How PHEV technology influences supply chain sustainability

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Tech Evolution

Plug-in Hybrid Electric Vehicle (PHEV) technology has undergone significant evolution since its inception, marking key milestones in the automotive industry's journey towards sustainability. The development of PHEV technology can be traced back to the early 2000s, with Toyota's introduction of the Prius, which, although not a plug-in hybrid, laid the groundwork for future PHEV innovations.

The first commercial PHEV, the BYD F3DM, was launched in China in 2008, signaling the beginning of a new era in automotive technology. This was quickly followed by the Chevrolet Volt in 2010, which gained widespread attention in the North American market. These early models demonstrated the potential of PHEVs to bridge the gap between conventional internal combustion engine vehicles and fully electric vehicles.

As the technology matured, PHEVs saw improvements in battery capacity, electric range, and overall efficiency. The second generation of PHEVs, emerging around 2015, featured enhanced electric-only driving ranges, often exceeding 30 miles. This improvement was largely due to advancements in lithium-ion battery technology, which allowed for greater energy density and reduced costs.

The integration of smart charging systems and vehicle-to-grid (V2G) capabilities marked another significant step in PHEV evolution. These features not only optimized charging processes but also enabled PHEVs to contribute to grid stability, enhancing their role in sustainable energy ecosystems.

Recent developments have focused on increasing the electric range of PHEVs, with some models now capable of traveling over 50 miles on electric power alone. This progress has been accompanied by advancements in powertrain efficiency, lightweight materials, and aerodynamics, all contributing to improved overall vehicle performance and reduced emissions.

The evolution of PHEV technology has also seen a shift towards more diverse vehicle types. Initially limited to sedans and compact cars, PHEVs now span a wide range of vehicle categories, including SUVs, crossovers, and even high-performance sports cars. This diversification has played a crucial role in broadening market appeal and accelerating adoption rates.

Looking ahead, the PHEV technology roadmap includes further improvements in battery technology, with a focus on solid-state batteries that promise higher energy density and faster charging times. Additionally, the integration of artificial intelligence and machine learning algorithms is expected to optimize power management systems, further enhancing the efficiency and performance of PHEVs.

The first commercial PHEV, the BYD F3DM, was launched in China in 2008, signaling the beginning of a new era in automotive technology. This was quickly followed by the Chevrolet Volt in 2010, which gained widespread attention in the North American market. These early models demonstrated the potential of PHEVs to bridge the gap between conventional internal combustion engine vehicles and fully electric vehicles.

As the technology matured, PHEVs saw improvements in battery capacity, electric range, and overall efficiency. The second generation of PHEVs, emerging around 2015, featured enhanced electric-only driving ranges, often exceeding 30 miles. This improvement was largely due to advancements in lithium-ion battery technology, which allowed for greater energy density and reduced costs.

The integration of smart charging systems and vehicle-to-grid (V2G) capabilities marked another significant step in PHEV evolution. These features not only optimized charging processes but also enabled PHEVs to contribute to grid stability, enhancing their role in sustainable energy ecosystems.

Recent developments have focused on increasing the electric range of PHEVs, with some models now capable of traveling over 50 miles on electric power alone. This progress has been accompanied by advancements in powertrain efficiency, lightweight materials, and aerodynamics, all contributing to improved overall vehicle performance and reduced emissions.

The evolution of PHEV technology has also seen a shift towards more diverse vehicle types. Initially limited to sedans and compact cars, PHEVs now span a wide range of vehicle categories, including SUVs, crossovers, and even high-performance sports cars. This diversification has played a crucial role in broadening market appeal and accelerating adoption rates.

Looking ahead, the PHEV technology roadmap includes further improvements in battery technology, with a focus on solid-state batteries that promise higher energy density and faster charging times. Additionally, the integration of artificial intelligence and machine learning algorithms is expected to optimize power management systems, further enhancing the efficiency and performance of PHEVs.

Market Demand Analysis

The market demand for Plug-in Hybrid Electric Vehicles (PHEVs) has been steadily increasing in recent years, driven by growing environmental concerns, stricter emissions regulations, and advancements in battery technology. This surge in demand has significant implications for supply chain sustainability, as it necessitates a shift in production processes, material sourcing, and logistics management.

