How to Address Nichrome's Limitations in High-Stress Environments?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Challenges

Nichrome, an alloy composed primarily of nickel and chromium, has been widely used in various high-temperature applications due to its excellent resistance to oxidation and corrosion. However, when exposed to high-stress environments, nichrome faces several significant challenges that limit its performance and reliability.

One of the primary limitations of nichrome in high-stress environments is its susceptibility to creep deformation. At elevated temperatures and under sustained loads, nichrome can experience a gradual, time-dependent plastic deformation, which can lead to component failure over time. This creep behavior becomes particularly problematic in applications such as gas turbines, where components are subjected to both high temperatures and mechanical stresses for extended periods.

Another challenge is the potential for embrittlement in certain environments. In the presence of sulfur-containing gases or other corrosive elements, nichrome can undergo a process called sulfidation, which leads to the formation of brittle nickel sulfides. This embrittlement significantly reduces the material's ductility and toughness, making it more prone to cracking and failure under stress.

Thermal fatigue is also a concern for nichrome in high-stress environments. Repeated cycles of heating and cooling can induce thermal stresses, leading to the formation and propagation of cracks. This is particularly problematic in applications with frequent thermal cycling, such as in aerospace components or industrial furnaces.

Furthermore, nichrome's relatively low strength at high temperatures compared to some other high-temperature alloys can be a limiting factor in certain applications. While it maintains good oxidation resistance, its mechanical properties degrade more rapidly at extreme temperatures compared to some newer superalloys, restricting its use in the most demanding high-temperature, high-stress applications.

The formation of volatile chromium oxides at very high temperatures (above 1000°C) can also pose challenges. These oxides can evaporate, leading to a gradual loss of the protective chromium-rich surface layer that gives nichrome its excellent corrosion resistance. This phenomenon, known as chromium depletion, can compromise the long-term durability of nichrome components in extreme environments.

Lastly, nichrome's electrical properties, while advantageous in many applications, can be a limitation in high-stress environments where electrical stability is crucial. The alloy's electrical resistance can change with temperature and stress, potentially affecting the performance of precision instruments or heating elements that rely on consistent electrical characteristics.

Addressing these challenges requires a multifaceted approach, including the development of advanced coatings, alloying strategies, and novel processing techniques to enhance nichrome's performance in high-stress environments. Research into these areas is ongoing, with the goal of expanding the operational envelope of this versatile alloy.

One of the primary limitations of nichrome in high-stress environments is its susceptibility to creep deformation. At elevated temperatures and under sustained loads, nichrome can experience a gradual, time-dependent plastic deformation, which can lead to component failure over time. This creep behavior becomes particularly problematic in applications such as gas turbines, where components are subjected to both high temperatures and mechanical stresses for extended periods.

Another challenge is the potential for embrittlement in certain environments. In the presence of sulfur-containing gases or other corrosive elements, nichrome can undergo a process called sulfidation, which leads to the formation of brittle nickel sulfides. This embrittlement significantly reduces the material's ductility and toughness, making it more prone to cracking and failure under stress.

Thermal fatigue is also a concern for nichrome in high-stress environments. Repeated cycles of heating and cooling can induce thermal stresses, leading to the formation and propagation of cracks. This is particularly problematic in applications with frequent thermal cycling, such as in aerospace components or industrial furnaces.

Furthermore, nichrome's relatively low strength at high temperatures compared to some other high-temperature alloys can be a limiting factor in certain applications. While it maintains good oxidation resistance, its mechanical properties degrade more rapidly at extreme temperatures compared to some newer superalloys, restricting its use in the most demanding high-temperature, high-stress applications.

The formation of volatile chromium oxides at very high temperatures (above 1000°C) can also pose challenges. These oxides can evaporate, leading to a gradual loss of the protective chromium-rich surface layer that gives nichrome its excellent corrosion resistance. This phenomenon, known as chromium depletion, can compromise the long-term durability of nichrome components in extreme environments.

