How to Analyze Nichrome Properties in Chemical Technology?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Analysis Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in chemical technology for decades. Its unique properties have made it indispensable in various applications, particularly in high-temperature environments. The evolution of nichrome analysis techniques has paralleled advancements in materials science and chemical engineering, reflecting the growing demand for precise characterization of this versatile alloy.

The development of nichrome analysis methods can be traced back to the early 20th century when the alloy was first introduced. Initially, rudimentary techniques focused on basic compositional analysis and mechanical testing. As the importance of nichrome in industrial applications grew, so did the sophistication of analytical methods. The mid-20th century saw the introduction of spectroscopic techniques, which allowed for more accurate elemental analysis and paved the way for understanding the alloy's microstructure.

In recent years, the field of nichrome analysis has experienced a significant leap forward, driven by the need for more precise control over material properties in critical applications. Advanced microscopy techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), have enabled researchers to visualize the alloy's structure at nanoscale levels. This has led to a deeper understanding of how composition and processing affect nichrome's properties.

The current technological landscape demands increasingly sophisticated analysis of nichrome properties. Industries such as aerospace, energy, and electronics require materials that can withstand extreme conditions while maintaining specific electrical and thermal characteristics. This has spurred the development of novel analytical approaches, including in-situ high-temperature testing and advanced computational modeling of alloy behavior.

The primary objective of modern nichrome analysis in chemical technology is to establish a comprehensive understanding of the alloy's behavior under various conditions. This includes investigating its resistance to corrosion, oxidation, and thermal fatigue, as well as its electrical conductivity and thermal expansion characteristics. By gaining insights into these properties, researchers aim to optimize nichrome compositions and processing techniques for specific applications.

Another crucial goal is to develop predictive models that can accurately forecast nichrome's performance in different environments. This involves integrating data from multiple analytical techniques and leveraging machine learning algorithms to identify patterns and correlations. Such models would significantly reduce the time and cost associated with material development and testing.

As we look to the future, the field of nichrome analysis is poised for further innovation. Emerging technologies, such as artificial intelligence-driven materials discovery and atomic-scale 3D printing, promise to revolutionize how we design, analyze, and optimize nichrome alloys. These advancements will not only enhance our understanding of existing nichrome properties but also open up possibilities for creating novel alloy compositions with tailored characteristics for next-generation applications in chemical technology.

The development of nichrome analysis methods can be traced back to the early 20th century when the alloy was first introduced. Initially, rudimentary techniques focused on basic compositional analysis and mechanical testing. As the importance of nichrome in industrial applications grew, so did the sophistication of analytical methods. The mid-20th century saw the introduction of spectroscopic techniques, which allowed for more accurate elemental analysis and paved the way for understanding the alloy's microstructure.

In recent years, the field of nichrome analysis has experienced a significant leap forward, driven by the need for more precise control over material properties in critical applications. Advanced microscopy techniques, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), have enabled researchers to visualize the alloy's structure at nanoscale levels. This has led to a deeper understanding of how composition and processing affect nichrome's properties.

The current technological landscape demands increasingly sophisticated analysis of nichrome properties. Industries such as aerospace, energy, and electronics require materials that can withstand extreme conditions while maintaining specific electrical and thermal characteristics. This has spurred the development of novel analytical approaches, including in-situ high-temperature testing and advanced computational modeling of alloy behavior.

The primary objective of modern nichrome analysis in chemical technology is to establish a comprehensive understanding of the alloy's behavior under various conditions. This includes investigating its resistance to corrosion, oxidation, and thermal fatigue, as well as its electrical conductivity and thermal expansion characteristics. By gaining insights into these properties, researchers aim to optimize nichrome compositions and processing techniques for specific applications.

Another crucial goal is to develop predictive models that can accurately forecast nichrome's performance in different environments. This involves integrating data from multiple analytical techniques and leveraging machine learning algorithms to identify patterns and correlations. Such models would significantly reduce the time and cost associated with material development and testing.