Consumer preferences are shifting towards more sustainable transportation options, with PHEVs offering a compromise between traditional internal combustion engines and fully electric vehicles. This transition is reflected in the global PHEV market, which is projected to grow at a compound annual growth rate (CAGR) of over 30% in the coming years. The increasing adoption of PHEVs is particularly notable in regions with well-developed charging infrastructure and supportive government policies.

The automotive industry is responding to this demand by expanding PHEV model offerings and investing in production capacity. Major automakers are allocating substantial resources to develop and manufacture PHEVs, recognizing their potential as a bridge technology in the transition to fully electric mobility. This shift is creating new opportunities and challenges for suppliers across the automotive value chain.

From a supply chain perspective, the rise of PHEVs is driving demand for specific components and materials. Battery production, in particular, is a critical area of focus, with lithium-ion batteries being the predominant technology. The increased demand for battery materials such as lithium, cobalt, and nickel is reshaping global supply chains and prompting concerns about resource availability and sustainable sourcing practices.

The integration of electric powertrains alongside traditional combustion engines in PHEVs also requires suppliers to adapt their production capabilities. This dual-system approach necessitates a more complex supply chain, with manufacturers needing to manage both conventional automotive components and specialized electric vehicle parts. The result is a transformation of existing supply networks and the emergence of new suppliers specializing in electric vehicle technologies.

Market trends indicate a growing consumer preference for PHEVs with longer electric-only driving ranges, which is influencing battery development and vehicle design. This demand for improved performance is pushing manufacturers to innovate in areas such as battery energy density, power electronics, and lightweight materials, further impacting supply chain dynamics.

The market demand for PHEVs is also shaped by regulatory environments, with many countries implementing incentives for low-emission vehicles and setting targets for phasing out conventional internal combustion engines. These policies are accelerating the adoption of PHEVs and creating a more predictable demand trajectory, allowing supply chains to plan and invest accordingly.

As the PHEV market expands, there is an increasing focus on the lifecycle sustainability of these vehicles. This includes considerations for battery production, use-phase emissions, and end-of-life recycling. The demand for more sustainable practices throughout the PHEV lifecycle is influencing supply chain strategies, with a growing emphasis on circular economy principles and responsible sourcing of materials.

Consumer preferences are shifting towards more sustainable transportation options, with PHEVs offering a compromise between traditional internal combustion engines and fully electric vehicles. This transition is reflected in the global PHEV market, which is projected to grow at a compound annual growth rate (CAGR) of over 30% in the coming years. The increasing adoption of PHEVs is particularly notable in regions with well-developed charging infrastructure and supportive government policies.

The automotive industry is responding to this demand by expanding PHEV model offerings and investing in production capacity. Major automakers are allocating substantial resources to develop and manufacture PHEVs, recognizing their potential as a bridge technology in the transition to fully electric mobility. This shift is creating new opportunities and challenges for suppliers across the automotive value chain.

From a supply chain perspective, the rise of PHEVs is driving demand for specific components and materials. Battery production, in particular, is a critical area of focus, with lithium-ion batteries being the predominant technology. The increased demand for battery materials such as lithium, cobalt, and nickel is reshaping global supply chains and prompting concerns about resource availability and sustainable sourcing practices.

The integration of electric powertrains alongside traditional combustion engines in PHEVs also requires suppliers to adapt their production capabilities. This dual-system approach necessitates a more complex supply chain, with manufacturers needing to manage both conventional automotive components and specialized electric vehicle parts. The result is a transformation of existing supply networks and the emergence of new suppliers specializing in electric vehicle technologies.

Market trends indicate a growing consumer preference for PHEVs with longer electric-only driving ranges, which is influencing battery development and vehicle design. This demand for improved performance is pushing manufacturers to innovate in areas such as battery energy density, power electronics, and lightweight materials, further impacting supply chain dynamics.

