How Piezoelectric Sensors Improve Robotics Accuracy

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensors in Robotics: Background and Objectives

Piezoelectric sensors have emerged as a transformative technology in the field of robotics, offering unprecedented levels of accuracy and precision in motion control and force sensing. The development of these sensors can be traced back to the discovery of the piezoelectric effect by Pierre and Jacques Curie in 1880. This effect, which allows certain materials to generate an electric charge in response to applied mechanical stress, has since been harnessed for various applications, including robotics.

The evolution of piezoelectric sensors in robotics has been driven by the increasing demand for more sophisticated and precise robotic systems across industries. From manufacturing and healthcare to aerospace and exploration, the need for robots capable of performing intricate tasks with high accuracy has propelled research and development in this field. The integration of piezoelectric sensors into robotic systems represents a significant leap forward in addressing these demands.

The primary objective of incorporating piezoelectric sensors into robotics is to enhance the accuracy and responsiveness of robotic movements and interactions. These sensors enable robots to detect and measure minute forces and vibrations, allowing for real-time adjustments and fine-tuned control. This capability is particularly crucial in applications requiring delicate handling, such as surgical robots or assembly line robots working with fragile components.

Another key goal is to improve the overall efficiency and reliability of robotic systems. By providing precise feedback on force and position, piezoelectric sensors help minimize errors and reduce the need for constant recalibration. This not only enhances the performance of robots but also extends their operational lifespan and reduces maintenance requirements.

Furthermore, the integration of piezoelectric sensors aims to expand the range of tasks that robots can perform. With enhanced sensory capabilities, robots can adapt to more complex and variable environments, opening up new possibilities in fields such as environmental monitoring, search and rescue operations, and space exploration.

The ongoing research in piezoelectric sensors for robotics focuses on several key areas. These include developing more sensitive and durable sensor materials, improving signal processing techniques to extract meaningful data from sensor outputs, and creating innovative sensor designs that can be seamlessly integrated into various robotic structures. Additionally, there is a growing emphasis on miniaturization, allowing for the incorporation of these sensors into smaller and more agile robotic systems.

As we look to the future, the continued advancement of piezoelectric sensor technology in robotics promises to push the boundaries of what is possible in automated systems. The ultimate goal is to create robots that can interact with their environment with a level of precision and adaptability that rivals or even surpasses human capabilities, ushering in a new era of robotic applications across diverse fields.

The evolution of piezoelectric sensors in robotics has been driven by the increasing demand for more sophisticated and precise robotic systems across industries. From manufacturing and healthcare to aerospace and exploration, the need for robots capable of performing intricate tasks with high accuracy has propelled research and development in this field. The integration of piezoelectric sensors into robotic systems represents a significant leap forward in addressing these demands.

The primary objective of incorporating piezoelectric sensors into robotics is to enhance the accuracy and responsiveness of robotic movements and interactions. These sensors enable robots to detect and measure minute forces and vibrations, allowing for real-time adjustments and fine-tuned control. This capability is particularly crucial in applications requiring delicate handling, such as surgical robots or assembly line robots working with fragile components.

Another key goal is to improve the overall efficiency and reliability of robotic systems. By providing precise feedback on force and position, piezoelectric sensors help minimize errors and reduce the need for constant recalibration. This not only enhances the performance of robots but also extends their operational lifespan and reduces maintenance requirements.

Furthermore, the integration of piezoelectric sensors aims to expand the range of tasks that robots can perform. With enhanced sensory capabilities, robots can adapt to more complex and variable environments, opening up new possibilities in fields such as environmental monitoring, search and rescue operations, and space exploration.

The ongoing research in piezoelectric sensors for robotics focuses on several key areas. These include developing more sensitive and durable sensor materials, improving signal processing techniques to extract meaningful data from sensor outputs, and creating innovative sensor designs that can be seamlessly integrated into various robotic structures. Additionally, there is a growing emphasis on miniaturization, allowing for the incorporation of these sensors into smaller and more agile robotic systems.

