How Nichrome Is Transforming Resistance Manufacturing?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has undergone a remarkable evolution since its inception in the early 20th century. This evolution has significantly transformed resistance manufacturing, revolutionizing various industries that rely on electrical heating elements.

The journey of nichrome began in 1905 when Albert Marsh, an American engineer, patented the alloy. Initially developed as a more durable alternative to pure nickel in electrical resistance applications, nichrome quickly gained popularity due to its superior properties. The alloy's high melting point, excellent oxidation resistance, and stable electrical resistance across a wide temperature range made it an ideal material for heating elements.

As the demand for more efficient and reliable heating solutions grew, nichrome continued to evolve. Manufacturers experimented with different compositions, fine-tuning the nickel-chromium ratio and introducing small amounts of other elements like iron, aluminum, or silicon. These modifications led to the development of various grades of nichrome, each optimized for specific applications and operating conditions.

The 1950s and 1960s saw a significant leap in nichrome technology with the advent of precision manufacturing techniques. These advancements allowed for the production of thinner and more uniform nichrome wires and ribbons, enabling the creation of more compact and energy-efficient heating elements. This development was particularly crucial for the emerging consumer electronics and appliance industries.

In the latter part of the 20th century, the focus shifted towards enhancing the longevity and performance of nichrome-based heating elements. Researchers developed new coating technologies and surface treatments to further improve the alloy's oxidation resistance and thermal stability. These innovations extended the lifespan of nichrome elements and allowed them to operate at even higher temperatures, opening up new applications in industrial processes and aerospace.

The turn of the millennium brought about a renewed interest in nichrome as the world moved towards more energy-efficient and environmentally friendly technologies. The alloy's ability to rapidly heat and cool, coupled with its durability, made it an excellent choice for applications in electric vehicles, renewable energy systems, and advanced manufacturing processes.

Today, nichrome continues to evolve, with ongoing research focused on nano-engineered structures and advanced composites. These cutting-edge developments aim to push the boundaries of what's possible in resistance manufacturing, promising even greater efficiency, durability, and performance in the future.

The journey of nichrome began in 1905 when Albert Marsh, an American engineer, patented the alloy. Initially developed as a more durable alternative to pure nickel in electrical resistance applications, nichrome quickly gained popularity due to its superior properties. The alloy's high melting point, excellent oxidation resistance, and stable electrical resistance across a wide temperature range made it an ideal material for heating elements.

As the demand for more efficient and reliable heating solutions grew, nichrome continued to evolve. Manufacturers experimented with different compositions, fine-tuning the nickel-chromium ratio and introducing small amounts of other elements like iron, aluminum, or silicon. These modifications led to the development of various grades of nichrome, each optimized for specific applications and operating conditions.

The 1950s and 1960s saw a significant leap in nichrome technology with the advent of precision manufacturing techniques. These advancements allowed for the production of thinner and more uniform nichrome wires and ribbons, enabling the creation of more compact and energy-efficient heating elements. This development was particularly crucial for the emerging consumer electronics and appliance industries.

In the latter part of the 20th century, the focus shifted towards enhancing the longevity and performance of nichrome-based heating elements. Researchers developed new coating technologies and surface treatments to further improve the alloy's oxidation resistance and thermal stability. These innovations extended the lifespan of nichrome elements and allowed them to operate at even higher temperatures, opening up new applications in industrial processes and aerospace.

The turn of the millennium brought about a renewed interest in nichrome as the world moved towards more energy-efficient and environmentally friendly technologies. The alloy's ability to rapidly heat and cool, coupled with its durability, made it an excellent choice for applications in electric vehicles, renewable energy systems, and advanced manufacturing processes.

Today, nichrome continues to evolve, with ongoing research focused on nano-engineered structures and advanced composites. These cutting-edge developments aim to push the boundaries of what's possible in resistance manufacturing, promising even greater efficiency, durability, and performance in the future.

Market Demand Analysis

The market demand for nichrome in resistance manufacturing has been experiencing significant growth, driven by the increasing need for high-performance heating elements across various industries. Nichrome, an alloy primarily composed of nickel and chromium, has become a preferred material due to its excellent electrical resistance properties and ability to withstand high temperatures.

In the consumer electronics sector, the demand for nichrome-based heating elements has surged, particularly in appliances such as hair dryers, toasters, and electric kettles. The growing consumer base and rising disposable incomes in emerging markets have contributed to this trend. Additionally, the automotive industry has shown increased interest in nichrome for applications in heated seats, defrosting systems, and catalytic converters, further boosting market demand.

The industrial sector represents another significant market for nichrome resistance manufacturing. The material's durability and consistent performance make it ideal for use in industrial furnaces, kilns, and heat treatment equipment. As manufacturing processes become more advanced and energy-efficient, the demand for precise temperature control systems utilizing nichrome elements continues to rise.

