How Nichrome Wire Contributes to Modern Substation Design?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Wire Evolution

Nichrome wire has undergone significant evolution since its invention in the early 20th century, playing an increasingly crucial role in modern substation design. Initially developed as a resistance alloy for heating elements, nichrome's unique properties have led to its adoption in various electrical applications, including substations.

The evolution of nichrome wire in substation design can be traced through several key stages. In the early days of electrical power distribution, substations relied primarily on copper and aluminum conductors. However, as power demands increased and substation designs became more complex, the need for materials with specific electrical and thermal properties grew.

During the mid-20th century, nichrome wire began to find its place in substation equipment, particularly in resistive components and heating elements. Its high resistance to oxidation and corrosion, coupled with its ability to withstand high temperatures, made it an ideal choice for applications where reliability and longevity were paramount.

As substation technology advanced, so did the applications of nichrome wire. In the 1970s and 1980s, the increasing focus on energy efficiency and power quality led to the development of more sophisticated substation equipment. Nichrome wire found new uses in voltage regulators, power factor correction devices, and harmonic filters, where its stable resistance characteristics across a wide temperature range proved invaluable.

The digital age brought about another significant shift in substation design, with the integration of smart grid technologies and advanced monitoring systems. Nichrome wire adapted to these changes, finding applications in precision sensing devices and calibration equipment within substations. Its consistent electrical properties made it ideal for creating accurate reference standards and measurement devices.

In recent years, the push for more compact and efficient substation designs has further expanded the role of nichrome wire. Its use in miniaturized components and high-power density applications has allowed for the development of smaller, more efficient substation equipment. Additionally, the growing emphasis on renewable energy integration has created new challenges in substation design, where nichrome wire's unique properties continue to prove beneficial in managing variable power flows and maintaining grid stability.

The evolution of nichrome wire in substation design reflects broader trends in electrical engineering and power distribution. From its humble beginnings as a heating element material to its current status as a versatile component in advanced substation equipment, nichrome wire has consistently adapted to meet the changing needs of the electrical industry. As substations continue to evolve towards smarter, more efficient designs, nichrome wire is likely to remain a key material, with ongoing research and development potentially unlocking new applications and improvements in its performance characteristics.

The evolution of nichrome wire in substation design can be traced through several key stages. In the early days of electrical power distribution, substations relied primarily on copper and aluminum conductors. However, as power demands increased and substation designs became more complex, the need for materials with specific electrical and thermal properties grew.

During the mid-20th century, nichrome wire began to find its place in substation equipment, particularly in resistive components and heating elements. Its high resistance to oxidation and corrosion, coupled with its ability to withstand high temperatures, made it an ideal choice for applications where reliability and longevity were paramount.

As substation technology advanced, so did the applications of nichrome wire. In the 1970s and 1980s, the increasing focus on energy efficiency and power quality led to the development of more sophisticated substation equipment. Nichrome wire found new uses in voltage regulators, power factor correction devices, and harmonic filters, where its stable resistance characteristics across a wide temperature range proved invaluable.

The digital age brought about another significant shift in substation design, with the integration of smart grid technologies and advanced monitoring systems. Nichrome wire adapted to these changes, finding applications in precision sensing devices and calibration equipment within substations. Its consistent electrical properties made it ideal for creating accurate reference standards and measurement devices.

In recent years, the push for more compact and efficient substation designs has further expanded the role of nichrome wire. Its use in miniaturized components and high-power density applications has allowed for the development of smaller, more efficient substation equipment. Additionally, the growing emphasis on renewable energy integration has created new challenges in substation design, where nichrome wire's unique properties continue to prove beneficial in managing variable power flows and maintaining grid stability.

The evolution of nichrome wire in substation design reflects broader trends in electrical engineering and power distribution. From its humble beginnings as a heating element material to its current status as a versatile component in advanced substation equipment, nichrome wire has consistently adapted to meet the changing needs of the electrical industry. As substations continue to evolve towards smarter, more efficient designs, nichrome wire is likely to remain a key material, with ongoing research and development potentially unlocking new applications and improvements in its performance characteristics.