The market demand for PHEVs is also shaped by regulatory environments, with many countries implementing incentives for low-emission vehicles and setting targets for phasing out conventional internal combustion engines. These policies are accelerating the adoption of PHEVs and creating a more predictable demand trajectory, allowing supply chains to plan and invest accordingly.

As the PHEV market expands, there is an increasing focus on the lifecycle sustainability of these vehicles. This includes considerations for battery production, use-phase emissions, and end-of-life recycling. The demand for more sustainable practices throughout the PHEV lifecycle is influencing supply chain strategies, with a growing emphasis on circular economy principles and responsible sourcing of materials.

PHEV Supply Challenges

The integration of Plug-in Hybrid Electric Vehicle (PHEV) technology into automotive supply chains presents significant challenges that require careful consideration and strategic planning. One of the primary obstacles is the complexity of managing dual powertrain components, which necessitates a more intricate supply network. Suppliers must now provide both traditional internal combustion engine parts and electric drivetrain components, leading to increased coordination efforts and potential bottlenecks in production.

The battery supply chain for PHEVs is particularly challenging. The demand for high-capacity lithium-ion batteries has surged, creating a highly competitive market for raw materials such as lithium, cobalt, and nickel. This competition has led to price volatility and supply constraints, which can disrupt production schedules and impact overall supply chain stability. Furthermore, the geopolitical implications of sourcing these materials from specific regions add another layer of complexity to supply chain management.

Another significant challenge is the need for specialized manufacturing facilities and processes. PHEV production requires new assembly lines, testing equipment, and quality control measures that differ from traditional vehicle manufacturing. This necessitates substantial investments in infrastructure and workforce training, which can strain resources and potentially lead to supply chain inefficiencies during the transition period.

The integration of software and electronics into PHEVs also introduces new supply chain challenges. These vehicles rely heavily on advanced software systems and electronic components, which require partnerships with technology suppliers that may be new to the automotive industry. Ensuring the reliability and security of these components, as well as managing software updates throughout the vehicle's lifecycle, adds complexity to the supply chain and aftersales service networks.

Regulatory compliance presents another hurdle for PHEV supply chains. As governments worldwide implement stricter emissions standards and incentivize electric vehicle adoption, manufacturers must navigate a complex landscape of regulations that can vary significantly between markets. This requires a flexible supply chain that can adapt to different regional requirements and potentially localize production to meet specific market demands.

Lastly, the sustainability aspect of PHEV supply chains poses both challenges and opportunities. While PHEVs offer improved environmental performance compared to conventional vehicles, the production of batteries and electronic components raises concerns about resource depletion and end-of-life recycling. Developing sustainable practices for sourcing materials, manufacturing processes, and recycling infrastructure is crucial for long-term supply chain sustainability but requires significant investment and innovation.

The battery supply chain for PHEVs is particularly challenging. The demand for high-capacity lithium-ion batteries has surged, creating a highly competitive market for raw materials such as lithium, cobalt, and nickel. This competition has led to price volatility and supply constraints, which can disrupt production schedules and impact overall supply chain stability. Furthermore, the geopolitical implications of sourcing these materials from specific regions add another layer of complexity to supply chain management.

Another significant challenge is the need for specialized manufacturing facilities and processes. PHEV production requires new assembly lines, testing equipment, and quality control measures that differ from traditional vehicle manufacturing. This necessitates substantial investments in infrastructure and workforce training, which can strain resources and potentially lead to supply chain inefficiencies during the transition period.

The integration of software and electronics into PHEVs also introduces new supply chain challenges. These vehicles rely heavily on advanced software systems and electronic components, which require partnerships with technology suppliers that may be new to the automotive industry. Ensuring the reliability and security of these components, as well as managing software updates throughout the vehicle's lifecycle, adds complexity to the supply chain and aftersales service networks.

Regulatory compliance presents another hurdle for PHEV supply chains. As governments worldwide implement stricter emissions standards and incentivize electric vehicle adoption, manufacturers must navigate a complex landscape of regulations that can vary significantly between markets. This requires a flexible supply chain that can adapt to different regional requirements and potentially localize production to meet specific market demands.