The aerospace and defense industries have also contributed to the growing market for nichrome-based resistance products. The material's ability to maintain stability under extreme conditions makes it valuable for aircraft de-icing systems and missile guidance components. This specialized application segment, while smaller in volume, offers higher profit margins and drives technological advancements in nichrome manufacturing.

Environmental concerns and energy efficiency regulations have further propelled the demand for nichrome in resistance manufacturing. As industries seek to reduce energy consumption and improve the efficiency of heating systems, nichrome's superior heat distribution properties make it an attractive choice. This trend is particularly evident in the HVAC sector, where nichrome-based heating elements are being increasingly adopted in energy-efficient climate control systems.

The global shift towards renewable energy sources has opened new avenues for nichrome applications. Solar thermal power plants and wind turbine systems often require reliable heating elements for various processes, creating additional demand for nichrome-based products. This emerging market segment presents significant growth potential for manufacturers in the coming years.

While the overall market demand for nichrome in resistance manufacturing is robust, it is not without challenges. Fluctuations in raw material prices, particularly nickel, can impact production costs and market dynamics. Additionally, the development of alternative materials and technologies may pose competition in certain application areas. However, the unique combination of properties offered by nichrome continues to make it a preferred choice in many resistance manufacturing applications, ensuring sustained market demand for the foreseeable future.

In the consumer electronics sector, the demand for nichrome-based heating elements has surged, particularly in appliances such as hair dryers, toasters, and electric kettles. The growing consumer base and rising disposable incomes in emerging markets have contributed to this trend. Additionally, the automotive industry has shown increased interest in nichrome for applications in heated seats, defrosting systems, and catalytic converters, further boosting market demand.

The industrial sector represents another significant market for nichrome resistance manufacturing. The material's durability and consistent performance make it ideal for use in industrial furnaces, kilns, and heat treatment equipment. As manufacturing processes become more advanced and energy-efficient, the demand for precise temperature control systems utilizing nichrome elements continues to rise.

The aerospace and defense industries have also contributed to the growing market for nichrome-based resistance products. The material's ability to maintain stability under extreme conditions makes it valuable for aircraft de-icing systems and missile guidance components. This specialized application segment, while smaller in volume, offers higher profit margins and drives technological advancements in nichrome manufacturing.

Environmental concerns and energy efficiency regulations have further propelled the demand for nichrome in resistance manufacturing. As industries seek to reduce energy consumption and improve the efficiency of heating systems, nichrome's superior heat distribution properties make it an attractive choice. This trend is particularly evident in the HVAC sector, where nichrome-based heating elements are being increasingly adopted in energy-efficient climate control systems.

The global shift towards renewable energy sources has opened new avenues for nichrome applications. Solar thermal power plants and wind turbine systems often require reliable heating elements for various processes, creating additional demand for nichrome-based products. This emerging market segment presents significant growth potential for manufacturers in the coming years.

While the overall market demand for nichrome in resistance manufacturing is robust, it is not without challenges. Fluctuations in raw material prices, particularly nickel, can impact production costs and market dynamics. Additionally, the development of alternative materials and technologies may pose competition in certain application areas. However, the unique combination of properties offered by nichrome continues to make it a preferred choice in many resistance manufacturing applications, ensuring sustained market demand for the foreseeable future.

Technical Challenges

The manufacturing of nichrome resistance elements faces several technical challenges that are currently shaping the industry's landscape. One of the primary obstacles is achieving precise control over the alloy composition. Nichrome typically consists of nickel and chromium, with the exact ratio varying depending on the desired properties. Maintaining consistency in this composition across large production batches is crucial for ensuring uniform resistance characteristics.

Another significant challenge lies in the heat treatment process of nichrome wire. The thermal cycling during manufacturing can lead to microstructural changes, affecting the material's electrical and mechanical properties. Achieving the optimal balance between ductility and strength while maintaining the desired resistivity requires sophisticated heat treatment protocols and stringent quality control measures.

The miniaturization trend in electronics poses additional challenges for nichrome resistance manufacturing. As devices become smaller, the demand for thinner nichrome wires and more compact resistance elements increases. This necessitates advancements in drawing and shaping techniques to produce ultra-fine wires without compromising their electrical properties or mechanical integrity.

Corrosion resistance is another critical aspect that manufacturers must address. While nichrome generally exhibits good corrosion resistance, certain applications may expose the material to harsh environments. Developing surface treatments or protective coatings that enhance corrosion resistance without affecting electrical performance is an ongoing area of research and development.

The quest for higher temperature resistance is driving innovation in nichrome alloy formulations. Traditional nichrome compositions may not meet the demands of extreme high-temperature applications. Researchers are exploring new alloy combinations and manufacturing techniques to push the temperature limits of nichrome-based resistance elements.

Environmental concerns and regulatory pressures are also influencing nichrome manufacturing. The industry is challenged to develop more sustainable production processes, reduce waste, and minimize the use of hazardous materials. This includes exploring alternative cleaning and etching methods that are less environmentally impactful.

