How Nichrome Revolutionizes Cooking Appliance Durability?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in Appliances: Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in revolutionizing the durability and efficiency of cooking appliances since its introduction in the early 20th century. The evolution of nichrome in appliance manufacturing represents a significant milestone in the advancement of kitchen technology, marking a shift from traditional materials to more robust and heat-resistant alternatives.

The development of nichrome can be traced back to 1905 when Albert Marsh, an American engineer, patented this groundbreaking alloy. Initially utilized in electrical resistance heating elements, nichrome quickly found its way into various cooking appliances due to its exceptional properties. The primary objective behind the adoption of nichrome was to enhance the longevity and performance of heating elements in devices such as toasters, ovens, and electric stoves.

As the appliance industry progressed, manufacturers recognized the potential of nichrome to address several key challenges in cooking equipment design. The alloy's high melting point, excellent oxidation resistance, and stable electrical properties made it an ideal candidate for improving the durability of heating elements. This led to a gradual shift away from less efficient materials like iron or copper, which were prone to rapid degradation under high-temperature conditions.

The integration of nichrome into cooking appliances aimed to achieve multiple technical objectives. Firstly, it sought to extend the operational lifespan of heating elements, reducing the frequency of replacements and repairs. Secondly, nichrome's superior heat distribution properties enabled more uniform cooking temperatures, enhancing the overall cooking experience for consumers. Lastly, the alloy's resistance to corrosion and oxidation at high temperatures contributed to improved safety standards in kitchen appliances.

Throughout the 20th century, ongoing research and development efforts focused on optimizing the composition and manufacturing processes of nichrome for specific appliance applications. This continuous evolution led to the creation of various grades of nichrome, each tailored to meet the unique requirements of different cooking devices. The trend towards energy efficiency in recent decades has further propelled the refinement of nichrome-based heating elements, aligning with global sustainability goals.

Today, the objectives for nichrome in cooking appliances have expanded beyond mere durability. Modern appliance manufacturers are exploring ways to leverage nichrome's properties to create smarter, more responsive heating systems. This includes the development of precision-controlled heating elements that can rapidly adjust temperatures, contributing to more sophisticated cooking technologies and improved energy management in household appliances.

The development of nichrome can be traced back to 1905 when Albert Marsh, an American engineer, patented this groundbreaking alloy. Initially utilized in electrical resistance heating elements, nichrome quickly found its way into various cooking appliances due to its exceptional properties. The primary objective behind the adoption of nichrome was to enhance the longevity and performance of heating elements in devices such as toasters, ovens, and electric stoves.

As the appliance industry progressed, manufacturers recognized the potential of nichrome to address several key challenges in cooking equipment design. The alloy's high melting point, excellent oxidation resistance, and stable electrical properties made it an ideal candidate for improving the durability of heating elements. This led to a gradual shift away from less efficient materials like iron or copper, which were prone to rapid degradation under high-temperature conditions.

The integration of nichrome into cooking appliances aimed to achieve multiple technical objectives. Firstly, it sought to extend the operational lifespan of heating elements, reducing the frequency of replacements and repairs. Secondly, nichrome's superior heat distribution properties enabled more uniform cooking temperatures, enhancing the overall cooking experience for consumers. Lastly, the alloy's resistance to corrosion and oxidation at high temperatures contributed to improved safety standards in kitchen appliances.

Throughout the 20th century, ongoing research and development efforts focused on optimizing the composition and manufacturing processes of nichrome for specific appliance applications. This continuous evolution led to the creation of various grades of nichrome, each tailored to meet the unique requirements of different cooking devices. The trend towards energy efficiency in recent decades has further propelled the refinement of nichrome-based heating elements, aligning with global sustainability goals.

Today, the objectives for nichrome in cooking appliances have expanded beyond mere durability. Modern appliance manufacturers are exploring ways to leverage nichrome's properties to create smarter, more responsive heating systems. This includes the development of precision-controlled heating elements that can rapidly adjust temperatures, contributing to more sophisticated cooking technologies and improved energy management in household appliances.