Lastly, nichrome's electrical properties, while advantageous in many applications, can be a limitation in high-stress environments where electrical stability is crucial. The alloy's electrical resistance can change with temperature and stress, potentially affecting the performance of precision instruments or heating elements that rely on consistent electrical characteristics.

Addressing these challenges requires a multifaceted approach, including the development of advanced coatings, alloying strategies, and novel processing techniques to enhance nichrome's performance in high-stress environments. Research into these areas is ongoing, with the goal of expanding the operational envelope of this versatile alloy.

Market Demand Analysis

The market demand for addressing Nichrome's limitations in high-stress environments has been steadily increasing across various industries. This growth is primarily driven by the expanding applications of Nichrome in sectors such as aerospace, automotive, and industrial manufacturing, where materials are subjected to extreme conditions.

In the aerospace industry, there is a significant demand for materials that can withstand high temperatures and corrosive environments. As aircraft engines become more efficient and operate at higher temperatures, the need for improved Nichrome alloys has become critical. The market for high-performance alloys in aerospace is projected to grow substantially in the coming years, with Nichrome playing a crucial role.

The automotive sector also presents a growing market for enhanced Nichrome solutions. With the trend towards more fuel-efficient engines and the increasing adoption of electric vehicles, there is a rising demand for materials that can handle higher operating temperatures and stresses. Nichrome's potential applications in battery technologies and thermal management systems further contribute to this market growth.

In industrial manufacturing, particularly in sectors such as chemical processing and power generation, the demand for materials that can withstand corrosive environments and high temperatures continues to rise. Improved Nichrome alloys could significantly enhance the durability and efficiency of equipment in these industries, driving market demand.

The electronics industry represents another significant market for advanced Nichrome solutions. As electronic devices become more compact and powerful, the need for materials that can efficiently dissipate heat and withstand high temperatures has increased. This trend is particularly evident in the development of 5G technologies and high-performance computing systems.

Market analysis indicates that the global high-temperature alloys market, which includes Nichrome, is expected to experience substantial growth in the coming years. This growth is attributed to the increasing demand for materials that can perform under extreme conditions across various industries.

However, the market also faces challenges. The high cost of developing and manufacturing advanced Nichrome alloys can be a limiting factor for some applications. Additionally, competition from alternative materials and alloys presents a challenge to market growth.

Despite these challenges, the overall market outlook for improved Nichrome solutions remains positive. The continuous push for higher performance and efficiency across industries is likely to sustain and potentially accelerate the demand for advanced Nichrome alloys capable of withstanding high-stress environments.

In the aerospace industry, there is a significant demand for materials that can withstand high temperatures and corrosive environments. As aircraft engines become more efficient and operate at higher temperatures, the need for improved Nichrome alloys has become critical. The market for high-performance alloys in aerospace is projected to grow substantially in the coming years, with Nichrome playing a crucial role.

The automotive sector also presents a growing market for enhanced Nichrome solutions. With the trend towards more fuel-efficient engines and the increasing adoption of electric vehicles, there is a rising demand for materials that can handle higher operating temperatures and stresses. Nichrome's potential applications in battery technologies and thermal management systems further contribute to this market growth.

In industrial manufacturing, particularly in sectors such as chemical processing and power generation, the demand for materials that can withstand corrosive environments and high temperatures continues to rise. Improved Nichrome alloys could significantly enhance the durability and efficiency of equipment in these industries, driving market demand.

The electronics industry represents another significant market for advanced Nichrome solutions. As electronic devices become more compact and powerful, the need for materials that can efficiently dissipate heat and withstand high temperatures has increased. This trend is particularly evident in the development of 5G technologies and high-performance computing systems.

Market analysis indicates that the global high-temperature alloys market, which includes Nichrome, is expected to experience substantial growth in the coming years. This growth is attributed to the increasing demand for materials that can perform under extreme conditions across various industries.