Lastly, the integration of nichrome elements into complex electronic assemblies presents its own set of challenges. Ensuring reliable electrical connections, managing thermal expansion mismatches, and preventing contamination during assembly processes are critical considerations. Manufacturers must develop innovative packaging and integration solutions to address these issues while meeting the performance requirements of modern electronic devices.

Another significant challenge lies in the heat treatment process of nichrome wire. The thermal cycling during manufacturing can lead to microstructural changes, affecting the material's electrical and mechanical properties. Achieving the optimal balance between ductility and strength while maintaining the desired resistivity requires sophisticated heat treatment protocols and stringent quality control measures.

The miniaturization trend in electronics poses additional challenges for nichrome resistance manufacturing. As devices become smaller, the demand for thinner nichrome wires and more compact resistance elements increases. This necessitates advancements in drawing and shaping techniques to produce ultra-fine wires without compromising their electrical properties or mechanical integrity.

Corrosion resistance is another critical aspect that manufacturers must address. While nichrome generally exhibits good corrosion resistance, certain applications may expose the material to harsh environments. Developing surface treatments or protective coatings that enhance corrosion resistance without affecting electrical performance is an ongoing area of research and development.

The quest for higher temperature resistance is driving innovation in nichrome alloy formulations. Traditional nichrome compositions may not meet the demands of extreme high-temperature applications. Researchers are exploring new alloy combinations and manufacturing techniques to push the temperature limits of nichrome-based resistance elements.

Environmental concerns and regulatory pressures are also influencing nichrome manufacturing. The industry is challenged to develop more sustainable production processes, reduce waste, and minimize the use of hazardous materials. This includes exploring alternative cleaning and etching methods that are less environmentally impactful.

Lastly, the integration of nichrome elements into complex electronic assemblies presents its own set of challenges. Ensuring reliable electrical connections, managing thermal expansion mismatches, and preventing contamination during assembly processes are critical considerations. Manufacturers must develop innovative packaging and integration solutions to address these issues while meeting the performance requirements of modern electronic devices.

Current Manufacturing

01 Composition and properties of nichrome alloys

Nichrome alloys are typically composed of nickel and chromium, with varying ratios to achieve specific electrical resistance properties. These alloys are known for their high resistance to oxidation and corrosion, making them suitable for use in high-temperature applications. The composition can be adjusted to optimize resistance characteristics for different uses.- Composition and properties of nichrome alloys: Nichrome alloys are typically composed of nickel and chromium, with varying ratios to achieve specific electrical resistance properties. These alloys are known for their high resistance to oxidation and corrosion, making them suitable for use in high-temperature applications. The composition can be adjusted to optimize resistance characteristics for different purposes.

- Nichrome resistance wire manufacturing techniques: Various manufacturing techniques are employed to produce nichrome resistance wires with desired properties. These may include precise control of alloy composition, heat treatment processes, and drawing methods to achieve specific resistance values and mechanical characteristics. Advanced manufacturing processes can enhance the uniformity and stability of the resistance properties.

- Applications of nichrome resistance in electronic devices: Nichrome resistance elements are widely used in electronic devices for various purposes. They can be found in heating elements, resistors, and sensors. The high stability and predictable resistance characteristics of nichrome make it suitable for precision applications in electronics, including temperature control systems and measurement devices.

- Nichrome resistance in thin film technology: Nichrome is utilized in thin film technology for creating precise resistive elements. The deposition of nichrome thin films allows for the fabrication of miniaturized resistors with controlled resistance values. This technology is crucial in the production of integrated circuits and microelectronic devices, where space-efficient and accurate resistive components are required.

- Optimization and control of nichrome resistance: Methods for optimizing and controlling nichrome resistance involve adjusting factors such as alloy composition, heat treatment, and physical dimensions. Techniques may include precise temperature control during manufacturing, surface treatment processes, and the use of additives to fine-tune resistance properties. These optimizations aim to achieve specific resistance values and improve the stability and longevity of nichrome resistive elements.

02 Manufacturing processes for nichrome resistance elements

Various manufacturing techniques are employed to produce nichrome resistance elements, including wire drawing, thin film deposition, and powder metallurgy. These processes aim to create uniform and stable resistance properties in the final product. Heat treatment and surface finishing methods may be applied to enhance performance and durability.Expand Specific Solutions03 Applications of nichrome resistance in electronic devices

Nichrome resistance elements are widely used in electronic devices such as heating elements, sensors, and precision resistors. Their stability and predictable resistance characteristics make them ideal for applications requiring accurate temperature control or voltage regulation. They are also used in aerospace and automotive industries for various sensing and heating applications.Expand Specific Solutions04 Improving nichrome resistance performance

Research focuses on enhancing the performance of nichrome resistance elements through various methods. These include developing new alloy compositions, implementing advanced coating techniques to improve oxidation resistance, and optimizing the microstructure of the material. Efforts are also made to increase the lifespan and reliability of nichrome resistance components in harsh environments.Expand Specific Solutions05 Nichrome resistance in thin film technology