Market Demand for Durable Cooking Appliances

The market demand for durable cooking appliances has been steadily increasing in recent years, driven by several key factors. Consumers are increasingly seeking appliances that offer long-term reliability and value for money, recognizing that investing in durable products can lead to significant cost savings over time. This trend is particularly evident in the kitchen appliance sector, where frequent use and exposure to high temperatures make durability a critical factor.

The growing focus on sustainability and environmental consciousness has also contributed to the demand for more durable cooking appliances. Consumers are becoming more aware of the environmental impact of disposable or short-lived products, leading to a preference for appliances that have a longer lifespan and reduce waste. This shift in consumer behavior has prompted manufacturers to prioritize durability in their product design and marketing strategies.

In the commercial sector, the demand for durable cooking appliances is even more pronounced. Restaurants, hotels, and other food service establishments require equipment that can withstand continuous, heavy-duty use while maintaining consistent performance. The high cost of equipment downtime and replacement in commercial kitchens makes durability a top priority for these businesses.

The rise of smart home technology has also influenced the market for durable cooking appliances. Consumers are looking for appliances that not only last longer but also integrate seamlessly with their connected home ecosystems. This has led to the development of more sophisticated, durable appliances that incorporate advanced materials and technologies to enhance both longevity and functionality.

Market research indicates that the global durable cookware market is expected to grow significantly in the coming years. This growth is attributed to factors such as increasing disposable income, changing lifestyles, and a growing appreciation for high-quality kitchen equipment. The market is seeing a particular surge in demand for premium, long-lasting cooking appliances made with advanced materials like nichrome.

The COVID-19 pandemic has further accelerated the demand for durable cooking appliances. With more people cooking at home and investing in their kitchen spaces, there has been a notable increase in purchases of high-quality, long-lasting cooking equipment. This trend is expected to continue even as pandemic restrictions ease, as many consumers have developed new cooking habits and preferences for home-prepared meals.

Manufacturers are responding to this market demand by investing in research and development to improve the durability of their products. This includes exploring new materials, such as advanced alloys and coatings, as well as innovative design techniques that enhance the longevity of cooking appliances. The use of nichrome in heating elements, for example, has become a key selling point for many manufacturers, highlighting its superior durability and heat resistance properties.

The growing focus on sustainability and environmental consciousness has also contributed to the demand for more durable cooking appliances. Consumers are becoming more aware of the environmental impact of disposable or short-lived products, leading to a preference for appliances that have a longer lifespan and reduce waste. This shift in consumer behavior has prompted manufacturers to prioritize durability in their product design and marketing strategies.

In the commercial sector, the demand for durable cooking appliances is even more pronounced. Restaurants, hotels, and other food service establishments require equipment that can withstand continuous, heavy-duty use while maintaining consistent performance. The high cost of equipment downtime and replacement in commercial kitchens makes durability a top priority for these businesses.

The rise of smart home technology has also influenced the market for durable cooking appliances. Consumers are looking for appliances that not only last longer but also integrate seamlessly with their connected home ecosystems. This has led to the development of more sophisticated, durable appliances that incorporate advanced materials and technologies to enhance both longevity and functionality.

Market research indicates that the global durable cookware market is expected to grow significantly in the coming years. This growth is attributed to factors such as increasing disposable income, changing lifestyles, and a growing appreciation for high-quality kitchen equipment. The market is seeing a particular surge in demand for premium, long-lasting cooking appliances made with advanced materials like nichrome.

The COVID-19 pandemic has further accelerated the demand for durable cooking appliances. With more people cooking at home and investing in their kitchen spaces, there has been a notable increase in purchases of high-quality, long-lasting cooking equipment. This trend is expected to continue even as pandemic restrictions ease, as many consumers have developed new cooking habits and preferences for home-prepared meals.

Manufacturers are responding to this market demand by investing in research and development to improve the durability of their products. This includes exploring new materials, such as advanced alloys and coatings, as well as innovative design techniques that enhance the longevity of cooking appliances. The use of nichrome in heating elements, for example, has become a key selling point for many manufacturers, highlighting its superior durability and heat resistance properties.