Lastly, the sustainability aspect of PHEV supply chains poses both challenges and opportunities. While PHEVs offer improved environmental performance compared to conventional vehicles, the production of batteries and electronic components raises concerns about resource depletion and end-of-life recycling. Developing sustainable practices for sourcing materials, manufacturing processes, and recycling infrastructure is crucial for long-term supply chain sustainability but requires significant investment and innovation.

Current PHEV Solutions

01 Supply chain management for PHEV components

Effective supply chain management is crucial for PHEV technology sustainability. This involves optimizing the sourcing, production, and distribution of components specific to plug-in hybrid electric vehicles. Strategies include implementing digital tracking systems, improving inventory management, and enhancing supplier relationships to ensure a stable and efficient supply of critical PHEV components.- Supply chain management for PHEV components: Efficient supply chain management is crucial for PHEV technology sustainability. This involves optimizing the sourcing, production, and distribution of components specific to plug-in hybrid electric vehicles. Strategies may include implementing just-in-time inventory systems, developing strong relationships with suppliers, and utilizing advanced logistics technologies to reduce waste and improve efficiency.

- Sustainable battery production and recycling: Focusing on sustainable battery production and recycling processes is essential for PHEV technology. This includes developing eco-friendly manufacturing methods, sourcing materials responsibly, and implementing efficient recycling programs to recover valuable materials from used batteries. Innovations in battery chemistry and design can also contribute to improved sustainability and reduced environmental impact.

- Energy-efficient manufacturing processes: Implementing energy-efficient manufacturing processes for PHEV components is crucial for supply chain sustainability. This involves adopting renewable energy sources in production facilities, optimizing production lines to reduce energy consumption, and utilizing smart manufacturing technologies to minimize waste and improve overall efficiency in the manufacturing of PHEV components.

- Sustainable sourcing of raw materials: Ensuring sustainable sourcing of raw materials for PHEV components is vital for supply chain sustainability. This includes developing strategies to responsibly source critical materials such as rare earth elements, implementing traceability systems to monitor the origin of materials, and exploring alternative materials that have a lower environmental impact while maintaining performance standards.

- Circular economy principles in PHEV supply chain: Incorporating circular economy principles in the PHEV supply chain can significantly enhance sustainability. This involves designing components for easy disassembly and reuse, implementing take-back programs for end-of-life vehicles, and developing innovative business models that promote the reuse and refurbishment of PHEV components. These practices can help reduce waste and extend the lifecycle of materials used in PHEV technology.

02 Sustainable battery production and recycling

Developing sustainable practices for battery production and recycling is essential for PHEV technology. This includes improving the efficiency of battery manufacturing processes, reducing the environmental impact of raw material extraction, and implementing effective recycling programs for end-of-life batteries. Advanced recycling technologies and circular economy principles are being applied to minimize waste and maximize resource recovery.Expand Specific Solutions03 Energy-efficient manufacturing processes

Implementing energy-efficient manufacturing processes is key to enhancing the sustainability of PHEV production. This involves adopting renewable energy sources in manufacturing facilities, optimizing production line efficiency, and reducing overall energy consumption. Advanced technologies such as IoT and AI are being utilized to monitor and improve energy usage throughout the manufacturing process.Expand Specific Solutions04 Sustainable sourcing of raw materials

Ensuring sustainable sourcing of raw materials is critical for PHEV supply chain sustainability. This includes developing responsible mining practices, exploring alternative materials with lower environmental impact, and implementing traceability systems to verify the ethical and sustainable origin of materials used in PHEV components. Collaboration with suppliers and industry partners is essential to achieve these goals.Expand Specific Solutions05 Life cycle assessment and carbon footprint reduction

Conducting comprehensive life cycle assessments and implementing strategies to reduce the carbon footprint of PHEVs is crucial for long-term sustainability. This involves analyzing the environmental impact of PHEVs from production to end-of-life, identifying areas for improvement, and developing innovative solutions to minimize emissions and resource consumption throughout the vehicle's lifecycle.Expand Specific Solutions