Thin film nichrome resistors are becoming increasingly important in miniaturized electronic devices. These resistors offer advantages such as precise resistance values, low temperature coefficients, and excellent stability. Deposition techniques like sputtering or evaporation are used to create thin nichrome films with controlled thickness and composition, enabling the production of high-precision resistive elements for integrated circuits and microelectronics.Expand Specific Solutions

Key Industry Players

The nichrome resistance manufacturing industry is experiencing a transformative phase, driven by technological advancements and growing demand across various sectors. The market is in a mature stage but continues to evolve, with a global market size estimated to be in the billions of dollars. Technological maturity varies among key players, with companies like Fujitsu Ltd., Shin-Etsu Chemical Co., Ltd., and Skyworks Solutions, Inc. leading in innovation and product development. These firms are investing heavily in R&D to enhance nichrome properties, improve manufacturing processes, and expand applications in electronics, aerospace, and energy sectors. Emerging players such as Yancheng Xinyang Electric Heating Material Co., Ltd. and Chengdu Advanced Metal Materials Industry Technology Research Institute Co., Ltd. are also contributing to the competitive landscape, focusing on specialized nichrome products and regional market penetration.

Yancheng Xinyang Electric Heating Material Co., Ltd.

Technical Solution: Yancheng Xinyang Electric Heating Material Co., Ltd. has developed advanced nichrome alloy manufacturing techniques to produce high-quality resistance wires. Their process involves precise control of nickel and chromium ratios, typically around 80% nickel and 20% chromium[1], to achieve optimal electrical resistance and temperature stability. The company utilizes vacuum melting and continuous casting methods to ensure uniform composition and minimize impurities. Their nichrome wires undergo multiple drawing and annealing cycles to enhance tensile strength and maintain consistent resistivity across batches[3]. The company has also implemented automated quality control systems using laser micrometry and electrical testing to ensure each produced wire meets stringent specifications for resistance tolerance and dimensional accuracy.

Strengths: Consistent quality, high temperature stability, and precise resistance control. Weaknesses: Higher production costs compared to less specialized alloys, limited flexibility in customization for specific applications.

KOA Co. Ltd.

Technical Solution: KOA Co. Ltd. has revolutionized nichrome-based resistor manufacturing through their proprietary thin-film deposition technology. Their process involves sputtering a precisely controlled nichrome alloy onto ceramic substrates, typically alumina, in a high-vacuum environment[2]. This method allows for extremely thin and uniform nichrome layers, often less than 100 nanometers thick[4]. KOA has developed a laser trimming technique that adjusts the resistance value of each component with an accuracy of up to 0.01%[5]. The company has also integrated advanced oxidation protection layers and specialized termination materials to enhance the long-term stability and reliability of their nichrome resistors. KOA's manufacturing process includes in-line monitoring systems that use X-ray fluorescence spectroscopy to continuously verify the composition and thickness of the nichrome films during production.

Strengths: Exceptional precision in resistance values, miniaturization capabilities, and high stability over time and temperature. Weaknesses: Higher unit cost for low-volume production, limited power handling compared to wirewound resistors.