As we look to the future, the continued advancement of piezoelectric sensor technology in robotics promises to push the boundaries of what is possible in automated systems. The ultimate goal is to create robots that can interact with their environment with a level of precision and adaptability that rivals or even surpasses human capabilities, ushering in a new era of robotic applications across diverse fields.

Market Demand for High-Precision Robotics

The market demand for high-precision robotics has been experiencing significant growth in recent years, driven by the increasing need for automation and precision in various industries. This demand is particularly pronounced in sectors such as manufacturing, healthcare, aerospace, and electronics, where even the slightest inaccuracies can lead to substantial losses or compromised product quality.

In the manufacturing sector, high-precision robotics are becoming essential for tasks that require extreme accuracy, such as microelectronics assembly, semiconductor fabrication, and advanced materials processing. The miniaturization trend in consumer electronics and the complexity of modern devices necessitate robotic systems capable of manipulating components at microscopic levels with unprecedented precision.

The healthcare industry is another major driver of demand for high-precision robotics. Surgical robots, for instance, are revolutionizing medical procedures by offering enhanced precision, minimally invasive techniques, and reduced recovery times for patients. As the population ages and the prevalence of chronic diseases increases, the demand for such advanced medical technologies is expected to surge.

Aerospace and defense sectors also contribute significantly to the market demand for high-precision robotics. These industries require robots capable of performing intricate tasks in the production of aircraft components, satellite systems, and advanced weaponry. The need for absolute precision in these applications is paramount, as even minor errors can have catastrophic consequences.

The automotive industry is yet another sector fueling the demand for high-precision robotics. As vehicles become more complex and incorporate advanced driver assistance systems (ADAS) and autonomous driving capabilities, the need for precise manufacturing and assembly processes has intensified. High-precision robots are crucial in ensuring the accurate placement and calibration of sensors, cameras, and other critical components that enable these advanced features.

Furthermore, the growing adoption of Industry 4.0 principles and the Internet of Things (IoT) is creating new opportunities for high-precision robotics. Smart factories and connected production systems require robots that can seamlessly integrate with other machines and systems, performing tasks with high accuracy while also collecting and processing data in real-time.

The market demand is not limited to hardware alone. There is an increasing need for sophisticated software and control systems that can enhance the precision and capabilities of robotic systems. This includes advanced algorithms for motion planning, real-time error correction, and adaptive control mechanisms that can compensate for environmental variations and wear-and-tear.

As industries continue to push the boundaries of what is possible in terms of precision and efficiency, the demand for high-precision robotics is expected to grow exponentially. This trend is likely to drive further innovation in sensor technologies, actuator designs, and control systems, with piezoelectric sensors playing a crucial role in improving the accuracy and performance of these advanced robotic systems.

In the manufacturing sector, high-precision robotics are becoming essential for tasks that require extreme accuracy, such as microelectronics assembly, semiconductor fabrication, and advanced materials processing. The miniaturization trend in consumer electronics and the complexity of modern devices necessitate robotic systems capable of manipulating components at microscopic levels with unprecedented precision.

The healthcare industry is another major driver of demand for high-precision robotics. Surgical robots, for instance, are revolutionizing medical procedures by offering enhanced precision, minimally invasive techniques, and reduced recovery times for patients. As the population ages and the prevalence of chronic diseases increases, the demand for such advanced medical technologies is expected to surge.

Aerospace and defense sectors also contribute significantly to the market demand for high-precision robotics. These industries require robots capable of performing intricate tasks in the production of aircraft components, satellite systems, and advanced weaponry. The need for absolute precision in these applications is paramount, as even minor errors can have catastrophic consequences.

The automotive industry is yet another sector fueling the demand for high-precision robotics. As vehicles become more complex and incorporate advanced driver assistance systems (ADAS) and autonomous driving capabilities, the need for precise manufacturing and assembly processes has intensified. High-precision robots are crucial in ensuring the accurate placement and calibration of sensors, cameras, and other critical components that enable these advanced features.