As we look to the future, the field of nichrome analysis is poised for further innovation. Emerging technologies, such as artificial intelligence-driven materials discovery and atomic-scale 3D printing, promise to revolutionize how we design, analyze, and optimize nichrome alloys. These advancements will not only enhance our understanding of existing nichrome properties but also open up possibilities for creating novel alloy compositions with tailored characteristics for next-generation applications in chemical technology.

Market Demand for Nichrome Applications

The market demand for nichrome applications has been steadily growing across various industries due to its unique properties and versatile uses. In the chemical technology sector, nichrome's resistance to corrosion and high temperatures makes it particularly valuable for analytical instruments and laboratory equipment. The global market for laboratory equipment, which includes nichrome-based products, is projected to reach significant growth in the coming years, driven by increased research and development activities in pharmaceuticals, biotechnology, and environmental sciences.

Chemical processing industries have shown a rising demand for nichrome in the construction of reaction vessels, heat exchangers, and distillation columns. The material's ability to withstand harsh chemical environments while maintaining structural integrity at high temperatures has made it indispensable in these applications. Furthermore, the petrochemical industry's expansion, especially in emerging economies, has contributed to the increased demand for nichrome-based equipment and components.

In the field of sensors and measurement devices, nichrome finds extensive use in thermocouples and resistance temperature detectors (RTDs). The growing emphasis on process automation and quality control in chemical manufacturing has led to a surge in demand for these precision measurement tools. This trend is expected to continue as industries strive for greater efficiency and compliance with stringent quality standards.

The electronics industry, particularly in the production of resistors and heating elements, represents another significant market for nichrome applications. With the ongoing miniaturization of electronic devices and the need for more efficient power management systems, the demand for high-performance resistive materials like nichrome continues to rise.

Environmental concerns and energy efficiency regulations have also positively impacted the nichrome market. The material's use in catalytic converters and emission control systems has seen increased adoption as industries work to meet stricter environmental standards. Additionally, the renewable energy sector, especially in solar thermal applications, has emerged as a promising market for nichrome-based components.

Despite the positive market outlook, challenges such as fluctuating raw material prices and the development of alternative materials could impact the growth trajectory of nichrome applications. However, ongoing research into enhancing nichrome properties and exploring new applications in chemical technology is likely to open up new market opportunities and sustain demand in the foreseeable future.

Chemical processing industries have shown a rising demand for nichrome in the construction of reaction vessels, heat exchangers, and distillation columns. The material's ability to withstand harsh chemical environments while maintaining structural integrity at high temperatures has made it indispensable in these applications. Furthermore, the petrochemical industry's expansion, especially in emerging economies, has contributed to the increased demand for nichrome-based equipment and components.

In the field of sensors and measurement devices, nichrome finds extensive use in thermocouples and resistance temperature detectors (RTDs). The growing emphasis on process automation and quality control in chemical manufacturing has led to a surge in demand for these precision measurement tools. This trend is expected to continue as industries strive for greater efficiency and compliance with stringent quality standards.

The electronics industry, particularly in the production of resistors and heating elements, represents another significant market for nichrome applications. With the ongoing miniaturization of electronic devices and the need for more efficient power management systems, the demand for high-performance resistive materials like nichrome continues to rise.

Environmental concerns and energy efficiency regulations have also positively impacted the nichrome market. The material's use in catalytic converters and emission control systems has seen increased adoption as industries work to meet stricter environmental standards. Additionally, the renewable energy sector, especially in solar thermal applications, has emerged as a promising market for nichrome-based components.

Despite the positive market outlook, challenges such as fluctuating raw material prices and the development of alternative materials could impact the growth trajectory of nichrome applications. However, ongoing research into enhancing nichrome properties and exploring new applications in chemical technology is likely to open up new market opportunities and sustain demand in the foreseeable future.