Nichrome Innovations

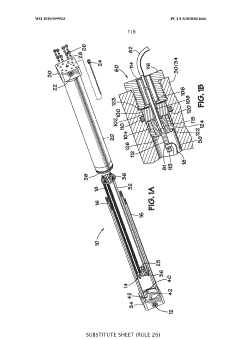

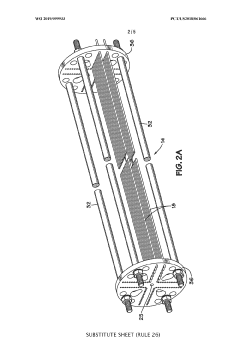

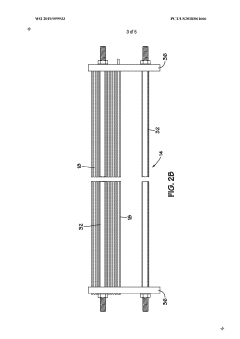

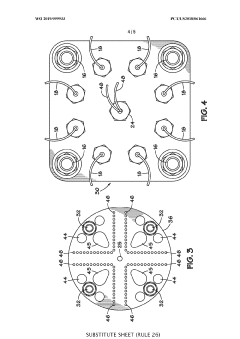

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

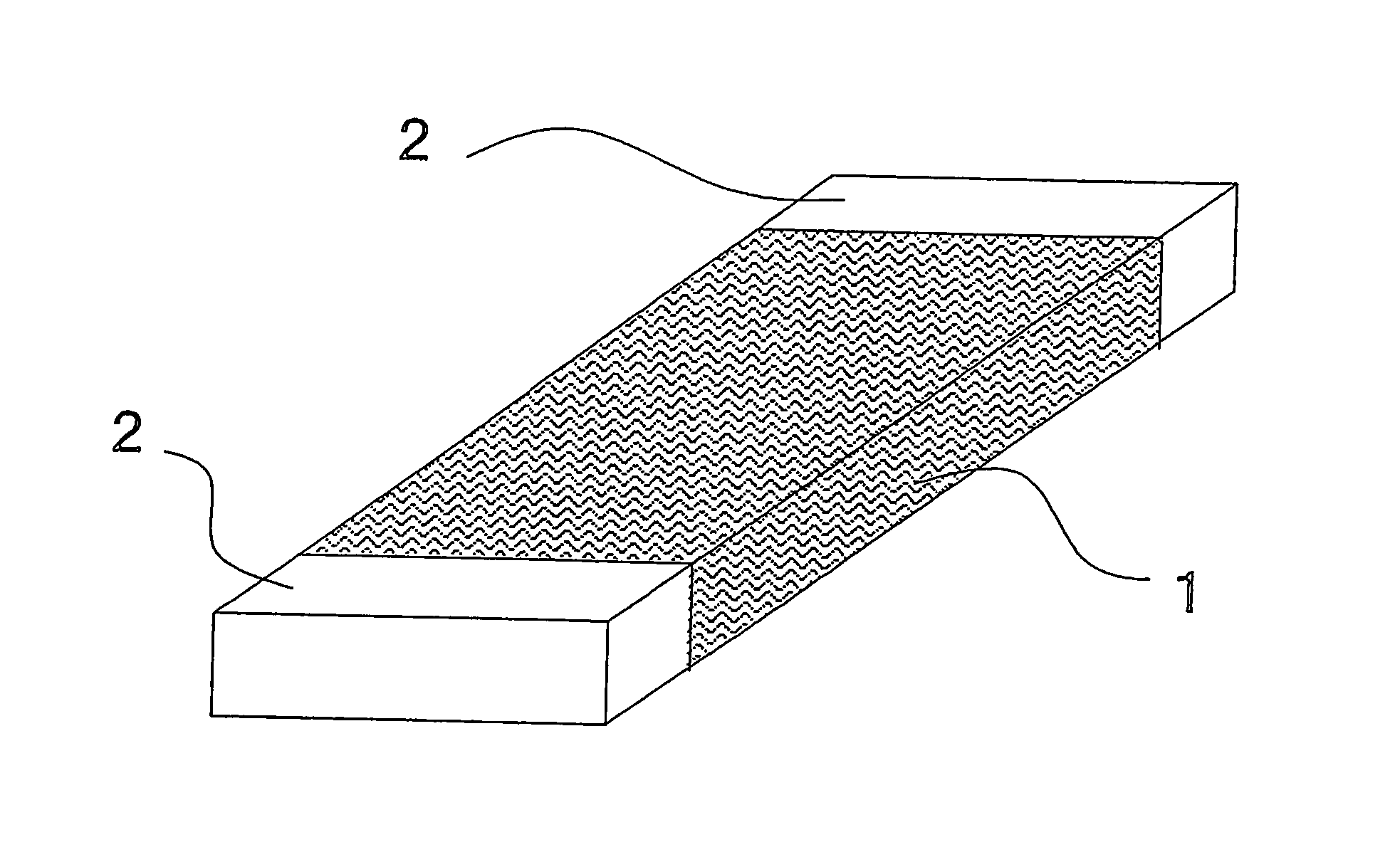

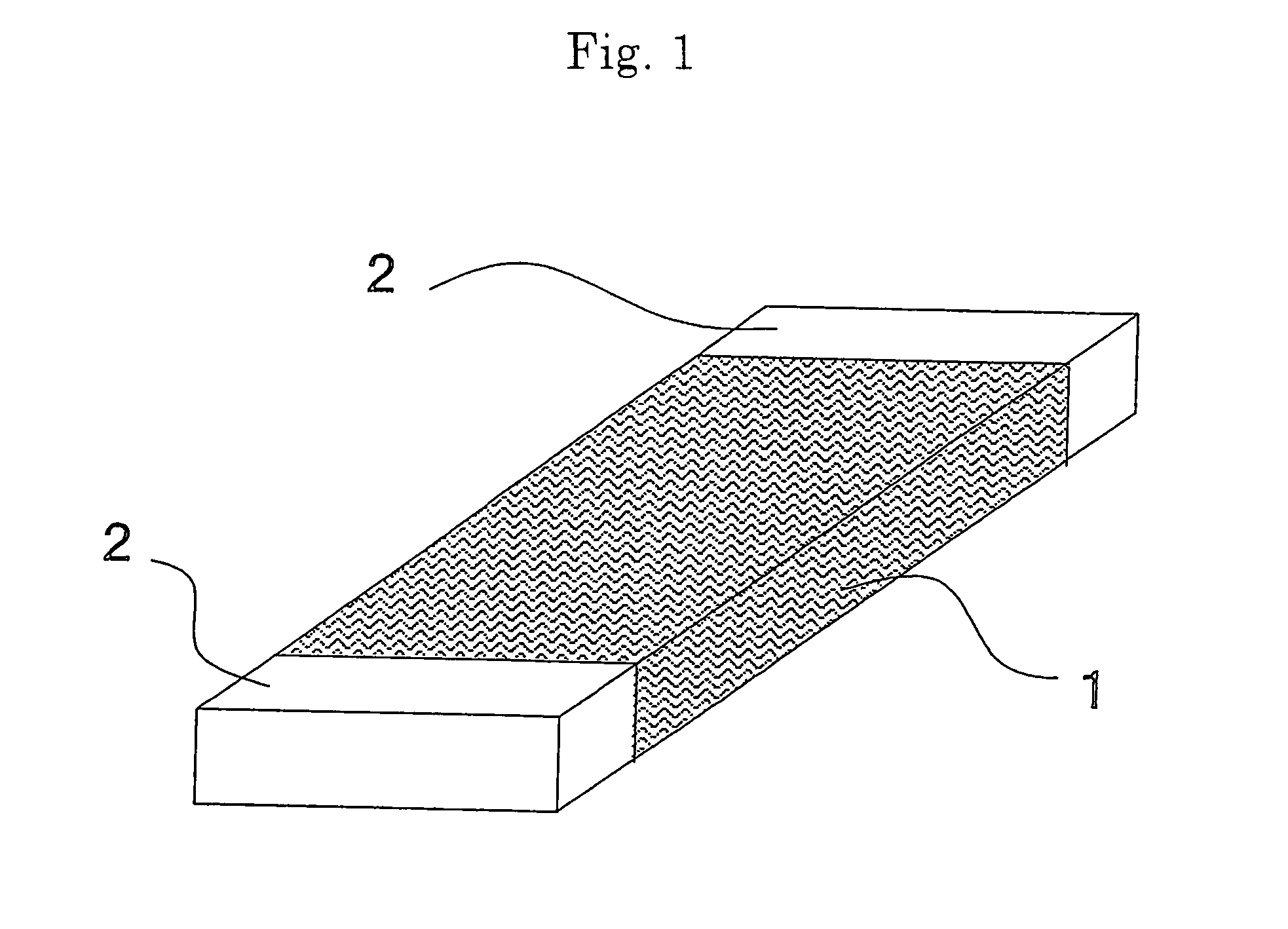

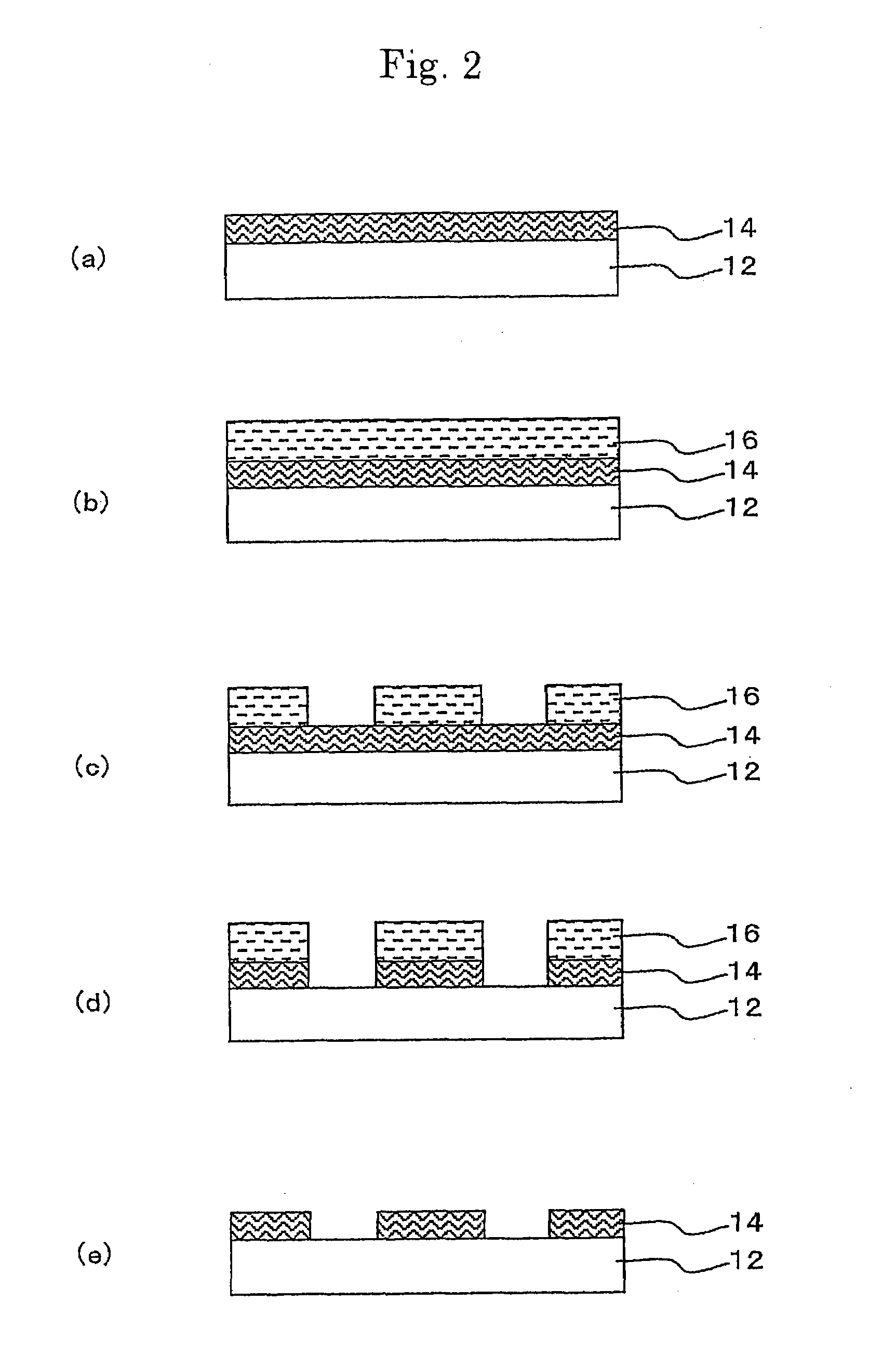

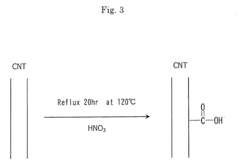

Resistance element, method of manufacturing the same, and thermistor

PatentInactiveUS7217374B2

Innovation

- A carbon nanotube resistance element with a mesh structure formed by cross-linking carbon nanotubes through specific cross-linked sites, using a non-self-polymerizable cross-linking agent to control the resistance value and ensure stability, allowing for microfabrication of desired resistance patterns.

Economic Impact

The economic impact of nichrome's transformation in resistance manufacturing is significant and far-reaching. This alloy, composed primarily of nickel and chromium, has revolutionized the production of heating elements and resistors, leading to substantial cost savings and efficiency improvements across various industries.

In the manufacturing sector, nichrome's unique properties have enabled the production of more durable and reliable heating elements. This has resulted in reduced maintenance costs and extended product lifespans, translating to significant savings for manufacturers and end-users alike. The improved performance of nichrome-based heating elements has also led to energy efficiency gains, contributing to lower operational costs for businesses and reduced environmental impact.