Substation Market Trends

The substation market is experiencing significant growth and transformation, driven by the increasing demand for reliable electricity distribution and the integration of renewable energy sources. The global substation market is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2021 to 2026, reaching a value of $170.5 billion by the end of the forecast period. This growth is primarily attributed to the rising investments in power infrastructure modernization and the need for efficient energy transmission systems.

One of the key trends shaping the substation market is the shift towards digital substations. These advanced facilities leverage intelligent electronic devices (IEDs), communication networks, and automation systems to enhance operational efficiency and reliability. The adoption of digital substations is expected to reduce maintenance costs, improve grid stability, and enable real-time monitoring and control of power distribution networks.

Another significant trend is the increasing focus on renewable energy integration. As countries worldwide aim to reduce their carbon footprint and meet sustainability goals, there is a growing need for substations capable of handling the intermittent nature of renewable energy sources. This has led to the development of flexible and adaptive substation designs that can efficiently manage the variability of renewable power generation.

The substation market is also witnessing a surge in demand for gas-insulated substations (GIS). These compact and space-efficient solutions are particularly popular in urban areas where land availability is limited. GIS offers advantages such as reduced footprint, enhanced safety, and improved reliability, making them an attractive option for both new installations and substation upgrades.

In terms of regional trends, Asia Pacific is expected to dominate the substation market growth, driven by rapid urbanization, industrialization, and government initiatives to expand and modernize power infrastructure. Countries like China and India are investing heavily in smart grid technologies and renewable energy projects, creating substantial opportunities for substation manufacturers and service providers.

The market is also seeing increased adoption of modular and prefabricated substation solutions. These pre-engineered systems offer faster deployment, reduced on-site construction time, and improved quality control. The modular approach is particularly beneficial for remote locations and temporary power requirements, providing flexibility and scalability to meet evolving energy needs.

As the substation market continues to evolve, there is a growing emphasis on cybersecurity measures to protect critical power infrastructure from potential cyber threats. This has led to the development of advanced security protocols and the integration of robust cybersecurity features into substation designs, ensuring the resilience and reliability of power distribution networks.

One of the key trends shaping the substation market is the shift towards digital substations. These advanced facilities leverage intelligent electronic devices (IEDs), communication networks, and automation systems to enhance operational efficiency and reliability. The adoption of digital substations is expected to reduce maintenance costs, improve grid stability, and enable real-time monitoring and control of power distribution networks.

Another significant trend is the increasing focus on renewable energy integration. As countries worldwide aim to reduce their carbon footprint and meet sustainability goals, there is a growing need for substations capable of handling the intermittent nature of renewable energy sources. This has led to the development of flexible and adaptive substation designs that can efficiently manage the variability of renewable power generation.

The substation market is also witnessing a surge in demand for gas-insulated substations (GIS). These compact and space-efficient solutions are particularly popular in urban areas where land availability is limited. GIS offers advantages such as reduced footprint, enhanced safety, and improved reliability, making them an attractive option for both new installations and substation upgrades.

In terms of regional trends, Asia Pacific is expected to dominate the substation market growth, driven by rapid urbanization, industrialization, and government initiatives to expand and modernize power infrastructure. Countries like China and India are investing heavily in smart grid technologies and renewable energy projects, creating substantial opportunities for substation manufacturers and service providers.

The market is also seeing increased adoption of modular and prefabricated substation solutions. These pre-engineered systems offer faster deployment, reduced on-site construction time, and improved quality control. The modular approach is particularly beneficial for remote locations and temporary power requirements, providing flexibility and scalability to meet evolving energy needs.

As the substation market continues to evolve, there is a growing emphasis on cybersecurity measures to protect critical power infrastructure from potential cyber threats. This has led to the development of advanced security protocols and the integration of robust cybersecurity features into substation designs, ensuring the resilience and reliability of power distribution networks.