Nichrome Technology: Current State and Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has become a cornerstone in the development of durable cooking appliances. The current state of nichrome technology in this field is characterized by its widespread adoption and continuous refinement. Manufacturers have embraced nichrome for its exceptional heat resistance, corrosion resistance, and electrical conductivity, making it an ideal material for heating elements in a variety of cooking appliances.

One of the primary challenges in the application of nichrome technology is achieving the optimal balance between durability and performance. While nichrome offers superior longevity compared to many alternative materials, there is an ongoing effort to extend its lifespan even further, particularly in high-temperature environments. Researchers are exploring ways to enhance the alloy's composition and structure to improve its resistance to oxidation and thermal fatigue, which are common issues in cooking appliances.

Another significant challenge lies in the manufacturing process of nichrome components. Precision in production is crucial to ensure consistent performance and longevity across different appliances. Manufacturers are investing in advanced production techniques, such as improved wire drawing and coating processes, to enhance the quality and uniformity of nichrome heating elements.

The integration of nichrome technology with smart cooking systems presents both opportunities and challenges. As cooking appliances become more sophisticated, incorporating features like precise temperature control and remote operation, the demands on heating elements increase. Engineers are working to develop nichrome-based systems that can respond quickly to temperature changes and maintain accuracy over extended periods.

Cost considerations remain a persistent challenge in nichrome technology. While the material's durability often justifies its higher initial cost, there is constant pressure to optimize production processes and reduce expenses without compromising quality. This has led to research into alternative alloy compositions that might offer similar properties at a lower cost.

Environmental concerns are also shaping the current state and future direction of nichrome technology in cooking appliances. There is a growing focus on developing more energy-efficient heating elements and exploring recycling methods for nichrome components at the end of their lifecycle. This aligns with broader industry trends towards sustainability and responsible resource management.

In terms of geographical distribution, the development and production of nichrome technology for cooking appliances are concentrated in regions with advanced manufacturing capabilities, particularly in East Asia, North America, and Europe. However, emerging markets are increasingly becoming involved in both production and consumption, driving innovation in cost-effective applications of nichrome technology.

One of the primary challenges in the application of nichrome technology is achieving the optimal balance between durability and performance. While nichrome offers superior longevity compared to many alternative materials, there is an ongoing effort to extend its lifespan even further, particularly in high-temperature environments. Researchers are exploring ways to enhance the alloy's composition and structure to improve its resistance to oxidation and thermal fatigue, which are common issues in cooking appliances.

Another significant challenge lies in the manufacturing process of nichrome components. Precision in production is crucial to ensure consistent performance and longevity across different appliances. Manufacturers are investing in advanced production techniques, such as improved wire drawing and coating processes, to enhance the quality and uniformity of nichrome heating elements.

The integration of nichrome technology with smart cooking systems presents both opportunities and challenges. As cooking appliances become more sophisticated, incorporating features like precise temperature control and remote operation, the demands on heating elements increase. Engineers are working to develop nichrome-based systems that can respond quickly to temperature changes and maintain accuracy over extended periods.

Cost considerations remain a persistent challenge in nichrome technology. While the material's durability often justifies its higher initial cost, there is constant pressure to optimize production processes and reduce expenses without compromising quality. This has led to research into alternative alloy compositions that might offer similar properties at a lower cost.

Environmental concerns are also shaping the current state and future direction of nichrome technology in cooking appliances. There is a growing focus on developing more energy-efficient heating elements and exploring recycling methods for nichrome components at the end of their lifecycle. This aligns with broader industry trends towards sustainability and responsible resource management.

In terms of geographical distribution, the development and production of nichrome technology for cooking appliances are concentrated in regions with advanced manufacturing capabilities, particularly in East Asia, North America, and Europe. However, emerging markets are increasingly becoming involved in both production and consumption, driving innovation in cost-effective applications of nichrome technology.