Furthermore, the growing adoption of Industry 4.0 principles and the Internet of Things (IoT) is creating new opportunities for high-precision robotics. Smart factories and connected production systems require robots that can seamlessly integrate with other machines and systems, performing tasks with high accuracy while also collecting and processing data in real-time.

The market demand is not limited to hardware alone. There is an increasing need for sophisticated software and control systems that can enhance the precision and capabilities of robotic systems. This includes advanced algorithms for motion planning, real-time error correction, and adaptive control mechanisms that can compensate for environmental variations and wear-and-tear.

As industries continue to push the boundaries of what is possible in terms of precision and efficiency, the demand for high-precision robotics is expected to grow exponentially. This trend is likely to drive further innovation in sensor technologies, actuator designs, and control systems, with piezoelectric sensors playing a crucial role in improving the accuracy and performance of these advanced robotic systems.

Current State and Challenges in Robotic Accuracy

The current state of robotic accuracy is characterized by significant advancements, yet persistent challenges remain. Modern robotics systems have achieved remarkable precision in controlled environments, with some industrial robots capable of sub-millimeter accuracy. This level of precision has been crucial in manufacturing, medical procedures, and scientific research. However, maintaining such accuracy in dynamic, real-world scenarios continues to be a significant hurdle.

One of the primary challenges in robotic accuracy is the inherent variability in mechanical systems. Factors such as wear and tear, temperature fluctuations, and material fatigue can lead to subtle changes in a robot's performance over time. These variations, while minor, can accumulate and result in noticeable inaccuracies, particularly in high-precision applications.

Environmental factors also play a crucial role in robotic accuracy. Vibrations from nearby machinery, changes in ambient temperature, and even air currents can affect a robot's ability to perform tasks with consistent precision. This is particularly problematic in industrial settings where multiple machines operate in close proximity.

Another significant challenge is the integration of sensory feedback with robotic control systems. While sensors have become increasingly sophisticated, translating sensory data into real-time adjustments in robotic movements remains complex. The delay between sensing and actuation, known as latency, can impact accuracy, especially in high-speed operations.

The complexity of robotic kinematics and dynamics presents another obstacle. As robots become more versatile and are designed to perform a wider range of tasks, their mechanical structures become more complex. This complexity makes it challenging to model and predict their behavior accurately, leading to potential discrepancies between intended and actual movements.

In the realm of collaborative robotics, where humans and robots work in close proximity, maintaining accuracy while ensuring safety introduces additional challenges. The need for robots to adapt their movements in real-time based on human presence and actions can compromise precision.

Despite these challenges, emerging technologies are paving the way for improvements. Advanced control algorithms, machine learning techniques, and more sophisticated sensor integration are being developed to enhance robotic accuracy. The use of adaptive control systems that can compensate for mechanical wear and environmental changes shows promise in maintaining long-term precision.

The pursuit of improved robotic accuracy continues to drive innovation in the field, with researchers and engineers exploring novel approaches to overcome these persistent challenges. As robotics applications expand into more diverse and demanding environments, the need for enhanced accuracy becomes increasingly critical, making this an area of intense focus and rapid development in the robotics industry.

One of the primary challenges in robotic accuracy is the inherent variability in mechanical systems. Factors such as wear and tear, temperature fluctuations, and material fatigue can lead to subtle changes in a robot's performance over time. These variations, while minor, can accumulate and result in noticeable inaccuracies, particularly in high-precision applications.

Environmental factors also play a crucial role in robotic accuracy. Vibrations from nearby machinery, changes in ambient temperature, and even air currents can affect a robot's ability to perform tasks with consistent precision. This is particularly problematic in industrial settings where multiple machines operate in close proximity.

Another significant challenge is the integration of sensory feedback with robotic control systems. While sensors have become increasingly sophisticated, translating sensory data into real-time adjustments in robotic movements remains complex. The delay between sensing and actuation, known as latency, can impact accuracy, especially in high-speed operations.

The complexity of robotic kinematics and dynamics presents another obstacle. As robots become more versatile and are designed to perform a wider range of tasks, their mechanical structures become more complex. This complexity makes it challenging to model and predict their behavior accurately, leading to potential discrepancies between intended and actual movements.