Nichrome Challenges

Despite the widespread use of nichrome wire in modern substation design, several challenges persist in its application. One of the primary concerns is the wire's susceptibility to oxidation at high temperatures. When exposed to elevated temperatures for extended periods, nichrome wire can form an oxide layer on its surface, potentially affecting its electrical properties and overall performance.

Another significant challenge is the potential for mechanical stress and fatigue. Nichrome wire in substations often undergoes thermal cycling, expanding and contracting as it heats up and cools down. This repeated stress can lead to material fatigue over time, potentially causing wire breakage or reduced efficiency.

The cost of nichrome wire is also a consideration in substation design. While it offers excellent resistance properties, nichrome is more expensive than some alternative materials. This cost factor can impact the overall budget of substation projects, especially in large-scale implementations.

Maintaining consistent electrical properties across different batches of nichrome wire can be challenging. Slight variations in composition or manufacturing processes can lead to differences in resistance and temperature coefficients, potentially affecting the precision of electrical systems in substations.

Environmental concerns also pose challenges. The production and disposal of nichrome wire involve processes that may have environmental implications. As sustainability becomes increasingly important in infrastructure design, finding more eco-friendly alternatives or improving the lifecycle management of nichrome wire is a growing concern.

The integration of nichrome wire with other materials and components in modern substations presents its own set of challenges. Ensuring compatibility with various insulation materials, connectors, and control systems while maintaining optimal performance can be complex.

Lastly, the long-term reliability of nichrome wire in harsh substation environments remains an ongoing challenge. Exposure to various environmental factors such as humidity, pollutants, and temperature extremes can impact the wire's longevity and performance. Developing more robust protective measures or alternative materials that can withstand these conditions without compromising electrical properties is an area of active research and development in the field of substation design.

Another significant challenge is the potential for mechanical stress and fatigue. Nichrome wire in substations often undergoes thermal cycling, expanding and contracting as it heats up and cools down. This repeated stress can lead to material fatigue over time, potentially causing wire breakage or reduced efficiency.

The cost of nichrome wire is also a consideration in substation design. While it offers excellent resistance properties, nichrome is more expensive than some alternative materials. This cost factor can impact the overall budget of substation projects, especially in large-scale implementations.

Maintaining consistent electrical properties across different batches of nichrome wire can be challenging. Slight variations in composition or manufacturing processes can lead to differences in resistance and temperature coefficients, potentially affecting the precision of electrical systems in substations.

Environmental concerns also pose challenges. The production and disposal of nichrome wire involve processes that may have environmental implications. As sustainability becomes increasingly important in infrastructure design, finding more eco-friendly alternatives or improving the lifecycle management of nichrome wire is a growing concern.

The integration of nichrome wire with other materials and components in modern substations presents its own set of challenges. Ensuring compatibility with various insulation materials, connectors, and control systems while maintaining optimal performance can be complex.

Lastly, the long-term reliability of nichrome wire in harsh substation environments remains an ongoing challenge. Exposure to various environmental factors such as humidity, pollutants, and temperature extremes can impact the wire's longevity and performance. Developing more robust protective measures or alternative materials that can withstand these conditions without compromising electrical properties is an area of active research and development in the field of substation design.

Current Nichrome Apps

01 Composition and properties of nichrome wire

Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and excellent heat resistance, making it suitable for various heating applications. The specific composition and properties of nichrome wire can be tailored to meet different requirements in terms of resistivity, temperature coefficient, and mechanical strength.- Composition and properties of nichrome wire: Nichrome wire is an alloy primarily composed of nickel and chromium. It is known for its high electrical resistance and excellent heat resistance, making it suitable for various heating applications. The specific composition and properties of nichrome wire can be tailored to meet different requirements in terms of resistivity, temperature coefficient, and mechanical strength.