Current State of Nichrome Analysis Techniques

The analysis of nichrome properties in chemical technology has seen significant advancements in recent years. Current techniques employ a multifaceted approach, combining various analytical methods to comprehensively characterize this important alloy. X-ray diffraction (XRD) remains a cornerstone technique, providing crucial information about the crystalline structure and phase composition of nichrome samples.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) has become increasingly prevalent, offering high-resolution imaging of surface morphology and elemental composition analysis. This combination allows researchers to examine the microstructure of nichrome and detect any inhomogeneities or impurities that may affect its properties.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are widely used to investigate the thermal behavior of nichrome. These methods provide valuable insights into phase transitions, oxidation resistance, and thermal stability, which are critical parameters for many applications of nichrome in chemical technology.

Electrochemical techniques, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), have gained prominence in assessing the corrosion resistance of nichrome in various chemical environments. These methods enable researchers to quantify corrosion rates and understand the mechanisms of corrosion protection offered by nichrome coatings.

Advanced spectroscopic techniques, such as X-ray photoelectron spectroscopy (XPS) and Auger electron spectroscopy (AES), are increasingly employed to analyze the surface chemistry of nichrome. These methods provide detailed information about the chemical state of elements and the composition of surface oxide layers, which play a crucial role in the alloy's performance in chemical applications.

Mechanical testing methods, including nanoindentation and tensile testing, are routinely used to evaluate the mechanical properties of nichrome. These techniques allow for the determination of hardness, elastic modulus, and strength, which are essential for predicting the material's behavior under various stress conditions in chemical processing equipment.

In recent years, computational modeling and simulation techniques have become integral to nichrome analysis. Density functional theory (DFT) calculations and molecular dynamics simulations are being used to predict and understand the atomic-scale properties and behavior of nichrome under different conditions, complementing experimental analyses.

The integration of these diverse analytical techniques, coupled with advanced data analysis methods, has significantly enhanced our ability to characterize nichrome properties comprehensively. This multidisciplinary approach enables researchers and engineers to optimize nichrome compositions and processing methods for specific chemical technology applications, leading to improved performance and reliability in demanding chemical environments.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) has become increasingly prevalent, offering high-resolution imaging of surface morphology and elemental composition analysis. This combination allows researchers to examine the microstructure of nichrome and detect any inhomogeneities or impurities that may affect its properties.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are widely used to investigate the thermal behavior of nichrome. These methods provide valuable insights into phase transitions, oxidation resistance, and thermal stability, which are critical parameters for many applications of nichrome in chemical technology.

Electrochemical techniques, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS), have gained prominence in assessing the corrosion resistance of nichrome in various chemical environments. These methods enable researchers to quantify corrosion rates and understand the mechanisms of corrosion protection offered by nichrome coatings.

Advanced spectroscopic techniques, such as X-ray photoelectron spectroscopy (XPS) and Auger electron spectroscopy (AES), are increasingly employed to analyze the surface chemistry of nichrome. These methods provide detailed information about the chemical state of elements and the composition of surface oxide layers, which play a crucial role in the alloy's performance in chemical applications.

Mechanical testing methods, including nanoindentation and tensile testing, are routinely used to evaluate the mechanical properties of nichrome. These techniques allow for the determination of hardness, elastic modulus, and strength, which are essential for predicting the material's behavior under various stress conditions in chemical processing equipment.

In recent years, computational modeling and simulation techniques have become integral to nichrome analysis. Density functional theory (DFT) calculations and molecular dynamics simulations are being used to predict and understand the atomic-scale properties and behavior of nichrome under different conditions, complementing experimental analyses.

The integration of these diverse analytical techniques, coupled with advanced data analysis methods, has significantly enhanced our ability to characterize nichrome properties comprehensively. This multidisciplinary approach enables researchers and engineers to optimize nichrome compositions and processing methods for specific chemical technology applications, leading to improved performance and reliability in demanding chemical environments.

