elements. These advancements not only improve performance but also decrease the frequency of replacements, thereby reducing waste and resource consumption.

In the context of global efforts to reduce greenhouse gas emissions, nichrome-based heating technologies play a crucial role. By enabling more efficient electric heating systems, they support the transition away from fossil fuel-based heating methods. This shift is particularly significant in regions with increasingly clean electricity grids, where the environmental benefits of electric heating are amplified.

The energy efficiency of nichrome-based heating technologies has seen substantial improvements in recent years. Advanced nichrome alloys and innovative coil designs have led to faster heat-up times and more uniform heat distribution. This results in reduced energy consumption during the initial heating phase and more consistent temperature maintenance. Some cutting-edge nichrome heating elements can achieve up to 95% energy efficiency, a marked improvement over older technologies.

Environmental impact is another crucial factor in the development of nichrome-equipped heating systems. The durability and corrosion resistance of nichrome allow for longer-lasting heating elements, reducing the need for frequent replacements and minimizing waste. Additionally, the ability of nichrome to operate efficiently at high temperatures enables the use of lower wattage heating elements, further reducing energy consumption and associated carbon emissions.

Nichrome's compatibility with smart home technologies has opened new avenues for energy optimization. Integration with IoT devices and AI-driven control systems allows for precise temperature regulation based on occupancy patterns, weather forecasts, and user preferences. This intelligent heating approach can lead to energy savings of up to 30% compared to traditional thermostat-controlled systems.

The recyclability of nichrome is another environmental advantage. At the end of a heating system's life cycle, the nichrome components can be easily separated and recycled, contributing to a circular economy approach in the HVAC industry. This recyclability, combined with the material's longevity, significantly reduces the overall environmental footprint of home heating systems.

Recent innovations in nichrome coating technologies have further enhanced its environmental profile. Nano-coatings applied to nichrome wires can improve heat transfer efficiency and reduce the formation of oxide layers, extending the operational life of heating elements. These advancements not only improve performance but also decrease the frequency of replacements, thereby reducing waste and resource consumption.

In the context of global efforts to reduce greenhouse gas emissions, nichrome-based heating technologies play a crucial role. By enabling more efficient electric heating systems, they support the transition away from fossil fuel-based heating methods. This shift is particularly significant in regions with increasingly clean electricity grids, where the environmental benefits of electric heating are amplified.

Integration with IoT and Smart Home Systems

The integration of Nichrome with IoT and smart home systems represents a significant leap forward in home heating technology. This convergence allows for unprecedented levels of control, efficiency, and customization in residential heating solutions. Nichrome, known for its excellent heat-generating properties, is being incorporated into smart heating elements that can communicate with central home automation systems.

These smart Nichrome-based heating systems can be controlled remotely via smartphone apps or voice assistants, enabling users to adjust their home temperature from anywhere. The integration also allows for more sophisticated scheduling and zoning capabilities, where different areas of the home can be heated to different temperatures based on occupancy and individual preferences.

Moreover, the combination of Nichrome and IoT technology enables real-time energy consumption monitoring. This data can be analyzed to optimize heating patterns, potentially resulting in significant energy savings. Smart algorithms can learn from user behavior and environmental conditions to automatically adjust heating settings for maximum comfort and efficiency.

The integration extends to predictive maintenance as well. IoT-enabled Nichrome heating systems can monitor their own performance and wear, alerting homeowners or service providers when maintenance is required. This proactive approach can extend the lifespan of heating equipment and prevent unexpected breakdowns.

Another key aspect of this integration is the ability to respond to dynamic electricity pricing. In areas with time-of-use electricity rates, smart Nichrome heating systems can adjust their operation to take advantage of lower-cost periods, further reducing energy bills for homeowners.

The compatibility with other smart home devices opens up new possibilities for holistic home management. For instance, Nichrome heating elements can work in tandem with smart windows and shades to optimize natural heat gain, or with occupancy sensors to heat only occupied spaces.

As the smart home ecosystem continues to evolve, Nichrome-based heating solutions are poised to play a central role in creating more comfortable, efficient, and sustainable living environments. The ongoing development of IoT protocols and AI algorithms will likely lead to even more sophisticated integration, potentially revolutionizing how we think about and manage home heating in the future.

These smart Nichrome-based heating systems can be controlled remotely via smartphone apps or voice assistants, enabling users to adjust their home temperature from anywhere. The integration also allows for more sophisticated scheduling and zoning capabilities, where different areas of the home can be heated to different temperatures based on occupancy and individual preferences.

Moreover, the combination of Nichrome and IoT technology enables real-time energy consumption monitoring. This data can be analyzed to optimize heating patterns, potentially resulting in significant energy savings. Smart algorithms can learn from user behavior and environmental conditions to automatically adjust heating settings for maximum comfort and efficiency.

The integration extends to predictive maintenance as well. IoT-enabled Nichrome heating systems can monitor their own performance and wear, alerting homeowners or service providers when maintenance is required. This proactive approach can extend the lifespan of heating equipment and prevent unexpected breakdowns.

Another key aspect of this integration is the ability to respond to dynamic electricity pricing. In areas with time-of-use electricity rates, smart Nichrome heating systems can adjust their operation to take advantage of lower-cost periods, further reducing energy bills for homeowners.

The compatibility with other smart home devices opens up new possibilities for holistic home management. For instance, Nichrome heating elements can work in tandem with smart windows and shades to optimize natural heat gain, or with occupancy sensors to heat only occupied spaces.

As the smart home ecosystem continues to evolve, Nichrome-based heating solutions are poised to play a central role in creating more comfortable, efficient, and sustainable living environments. The ongoing development of IoT protocols and AI algorithms will likely lead to even more sophisticated integration, potentially revolutionizing how we think about and manage home heating in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!