Key PHEV Manufacturers

The PHEV (Plug-in Hybrid Electric Vehicle) technology market is in a growth phase, with increasing adoption and investment from major automotive players. The global PHEV market size is projected to expand significantly in the coming years, driven by environmental regulations and consumer demand for fuel-efficient vehicles. Technologically, PHEVs are relatively mature, with ongoing improvements in battery capacity and charging infrastructure. Key players like Ford, Volvo, and BMW are actively developing and refining PHEV technologies, while emerging companies such as Guangzhou Automobile Group and Chery Automobile are also entering the market. The supply chain sustainability impact of PHEVs is complex, involving battery production, electric components, and traditional automotive parts, requiring manufacturers to balance environmental considerations with production efficiency.

Ford Global Technologies LLC

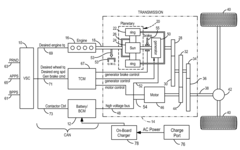

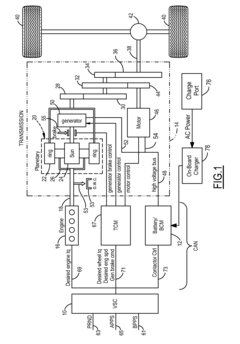

Technical Solution: Ford has developed an advanced PHEV technology that integrates a high-efficiency gasoline engine with a powerful electric motor and a lithium-ion battery pack. This system optimizes the use of both power sources, allowing for extended electric-only driving range and seamless transition to hybrid mode when needed. Ford's PHEV technology incorporates intelligent energy management systems that adapt to driving conditions and user preferences, maximizing fuel efficiency and reducing emissions[1]. The company has also implemented a modular design approach, which allows for easier component upgrades and recycling, contributing to supply chain sustainability[2]. Ford's PHEVs utilize regenerative braking and advanced thermal management systems to enhance overall efficiency and battery longevity[3].

Strengths: Extensive experience in hybrid technology, strong global supply chain network, and commitment to sustainability. Weaknesses: Dependency on battery suppliers and potential challenges in scaling up production to meet increasing demand.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed a PHEV technology specifically tailored for heavy-duty vehicles, focusing on long-haul transportation. Their system combines a high-capacity electric motor with a diesel engine, allowing for zero-emission operations in urban areas and efficient highway driving. Volvo's PHEV trucks utilize advanced power management software that optimizes the use of electric and diesel power based on route characteristics, load weight, and topography[4]. The company has also implemented a modular battery design that allows for easy replacement and upgrades, enhancing the longevity of the vehicle and reducing waste in the supply chain[5]. Volvo's PHEV technology incorporates fast-charging capabilities and intelligent geofencing to automatically switch to electric mode in designated low-emission zones[6].

Strengths: Expertise in heavy-duty vehicle electrification, strong focus on sustainability, and established presence in the trucking industry. Weaknesses: Higher initial costs compared to traditional diesel trucks and limited electric-only range for long-haul operations.

PHEV Innovation Focus

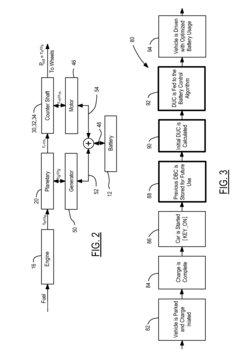

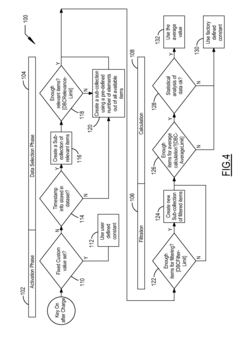

Adaptive Initial Estimation and Dynamic Determination and Update of Distance Until Charge of a Plug-In Hybrid Electric Vehicle

PatentActiveUS20110184600A1

Innovation

- A method and system that dynamically control battery usage based on the estimated or user-provided 'distance until charge' (DUC) value, utilizing historical data and real-time information from navigation systems to optimize battery depletion and charging strategies.

Sustainability Metrics

Sustainability metrics play a crucial role in assessing the impact of PHEV technology on supply chain sustainability. These metrics provide quantifiable measures to evaluate the environmental, social, and economic aspects of sustainability throughout the PHEV supply chain.