In the realm of collaborative robotics, where humans and robots work in close proximity, maintaining accuracy while ensuring safety introduces additional challenges. The need for robots to adapt their movements in real-time based on human presence and actions can compromise precision.

Despite these challenges, emerging technologies are paving the way for improvements. Advanced control algorithms, machine learning techniques, and more sophisticated sensor integration are being developed to enhance robotic accuracy. The use of adaptive control systems that can compensate for mechanical wear and environmental changes shows promise in maintaining long-term precision.

The pursuit of improved robotic accuracy continues to drive innovation in the field, with researchers and engineers exploring novel approaches to overcome these persistent challenges. As robotics applications expand into more diverse and demanding environments, the need for enhanced accuracy becomes increasingly critical, making this an area of intense focus and rapid development in the robotics industry.

Existing Piezoelectric Sensor Solutions for Robotics

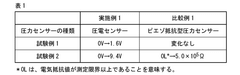

01 Improved sensor design for enhanced accuracy

Advanced piezoelectric sensor designs incorporate structural modifications and material optimizations to improve accuracy. These enhancements may include novel electrode configurations, specialized piezoelectric materials, or innovative sensor geometries that minimize interference and maximize sensitivity.- Improved sensor design for enhanced accuracy: Piezoelectric sensors can be designed with specific structures or materials to improve their accuracy. This may include using specialized electrode configurations, optimizing the piezoelectric material composition, or incorporating novel sensor geometries. These design improvements can lead to increased sensitivity, reduced noise, and better overall measurement accuracy.

- Signal processing techniques for accuracy enhancement: Advanced signal processing techniques can be applied to the output of piezoelectric sensors to improve their accuracy. This may involve digital filtering, noise reduction algorithms, or adaptive processing methods. By implementing these techniques, the sensor's performance can be optimized, leading to more precise and reliable measurements.

- Temperature compensation methods: Piezoelectric sensors are often sensitive to temperature variations, which can affect their accuracy. Implementing temperature compensation methods, such as using temperature sensors in conjunction with the piezoelectric element or developing temperature-resistant materials, can help maintain accuracy across a wide range of operating conditions.

- Calibration and self-calibration techniques: Accurate calibration is crucial for piezoelectric sensor performance. Developing advanced calibration techniques, including self-calibration methods, can significantly improve sensor accuracy. These techniques may involve periodic recalibration, in-situ calibration, or the use of reference standards to ensure consistent and precise measurements over time.

- Multi-axis sensing for improved accuracy: Incorporating multi-axis sensing capabilities in piezoelectric sensors can enhance their overall accuracy. By measuring forces or accelerations in multiple directions simultaneously, these sensors can provide more comprehensive and precise data. This approach can be particularly useful in applications requiring high-accuracy measurements in complex environments.

02 Signal processing techniques for accuracy improvement

Various signal processing methods are employed to enhance the accuracy of piezoelectric sensors. These techniques may involve digital filtering, noise reduction algorithms, or advanced data analysis methods to extract more precise measurements from the sensor output.Expand Specific Solutions03 Temperature compensation for improved accuracy

Temperature fluctuations can affect the accuracy of piezoelectric sensors. Implementing temperature compensation techniques, such as using temperature-sensitive elements or software-based correction algorithms, helps maintain sensor accuracy across a wide range of operating temperatures.Expand Specific Solutions04 Calibration methods for enhanced accuracy

Precise calibration procedures are crucial for maintaining the accuracy of piezoelectric sensors. These methods may include automated calibration systems, reference standards, or in-situ calibration techniques that ensure consistent and reliable sensor performance over time.Expand Specific Solutions05 Multi-axis sensing for improved accuracy

Incorporating multi-axis sensing capabilities in piezoelectric sensors can improve overall accuracy by providing a more comprehensive measurement of the target parameter. This approach allows for the detection and compensation of off-axis forces or movements that might otherwise introduce errors in single-axis sensors.Expand Specific Solutions