Existing Nichrome Applications in Cooking Appliances

01 Composition and structure optimization

Improving the durability of nichrome involves optimizing its composition and structure. This can include adjusting the ratio of nickel to chromium, adding other alloying elements, or modifying the microstructure through heat treatment or manufacturing processes. These modifications can enhance the material's resistance to oxidation, corrosion, and mechanical stress, thereby increasing its overall durability and lifespan.- Composition and structure optimization: Improving the durability of nichrome involves optimizing its composition and structure. This can include adjusting the ratio of nickel to chromium, adding other alloying elements, or modifying the microstructure through heat treatment or manufacturing processes. These modifications can enhance the material's resistance to oxidation, corrosion, and mechanical stress, thereby increasing its overall durability and lifespan.

- Surface treatment and coating: Applying surface treatments or protective coatings to nichrome can significantly improve its durability. These treatments may include oxidation-resistant coatings, ceramic layers, or other protective materials that shield the nichrome from harsh environments. Such coatings can enhance the material's resistance to high temperatures, corrosive substances, and wear, extending its service life in various applications.

- Environmental control and protection: Controlling the environment in which nichrome is used can greatly impact its durability. This may involve regulating temperature, humidity, or atmospheric composition to minimize oxidation and corrosion. Additionally, implementing protective measures such as encapsulation or using inert gas atmospheres can shield nichrome from harmful elements, thereby preserving its properties and extending its lifespan.

- Design optimization for stress distribution: Optimizing the design of nichrome components can improve their durability by ensuring better stress distribution and reducing localized wear. This may involve computer-aided design and simulation to identify and mitigate stress concentrations, as well as incorporating features that enhance the component's resistance to fatigue, creep, and other failure modes associated with long-term use under challenging conditions.

- Manufacturing process improvements: Enhancing the manufacturing processes used to produce nichrome components can lead to improved durability. This may include refining casting or forming techniques, implementing advanced heat treatment protocols, or utilizing precision machining methods. By optimizing these processes, the resulting nichrome products can exhibit superior microstructure, reduced defects, and enhanced mechanical properties, all contributing to increased durability.

02 Surface treatment and coating

Applying surface treatments or protective coatings to nichrome can significantly improve its durability. These treatments may include oxidation-resistant coatings, ceramic layers, or other specialized materials that protect the underlying nichrome from environmental factors and wear. Such coatings can extend the life of nichrome components, particularly in high-temperature or corrosive environments.Expand Specific Solutions03 Application-specific design

Enhancing nichrome durability often involves designing components specifically for their intended application. This can include optimizing the thickness, shape, or configuration of nichrome elements to distribute stress, improve heat dissipation, or reduce exposure to corrosive agents. By tailoring the design to the specific operating conditions, the overall durability and performance of nichrome components can be significantly improved.Expand Specific Solutions04 Environmental control and protection

Controlling the environment in which nichrome operates can greatly enhance its durability. This may involve using protective atmospheres, implementing temperature control systems, or employing methods to reduce exposure to corrosive elements. By managing the operating conditions, the degradation of nichrome can be slowed, extending its useful life and maintaining its performance characteristics over time.Expand Specific Solutions05 Maintenance and monitoring techniques

Developing effective maintenance and monitoring techniques can significantly improve the long-term durability of nichrome components. This includes implementing regular inspection schedules, using advanced diagnostic tools to detect early signs of wear or damage, and applying preventive maintenance procedures. By identifying and addressing potential issues before they become critical, the overall lifespan and reliability of nichrome elements can be extended.Expand Specific Solutions

Key Players in Nichrome and Appliance Manufacturing

The market for nichrome in cooking appliance durability is in a growth phase, driven by increasing demand for high-performance kitchen equipment. The global market size is expanding, with key players like SEB SA, BSH Hausgeräte GmbH, and Midea Group Co. Ltd. leading innovation. Technologically, nichrome applications are mature but evolving, with companies like Joyoung Co., Ltd. and Panasonic Holdings Corp. investing in R&D to enhance durability and energy efficiency. Emerging players such as Clad Metals LLC and Yancheng Xinyang Electric Heating Material Co., Ltd. are also contributing to market diversification and technological advancements in nichrome-based cooking appliances.