One key sustainability metric for PHEV technology is carbon footprint reduction. This metric measures the decrease in greenhouse gas emissions achieved by implementing PHEV technology compared to traditional internal combustion engine vehicles. It encompasses emissions from raw material extraction, component manufacturing, vehicle assembly, distribution, and end-of-life disposal. By tracking this metric, companies can demonstrate their contribution to climate change mitigation and align with global carbon reduction targets.

Energy efficiency is another important sustainability metric for PHEV supply chains. This metric evaluates the overall energy consumption across the supply chain, including energy used in production processes, transportation, and vehicle operation. Improved energy efficiency in PHEV technology can lead to reduced energy costs and lower environmental impact, contributing to a more sustainable supply chain.

Resource utilization is a critical metric that assesses the efficient use of raw materials and components in PHEV production. This metric tracks the consumption of critical resources such as rare earth metals, lithium, and other materials used in battery production. By optimizing resource utilization, companies can minimize waste, reduce environmental impact, and enhance the overall sustainability of the PHEV supply chain.

Water consumption and water quality impact are essential sustainability metrics, particularly in regions facing water scarcity. These metrics measure the amount of water used in PHEV production processes and the potential contamination of water sources. Implementing water-saving technologies and proper wastewater treatment can significantly improve these metrics and contribute to sustainable water management practices.

Waste reduction and recycling rates are crucial metrics for evaluating the circular economy aspects of PHEV supply chains. These metrics track the amount of waste generated during production and the percentage of materials that are recycled or reused. Improving these metrics can lead to reduced environmental impact and increased resource efficiency throughout the supply chain.

Social sustainability metrics are equally important in assessing the overall impact of PHEV technology on supply chain sustainability. These metrics include labor practices, worker safety, community engagement, and ethical sourcing of materials. By monitoring and improving these social metrics, companies can ensure that the PHEV supply chain contributes positively to the well-being of workers and communities involved in the production process.

Economic sustainability metrics, such as total cost of ownership, supply chain resilience, and local economic impact, provide insights into the long-term viability of PHEV technology. These metrics help assess the economic benefits of PHEV adoption, including potential cost savings for consumers and the creation of new job opportunities in the green technology sector.

One key sustainability metric for PHEV technology is carbon footprint reduction. This metric measures the decrease in greenhouse gas emissions achieved by implementing PHEV technology compared to traditional internal combustion engine vehicles. It encompasses emissions from raw material extraction, component manufacturing, vehicle assembly, distribution, and end-of-life disposal. By tracking this metric, companies can demonstrate their contribution to climate change mitigation and align with global carbon reduction targets.

Energy efficiency is another important sustainability metric for PHEV supply chains. This metric evaluates the overall energy consumption across the supply chain, including energy used in production processes, transportation, and vehicle operation. Improved energy efficiency in PHEV technology can lead to reduced energy costs and lower environmental impact, contributing to a more sustainable supply chain.

Resource utilization is a critical metric that assesses the efficient use of raw materials and components in PHEV production. This metric tracks the consumption of critical resources such as rare earth metals, lithium, and other materials used in battery production. By optimizing resource utilization, companies can minimize waste, reduce environmental impact, and enhance the overall sustainability of the PHEV supply chain.

Water consumption and water quality impact are essential sustainability metrics, particularly in regions facing water scarcity. These metrics measure the amount of water used in PHEV production processes and the potential contamination of water sources. Implementing water-saving technologies and proper wastewater treatment can significantly improve these metrics and contribute to sustainable water management practices.

Waste reduction and recycling rates are crucial metrics for evaluating the circular economy aspects of PHEV supply chains. These metrics track the amount of waste generated during production and the percentage of materials that are recycled or reused. Improving these metrics can lead to reduced environmental impact and increased resource efficiency throughout the supply chain.

Social sustainability metrics are equally important in assessing the overall impact of PHEV technology on supply chain sustainability. These metrics include labor practices, worker safety, community engagement, and ethical sourcing of materials. By monitoring and improving these social metrics, companies can ensure that the PHEV supply chain contributes positively to the well-being of workers and communities involved in the production process.