Key Players in Piezoelectric Sensor and Robotics Industries

The piezoelectric sensor market for robotics accuracy is in a growth phase, driven by increasing demand for precision in industrial automation and robotics. The market size is expanding, with a projected CAGR of over 5% in the coming years. Technologically, piezoelectric sensors are mature but continue to evolve, with companies like Robert Bosch GmbH, Murata Manufacturing, and DENSO Corp leading innovation. These firms are developing more sensitive and reliable sensors, integrating them with advanced robotics systems. Emerging players like Endress+Hauser and Siemens are also contributing to market competitiveness, focusing on specialized applications and improved sensor performance for enhanced robotics accuracy.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric sensors for robotics applications, focusing on improving accuracy and precision. Their sensors utilize high-performance piezoelectric ceramics and innovative electrode designs to enhance sensitivity and reduce noise. Murata's piezoelectric sensors incorporate multi-axis sensing capabilities, allowing for simultaneous measurement of force and torque in multiple directions[1]. This technology enables robots to perform complex tasks with greater dexterity and precision. Additionally, Murata has implemented temperature compensation techniques to maintain sensor accuracy across varying environmental conditions, ensuring consistent performance in diverse robotic applications[2].

Strengths: High sensitivity, multi-axis sensing capabilities, and temperature compensation. Weaknesses: Potentially higher cost due to advanced materials and manufacturing processes.

Siemens Corp.

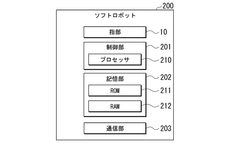

Technical Solution: Siemens has developed a comprehensive approach to integrating piezoelectric sensors in robotics systems to enhance accuracy. Their solution combines high-precision piezoelectric sensors with advanced signal processing algorithms and machine learning techniques. Siemens' piezoelectric sensors are designed to detect minute forces and vibrations, allowing robots to make real-time adjustments to their movements[3]. The company has also implemented a distributed sensing network architecture, where multiple piezoelectric sensors are strategically placed throughout the robotic system to provide a holistic view of the robot's interactions with its environment[4]. This approach enables more accurate force control and collision detection, significantly improving the overall accuracy and safety of robotic operations.

Strengths: Comprehensive system integration, advanced signal processing, and distributed sensing architecture. Weaknesses: Complexity of implementation and potential for increased system cost.

Core Innovations in Piezoelectric Sensing for Robotics

Robot, robot control device, and robot control method

PatentWO2023027194A1

Innovation

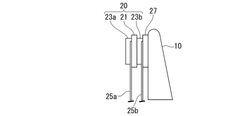

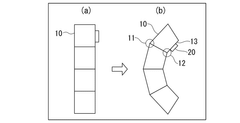

- A robot equipped with a piezoelectric sensor that detects minute pressure changes and vibrations, allowing for precise control of gripping force based on real-time feedback, enabling the robot to determine the type of object and adjust its gripping mechanism accordingly.

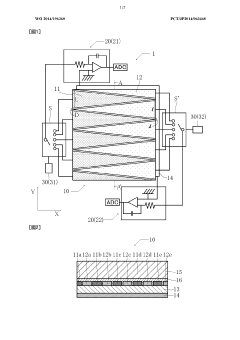

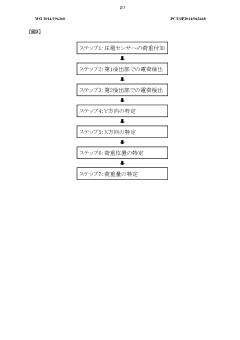

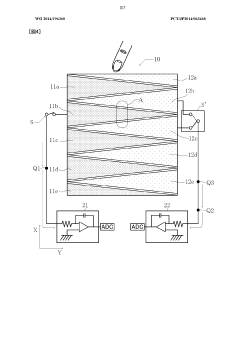

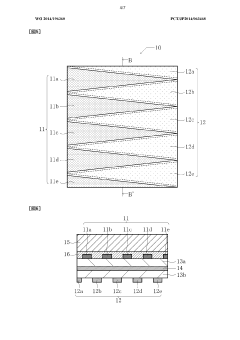

Piezoelectric sensor and electronic device

PatentWO2014196360A1

Innovation

- A piezoelectric sensor design featuring a piezoelectric layer with first and second electrodes arranged in a specific pattern, where the ratio of unit electrode sizes changes across the surface, allowing for position detection by calculating the ratio of electric charge generation, combined with a reference electrode to prevent crosstalk and enhance accuracy.