- Applications in heating elements: Nichrome wire is widely used in the manufacturing of heating elements for various appliances and industrial equipment. Its high resistance to oxidation at elevated temperatures and stable electrical properties make it ideal for use in electric heaters, ovens, hair dryers, and other heating devices. The wire can be formed into different shapes and configurations to suit specific heating requirements.

- Use in electronic components: Nichrome wire finds applications in electronic components, particularly in the production of resistors and potentiometers. Its precise electrical resistance characteristics allow for the creation of accurate and stable resistive elements. The wire can be wound or deposited on substrates to create various types of resistors used in electronic circuits and devices.

- Fabrication techniques for nichrome wire: Various fabrication techniques are employed in the production of nichrome wire to achieve desired properties and dimensions. These may include drawing, annealing, and surface treatment processes. Advanced manufacturing methods can be used to create ultra-fine nichrome wires or specialized coatings to enhance performance in specific applications.

- Integration in sensor technologies: Nichrome wire is utilized in the development of various sensor technologies. Its temperature-dependent resistance properties make it suitable for use in temperature sensors and thermal management systems. Additionally, nichrome wire can be incorporated into strain gauges and other sensing elements due to its stable electrical characteristics under mechanical stress.

02 Applications in heating elements

Nichrome wire is widely used in the manufacturing of heating elements for various devices and appliances. Its high resistance to oxidation at elevated temperatures and stable electrical properties make it ideal for use in electric heaters, ovens, hair dryers, and other heating appliances. The wire can be formed into different shapes and configurations to suit specific heating requirements.Expand Specific Solutions03 Use in electronic components

Nichrome wire finds applications in electronic components, particularly in the production of resistors and other circuit elements. Its precise electrical resistance characteristics allow for the creation of accurate and stable resistive components. The wire can be wound or deposited on substrates to create various types of resistors used in electronic circuits.Expand Specific Solutions04 Coating and surface treatment

Various coating and surface treatment techniques can be applied to nichrome wire to enhance its properties or provide additional functionality. These treatments may include oxidation-resistant coatings, insulating layers, or other functional coatings that improve the wire's performance in specific applications or environments.Expand Specific Solutions05 Manufacturing and processing techniques

The production of nichrome wire involves specific manufacturing and processing techniques to achieve the desired properties and dimensions. These may include precise alloying processes, drawing techniques to produce wire of various diameters, and heat treatment methods to optimize the wire's characteristics. Advanced manufacturing methods can be employed to produce nichrome wire with enhanced performance or specialized features.Expand Specific Solutions

Key Industry Players

The market for nichrome wire in modern substation design is in a mature phase, with established players and steady growth. The global substation market size is projected to reach $170 billion by 2026, driven by increasing power demand and grid modernization efforts. Technologically, nichrome wire applications are well-developed, with companies like State Grid Corp. of China, Siemens Corp., and ABB Group leading innovation. These industry giants, along with specialized manufacturers like Yancheng Xinyang Electric Heating Material Co., Ltd., are continuously improving nichrome wire's performance and reliability in substation components, particularly in heating elements and resistors.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed advanced substation designs incorporating Nichrome wire for improved performance and reliability. Their approach utilizes Nichrome wire in high-temperature sensing elements and resistive heating components within substations. The company has implemented a smart substation concept that integrates Nichrome-based sensors for real-time temperature monitoring, enabling predictive maintenance and enhanced operational efficiency[1]. Additionally, they have developed specialized Nichrome wire coatings to increase corrosion resistance and longevity in harsh substation environments[2]. State Grid's research has also focused on optimizing Nichrome wire gauge and composition for specific substation applications, resulting in improved power handling capabilities and reduced energy losses[3].

Strengths: Extensive experience in large-scale power infrastructure, strong R&D capabilities, and access to vast resources for implementation. Weaknesses: Potential over-reliance on traditional technologies and slower adoption of cutting-edge innovations compared to some international competitors.

Siemens Corp.