Economic sustainability metrics, such as total cost of ownership, supply chain resilience, and local economic impact, provide insights into the long-term viability of PHEV technology. These metrics help assess the economic benefits of PHEV adoption, including potential cost savings for consumers and the creation of new job opportunities in the green technology sector.

Circular Economy Impact

The integration of Plug-in Hybrid Electric Vehicle (PHEV) technology into supply chains has significant implications for the circular economy. PHEVs, by combining conventional internal combustion engines with electric powertrains, offer a transitional solution that bridges traditional automotive manufacturing with more sustainable practices. This hybrid approach necessitates a reimagining of supply chain structures to accommodate both conventional and electric components.

In the context of circular economy principles, PHEV technology promotes the reuse and recycling of materials, particularly in battery production and management. The lithium-ion batteries used in PHEVs require careful consideration of their lifecycle, from raw material extraction to end-of-life disposal or repurposing. This has led to the development of new recycling processes and the establishment of specialized facilities to handle battery components, contributing to a more circular approach in automotive manufacturing.

The dual nature of PHEVs also influences the supply chain's adaptability to circular economy practices. Manufacturers must balance the production of traditional combustion engine components with the newer electric drivetrain elements. This balance creates opportunities for suppliers to diversify their product lines and develop more sustainable manufacturing processes. For instance, suppliers may invest in technologies that allow for the refurbishment of used electric motors or the recovery of rare earth metals from electronic components.

Furthermore, PHEV technology encourages the development of more localized supply chains. The complexity of PHEV systems often requires closer collaboration between manufacturers and suppliers, leading to the establishment of regional production hubs. This localization can reduce transportation-related emissions and foster the development of circular economy practices within specific geographic areas.

The impact of PHEV technology on supply chain sustainability extends to the aftermarket and service sectors as well. The maintenance and repair of these vehicles require a new set of skills and tools, promoting the growth of specialized service centers. These centers often emphasize the refurbishment and reuse of components, aligning with circular economy principles and extending the lifespan of vehicle parts.

Lastly, the data generated by PHEVs through their advanced onboard systems provides valuable insights for supply chain optimization. This data can be used to predict component wear, optimize maintenance schedules, and improve overall vehicle longevity. By leveraging this information, manufacturers and suppliers can better align their production and distribution processes with circular economy goals, reducing waste and improving resource efficiency throughout the supply chain.

In the context of circular economy principles, PHEV technology promotes the reuse and recycling of materials, particularly in battery production and management. The lithium-ion batteries used in PHEVs require careful consideration of their lifecycle, from raw material extraction to end-of-life disposal or repurposing. This has led to the development of new recycling processes and the establishment of specialized facilities to handle battery components, contributing to a more circular approach in automotive manufacturing.

The dual nature of PHEVs also influences the supply chain's adaptability to circular economy practices. Manufacturers must balance the production of traditional combustion engine components with the newer electric drivetrain elements. This balance creates opportunities for suppliers to diversify their product lines and develop more sustainable manufacturing processes. For instance, suppliers may invest in technologies that allow for the refurbishment of used electric motors or the recovery of rare earth metals from electronic components.

Furthermore, PHEV technology encourages the development of more localized supply chains. The complexity of PHEV systems often requires closer collaboration between manufacturers and suppliers, leading to the establishment of regional production hubs. This localization can reduce transportation-related emissions and foster the development of circular economy practices within specific geographic areas.

The impact of PHEV technology on supply chain sustainability extends to the aftermarket and service sectors as well. The maintenance and repair of these vehicles require a new set of skills and tools, promoting the growth of specialized service centers. These centers often emphasize the refurbishment and reuse of components, aligning with circular economy principles and extending the lifespan of vehicle parts.

Lastly, the data generated by PHEVs through their advanced onboard systems provides valuable insights for supply chain optimization. This data can be used to predict component wear, optimize maintenance schedules, and improve overall vehicle longevity. By leveraging this information, manufacturers and suppliers can better align their production and distribution processes with circular economy goals, reducing waste and improving resource efficiency throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!