However, the market also faces challenges. The high cost of developing and manufacturing advanced Nichrome alloys can be a limiting factor for some applications. Additionally, competition from alternative materials and alloys presents a challenge to market growth.

Despite these challenges, the overall market outlook for improved Nichrome solutions remains positive. The continuous push for higher performance and efficiency across industries is likely to sustain and potentially accelerate the demand for advanced Nichrome alloys capable of withstanding high-stress environments.

Current Limitations

Nichrome, an alloy primarily composed of nickel and chromium, has been widely used in high-temperature applications due to its excellent heat resistance and oxidation resistance. However, in high-stress environments, Nichrome exhibits several limitations that hinder its performance and reliability.

One of the primary limitations of Nichrome in high-stress environments is its susceptibility to creep deformation. At elevated temperatures and under constant stress, Nichrome tends to undergo slow, continuous plastic deformation over time. This creep behavior can lead to dimensional changes, reduced structural integrity, and eventual failure of components made from Nichrome.

Another significant limitation is the material's relatively low strength at high temperatures. While Nichrome maintains its oxidation resistance at elevated temperatures, its mechanical strength decreases considerably. This reduction in strength limits its use in applications that require both high-temperature resistance and high load-bearing capacity.

Nichrome also faces challenges in terms of thermal fatigue resistance. In environments with rapid temperature fluctuations, the material can experience thermal cycling fatigue, leading to the formation and propagation of cracks. This limitation is particularly problematic in applications such as heating elements or aerospace components that undergo frequent thermal cycling.

The alloy's electrical properties also present limitations in certain high-stress environments. Although Nichrome is valued for its high electrical resistivity, which makes it suitable for heating elements, this property can be a drawback in applications requiring both high-temperature resistance and electrical conductivity.

Corrosion resistance is another area where Nichrome shows limitations in specific high-stress environments. While it generally exhibits good corrosion resistance, Nichrome can be susceptible to certain types of corrosive attack, particularly in the presence of sulfur-containing compounds at high temperatures. This vulnerability can lead to accelerated degradation and reduced service life in some industrial applications.

Furthermore, Nichrome's limited formability and machinability can pose challenges in manufacturing complex shapes or intricate components for high-stress applications. This limitation can restrict design flexibility and increase production costs for certain specialized parts.

Lastly, the cost of Nichrome, primarily due to its nickel content, can be a limiting factor in large-scale or cost-sensitive applications. This economic consideration often prompts the search for alternative materials that can provide similar performance at a lower cost, especially in high-volume production scenarios.

One of the primary limitations of Nichrome in high-stress environments is its susceptibility to creep deformation. At elevated temperatures and under constant stress, Nichrome tends to undergo slow, continuous plastic deformation over time. This creep behavior can lead to dimensional changes, reduced structural integrity, and eventual failure of components made from Nichrome.

Another significant limitation is the material's relatively low strength at high temperatures. While Nichrome maintains its oxidation resistance at elevated temperatures, its mechanical strength decreases considerably. This reduction in strength limits its use in applications that require both high-temperature resistance and high load-bearing capacity.

Nichrome also faces challenges in terms of thermal fatigue resistance. In environments with rapid temperature fluctuations, the material can experience thermal cycling fatigue, leading to the formation and propagation of cracks. This limitation is particularly problematic in applications such as heating elements or aerospace components that undergo frequent thermal cycling.

The alloy's electrical properties also present limitations in certain high-stress environments. Although Nichrome is valued for its high electrical resistivity, which makes it suitable for heating elements, this property can be a drawback in applications requiring both high-temperature resistance and electrical conductivity.

Corrosion resistance is another area where Nichrome shows limitations in specific high-stress environments. While it generally exhibits good corrosion resistance, Nichrome can be susceptible to certain types of corrosive attack, particularly in the presence of sulfur-containing compounds at high temperatures. This vulnerability can lead to accelerated degradation and reduced service life in some industrial applications.