Technical Solution: Siemens Corp. has made significant contributions to modern substation design through its innovative use of Nichrome wire technology. The company has developed a proprietary Nichrome alloy composition optimized for substation applications, offering enhanced thermal stability and electrical resistance properties[4]. Siemens' substation designs incorporate Nichrome wire in critical components such as current-limiting resistors and high-precision voltage dividers, improving overall system accuracy and protection[5]. Their advanced thermal management systems utilize Nichrome wire-based heating elements to prevent condensation and maintain optimal operating temperatures in sensitive equipment. Furthermore, Siemens has integrated Nichrome wire sensors into their digital substation solutions, enabling real-time monitoring of thermal conditions and facilitating predictive maintenance strategies[6].

Strengths: Strong global presence, extensive R&D capabilities, and a comprehensive portfolio of substation solutions. Weaknesses: Higher costs associated with premium technologies may limit adoption in price-sensitive markets.

Nichrome Innovations

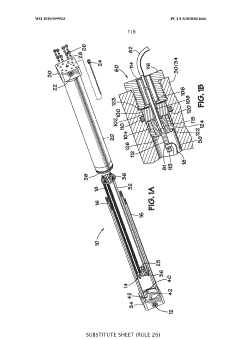

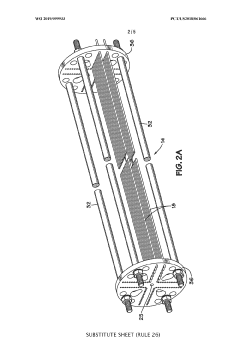

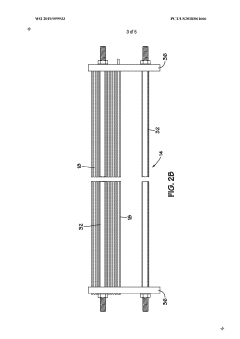

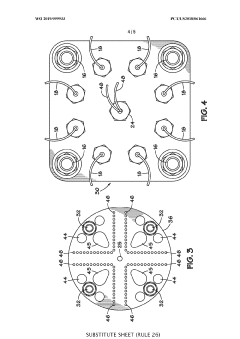

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

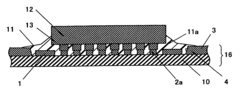

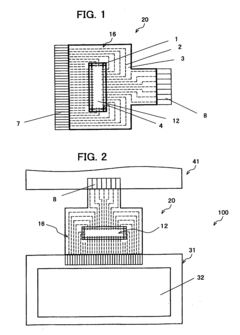

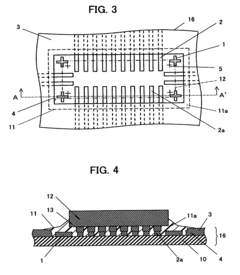

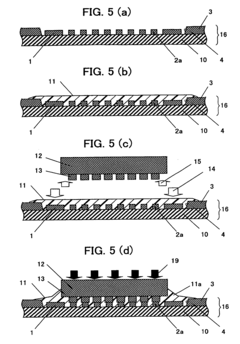

Semiconductor apparatus, manufacturing method thereof, semiconductor module apparatus using semiconductor apparatus, and wire substrate for semiconductor apparatus

PatentActiveUS20080251946A1

Innovation

- The semiconductor apparatus features an insulating substrate with mark patterns for alignment, where the entire upper face of each mark pattern is covered with insulating resin, allowing accurate detection and alignment without hindrance, and the mark patterns can be provided within or near the semiconductor element installation region, reducing the outer size and improving wiring freedom.

Substation Safety Regs

Substation safety regulations play a crucial role in ensuring the safe and reliable operation of modern electrical substations, including those incorporating nichrome wire technology. These regulations are designed to protect personnel, equipment, and the surrounding environment from potential hazards associated with high-voltage electrical systems.