Integration Challenges and Solutions

The integration of piezoelectric sensors into robotic systems presents several challenges that require innovative solutions. One primary obstacle is the precise placement and mounting of sensors to ensure optimal sensitivity and accuracy. Robots often operate in dynamic environments with varying temperatures, vibrations, and mechanical stresses, which can affect sensor performance. To address this, engineers are developing advanced mounting techniques that incorporate shock-absorbing materials and temperature-compensating elements to maintain sensor stability across diverse operating conditions.

Another significant challenge lies in signal processing and noise reduction. Piezoelectric sensors generate small electrical signals that can be susceptible to electromagnetic interference and environmental noise. This necessitates the implementation of sophisticated signal conditioning circuits and filtering algorithms. Recent advancements in digital signal processing have led to the development of adaptive filtering techniques that can dynamically adjust to changing noise profiles, significantly improving the signal-to-noise ratio and, consequently, the accuracy of robotic movements.

The integration of sensor data with robotic control systems poses yet another hurdle. Real-time processing of sensor inputs and their seamless incorporation into the robot's decision-making algorithms require high-speed data acquisition systems and low-latency communication protocols. To tackle this, researchers are exploring edge computing solutions that bring processing power closer to the sensors, reducing latency and enabling faster response times in robotic systems.

Power management is also a critical consideration, especially for mobile robots or those operating in remote locations. Piezoelectric sensors, while generally low-power devices, still contribute to the overall energy consumption of the system. Innovative energy harvesting techniques are being investigated, where the mechanical energy from the robot's movements is captured and converted into electrical energy to power the sensors, creating more energy-efficient and self-sustaining robotic systems.

Lastly, the calibration and maintenance of piezoelectric sensors in robotic applications present ongoing challenges. Environmental factors and wear over time can affect sensor performance, necessitating regular recalibration. To address this, researchers are developing self-calibrating sensor systems that can automatically adjust their parameters based on internal diagnostics and environmental feedback, ensuring consistent accuracy without frequent manual interventions.

Another significant challenge lies in signal processing and noise reduction. Piezoelectric sensors generate small electrical signals that can be susceptible to electromagnetic interference and environmental noise. This necessitates the implementation of sophisticated signal conditioning circuits and filtering algorithms. Recent advancements in digital signal processing have led to the development of adaptive filtering techniques that can dynamically adjust to changing noise profiles, significantly improving the signal-to-noise ratio and, consequently, the accuracy of robotic movements.

The integration of sensor data with robotic control systems poses yet another hurdle. Real-time processing of sensor inputs and their seamless incorporation into the robot's decision-making algorithms require high-speed data acquisition systems and low-latency communication protocols. To tackle this, researchers are exploring edge computing solutions that bring processing power closer to the sensors, reducing latency and enabling faster response times in robotic systems.

Power management is also a critical consideration, especially for mobile robots or those operating in remote locations. Piezoelectric sensors, while generally low-power devices, still contribute to the overall energy consumption of the system. Innovative energy harvesting techniques are being investigated, where the mechanical energy from the robot's movements is captured and converted into electrical energy to power the sensors, creating more energy-efficient and self-sustaining robotic systems.

Lastly, the calibration and maintenance of piezoelectric sensors in robotic applications present ongoing challenges. Environmental factors and wear over time can affect sensor performance, necessitating regular recalibration. To address this, researchers are developing self-calibrating sensor systems that can automatically adjust their parameters based on internal diagnostics and environmental feedback, ensuring consistent accuracy without frequent manual interventions.