Furthermore, Nichrome's limited formability and machinability can pose challenges in manufacturing complex shapes or intricate components for high-stress applications. This limitation can restrict design flexibility and increase production costs for certain specialized parts.

Lastly, the cost of Nichrome, primarily due to its nickel content, can be a limiting factor in large-scale or cost-sensitive applications. This economic consideration often prompts the search for alternative materials that can provide similar performance at a lower cost, especially in high-volume production scenarios.

Existing Solutions

01 Temperature limitations of nichrome

Nichrome has temperature limitations that affect its performance and durability in high-temperature applications. These limitations are related to its melting point, oxidation resistance, and structural stability at elevated temperatures. Understanding these limitations is crucial for designing heating elements and other components that use nichrome in high-temperature environments.- Thermal limitations of nichrome: Nichrome has limitations in terms of its thermal properties. It can experience degradation and reduced performance at high temperatures, affecting its use in heating elements and resistive components. The material's thermal expansion and conductivity characteristics also pose challenges in certain applications.

- Electrical resistance constraints: The electrical resistance of nichrome can be a limiting factor in some applications. Its resistance changes with temperature, which can affect the accuracy and stability of electrical circuits. Additionally, the relatively high resistance of nichrome may limit its use in low-power or high-frequency applications.

- Mechanical strength and durability issues: Nichrome has limitations in terms of mechanical strength and durability. It can be prone to fatigue and fracture under certain conditions, especially in applications involving repeated thermal cycling or mechanical stress. This can limit its lifespan and reliability in some use cases.

- Corrosion and oxidation susceptibility: Nichrome can be susceptible to corrosion and oxidation, particularly in harsh environments or at elevated temperatures. This can lead to degradation of its properties over time and limit its use in certain applications where long-term stability is crucial.

- Manufacturing and processing challenges: The manufacturing and processing of nichrome can present limitations. It may be difficult to achieve precise control over its composition and properties during production. Additionally, joining and forming nichrome components can be challenging due to its high melting point and specific material characteristics.

02 Electrical resistance changes in nichrome

The electrical resistance of nichrome can change with temperature and prolonged use, affecting its performance in electrical applications. This change in resistance can impact the accuracy and efficiency of devices using nichrome as a heating element or resistor. Strategies to mitigate or compensate for these resistance changes are important for maintaining consistent performance.Expand Specific Solutions03 Mechanical strength and fatigue of nichrome

Nichrome has limitations in terms of mechanical strength and fatigue resistance, especially in applications involving repeated thermal cycling or mechanical stress. These limitations can lead to deformation, cracking, or failure of nichrome components over time. Consideration of these factors is essential when designing parts that are subjected to both thermal and mechanical stresses.Expand Specific Solutions04 Corrosion and oxidation resistance of nichrome

While nichrome has good corrosion and oxidation resistance compared to many other alloys, it still has limitations in highly corrosive or oxidizing environments. The protective oxide layer formed on nichrome can break down under certain conditions, leading to accelerated corrosion or oxidation. Understanding these limitations is crucial for applications in harsh chemical or high-temperature oxidizing environments.Expand Specific Solutions05 Manufacturing and processing limitations of nichrome

Nichrome has certain limitations in terms of manufacturing and processing. These include challenges in welding, forming, and machining the alloy due to its hardness and work-hardening properties. Additionally, there may be limitations in producing nichrome in certain forms or sizes. These manufacturing constraints can impact the design and production of components using nichrome.Expand Specific Solutions

Key Industry Players

The competition landscape for addressing Nichrome's limitations in high-stress environments is in a mature phase, with a significant market size due to the material's widespread use in various industries. The technology's maturity is evident from the involvement of established players like Gaona Aero Material Co., Ltd., Northrop Grumman Systems Corp., and Central Iron & Steel Research Institute. These companies, along with research institutions such as the Institute of Metal Research Chinese Academy of Sciences and Central South University, are driving innovation in high-temperature alloys and advanced materials. The market is characterized by ongoing research and development efforts to enhance Nichrome's performance, with a focus on improving its durability and heat resistance for extreme conditions.