SEB SA

Technical Solution: SEB SA has developed advanced nichrome-based heating elements for their cooking appliances, incorporating a proprietary alloy composition that enhances durability and heat distribution. Their technology involves a multi-layer coating process that protects the nichrome core from oxidation and corrosion, significantly extending the lifespan of their products[1]. SEB's nichrome elements are designed to maintain consistent performance over time, with minimal degradation in heating efficiency. The company has also implemented a precision control system that regulates power input to the nichrome elements, reducing thermal stress and further improving longevity[3].

Strengths: Enhanced durability, improved heat distribution, and consistent performance. Weaknesses: Potentially higher production costs and complexity in manufacturing process.

Clad Metals LLC

Technical Solution: Clad Metals LLC has pioneered a unique approach to nichrome integration in cooking appliances by developing a clad metal composite that incorporates nichrome as a core material. This technology sandwiches a nichrome layer between two layers of highly conductive metals, creating a tri-ply structure that combines the durability and heating properties of nichrome with improved heat distribution[9]. The company's process involves precision bonding techniques that ensure the integrity of the layered structure under repeated thermal cycling. Clad Metals has also developed specialized edge treatments for their composite materials, preventing delamination and enhancing the overall lifespan of the heating elements[10].

Strengths: Excellent heat distribution, reduced hot spots, and improved overall durability. Weaknesses: Higher material costs and potential limitations in forming complex shapes.

Core Innovations in Nichrome Alloy Composition

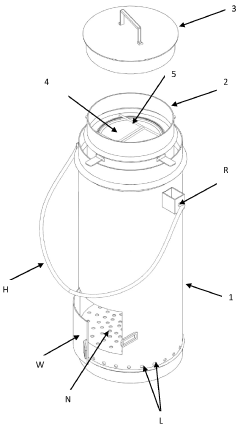

Gas fire ember element

PatentInactiveUS20100151398A1

Innovation

- Employing a bundle of heat and oxidation-resistant metal wires, such as Fecralloy or Nichrome, with specific cross-sectional areas and densities, which are ductile and can be formed into bundles or hollow structures to allow gas passage, providing a natural and cheerful glowing appearance by incandescing fibers.

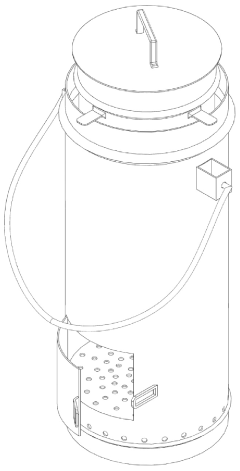

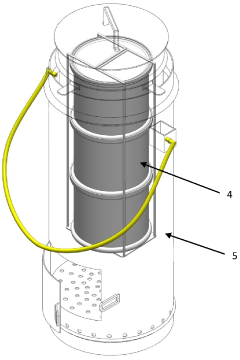

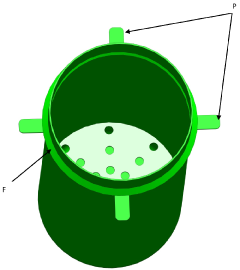

A portable cooker cum stove for cooking

PatentActiveIN201611007664A

Innovation

- A portable cooker cum stove utilizing biomass waste for fuel, featuring a combustion chamber with a secondary air supply system and a design allowing for simultaneous cooking of multiple dishes with minimal ash and smoke production.

Environmental Impact of Nichrome in Appliances

The environmental impact of nichrome in cooking appliances is a crucial consideration in the context of sustainability and eco-friendly manufacturing. Nichrome, an alloy primarily composed of nickel and chromium, has become a staple material in heating elements due to its excellent durability and heat resistance. However, its widespread use in cooking appliances raises important questions about its long-term environmental effects.