Existing Nichrome Analysis Solutions

01 Electrical properties of nichrome

Nichrome exhibits excellent electrical properties, making it suitable for various applications. It has high electrical resistance and low temperature coefficient of resistance, which allows for stable performance across a wide temperature range. These characteristics make nichrome ideal for use in heating elements, resistors, and other electrical components.- Composition and structure of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. The composition and structure of nichrome alloys can be tailored to achieve desired properties such as high electrical resistance, corrosion resistance, and heat resistance.

- Electrical properties of nichrome: Nichrome exhibits high electrical resistance, making it suitable for use in heating elements and resistors. The electrical properties of nichrome can be adjusted by altering its composition and manufacturing process, allowing for precise control of resistance and temperature coefficients.

- Thermal properties and heat resistance: Nichrome is known for its excellent heat resistance and high melting point. These properties make it ideal for use in high-temperature applications such as furnaces, ovens, and heating elements. The thermal stability of nichrome allows it to maintain its structural integrity and electrical properties at elevated temperatures.

- Corrosion resistance and oxidation behavior: Nichrome alloys exhibit good corrosion resistance and oxidation resistance, particularly at high temperatures. This is due to the formation of a protective chromium oxide layer on the surface, which helps prevent further oxidation and degradation of the material.

- Applications and manufacturing processes: Nichrome finds applications in various industries, including electronics, aerospace, and industrial heating. The manufacturing processes for nichrome alloys can include melting, casting, and various forming techniques such as wire drawing and sheet rolling. These processes can be optimized to achieve specific material properties and geometries for different applications.

02 Thermal properties of nichrome

Nichrome possesses remarkable thermal properties, including high melting point and resistance to oxidation at elevated temperatures. These attributes make it an excellent choice for high-temperature applications such as furnace heating elements, hot-wire anemometers, and thermal sensors. The material's ability to withstand extreme heat while maintaining its structural integrity contributes to its widespread use in thermal management systems.Expand Specific Solutions03 Mechanical properties of nichrome

Nichrome demonstrates favorable mechanical properties, including good tensile strength and ductility. These characteristics allow for easy fabrication and shaping of the material into various forms such as wires, ribbons, and sheets. The combination of strength and flexibility makes nichrome suitable for applications requiring both durability and formability.Expand Specific Solutions04 Corrosion resistance of nichrome

Nichrome exhibits excellent corrosion resistance, particularly in high-temperature environments. This property is attributed to the formation of a protective chromium oxide layer on the surface, which prevents further oxidation and degradation. The material's resistance to corrosion makes it suitable for use in harsh environments and extends the lifespan of components made from nichrome.Expand Specific Solutions05 Composition and alloying of nichrome

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application requirements. The composition can be adjusted to optimize certain properties, such as electrical resistance or oxidation resistance. Additional alloying elements may be incorporated to further enhance specific characteristics, allowing for customization of the material for different industrial uses.Expand Specific Solutions

Key Players in Nichrome Research and Development

The analysis of nichrome properties in chemical technology is currently in a mature stage of industry development, with a stable market size and well-established technological foundations. The competitive landscape is characterized by a mix of large multinational corporations and specialized research institutions. Companies like Baker Hughes Co., Schlumberger Technologies, Inc., and Lockheed Martin Corp. are key players, leveraging their extensive R&D capabilities and global presence. The technology's maturity is evident in its widespread application across various sectors, including aerospace, energy, and materials science. Research institutions such as the University of Science & Technology Beijing and Lanzhou University of Technology contribute to ongoing advancements, while specialized firms like Konfoong Materials International Co., Ltd. focus on niche applications, ensuring continued innovation in nichrome properties analysis.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed advanced techniques for analyzing nichrome properties in chemical technology, particularly for oil and gas applications. Their approach involves using high-temperature X-ray diffraction (HT-XRD) to study the structural changes of nichrome alloys under extreme conditions[1]. This method allows for real-time observation of phase transformations and thermal expansion behaviors. Additionally, they employ electrochemical impedance spectroscopy (EIS) to evaluate the corrosion resistance of nichrome coatings in harsh chemical environments[3]. Baker Hughes has also integrated machine learning algorithms to predict nichrome degradation rates based on operational data, enhancing the longevity of equipment used in chemical processing[5].