Gaona Aero Material Co., Ltd.

Technical Solution: Gaona Aero Material Co., Ltd. has focused on developing nichrome alloys with improved oxidation resistance for high-temperature aerospace applications. Their approach involves precise control of alloy composition, with a particular emphasis on optimizing the chromium-to-nickel ratio. They have successfully increased the chromium content to enhance oxidation resistance while maintaining the alloy's electrical and mechanical properties[10]. Gaona has also developed a proprietary surface treatment process that creates a dense, adherent chromia layer, providing additional protection against oxidation in high-stress environments[11]. Furthermore, they have implemented advanced manufacturing techniques, such as directional solidification, to produce nichrome components with enhanced creep resistance and improved grain structure for better performance in high-stress conditions[12].

Strengths: Excellent oxidation resistance, improved high-temperature stability, and enhanced creep properties. Weaknesses: Potentially higher production costs and limited applications outside of aerospace industry.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed proprietary nichrome-based alloys specifically designed for aerospace applications in high-stress environments. Their approach focuses on enhancing the alloy's resistance to thermal fatigue and creep through advanced alloying techniques. They have successfully incorporated small amounts of refractory metals, such as molybdenum and tungsten, to improve high-temperature strength without significantly increasing the alloy's density[7]. Northrop Grumman has also developed a unique heat treatment process that optimizes the distribution of strengthening precipitates throughout the microstructure, resulting in improved creep resistance at elevated temperatures[8]. Additionally, they have implemented advanced coating technologies, including thermal barrier coatings and environmental barrier coatings, to further protect nichrome components in extreme environments[9].

Strengths: Excellent high-temperature strength, improved creep resistance, and enhanced protection through advanced coatings. Weaknesses: Potentially higher material costs and more complex manufacturing processes.

Core Innovations

Modulating stress responses by a novel chromatin-associated guide RNA derived from transfer RNA

PatentPendingUS20230112054A1

Innovation

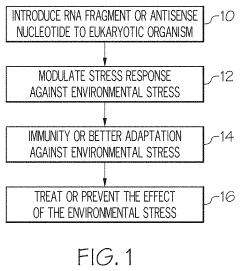

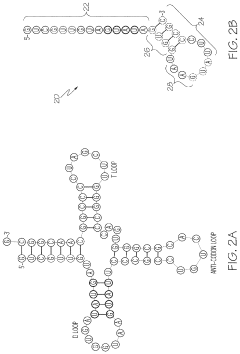

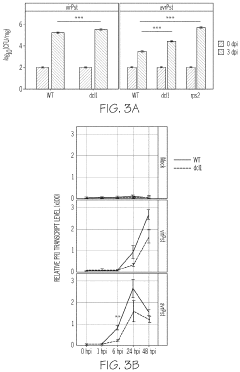

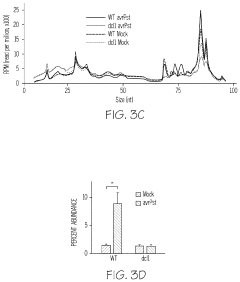

- Introducing specific RNA fragments (RFs) or antisense nucleotides that recognize and bind to stress-related sequences in plants, modulating the stress response by forming stem-loop structures and interacting with chromatin to induce defense genes and immunity.

Modulating stress responses by a novel chromatin-associated guide RNA derived from transfer RNA

PatentPendingUS20230112054A1

Innovation

- Introducing specific RNA fragments (RFs) or antisense nucleotides that recognize and bind to stress-related sequences in plants, modulating the stress response by forming stem-loop structures and interacting with chromatin to induce defense genes and immunity.