The automotive industry has particularly benefited from nichrome's advancements. Modern vehicles rely heavily on precise temperature control systems, which are often powered by nichrome-based heating elements. The increased reliability and efficiency of these components have contributed to improved fuel economy and reduced emissions, aligning with global efforts to combat climate change and meet stringent environmental regulations.

In the consumer electronics sector, nichrome's transformation has enabled the miniaturization of resistive components. This has facilitated the development of smaller, more energy-efficient devices, driving innovation and creating new market opportunities. The resulting expansion of the consumer electronics market has stimulated economic growth and job creation in related industries.

The aerospace industry has also experienced significant economic benefits from nichrome's advancements. The material's high temperature resistance and stability make it ideal for use in aircraft engines and other critical components. This has led to improved safety, reduced maintenance requirements, and extended service life for aerospace equipment, resulting in substantial cost savings for airlines and aerospace manufacturers.

Furthermore, the nichrome industry itself has seen considerable growth, with increased demand driving investment in research and development. This has led to the creation of high-skilled jobs in materials science, engineering, and manufacturing, contributing to economic development in regions with strong nichrome production capabilities.

The global supply chain for nichrome and related products has also expanded, fostering international trade and economic cooperation. Countries with significant nickel and chromium resources have found new opportunities for economic growth through the export of raw materials or finished nichrome products.

In conclusion, nichrome's transformation of resistance manufacturing has had a profound economic impact, driving innovation, improving efficiency, and creating new market opportunities across multiple industries. As the technology continues to evolve, it is likely to play an increasingly important role in shaping the global economy and advancing sustainable industrial practices.

In the manufacturing sector, nichrome's unique properties have enabled the production of more durable and reliable heating elements. This has resulted in reduced maintenance costs and extended product lifespans, translating to significant savings for manufacturers and end-users alike. The improved performance of nichrome-based heating elements has also led to energy efficiency gains, contributing to lower operational costs for businesses and reduced environmental impact.

The automotive industry has particularly benefited from nichrome's advancements. Modern vehicles rely heavily on precise temperature control systems, which are often powered by nichrome-based heating elements. The increased reliability and efficiency of these components have contributed to improved fuel economy and reduced emissions, aligning with global efforts to combat climate change and meet stringent environmental regulations.

In the consumer electronics sector, nichrome's transformation has enabled the miniaturization of resistive components. This has facilitated the development of smaller, more energy-efficient devices, driving innovation and creating new market opportunities. The resulting expansion of the consumer electronics market has stimulated economic growth and job creation in related industries.