One of the primary safety considerations in substations using nichrome wire is the management of heat generation. Nichrome wire, known for its high electrical resistance and heat-producing properties, requires careful implementation to prevent overheating and potential fire hazards. Safety regulations mandate the use of appropriate insulation materials and thermal management systems to dissipate heat effectively and maintain safe operating temperatures.

Electrical isolation and grounding requirements are also critical aspects of substation safety regulations. With nichrome wire components integrated into various substation equipment, proper isolation techniques must be employed to prevent electrical arcing and ensure the safety of maintenance personnel. Grounding systems must be designed to handle the specific characteristics of nichrome wire-based equipment, providing a safe path for fault currents and protecting against electrical shock hazards.

Electromagnetic compatibility (EMC) regulations are particularly relevant when incorporating nichrome wire technology in substations. The unique electromagnetic properties of nichrome wire can potentially interfere with sensitive control and communication systems. Safety regulations require comprehensive EMC testing and mitigation measures to ensure that nichrome wire-based components do not compromise the overall reliability and safety of the substation.

Personal protective equipment (PPE) requirements for substation workers must also be adapted to address the specific risks associated with nichrome wire technology. This may include specialized heat-resistant clothing, insulated tools, and enhanced safety protocols for working near nichrome wire-based equipment.

Regular inspection and maintenance procedures are mandated by safety regulations to ensure the ongoing integrity of nichrome wire components. These procedures typically include thermal imaging, resistance testing, and visual inspections to detect any signs of degradation or potential failure before they can lead to safety incidents.

Emergency response planning is another critical aspect of substation safety regulations. With the unique properties of nichrome wire, emergency protocols must be tailored to address potential incidents such as wire failure, overheating, or electrical faults. This includes specialized firefighting procedures and equipment suitable for electrical fires involving nichrome wire components.

In conclusion, substation safety regulations encompassing nichrome wire technology focus on heat management, electrical isolation, EMC compliance, personnel protection, maintenance protocols, and emergency preparedness. These comprehensive regulations ensure that the benefits of nichrome wire in modern substation design are realized without compromising safety standards.

One of the primary safety considerations in substations using nichrome wire is the management of heat generation. Nichrome wire, known for its high electrical resistance and heat-producing properties, requires careful implementation to prevent overheating and potential fire hazards. Safety regulations mandate the use of appropriate insulation materials and thermal management systems to dissipate heat effectively and maintain safe operating temperatures.

Electrical isolation and grounding requirements are also critical aspects of substation safety regulations. With nichrome wire components integrated into various substation equipment, proper isolation techniques must be employed to prevent electrical arcing and ensure the safety of maintenance personnel. Grounding systems must be designed to handle the specific characteristics of nichrome wire-based equipment, providing a safe path for fault currents and protecting against electrical shock hazards.

Electromagnetic compatibility (EMC) regulations are particularly relevant when incorporating nichrome wire technology in substations. The unique electromagnetic properties of nichrome wire can potentially interfere with sensitive control and communication systems. Safety regulations require comprehensive EMC testing and mitigation measures to ensure that nichrome wire-based components do not compromise the overall reliability and safety of the substation.

Personal protective equipment (PPE) requirements for substation workers must also be adapted to address the specific risks associated with nichrome wire technology. This may include specialized heat-resistant clothing, insulated tools, and enhanced safety protocols for working near nichrome wire-based equipment.

Regular inspection and maintenance procedures are mandated by safety regulations to ensure the ongoing integrity of nichrome wire components. These procedures typically include thermal imaging, resistance testing, and visual inspections to detect any signs of degradation or potential failure before they can lead to safety incidents.

Emergency response planning is another critical aspect of substation safety regulations. With the unique properties of nichrome wire, emergency protocols must be tailored to address potential incidents such as wire failure, overheating, or electrical faults. This includes specialized firefighting procedures and equipment suitable for electrical fires involving nichrome wire components.

In conclusion, substation safety regulations encompassing nichrome wire technology focus on heat management, electrical isolation, EMC compliance, personnel protection, maintenance protocols, and emergency preparedness. These comprehensive regulations ensure that the benefits of nichrome wire in modern substation design are realized without compromising safety standards.