Material Alternatives

In addressing the limitations of nichrome in high-stress environments, several material alternatives have emerged as potential replacements or improvements. These alternatives aim to overcome the challenges faced by nichrome, such as its susceptibility to oxidation and reduced performance at extreme temperatures.

One promising alternative is the use of nickel-based superalloys. These materials, including Inconel and Hastelloy, offer superior strength and corrosion resistance at high temperatures. They maintain their mechanical properties even in harsh environments, making them suitable for applications where nichrome falls short. Nickel-based superalloys also exhibit excellent creep resistance, a critical factor in high-stress scenarios.

Another category of materials gaining attention is refractory metal alloys. Composed of elements like molybdenum, tungsten, and tantalum, these alloys demonstrate exceptional heat resistance and strength at elevated temperatures. They can withstand extreme conditions that would cause nichrome to fail, making them ideal for aerospace and industrial applications requiring high-temperature stability.

Ceramic materials have also shown potential as alternatives to nichrome in certain high-stress environments. Silicon carbide and silicon nitride, for instance, offer excellent thermal shock resistance and low thermal expansion. These properties make them suitable for applications where rapid temperature changes occur, outperforming nichrome in such scenarios.

Intermetallic compounds, particularly those based on nickel and aluminum (e.g., NiAl), have emerged as another viable option. These materials combine the ductility of metals with the high-temperature strength of ceramics, offering a unique balance of properties. Their ordered crystal structure contributes to their stability at high temperatures, addressing some of nichrome's limitations.

Advanced coating technologies have also been developed to enhance the performance of existing materials. Thermal barrier coatings, for example, can be applied to nichrome or other base materials to improve their heat resistance and longevity in high-stress environments. These coatings often consist of ceramic materials that provide an additional layer of protection against thermal and oxidative stresses.

Composite materials, combining different elements or compounds, offer another avenue for addressing nichrome's limitations. Metal matrix composites reinforced with ceramic particles or fibers can provide enhanced strength and temperature resistance compared to nichrome alone. These composites allow for tailored properties to meet specific application requirements in high-stress environments.

One promising alternative is the use of nickel-based superalloys. These materials, including Inconel and Hastelloy, offer superior strength and corrosion resistance at high temperatures. They maintain their mechanical properties even in harsh environments, making them suitable for applications where nichrome falls short. Nickel-based superalloys also exhibit excellent creep resistance, a critical factor in high-stress scenarios.

Another category of materials gaining attention is refractory metal alloys. Composed of elements like molybdenum, tungsten, and tantalum, these alloys demonstrate exceptional heat resistance and strength at elevated temperatures. They can withstand extreme conditions that would cause nichrome to fail, making them ideal for aerospace and industrial applications requiring high-temperature stability.

Ceramic materials have also shown potential as alternatives to nichrome in certain high-stress environments. Silicon carbide and silicon nitride, for instance, offer excellent thermal shock resistance and low thermal expansion. These properties make them suitable for applications where rapid temperature changes occur, outperforming nichrome in such scenarios.

Intermetallic compounds, particularly those based on nickel and aluminum (e.g., NiAl), have emerged as another viable option. These materials combine the ductility of metals with the high-temperature strength of ceramics, offering a unique balance of properties. Their ordered crystal structure contributes to their stability at high temperatures, addressing some of nichrome's limitations.

Advanced coating technologies have also been developed to enhance the performance of existing materials. Thermal barrier coatings, for example, can be applied to nichrome or other base materials to improve their heat resistance and longevity in high-stress environments. These coatings often consist of ceramic materials that provide an additional layer of protection against thermal and oxidative stresses.

Composite materials, combining different elements or compounds, offer another avenue for addressing nichrome's limitations. Metal matrix composites reinforced with ceramic particles or fibers can provide enhanced strength and temperature resistance compared to nichrome alone. These composites allow for tailored properties to meet specific application requirements in high-stress environments.