Strengths: Comprehensive analysis techniques, real-time monitoring capabilities, and predictive maintenance solutions. Weaknesses: High equipment costs and complexity in data interpretation for field applications.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has pioneered a multi-faceted approach to analyzing nichrome properties in chemical technology, focusing on downhole tool applications. Their method combines high-resolution scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) to characterize the microstructure and elemental composition of nichrome alloys[2]. They have developed proprietary software that simulates the behavior of nichrome under various chemical and thermal stresses, allowing for accurate prediction of material performance in extreme environments[4]. Schlumberger also utilizes neutron diffraction techniques to study the residual stresses in nichrome components, which is crucial for understanding fatigue life and failure mechanisms[6]. Furthermore, they have implemented in-situ monitoring systems that use fiber optic sensors to track nichrome properties in real-time during chemical processes[8].

Strengths: Advanced simulation capabilities, in-situ monitoring, and comprehensive material characterization. Weaknesses: High reliance on proprietary technology and potential limitations in adapting to rapidly changing chemical environments.

Core Innovations in Nichrome Characterization

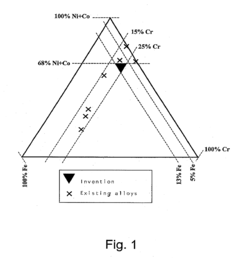

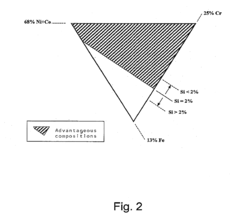

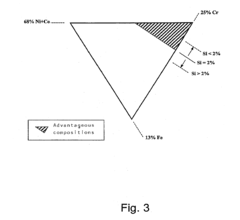

Ni-cr-fe alloy for high-temperature use

PatentInactiveUS20110259875A1

Innovation

- A Ni—Cr—Fe alloy composition with Cr 15-25%, Fe 5-13%, Si 1-3%, C <0.1%, and Nb <0.2%, with Ni making up the balance, and optional additions of other elements to achieve a low Ct-value and high resistivity, ensuring good hot workability and reduced raw material costs.

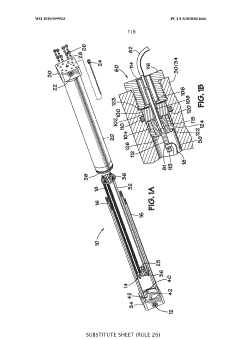

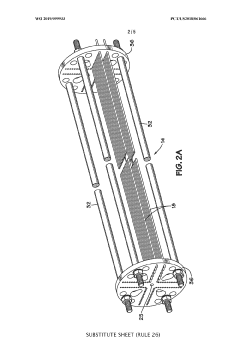

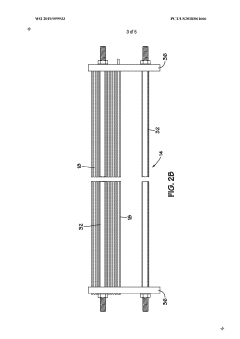

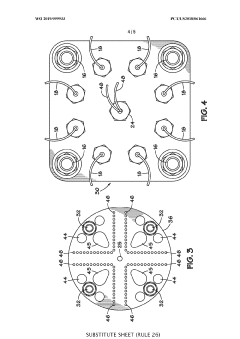

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

Environmental Impact of Nichrome Production

The production of nichrome, an alloy primarily composed of nickel and chromium, has significant environmental implications that warrant careful consideration. The manufacturing process involves mining, refining, and alloying activities, each contributing to various environmental impacts.