Environmental Impact and Sustainability Considerations

The integration of piezoelectric sensors in robotics has significant implications for environmental sustainability. These sensors, which convert mechanical stress into electrical signals, offer improved accuracy and efficiency in robotic systems, potentially reducing energy consumption and material waste. By enhancing the precision of robotic movements, piezoelectric sensors contribute to more efficient manufacturing processes, minimizing resource utilization and reducing the environmental footprint of industrial operations.

The use of piezoelectric sensors in robotics can lead to a decrease in the overall energy consumption of automated systems. With their ability to provide real-time feedback on force and pressure, these sensors enable robots to optimize their movements and adjust their power output accordingly. This results in more energy-efficient operations, reducing the carbon footprint associated with robotic applications across various industries.

Furthermore, the improved accuracy facilitated by piezoelectric sensors can contribute to a reduction in material waste. In manufacturing and assembly processes, robots equipped with these sensors can perform tasks with greater precision, minimizing errors and reducing the likelihood of producing defective parts. This not only conserves raw materials but also decreases the environmental impact associated with the disposal of faulty products.

The durability and longevity of piezoelectric sensors also play a role in sustainability considerations. These sensors are known for their robustness and ability to withstand harsh operating conditions, potentially extending the lifespan of robotic systems. Longer-lasting robots mean fewer replacements and less electronic waste, aligning with circular economy principles and reducing the environmental burden of manufacturing and disposing of robotic equipment.

However, it is important to consider the environmental impact of producing piezoelectric sensors themselves. The manufacturing process of these sensors often involves the use of lead-based materials, which can pose environmental and health risks if not properly managed. As such, research into lead-free alternatives and more environmentally friendly production methods is crucial for ensuring the overall sustainability of piezoelectric sensor technology in robotics.

In the context of sustainable development, the application of piezoelectric sensors in robotics also has the potential to contribute to more efficient resource management. For instance, in agricultural robotics, these sensors can enable more precise application of water, fertilizers, and pesticides, reducing overuse and minimizing environmental contamination. Similarly, in waste management and recycling, robots equipped with piezoelectric sensors can improve sorting accuracy, enhancing recycling efficiency and reducing the amount of waste sent to landfills.

The use of piezoelectric sensors in robotics can lead to a decrease in the overall energy consumption of automated systems. With their ability to provide real-time feedback on force and pressure, these sensors enable robots to optimize their movements and adjust their power output accordingly. This results in more energy-efficient operations, reducing the carbon footprint associated with robotic applications across various industries.

Furthermore, the improved accuracy facilitated by piezoelectric sensors can contribute to a reduction in material waste. In manufacturing and assembly processes, robots equipped with these sensors can perform tasks with greater precision, minimizing errors and reducing the likelihood of producing defective parts. This not only conserves raw materials but also decreases the environmental impact associated with the disposal of faulty products.

The durability and longevity of piezoelectric sensors also play a role in sustainability considerations. These sensors are known for their robustness and ability to withstand harsh operating conditions, potentially extending the lifespan of robotic systems. Longer-lasting robots mean fewer replacements and less electronic waste, aligning with circular economy principles and reducing the environmental burden of manufacturing and disposing of robotic equipment.

However, it is important to consider the environmental impact of producing piezoelectric sensors themselves. The manufacturing process of these sensors often involves the use of lead-based materials, which can pose environmental and health risks if not properly managed. As such, research into lead-free alternatives and more environmentally friendly production methods is crucial for ensuring the overall sustainability of piezoelectric sensor technology in robotics.

In the context of sustainable development, the application of piezoelectric sensors in robotics also has the potential to contribute to more efficient resource management. For instance, in agricultural robotics, these sensors can enable more precise application of water, fertilizers, and pesticides, reducing overuse and minimizing environmental contamination. Similarly, in waste management and recycling, robots equipped with piezoelectric sensors can improve sorting accuracy, enhancing recycling efficiency and reducing the amount of waste sent to landfills.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!