One of the primary environmental concerns associated with nichrome is the energy consumption during its production process. The extraction and refining of nickel and chromium, the main components of nichrome, require significant energy inputs, contributing to greenhouse gas emissions. Additionally, the manufacturing process of nichrome wire involves high-temperature treatments, further increasing the carbon footprint of the material.

On the positive side, the durability of nichrome in cooking appliances leads to extended product lifespans, potentially reducing the frequency of appliance replacements. This longevity can result in fewer discarded appliances, mitigating the environmental impact associated with electronic waste. The reduced need for replacement also translates to lower resource consumption and manufacturing emissions over time.

The recyclability of nichrome is another important factor to consider. While the alloy itself is recyclable, the process of separating it from other components in cooking appliances can be complex and energy-intensive. This complexity may lead to lower recycling rates for nichrome-containing appliances, potentially increasing the amount of material that ends up in landfills.

In terms of in-use environmental impact, nichrome's efficiency in converting electrical energy to heat helps reduce energy consumption during cooking. This improved efficiency can lead to lower electricity usage and, consequently, reduced carbon emissions from power generation. However, the potential release of nickel and chromium particles during the appliance's lifetime raises concerns about air and soil contamination.

The end-of-life disposal of nichrome-containing appliances presents another environmental challenge. Improper disposal can lead to the leaching of nickel and chromium into soil and water systems, potentially causing harm to ecosystems and human health. This risk underscores the importance of developing effective recycling and disposal protocols for appliances containing nichrome elements.

As the focus on environmental sustainability grows, manufacturers are exploring alternatives to nichrome that may offer similar performance with reduced environmental impact. These efforts include research into more easily recyclable materials and the development of heating elements that require less energy-intensive production processes.

In conclusion, while nichrome has revolutionized the durability of cooking appliances, its environmental impact is complex and multifaceted. Balancing the benefits of increased product longevity against the environmental costs of production and disposal remains a key challenge for the appliance industry. Future innovations in material science and manufacturing processes will be crucial in addressing these environmental concerns while maintaining the performance benefits that nichrome provides.

One of the primary environmental concerns associated with nichrome is the energy consumption during its production process. The extraction and refining of nickel and chromium, the main components of nichrome, require significant energy inputs, contributing to greenhouse gas emissions. Additionally, the manufacturing process of nichrome wire involves high-temperature treatments, further increasing the carbon footprint of the material.

On the positive side, the durability of nichrome in cooking appliances leads to extended product lifespans, potentially reducing the frequency of appliance replacements. This longevity can result in fewer discarded appliances, mitigating the environmental impact associated with electronic waste. The reduced need for replacement also translates to lower resource consumption and manufacturing emissions over time.

The recyclability of nichrome is another important factor to consider. While the alloy itself is recyclable, the process of separating it from other components in cooking appliances can be complex and energy-intensive. This complexity may lead to lower recycling rates for nichrome-containing appliances, potentially increasing the amount of material that ends up in landfills.

In terms of in-use environmental impact, nichrome's efficiency in converting electrical energy to heat helps reduce energy consumption during cooking. This improved efficiency can lead to lower electricity usage and, consequently, reduced carbon emissions from power generation. However, the potential release of nickel and chromium particles during the appliance's lifetime raises concerns about air and soil contamination.

The end-of-life disposal of nichrome-containing appliances presents another environmental challenge. Improper disposal can lead to the leaching of nickel and chromium into soil and water systems, potentially causing harm to ecosystems and human health. This risk underscores the importance of developing effective recycling and disposal protocols for appliances containing nichrome elements.

As the focus on environmental sustainability grows, manufacturers are exploring alternatives to nichrome that may offer similar performance with reduced environmental impact. These efforts include research into more easily recyclable materials and the development of heating elements that require less energy-intensive production processes.

In conclusion, while nichrome has revolutionized the durability of cooking appliances, its environmental impact is complex and multifaceted. Balancing the benefits of increased product longevity against the environmental costs of production and disposal remains a key challenge for the appliance industry. Future innovations in material science and manufacturing processes will be crucial in addressing these environmental concerns while maintaining the performance benefits that nichrome provides.