Mining operations for nickel and chromium ores can lead to substantial land disturbance, habitat destruction, and soil erosion. Open-pit mining, commonly used for these metals, often results in large-scale deforestation and landscape alterations. The extraction process also generates considerable amounts of waste rock and tailings, which can contaminate soil and water resources if not properly managed.

Water pollution is a major concern in nichrome production. Acid mine drainage, a byproduct of mining activities, can leach heavy metals and other toxic substances into surrounding water bodies. This contamination poses serious threats to aquatic ecosystems and can persist for decades after mining operations cease. Additionally, the refining processes for nickel and chromium require substantial water usage, potentially straining local water resources in areas of production.

Air quality is another critical environmental aspect affected by nichrome manufacturing. Smelting and refining operations release various air pollutants, including sulfur dioxide, nitrogen oxides, and particulate matter. These emissions contribute to air pollution, acid rain, and potential health risks for nearby communities. Furthermore, the high energy requirements of nichrome production result in significant greenhouse gas emissions, primarily carbon dioxide, contributing to global climate change.

The disposal of waste materials from nichrome production presents long-term environmental challenges. Slag, a byproduct of metal smelting, can contain hazardous substances that may leach into soil and groundwater if not properly contained. Proper management and disposal of these wastes are essential to minimize environmental risks and comply with increasingly stringent regulations.

Efforts to mitigate the environmental impact of nichrome production have led to the development of more sustainable practices. These include improved mining techniques that minimize land disturbance, advanced water treatment systems to reduce pollution, and more efficient smelting processes that lower energy consumption and emissions. Recycling of nichrome and its component metals has also gained importance as a means to reduce the demand for primary raw materials and associated environmental impacts.

In conclusion, while nichrome remains an important alloy in various industries, its production carries substantial environmental consequences. Balancing the economic benefits with environmental protection requires ongoing research, technological innovation, and stringent regulatory oversight to ensure sustainable practices throughout the nichrome production chain.

Mining operations for nickel and chromium ores can lead to substantial land disturbance, habitat destruction, and soil erosion. Open-pit mining, commonly used for these metals, often results in large-scale deforestation and landscape alterations. The extraction process also generates considerable amounts of waste rock and tailings, which can contaminate soil and water resources if not properly managed.

Water pollution is a major concern in nichrome production. Acid mine drainage, a byproduct of mining activities, can leach heavy metals and other toxic substances into surrounding water bodies. This contamination poses serious threats to aquatic ecosystems and can persist for decades after mining operations cease. Additionally, the refining processes for nickel and chromium require substantial water usage, potentially straining local water resources in areas of production.

Air quality is another critical environmental aspect affected by nichrome manufacturing. Smelting and refining operations release various air pollutants, including sulfur dioxide, nitrogen oxides, and particulate matter. These emissions contribute to air pollution, acid rain, and potential health risks for nearby communities. Furthermore, the high energy requirements of nichrome production result in significant greenhouse gas emissions, primarily carbon dioxide, contributing to global climate change.

The disposal of waste materials from nichrome production presents long-term environmental challenges. Slag, a byproduct of metal smelting, can contain hazardous substances that may leach into soil and groundwater if not properly contained. Proper management and disposal of these wastes are essential to minimize environmental risks and comply with increasingly stringent regulations.

Efforts to mitigate the environmental impact of nichrome production have led to the development of more sustainable practices. These include improved mining techniques that minimize land disturbance, advanced water treatment systems to reduce pollution, and more efficient smelting processes that lower energy consumption and emissions. Recycling of nichrome and its component metals has also gained importance as a means to reduce the demand for primary raw materials and associated environmental impacts.