The aerospace industry has also experienced significant economic benefits from nichrome's advancements. The material's high temperature resistance and stability make it ideal for use in aircraft engines and other critical components. This has led to improved safety, reduced maintenance requirements, and extended service life for aerospace equipment, resulting in substantial cost savings for airlines and aerospace manufacturers.

Furthermore, the nichrome industry itself has seen considerable growth, with increased demand driving investment in research and development. This has led to the creation of high-skilled jobs in materials science, engineering, and manufacturing, contributing to economic development in regions with strong nichrome production capabilities.

The global supply chain for nichrome and related products has also expanded, fostering international trade and economic cooperation. Countries with significant nickel and chromium resources have found new opportunities for economic growth through the export of raw materials or finished nichrome products.

In conclusion, nichrome's transformation of resistance manufacturing has had a profound economic impact, driving innovation, improving efficiency, and creating new market opportunities across multiple industries. As the technology continues to evolve, it is likely to play an increasingly important role in shaping the global economy and advancing sustainable industrial practices.

Sustainability Aspects

The sustainability aspects of nichrome in resistance manufacturing are becoming increasingly important as industries strive for more environmentally friendly practices. Nichrome, an alloy of nickel and chromium, offers several advantages in terms of sustainability compared to traditional resistance materials.

One of the key sustainability benefits of nichrome is its durability and longevity. The alloy's high resistance to oxidation and corrosion allows for extended product lifespans, reducing the need for frequent replacements. This longevity contributes to a decrease in overall material consumption and waste generation in the long term. Additionally, the superior heat resistance of nichrome enables it to maintain its properties under high-temperature conditions, further extending its useful life in various applications.

The energy efficiency of nichrome-based resistance elements is another crucial factor in its sustainability profile. Due to its high electrical resistivity, nichrome can generate the required heat output with less energy input compared to some alternative materials. This improved energy efficiency translates to reduced power consumption in heating applications, contributing to lower overall energy demands and associated carbon emissions.

Nichrome's recyclability is a significant advantage from a sustainability perspective. At the end of its life cycle, nichrome components can be recycled and reprocessed, conserving valuable resources and reducing the environmental impact associated with raw material extraction. The recycling process for nichrome is well-established, making it a viable option for closed-loop material systems in manufacturing.

The production of nichrome itself has seen advancements in sustainability. Manufacturers are increasingly adopting cleaner production methods, including the use of renewable energy sources in the manufacturing process and implementing more efficient resource management practices. These improvements help to reduce the carbon footprint associated with nichrome production.

Furthermore, the versatility of nichrome allows for its use in various sustainable technologies. For instance, it plays a crucial role in the development of more efficient heating systems for electric vehicles, contributing to the broader shift towards sustainable transportation. Its application in renewable energy technologies, such as solar thermal systems, also supports the transition to cleaner energy sources.

However, it is important to note that the mining and processing of nickel and chromium, the primary components of nichrome, still have environmental implications. Ongoing research and development efforts are focused on minimizing these impacts through improved mining techniques, more efficient extraction processes, and the exploration of alternative sourcing methods.

One of the key sustainability benefits of nichrome is its durability and longevity. The alloy's high resistance to oxidation and corrosion allows for extended product lifespans, reducing the need for frequent replacements. This longevity contributes to a decrease in overall material consumption and waste generation in the long term. Additionally, the superior heat resistance of nichrome enables it to maintain its properties under high-temperature conditions, further extending its useful life in various applications.

The energy efficiency of nichrome-based resistance elements is another crucial factor in its sustainability profile. Due to its high electrical resistivity, nichrome can generate the required heat output with less energy input compared to some alternative materials. This improved energy efficiency translates to reduced power consumption in heating applications, contributing to lower overall energy demands and associated carbon emissions.

Nichrome's recyclability is a significant advantage from a sustainability perspective. At the end of its life cycle, nichrome components can be recycled and reprocessed, conserving valuable resources and reducing the environmental impact associated with raw material extraction. The recycling process for nichrome is well-established, making it a viable option for closed-loop material systems in manufacturing.

The production of nichrome itself has seen advancements in sustainability. Manufacturers are increasingly adopting cleaner production methods, including the use of renewable energy sources in the manufacturing process and implementing more efficient resource management practices. These improvements help to reduce the carbon footprint associated with nichrome production.

Furthermore, the versatility of nichrome allows for its use in various sustainable technologies. For instance, it plays a crucial role in the development of more efficient heating systems for electric vehicles, contributing to the broader shift towards sustainable transportation. Its application in renewable energy technologies, such as solar thermal systems, also supports the transition to cleaner energy sources.

However, it is important to note that the mining and processing of nickel and chromium, the primary components of nichrome, still have environmental implications. Ongoing research and development efforts are focused on minimizing these impacts through improved mining techniques, more efficient extraction processes, and the exploration of alternative sourcing methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!