Safety Standards for Nichrome in Cooking Appliances

The implementation of safety standards for Nichrome in cooking appliances is crucial to ensure consumer protection and maintain industry credibility. These standards encompass various aspects of design, manufacturing, and usage to mitigate potential risks associated with Nichrome heating elements.

One of the primary safety considerations is the prevention of electrical hazards. Standards typically require proper insulation and grounding of Nichrome elements to prevent electric shock. This includes specifications for wire gauge, insulation materials, and connection methods that can withstand the high temperatures generated during operation.

Thermal management is another critical aspect of safety standards. Guidelines often stipulate maximum operating temperatures for Nichrome elements and surrounding components to prevent overheating and fire risks. This may involve the incorporation of thermal cutoff switches or temperature sensors that automatically shut down the appliance if unsafe temperatures are detected.

Mechanical integrity standards are also essential to ensure the durability of Nichrome elements under repeated thermal cycling. These standards may specify minimum tensile strength, elongation properties, and resistance to corrosion to prevent premature failure or breakage of the heating elements.

Safety standards also address the potential release of harmful substances. Nichrome alloys must comply with regulations regarding the emission of toxic fumes or particles when heated. This often involves testing procedures to verify that no hazardous materials are released during normal operation or in the event of element failure.

Electromagnetic compatibility (EMC) is another area covered by safety standards. Nichrome-based appliances must not generate electromagnetic interference that could affect other electronic devices, nor should they be susceptible to external electromagnetic fields that could compromise their operation.

To ensure compliance with these standards, manufacturers are typically required to undergo rigorous testing and certification processes. This may include thermal cycling tests, dielectric strength tests, and long-term reliability assessments. Third-party certification bodies often conduct these tests and issue safety marks or certifications that indicate compliance with relevant standards.

Regular updates to safety standards are necessary to keep pace with technological advancements and emerging risks. Industry stakeholders, regulatory bodies, and consumer advocacy groups collaborate to revise and enhance these standards periodically, ensuring that they remain relevant and effective in protecting users of Nichrome-equipped cooking appliances.

One of the primary safety considerations is the prevention of electrical hazards. Standards typically require proper insulation and grounding of Nichrome elements to prevent electric shock. This includes specifications for wire gauge, insulation materials, and connection methods that can withstand the high temperatures generated during operation.

Thermal management is another critical aspect of safety standards. Guidelines often stipulate maximum operating temperatures for Nichrome elements and surrounding components to prevent overheating and fire risks. This may involve the incorporation of thermal cutoff switches or temperature sensors that automatically shut down the appliance if unsafe temperatures are detected.

Mechanical integrity standards are also essential to ensure the durability of Nichrome elements under repeated thermal cycling. These standards may specify minimum tensile strength, elongation properties, and resistance to corrosion to prevent premature failure or breakage of the heating elements.

Safety standards also address the potential release of harmful substances. Nichrome alloys must comply with regulations regarding the emission of toxic fumes or particles when heated. This often involves testing procedures to verify that no hazardous materials are released during normal operation or in the event of element failure.

Electromagnetic compatibility (EMC) is another area covered by safety standards. Nichrome-based appliances must not generate electromagnetic interference that could affect other electronic devices, nor should they be susceptible to external electromagnetic fields that could compromise their operation.

To ensure compliance with these standards, manufacturers are typically required to undergo rigorous testing and certification processes. This may include thermal cycling tests, dielectric strength tests, and long-term reliability assessments. Third-party certification bodies often conduct these tests and issue safety marks or certifications that indicate compliance with relevant standards.

Regular updates to safety standards are necessary to keep pace with technological advancements and emerging risks. Industry stakeholders, regulatory bodies, and consumer advocacy groups collaborate to revise and enhance these standards periodically, ensuring that they remain relevant and effective in protecting users of Nichrome-equipped cooking appliances.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!