In conclusion, while nichrome remains an important alloy in various industries, its production carries substantial environmental consequences. Balancing the economic benefits with environmental protection requires ongoing research, technological innovation, and stringent regulatory oversight to ensure sustainable practices throughout the nichrome production chain.

Nichrome Safety and Handling Protocols

Nichrome safety and handling protocols are crucial aspects of working with this alloy in chemical technology applications. The primary concern when dealing with nichrome is its potential to release toxic fumes when heated to high temperatures. To mitigate this risk, proper ventilation systems must be in place, and workers should wear appropriate personal protective equipment (PPE), including respirators with filters designed for metal fumes.

When handling nichrome wire or sheets, it is essential to use cut-resistant gloves to prevent injuries from sharp edges. Additionally, safety glasses or face shields should be worn to protect the eyes from metal particles or splashes during chemical processes. In laboratory settings, nichrome components should be stored in clearly labeled containers, away from incompatible materials and sources of heat or ignition.

Before using nichrome in chemical experiments or processes, a thorough risk assessment should be conducted. This assessment should consider the specific chemical environment, temperature ranges, and potential reactions that may occur. Based on this evaluation, appropriate safety measures can be implemented, such as using fume hoods, installing fire suppression systems, or implementing emergency shutdown procedures.

Proper disposal of nichrome waste is another critical aspect of safety protocols. Used nichrome components may contain residual chemicals or contaminants, requiring specialized disposal methods. Facilities should establish clear guidelines for the collection, storage, and disposal of nichrome waste, in compliance with local environmental regulations.

Training programs for personnel working with nichrome are essential. These programs should cover the physical and chemical properties of nichrome, potential hazards, proper handling techniques, and emergency response procedures. Regular refresher courses and safety drills can help maintain a high level of awareness and preparedness among staff.

When analyzing nichrome properties in chemical technology, it is important to consider the potential for chemical reactions between nichrome and the substances it comes into contact with. Compatibility tests should be performed before introducing nichrome into new chemical processes. This may involve small-scale experiments to observe any unexpected reactions or changes in the nichrome's properties.

Lastly, maintaining detailed records of nichrome usage, including batch numbers, exposure conditions, and any observed changes in properties, is crucial for ongoing safety management and quality control. These records can help identify potential issues early and inform future safety protocols and handling procedures.

When handling nichrome wire or sheets, it is essential to use cut-resistant gloves to prevent injuries from sharp edges. Additionally, safety glasses or face shields should be worn to protect the eyes from metal particles or splashes during chemical processes. In laboratory settings, nichrome components should be stored in clearly labeled containers, away from incompatible materials and sources of heat or ignition.

Before using nichrome in chemical experiments or processes, a thorough risk assessment should be conducted. This assessment should consider the specific chemical environment, temperature ranges, and potential reactions that may occur. Based on this evaluation, appropriate safety measures can be implemented, such as using fume hoods, installing fire suppression systems, or implementing emergency shutdown procedures.

Proper disposal of nichrome waste is another critical aspect of safety protocols. Used nichrome components may contain residual chemicals or contaminants, requiring specialized disposal methods. Facilities should establish clear guidelines for the collection, storage, and disposal of nichrome waste, in compliance with local environmental regulations.

Training programs for personnel working with nichrome are essential. These programs should cover the physical and chemical properties of nichrome, potential hazards, proper handling techniques, and emergency response procedures. Regular refresher courses and safety drills can help maintain a high level of awareness and preparedness among staff.

When analyzing nichrome properties in chemical technology, it is important to consider the potential for chemical reactions between nichrome and the substances it comes into contact with. Compatibility tests should be performed before introducing nichrome into new chemical processes. This may involve small-scale experiments to observe any unexpected reactions or changes in the nichrome's properties.

Lastly, maintaining detailed records of nichrome usage, including batch numbers, exposure conditions, and any observed changes in properties, is crucial for ongoing safety management and quality control. These records can help identify potential issues early and inform future safety protocols and handling procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!