Environmental Impact

The environmental impact of addressing nichrome's limitations in high-stress environments is a critical consideration in the development and implementation of new solutions. Nichrome, an alloy of nickel and chromium, is widely used in various industrial applications due to its high resistance to heat and corrosion. However, its limitations in extreme conditions have led to the exploration of alternative materials and technologies.

One of the primary environmental concerns associated with nichrome is the potential release of toxic metals into the environment during manufacturing, use, and disposal. Nickel and chromium, the main components of nichrome, can have detrimental effects on ecosystems and human health if not properly managed. As new solutions are developed to address nichrome's limitations, it is crucial to assess their environmental footprint throughout their lifecycle.

The production of alternative materials or coatings may involve energy-intensive processes, potentially increasing greenhouse gas emissions. However, if these new solutions lead to improved durability and longevity of components in high-stress environments, they could ultimately reduce the need for frequent replacements, thereby decreasing overall resource consumption and waste generation.

Water pollution is another environmental aspect to consider. The manufacturing processes for nichrome and its alternatives often involve the use of chemicals and water-intensive operations. Ensuring proper wastewater treatment and minimizing water usage in these processes is essential to mitigate negative impacts on aquatic ecosystems.

The recyclability of materials used to address nichrome's limitations is a key factor in their environmental sustainability. Developing solutions that can be easily recycled or reused at the end of their life cycle can significantly reduce the environmental burden associated with their production and disposal. This approach aligns with the principles of a circular economy and helps conserve valuable resources.

Furthermore, the potential for reducing energy consumption in high-stress applications by implementing more efficient materials or technologies can have far-reaching environmental benefits. Improved performance in extreme conditions may lead to enhanced energy efficiency in various industrial processes, contributing to overall reductions in carbon emissions and resource utilization.

As research and development efforts continue to address nichrome's limitations, it is imperative to integrate environmental considerations into the design and evaluation of new solutions. Life cycle assessments and environmental impact studies should be conducted to comprehensively understand the ecological implications of proposed alternatives. By prioritizing environmentally friendly approaches, the industry can work towards sustainable innovations that not only overcome technical challenges but also contribute to global environmental protection efforts.

One of the primary environmental concerns associated with nichrome is the potential release of toxic metals into the environment during manufacturing, use, and disposal. Nickel and chromium, the main components of nichrome, can have detrimental effects on ecosystems and human health if not properly managed. As new solutions are developed to address nichrome's limitations, it is crucial to assess their environmental footprint throughout their lifecycle.

The production of alternative materials or coatings may involve energy-intensive processes, potentially increasing greenhouse gas emissions. However, if these new solutions lead to improved durability and longevity of components in high-stress environments, they could ultimately reduce the need for frequent replacements, thereby decreasing overall resource consumption and waste generation.

Water pollution is another environmental aspect to consider. The manufacturing processes for nichrome and its alternatives often involve the use of chemicals and water-intensive operations. Ensuring proper wastewater treatment and minimizing water usage in these processes is essential to mitigate negative impacts on aquatic ecosystems.

The recyclability of materials used to address nichrome's limitations is a key factor in their environmental sustainability. Developing solutions that can be easily recycled or reused at the end of their life cycle can significantly reduce the environmental burden associated with their production and disposal. This approach aligns with the principles of a circular economy and helps conserve valuable resources.

Furthermore, the potential for reducing energy consumption in high-stress applications by implementing more efficient materials or technologies can have far-reaching environmental benefits. Improved performance in extreme conditions may lead to enhanced energy efficiency in various industrial processes, contributing to overall reductions in carbon emissions and resource utilization.

As research and development efforts continue to address nichrome's limitations, it is imperative to integrate environmental considerations into the design and evaluation of new solutions. Life cycle assessments and environmental impact studies should be conducted to comprehensively understand the ecological implications of proposed alternatives. By prioritizing environmentally friendly approaches, the industry can work towards sustainable innovations that not only overcome technical challenges but also contribute to global environmental protection efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!