Environmental Impact

The environmental impact of nichrome wire in modern substation design is a crucial consideration in the ongoing efforts to create more sustainable and eco-friendly power distribution systems. Nichrome wire, an alloy of nickel and chromium, plays a significant role in various components of substations, particularly in resistive elements and heating applications.

One of the primary environmental benefits of using nichrome wire in substations is its durability and longevity. The high resistance to corrosion and oxidation exhibited by nichrome wire contributes to extended equipment lifespans, reducing the frequency of replacements and, consequently, the overall environmental footprint associated with manufacturing and disposal of substation components.

Furthermore, the excellent heat resistance properties of nichrome wire enable more efficient operation of substation equipment. This improved efficiency translates to reduced energy losses and lower overall power consumption, indirectly contributing to decreased greenhouse gas emissions from power generation facilities.

However, the production of nichrome wire does have some environmental implications. The mining and processing of nickel and chromium, the primary constituents of nichrome, can have significant environmental impacts, including habitat disruption, water pollution, and energy-intensive refining processes. Manufacturers and substation designers must carefully consider these upstream environmental costs when evaluating the overall sustainability of nichrome wire applications.

In terms of end-of-life considerations, nichrome wire presents both challenges and opportunities. While the wire itself is recyclable, the complex nature of substation equipment can make separation and recovery of nichrome components difficult. Developing more efficient recycling processes for substation materials, including nichrome wire, is an area of ongoing research and development in the industry.

The use of nichrome wire in modern substation design also intersects with broader environmental initiatives in the power sector. For instance, the wire's properties make it well-suited for use in smart grid technologies and renewable energy integration systems, which are critical for reducing the overall environmental impact of electricity distribution and consumption.

As environmental regulations become increasingly stringent, the role of nichrome wire in substation design may evolve. Future developments may focus on enhancing the material's properties to further improve energy efficiency and reduce environmental impact throughout its lifecycle. Additionally, research into alternative materials that offer similar performance characteristics with potentially lower environmental costs is an area of active exploration in the field of substation design and electrical engineering.

One of the primary environmental benefits of using nichrome wire in substations is its durability and longevity. The high resistance to corrosion and oxidation exhibited by nichrome wire contributes to extended equipment lifespans, reducing the frequency of replacements and, consequently, the overall environmental footprint associated with manufacturing and disposal of substation components.

Furthermore, the excellent heat resistance properties of nichrome wire enable more efficient operation of substation equipment. This improved efficiency translates to reduced energy losses and lower overall power consumption, indirectly contributing to decreased greenhouse gas emissions from power generation facilities.

However, the production of nichrome wire does have some environmental implications. The mining and processing of nickel and chromium, the primary constituents of nichrome, can have significant environmental impacts, including habitat disruption, water pollution, and energy-intensive refining processes. Manufacturers and substation designers must carefully consider these upstream environmental costs when evaluating the overall sustainability of nichrome wire applications.

In terms of end-of-life considerations, nichrome wire presents both challenges and opportunities. While the wire itself is recyclable, the complex nature of substation equipment can make separation and recovery of nichrome components difficult. Developing more efficient recycling processes for substation materials, including nichrome wire, is an area of ongoing research and development in the industry.

The use of nichrome wire in modern substation design also intersects with broader environmental initiatives in the power sector. For instance, the wire's properties make it well-suited for use in smart grid technologies and renewable energy integration systems, which are critical for reducing the overall environmental impact of electricity distribution and consumption.

As environmental regulations become increasingly stringent, the role of nichrome wire in substation design may evolve. Future developments may focus on enhancing the material's properties to further improve energy efficiency and reduce environmental impact throughout its lifecycle. Additionally, research into alternative materials that offer similar performance characteristics with potentially lower environmental costs is an area of active exploration in the field of substation design and electrical engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!